Method for fabricating porous TiO2 thin film by utilizing nano-crystalline TiO2 hydrosol

A technology of porous film and hydrosol, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of poor heat resistance and limitations, and achieve the effects of good dispersion, low equipment cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

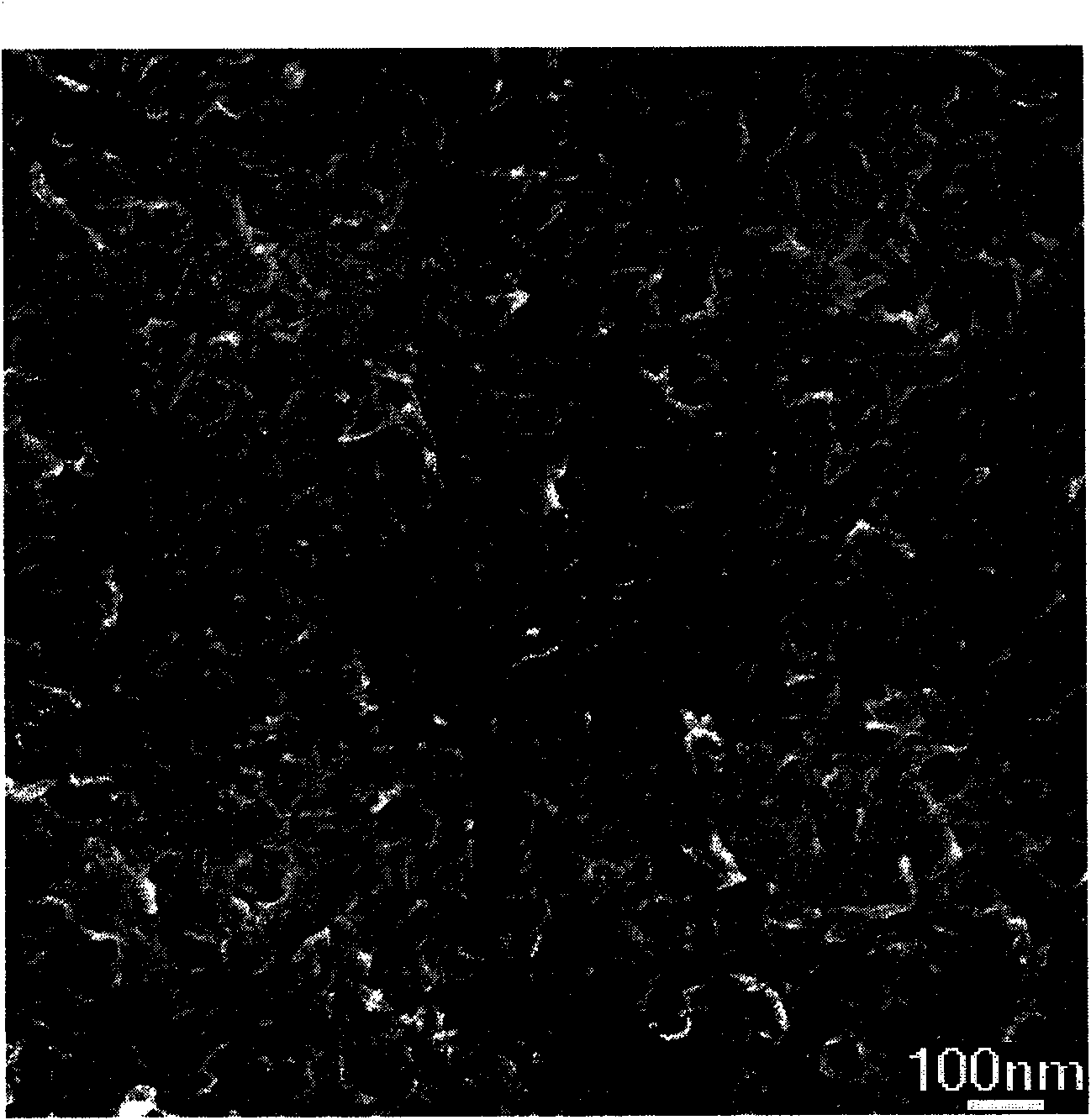

Image

Examples

Embodiment 1

[0024] Example 1: Dissolve titanium sulfate solid in water to form a 0.2M solution, add dropwise 3M ammonia water under stirring and adjust the pH value to 7.5-8.0 to obtain a white precipitate, which is then aged for 20 hours and then filtered and washed until the conductivity of the filtrate is less than 100μs / cm, then dissolve the resulting filter cake in water, ultrasonic for 0.5h, then add H 2 o 2 After the dropwise addition, the temperature was slowly raised to 100°C, and refluxed at 100°C for 4h. After the reaction was completed, the TiO 2 The sol was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, sealed, placed in an oven, and heated at 120°C for 15h to obtain TiO 2 Sol. At room temperature, the prepared TiO 2 The sol is coated on the cleaned indium-doped tin oxide (ITO) conductive glass, repeated several times, and dried at room temperature to obtain TiO 2 porous film.

Embodiment 2

[0025] Example 2: Dissolve the titanium sulfate solid in water to make a 0.2M solution, add dropwise 3M ammonia water under stirring and adjust the pH value to 7.5-8.0 to obtain a white precipitate, which is then aged for 10 hours and then filtered and washed until the conductivity of the filtrate is less than 100μs / cm, then dissolve the obtained filter cake in absolute ethanol, ultrasonic for 1h, and then dropwise add H 2 o 2 After the dropwise addition, the temperature was slowly raised to 78°C, and refluxed at 78°C for 6h. After the reaction was completed, the TiO 2 The sol was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, sealed, placed in an oven, and heated at 120°C for 15 hours. After the reaction was completed, it was filtered by suction and ultrasonically redispersed in water. At 80°C, it was sprayed Prepared TiO 2 The hydrosol is coated on a cleaned flexible conductive substrate polyethylene terephthalate / indium-doped tin oxide (PET...

Embodiment 3

[0026] Example 3: Dissolve the titanium sulfate solid in water to form a 0.1M solution, add dropwise 3M ammonia water under stirring and adjust the pH value to 7.5-8.0 to obtain a white precipitate, which is then aged for 18 hours and then filtered and washed until the conductivity of the filtrate is less than 100 μs / cm, and then the resulting filter cake was dissolved in a mixed solvent of water and ethanol with a volume ratio of 1:1, ultrasonicated for 1 h, and then added dropwise with stirring in an ice bath. 2 o 2 After the dropwise addition, the temperature was slowly raised to 90°C, and refluxed at 90°C for 5h. After the reaction was completed, the TiO 2 The sol was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, sealed, placed in an oven, and heated at 140 °C for 12 h. At room temperature, the prepared TiO 2 The sol is coated on the cleaned fluorine-doped tin oxide (FTO) conductive glass, repeated several times, and dried at room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com