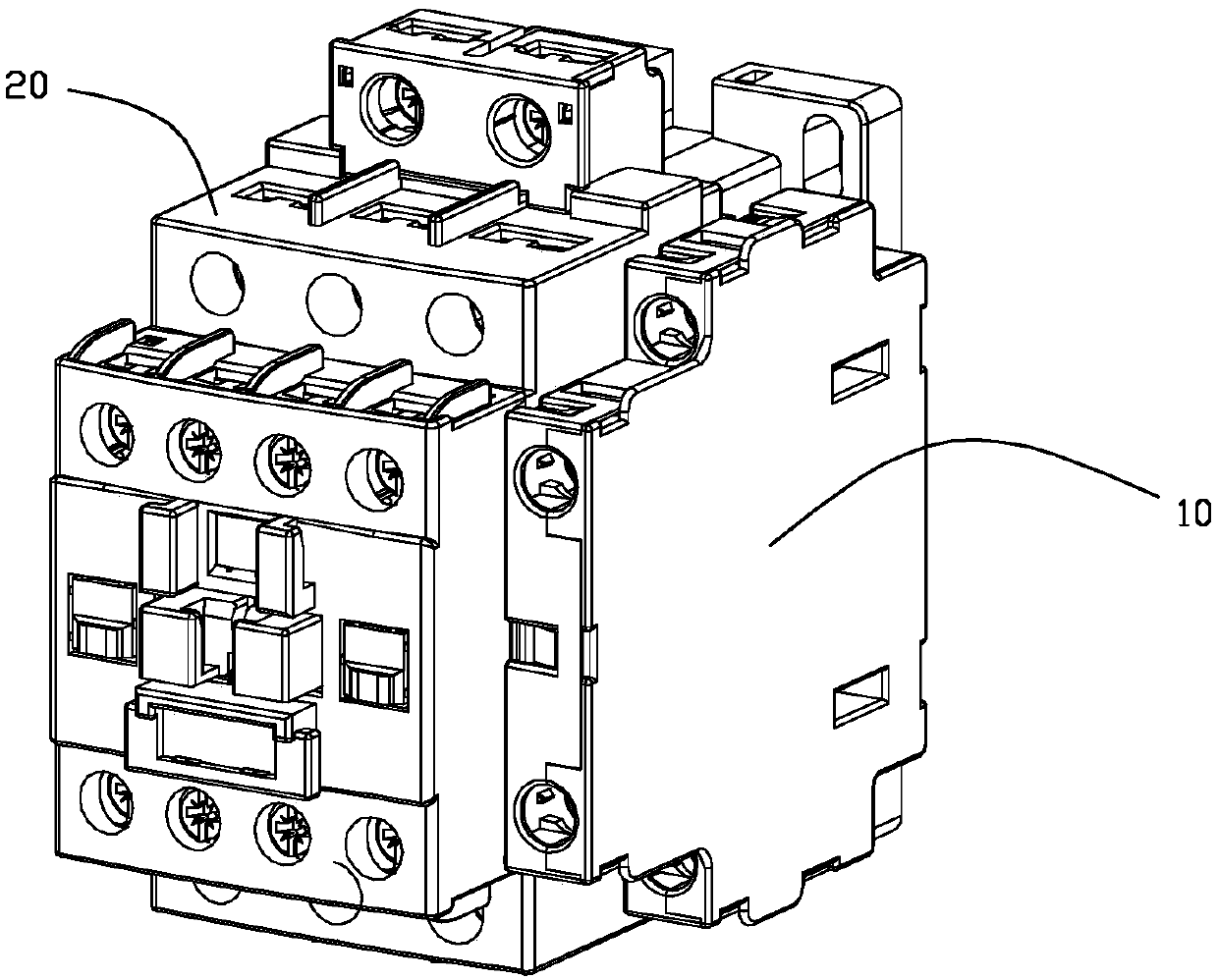

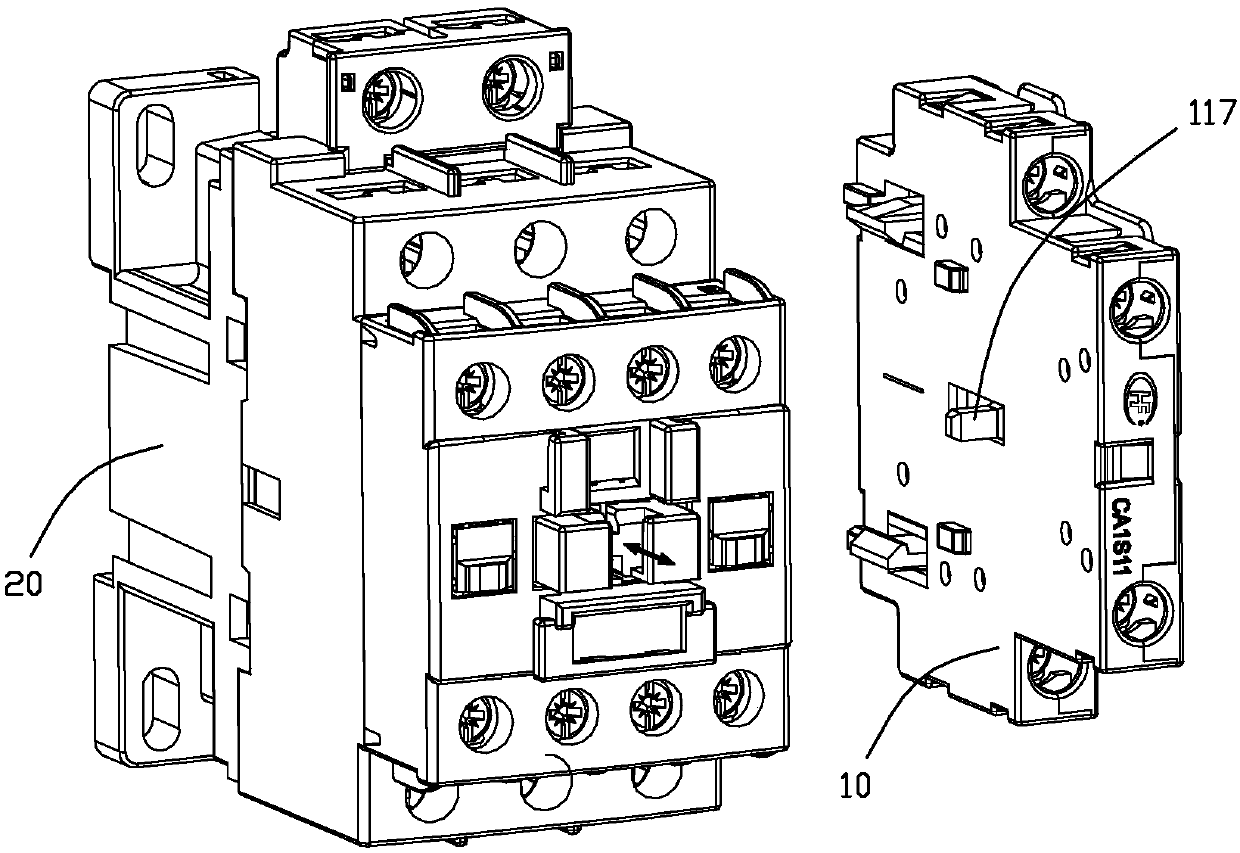

Side-hung auxiliary contact module with contact adhesion self-locking function

An auxiliary contact and self-locking technology, which is applied in the direction of electromagnetic relay details, relays, electrical components, etc., can solve the waste of resources, the failure to realize the locking of the moving contact at the normal end, and the contact cannot meet the application of mechanical interlocking contacts Demand and other issues to achieve the effect of ensuring safety, reducing burden and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

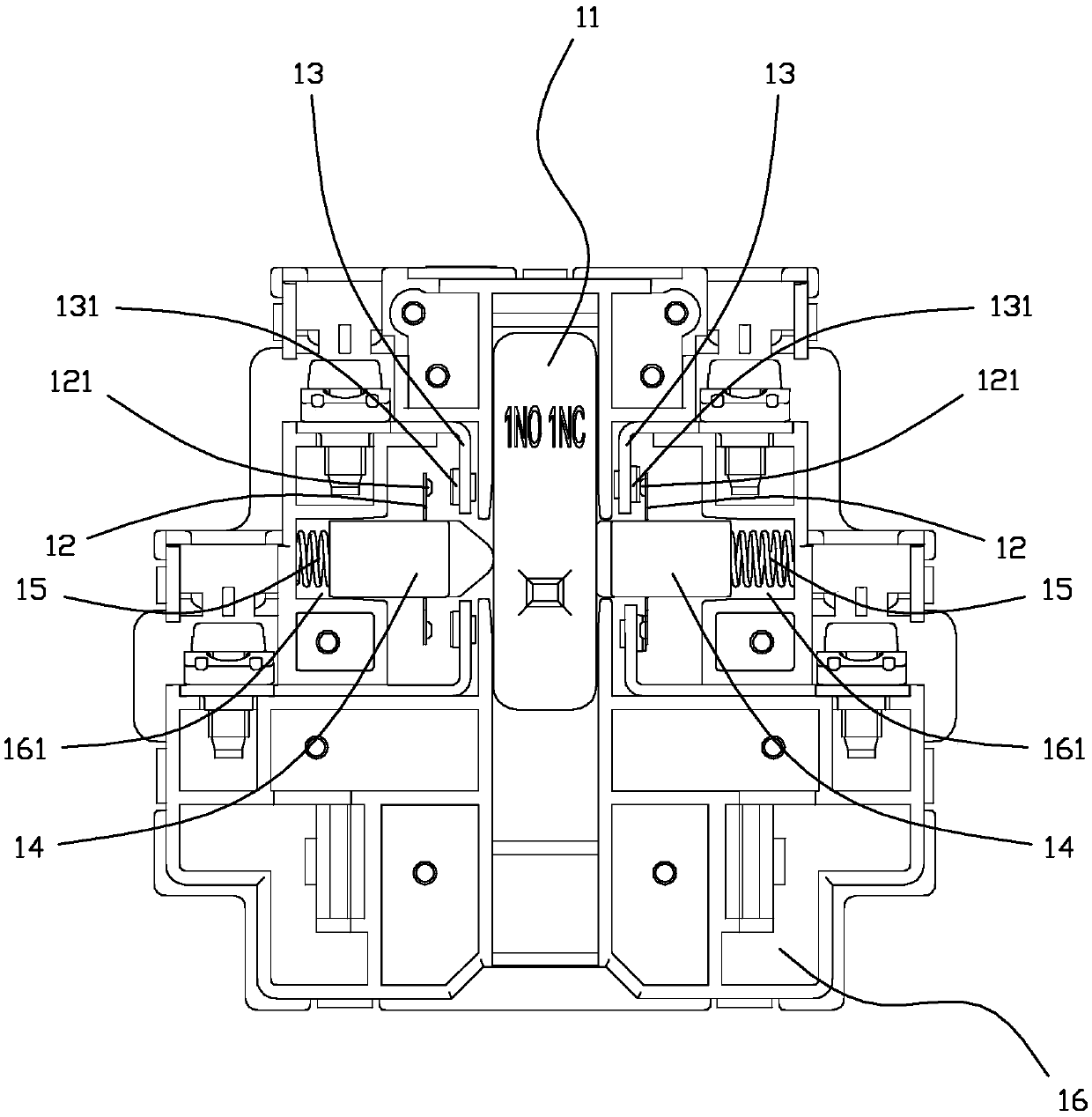

[0049] In this embodiment, the working states of the moving contacts 12 on both sides of the sliding bar 11 are mutually exclusive. Correspondingly, the specification of the sliding bar 11 is 1NO1NC, that is, NO+NC (normal open+normal close: normally open+normally closed). Such as image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the moving contacts 12 on both sides of the sliding bar 11 are in the opposite working state at the same time under the action of the sliding bar 11; when the moving contact 12 on one side of the sliding bar 11 is closed with the static contact 13, the sliding bar The movable contact 12 on the other side of 11 is locked by the slide bar 11 and keeps disconnected from the static contact 13. Since the moving direction of the moving contact 12 is inconsistent with the moving direction of the body contactor 20, and through the mechanical action of the sliding rod 11, the moving contacts 12 on both sides of the sliding rod 11 form a mechanical inte...

Embodiment 2

[0061] In this embodiment, the moving contacts 12 on both sides of the sliding bar 11 work in the same state. Correspondingly, the specification of the sliding bar 11 is 2NO, that is, the initial working state of this embodiment is the auxiliary contact normally open. Such as Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, the moving contacts 12 on both sides of the sliding bar 11 are in the same working state at the same time under the action of the sliding bar 11; closed; or simultaneously drive the moving contacts 12 and the static contacts 13 on both sides to maintain the disconnected state.

[0062] Such as Figure 12 , Figure 14 , Figure 15 , Figure 16 As shown, the specific structure is as follows: the slide bar 11 is provided with a release section 114 and a locking section 115, the width of the release section 114 is smaller than that of the locking section 115, and they are arranged coaxially; the connection position between the release section ...

Embodiment 3

[0066] In this embodiment, the moving contacts 12 on both sides of the sliding bar 11 work in the same state. Correspondingly, the specification of the sliding bar 11 is 2NC, that is, the initial working state of this embodiment is that the auxiliary contact is normally closed. Such as Figure 17 , Figure 18 , Figure 19 , Figure 10 As shown, the moving contacts 12 on both sides of the sliding bar 11 are in the same working state at the same time under the action of the sliding bar 11; closed; or simultaneously drive the moving contacts 12 and the static contacts 13 on both sides to maintain the disconnected state.

[0067] Such as Figure 18 , Figure 20 , Figure 21 , Figure 22 As shown, the positions or directions of the release section 114 and the locking section 115 of this embodiment are opposite to those of the second embodiment, and furthermore, the only difference from the second embodiment is the initial working state.

[0068] Other parts are identical with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com