Cigarette tinfoil positioning, trimming and cutting device

A cutting device and tinfoil technology, applied in metal processing and other directions, can solve the problems of lack of tension in tinfoil, low cutting accuracy, and paper jams in the cutting machine, and achieve the effects of preventing paper jams, low installation accuracy and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

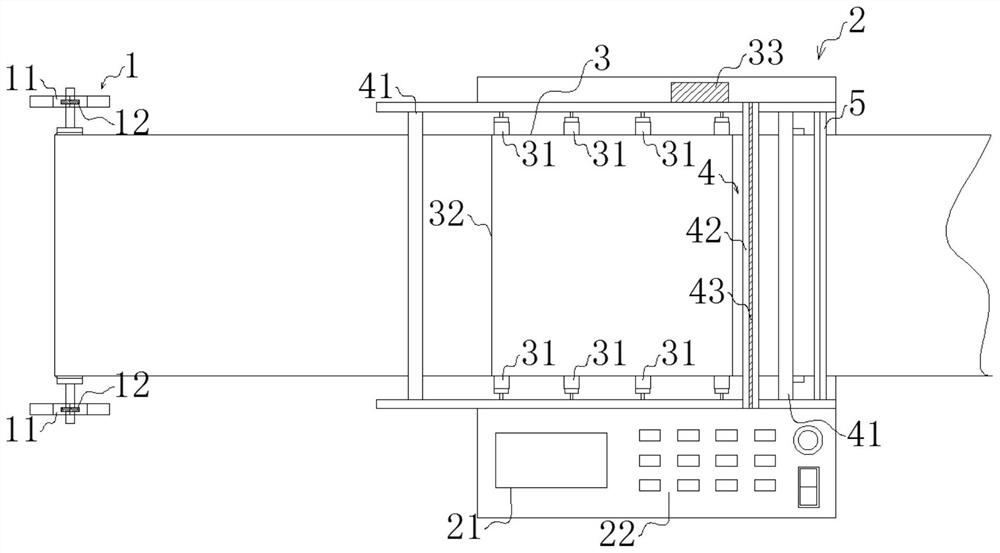

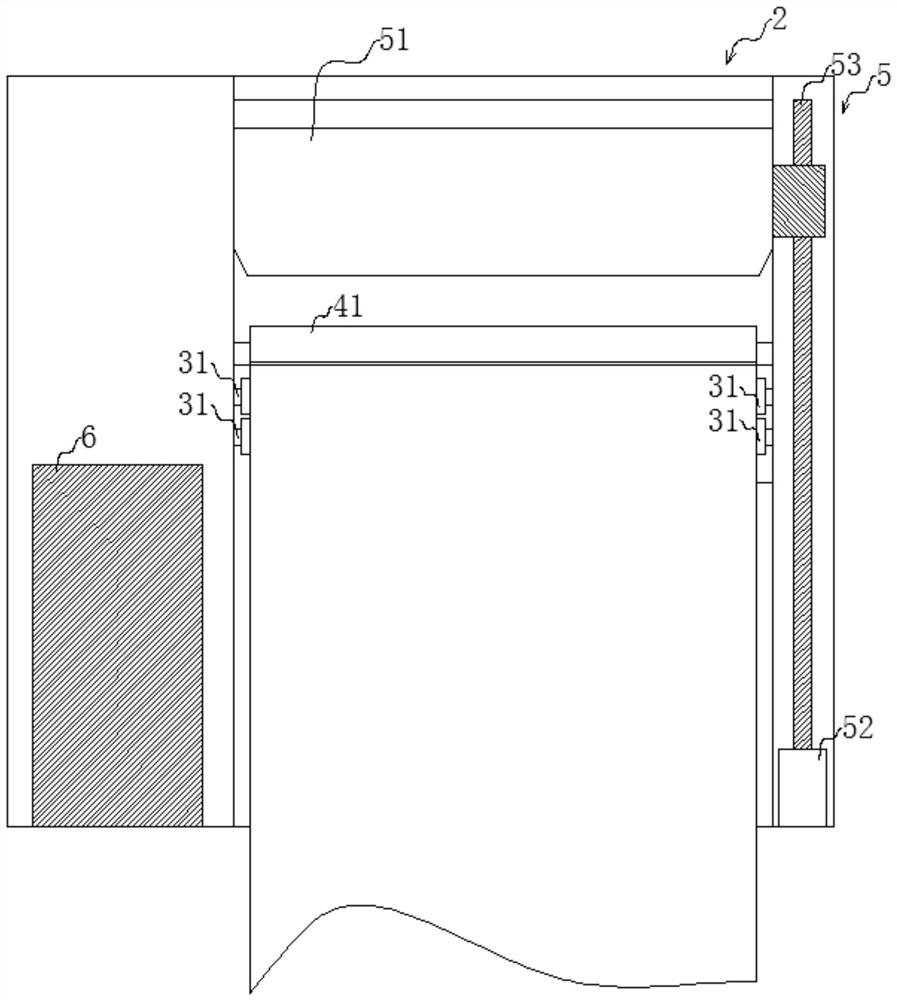

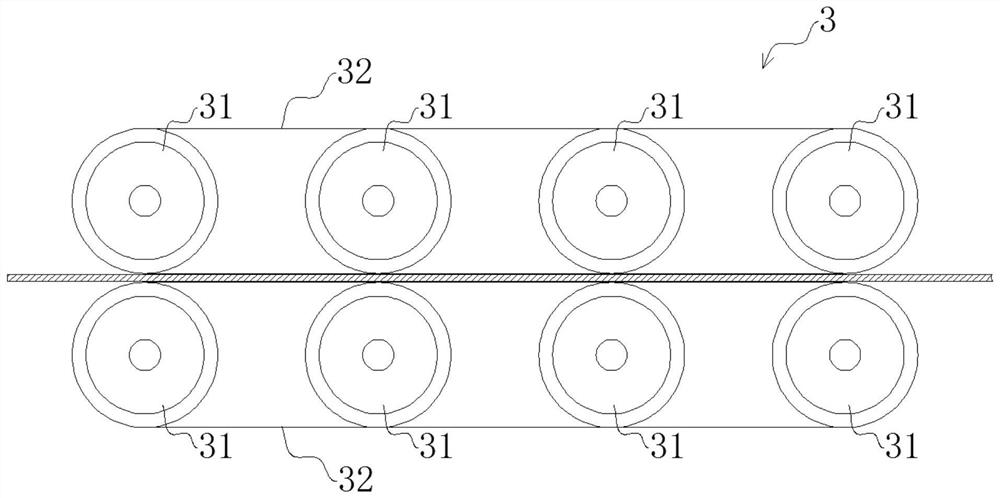

[0021] The following is attached Figure 1-3 To further describe the application in detail, the following examples are only exemplary, and can only be used to explain and illustrate the technical solution of the application, and cannot be construed as a limitation to the technical solution of the application.

[0022] This embodiment discloses a cigarette tin foil positioning trimming and cutting device, refer to figure 1 and figure 2 , including a support frame 1, a cutting body 2, a transmission assembly 3, a positioning assembly 4, a cutting assembly 5 and a control unit 6, the support frame 1 is arranged at intervals on one side of the cutting body 2, and the support frame 1 provides a stable support for the tinfoil roll , the cutting body 2 provides a stable installation position for other components, the transmission assembly 3 and the positioning assembly 4 are arranged on the top of the cutting body 2, and the positioning assembly 4 is arranged on both sides of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com