Electroplating method for automobile trunk decoration strip

A technology for trunks and decorative strips, which is applied in jewelry and other fields, and can solve problems such as poor coating ability, blistering, and inadequate plastic surface treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

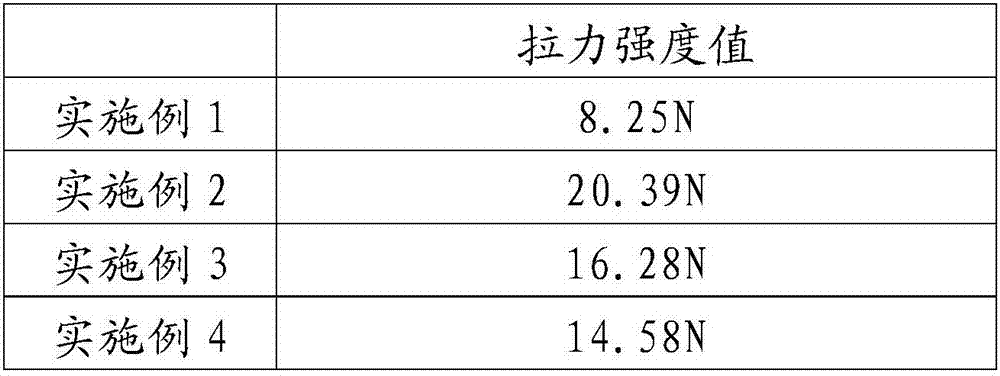

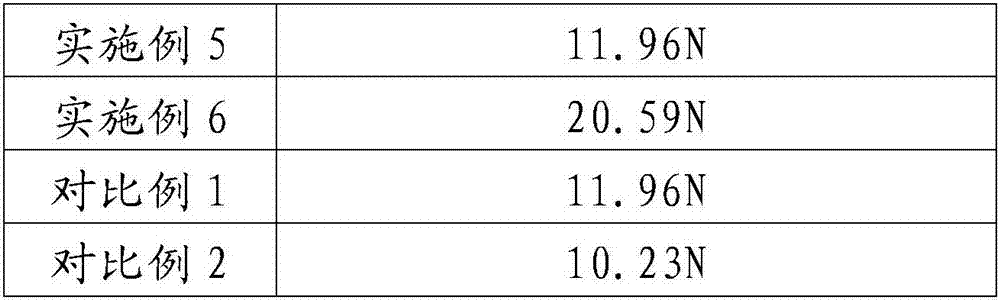

Examples

Embodiment 1

[0033] Embodiment 1, the automobile trunk decorative strip electroplating method of the present invention comprises the following steps:

[0034] 1. Pretreatment before electroplating

[0035] The substrate to be electroplated is pre-treated for electroplating, and the following steps are performed in sequence:

[0036] (1) Ultrasonic wax removal: Soak the parts to be plated in a wax removal solution at a temperature of 55°C-65°C (a wax remover with a concentration of 20ml / L-40ml / L) for 3min-5min.

[0037] (2) Ultrasonic degreasing: Put the parts to be plated into the degreasing liquid in the ultrasonic device. The degreasing liquid includes the following components: 1mol / L sodium hydroxide, 1mol / L sodium carbonate and 0.1mol / L dodecane Sodium sulfonate; soak the two-color plastic for 5 minutes at the temperature of the degreasing solution at 50°C, take it out and wash it with tap water.

[0038] (3) Pre-roughening: Soak the parts to be plated after cleaning in the above ste...

Embodiment 2

[0067] Prepare the plated part Y2 according to the method of Example 1, the difference is that the temperature of the electroplating solution in the Watt nickel plating is 50°C, the electroplating time is 10min, and the electroplating voltage is 3.5V;

[0068] The temperature of the electroplating solution in acid copper plating is 22°C, the electroplating time is 40min, and the electroplating steady current is 720A;

[0069] The temperature of the electroplating solution in semi-gloss nickel plating is 50°C, the electroplating time is 30minmin, and the electroplating steady current is 810A;

[0070] The temperature of the electroplating solution in the secondary high-sulfur nickel plating is 55°C, the electroplating time is 5min, and the electroplating steady flow is 720-A;

[0071] The temperature of the electroplating solution in the bright nickel plating is 50°C, the electroplating time is 20min, and the electroplating steady current is 630A;

[0072] The temperature of t...

Embodiment 3

[0075] Prepare the plated part Y3 according to the method of Example 1, the difference is that the temperature of the electroplating solution in the Watt nickel plating is 60°C, the electroplating time is 12min, and the electroplating voltage is 4.5V;

[0076] The temperature of the electroplating solution in acid copper plating is 28°C, the electroplating time is 48min, and the electroplating steady current is 880A;

[0077] The temperature of the electroplating solution in semi-gloss nickel plating is 60°C, the electroplating time is 36min, and the electroplating steady current is 990A;

[0078] The temperature of the electroplating solution in the secondary high-sulfur nickel plating is 65°C, the electroplating time is 6min, and the electroplating steady current is 880A;

[0079] The temperature of the electroplating solution in the bright nickel plating is 60°C, the electroplating time is 24min, and the electroplating steady current is 770A;

[0080] The temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com