Bag culture system for large-scale production of solanaceous vegetables

A technology for cultivation of solanaceous fruits and bag cultivation is applied in the field of bag cultivation system for large-scale production of solanaceous fruits and vegetables, and can solve the problems such as troublesome cultivation of cultivation bags, unreusable water and nutrient solution, unreasonable design specifications of cultivation bags, and the like, Achieve the effect of improving crop yield and quality, preventing the spread of soil-borne diseases, and reducing the occurrence of vegetable diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The bag cultivation system for large-scale production of solanaceous vegetables provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

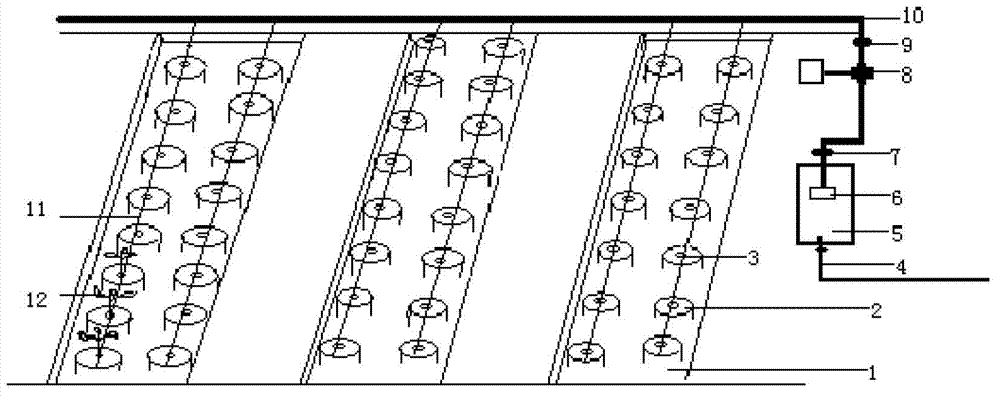

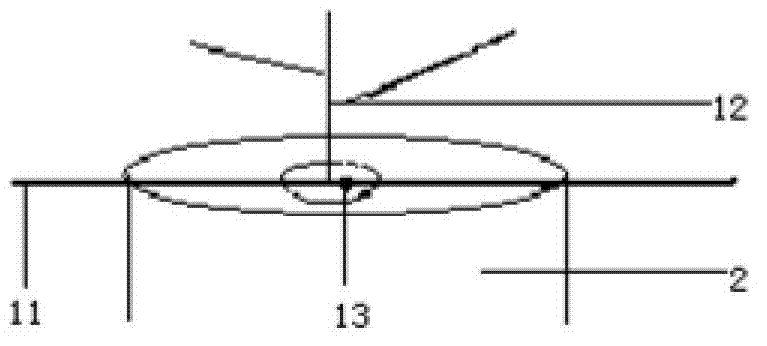

[0019] Such as figure 1 , 2 As shown, the bag cultivation system for large-scale production of solanaceous vegetables provided by the present invention includes a plurality of cultivation tanks 1, a plurality of cultivation bags 2, water inlet pipe 4, water storage tank 5, water pump 6, fertilizer applicator 8, filter 9. Drip irrigation main pipe 10, a plurality of drip irrigation branch pipes 12 and a plurality of drippers 13; wherein the cultivation tank 1 is in the shape of a cuboid, and a plurality of cultivation tanks 1 are sunken and formed side by side on the greenhouse floor; A round hole 3 is formed, and at least one row of upright cultivation bags 2 is arranged in each cultivation groove 1, and a space is left between adjacent cultivation bags ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com