Method for stamping automobile beam piece

A technology for stamping and forming of automobile beams, which is applied in the field of stamping and forming of automobile beams, can solve the problems of distortion and springback of beam shape characteristics, difficulty in correcting the mold surface, and unfavorable use of machine tools, so as to achieve small forming springback and increase material utilization. rate, the effect of reducing the number of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

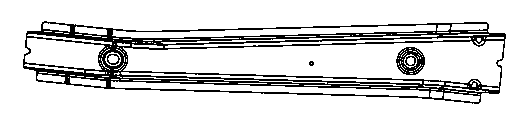

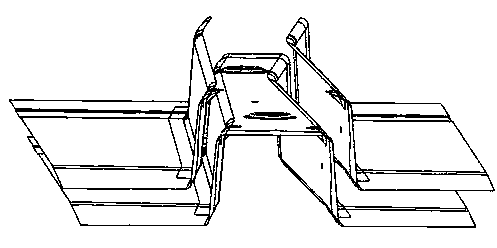

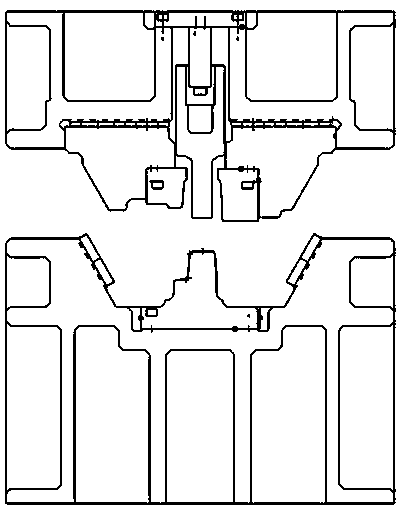

[0017] The invention relates to a stamping forming method of an automobile beam, which adopts a flanging process and a side shaping process to replace the previous drawing process, and reduces the relatively serious twisting and springback in the drawing process. In the flanging process, by adjusting the gap between the flanging knife block and the punch, it was found that the larger the gap between the flanging knife block and the punch, the smaller the springback of the part. In order to control the complexity of the mold and the size of the mold, it is better to have a clearance of 10-20mm between the flanging knife block and the punch. In the side shaping process, the shaping angle can also affect the springback of the part. After many experiments and researches, the shaping angle is preferably between 45° and 60°. Since the shape of the part is mainly achieved by the side shaping process, there is no need to consider the problem that the undercut of the mold surface canno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com