Method for exfoliation and transfer of GaN-on-Si epitaxial layer

A stripping transfer, silicon-based nitrogen technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of lack of good, inability to grow substrate materials, development and application limitations, and achieve a wide range of materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

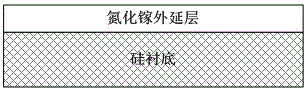

[0039] ① Soak the GaN epitaxial wafers and glass wafers grown on silicon substrates in 10% hydrochloric acid (HCl) for 30 seconds, then rinse with deionized water, and dry them in a dryer;

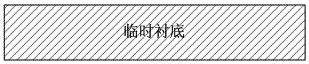

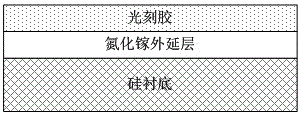

[0040] ② Spin-coat photoresist on the front side of the GaN-on-Si wafer, and paste the GaN-on-Si epitaxial wafer on the temporary carrier through the photoresist; the rotation speed is 2000 rpm, the acceleration is 2000 rpm, spin coating The time is 90 seconds;

[0041] ③ Place the silicon-based gallium nitride wafer coated with photoresist facing up on the heating plate, the temperature of the hot plate is 110 degrees Celsius, and the baking time is 2 minutes;

[0042] ④Take the silicon-based gallium nitride wafer from the hot plate and stack it on the front side of the sapphire, fix it with a fixture and put it into the bonding machine for bonding. The bonding force is 4000N and the bonding time is 60 minutes;

[0043] ⑤ Take 100ml of analytically pure hydrofluoric acid (HF) solution an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com