Preparation technique for silicon carbide heating element

A technology of heating element and preparation process, which is applied in the field of preparation of ceramic materials for the heating part of silicon carbide heating element, and can solve the problems of high equipment requirements, complicated process, high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

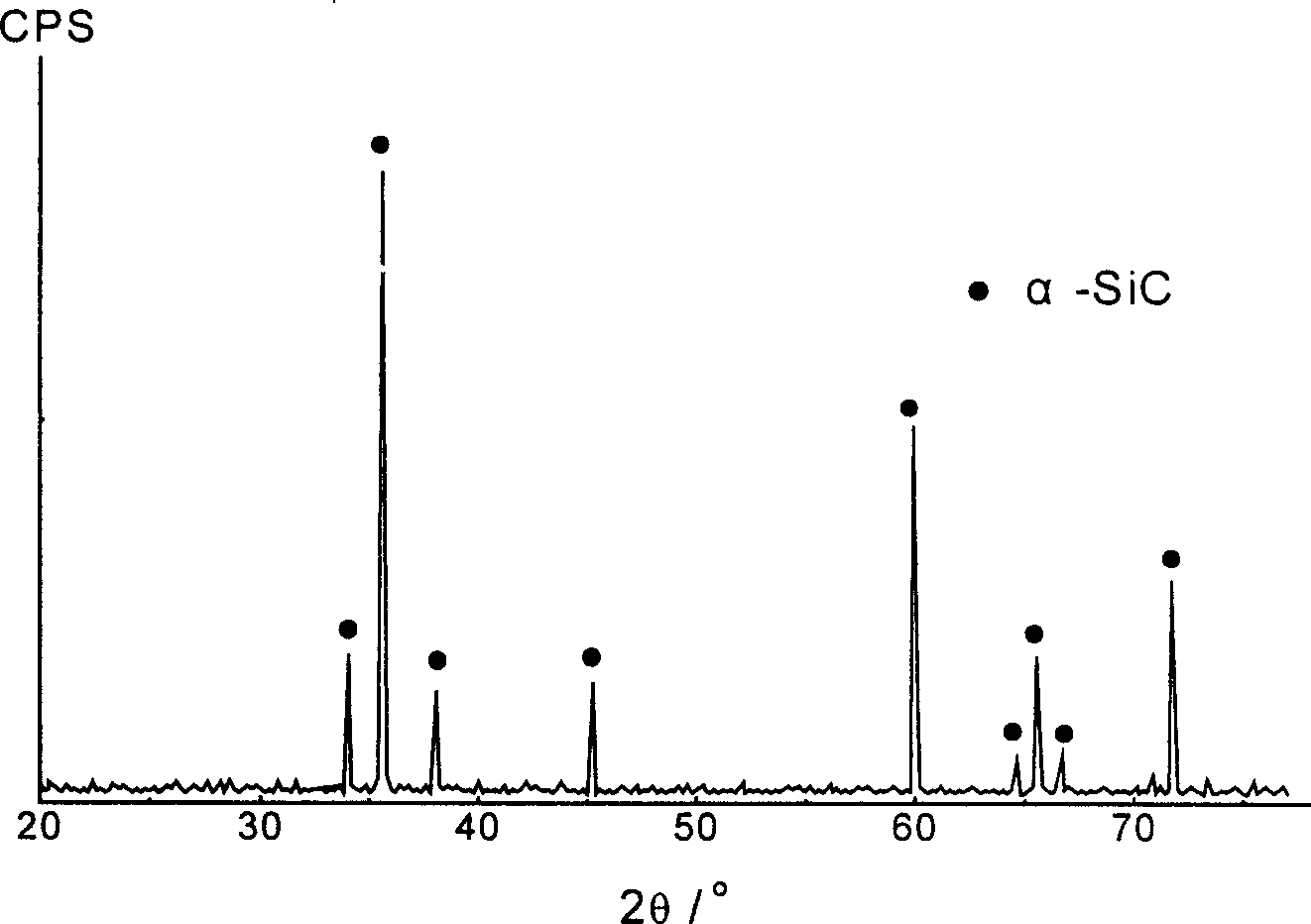

Image

Examples

Embodiment 1

[0034] Step 1: Mix silicon carbide powder with particle size number 30 mesh mass fraction of 0.35, 80 mesh mass fraction of 0.25, 0.2 petroleum coke powder, 0.10 graphite powder, and 0.10 silicon powder on a mixer or wheel mill for 0.5 hours ;

[0035] Step 2: Add an alcohol-soluble phenolic resin with a mass fraction of 0.12, an organic plasticizer and ethanol to the above-mentioned homogeneously mixed powder, and roll on a wheel mill for 1 hour;

[0036] Step 3: Break the rolling material into blocks and place it at room temperature;

[0037] Step 4: Crushing and crushing the dried raw materials, passing through an 8-mesh sieve to granulate, and set aside;

[0038]Step 5: Add the raw materials to be used into water-soluble phenolic resin with a mass fraction of 0.15, and mix and grind for 30 minutes;

[0039] Step 6: Seal the mixed and milled raw materials and place them for 6 hours;

[0040] Step 7: The raw material is continuously extruded on a screw extruder or a pisto...

Embodiment 2

[0047] Step 1: Mix silicon carbide powder with a particle size of 60 mesh and a mass fraction of 0.65, 0.2 petroleum coke powder, 0.05 activated carbon powder, and 0.10 silicon powder on a mixer or a wheel mill for 0.5 hours;

[0048] Step 2: Add an alcohol-soluble phenolic resin with a mass fraction of 0.12, an organic plasticizer and ethanol to the above-mentioned homogeneously mixed powder, and roll on a wheel mill for 1 hour;

[0049] Step 3: Break the rolling material into blocks and place it at room temperature;

[0050] Step 4: Crushing and crushing the dried raw materials, passing through an 8-mesh sieve to granulate, and set aside;

[0051] Step 5: Add the raw materials to be used into water-soluble phenolic resin with a mass fraction of 0.15, and mix and grind for 30 minutes;

[0052] Step 6: Seal the mixed and milled raw materials and place them for 6 hours;

[0053] Step 7: The raw material is continuously extruded on a screw extruder or a piston extruder to form...

Embodiment 3

[0060] Step 1: Mix silicon carbide powder with particle size number 120 mesh mass fraction of 0.60 and 180 mesh mass fraction of 0.25, petroleum coke powder of 0.10, and activated carbon powder of 0.05 in a mixer or wheel mill for 0.5 hours;

[0061] Step 2: Add an alcohol-soluble phenolic resin with a mass fraction of 0.10, an organic plasticizer and ethanol to the above-mentioned homogeneously mixed powder, and roll on a wheel mill for 1 hour;

[0062] Step 3: Break the compacted material into blocks, and place it at room temperature for drying;

[0063] Step 4: Crushing and crushing the dried raw materials, passing through a 40-mesh sieve to granulate, and set aside;

[0064] Step 5: Add the raw materials to be used into water-soluble phenolic resin with a mass fraction of 0.08, and mix and grind for 30 minutes;

[0065] Step 6: Seal the mixed and milled raw materials and place them for 6 hours;

[0066] Step 7: The raw material is continuously extruded on a screw extrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com