Calcium phosphate/zirconium oxide gradient porous scaffold as well as preparation method and application

A gradient porous, calcium phosphate technology, applied in the field of biomedical materials, can solve problems such as the difficulty of gradient pore structure, and achieve the effect of facilitating the transportation of nutrients and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

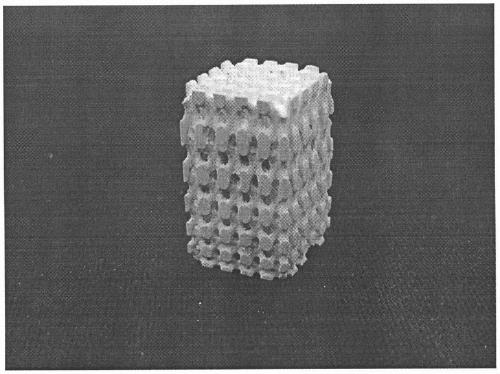

[0034] The preparation of implementation example 1 gradient porous support

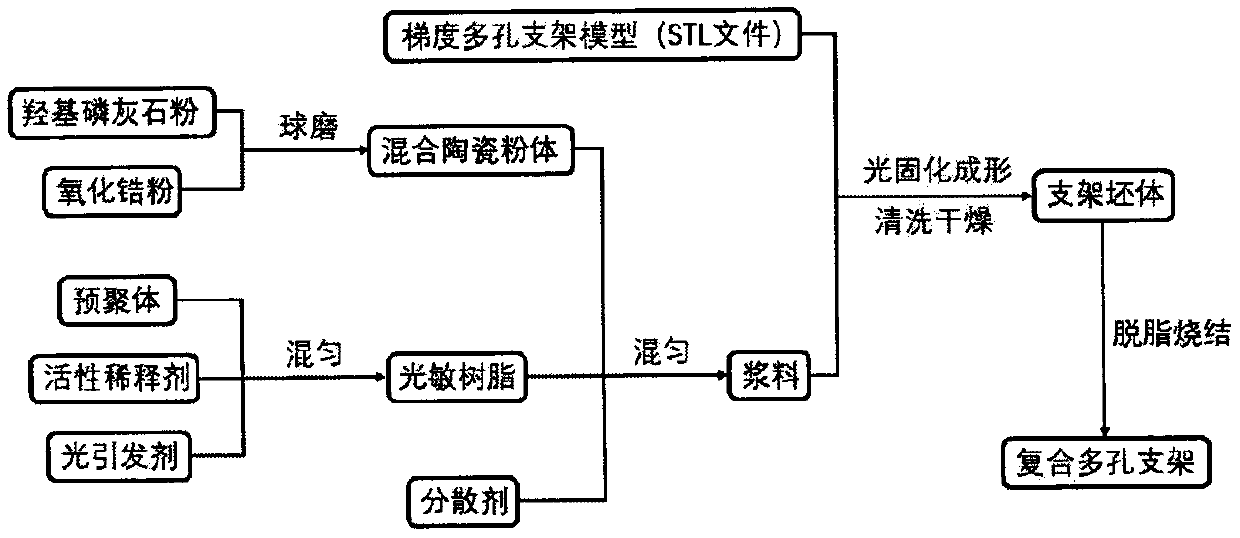

[0035] like figure 1 Shown, a kind of preparation method of calcium phosphate / zirconia controllable gradient porous support is realized through the following steps:

[0036] Step 1. Modeling: use modeling software to design a three-dimensional diagram of the gradient porous scaffold, and save it as an STL file;

[0037] Step 2, ball milling and mixing: mix the hydroxyapatite powder with a particle size of 10 μm and the zirconia powder with a particle size of 300 nm in a mass ratio of 90:10, put them into a planetary ball mill and mill at 100 r / min for 2 hours;

[0038] Step 3. Slurry preparation: add the mixed ceramic powder obtained in step 2 to a photosensitive resin and a dispersant and mix evenly. The mass composition of each component of the slurry is as follows: the mixed ceramic powder is 55%, the photosensitive resin is 43%, and the dispersant is 2%;

[0039] Step 4, green body forming: imp...

Embodiment 2

[0043] Implementation Example 2 Different Aperture Scaffold Cell Proliferation Experiment

[0044] The difference between this implementation example and implementation example 1 is that in step 1, modeling software is used to design a three-dimensional view of a single-aperture bracket, and the rest are basically the same as implementation example 1, and will not be repeated here.

[0045] Finally, porous scaffolds with average pore diameters of 200-300 μm, 300-400 μm, and 400-500 μm are obtained.

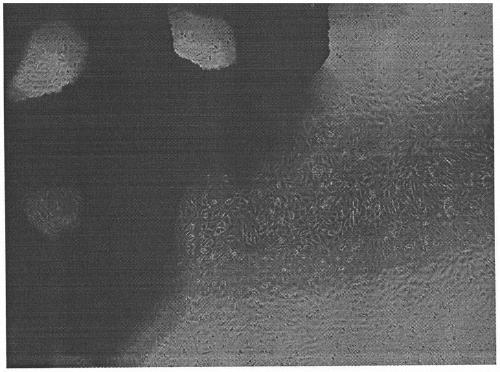

[0046] CCK-8 cell proliferation experiment: scaffolds with different pore diameters were sterilized by high temperature and high pressure, and put into 24-well plates. Inoculate 1ml of MC3T3-E1 cell suspension with a concentration of 5×10 cells / ml in each well, and culture it in a cell incubator at 37°C and 5% CO2, such as image 3 shown. After 24 hours, the scaffolds were taken out, placed in a new 24-well plate, and culture medium was added to continue culturing, and the mediu...

Embodiment 3

[0048] Implementation Example 3 Composite Porous Material Mechanical Properties Test

[0049] The difference between this implementation example and implementation example 1 is: step 1 uses modeling software to design a three-dimensional map of a single-aperture stent, and step 2 the mass ratio of hydroxyapatite to zirconia is 100 / 0, 90 / 10, 80 / 20, 70 / 30, 0 / 100. The rest are basically the same as those in Example 1, and will not be repeated here.

[0050] The compressive strength test was carried out on the prepared composite porous scaffold, and the test results are shown in the table below. The results show that the compressive strength increases gradually with the increase of zirconia incorporation in the hydroxyapatite matrix. The porous composite scaffolds with different proportions can be applied to filling or replacing bone defects in different parts.

[0051] Hydroxyapatite / zirconia mass ratio Compressive strength / MPa 100 / 0 15.25 90 / 10 21.34 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com