UV curing intaglio printing ink and preparation thereof

A technology of gravure printing ink and rolling ink, which is applied in the field of UV gravure printing ink and its preparation, can solve the problems of long drying cycle, easy dry plate, dry roll and poor transferability, and achieve good stability on the machine, fast curing speed, Excellent effect of scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

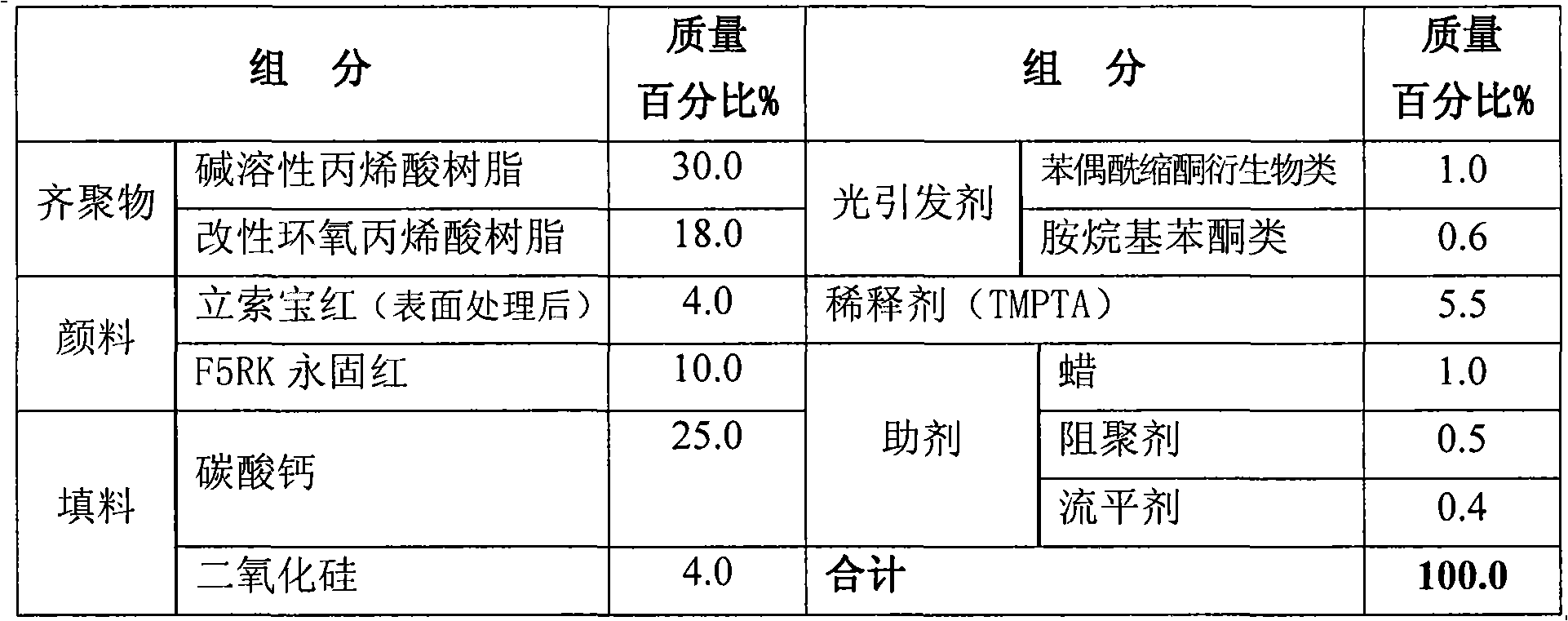

[0029] The red UV curable gravure ink comprises the following components by mass percentage as shown in Table 1:

[0030] Oligomer 48.0%

[0031] Photoinitiator 1.6%

[0032] Pigment 14%

[0033] Thinner (select TMPTA) 5.5%

[0034] Auxiliary 1.9%

[0035] Filler 29%

[0036] Among them, the oligomer includes alkali-soluble acrylic resin and 18% modified epoxy acrylic resin in mass percent respectively accounting for the sum of all components of 30%; Acyl ketal derivatives photoinitiator and 0.6% aminoalkyl phenone photoinitiator; pigments include 4% surface-treated Rixor Red and 10% F5RK of the sum of all components by mass percentage Everlasting red; fillers include 4% silicon dioxide and 25% calcium carbonate in the sum of all components by mass percentage; additives include 0.5% polymerization inhibitor and 0.4% leveling agent in the sum of all components by mass percentage agent and 1.0% wax.

[0037] Table 1 Mass percentage of red UV curing gravure printing ink co...

Embodiment 2

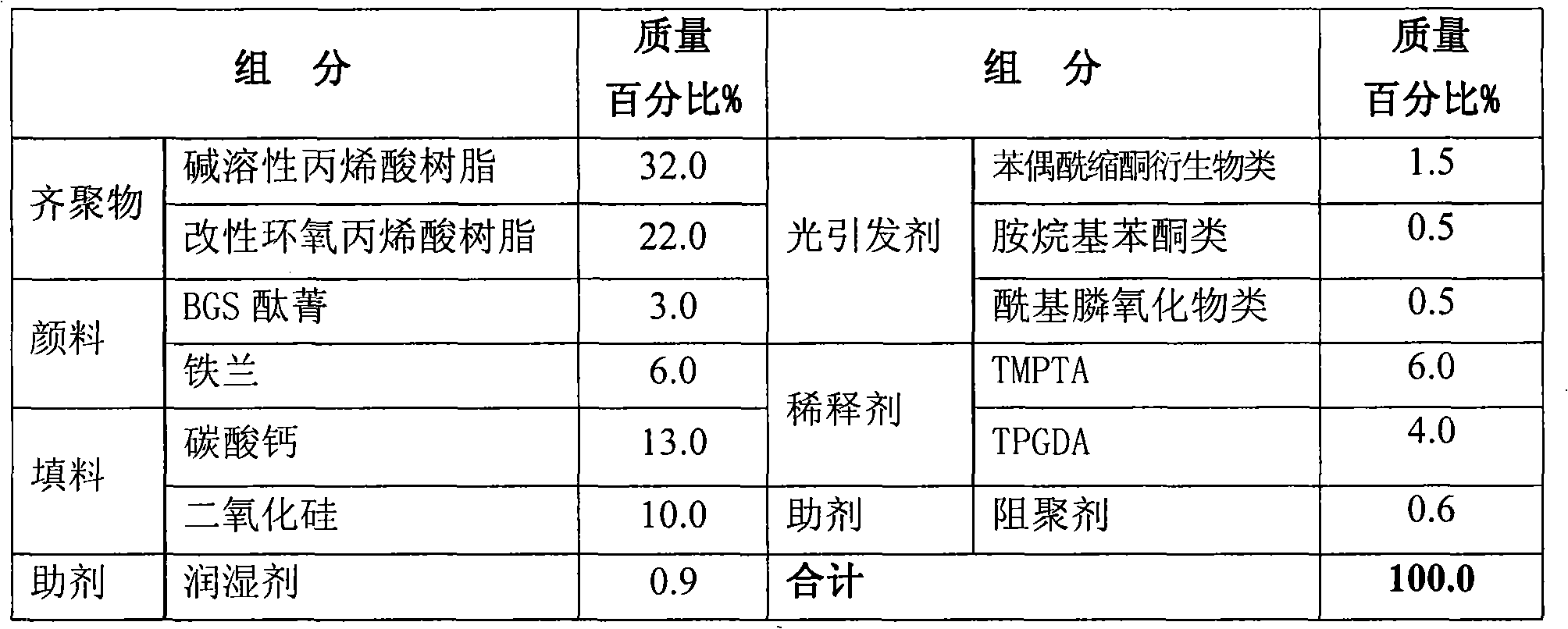

[0042] The component mass percent of blue UV curing gravure printing ink is as shown in table 2:

[0043] Oligomer 54%

[0044] Photoinitiator 2.5%

[0045] Pigment 9.0%

[0046] Thinner 10.0%

[0047] Auxiliary 1.5%

[0048] Filler 23.0%

[0049] Among them, the oligomer includes alkali-soluble acrylic resin and 22% modified epoxy acrylic resin in mass percent respectively accounting for the sum of all components of 32%; Acyl ketal derivatives photoinitiator, 0.5% amino alkyl phenone photoinitiator, 0.5% acyl phosphine oxides; pigments include BGS phthalocyanine and 6% by mass percentage of the sum of all components % Tillandsia; fillers include 10% silicon dioxide and 13% calcium carbonate in the sum of all components by mass percentage; additives include 0.6% polymerization inhibitor and 0.9% wetting agent in the sum of all components by mass percentage aerosol.

[0050] Table 2 The mass percentage of blue UV curing gravure printing ink components

[0051]

[005...

Embodiment 3

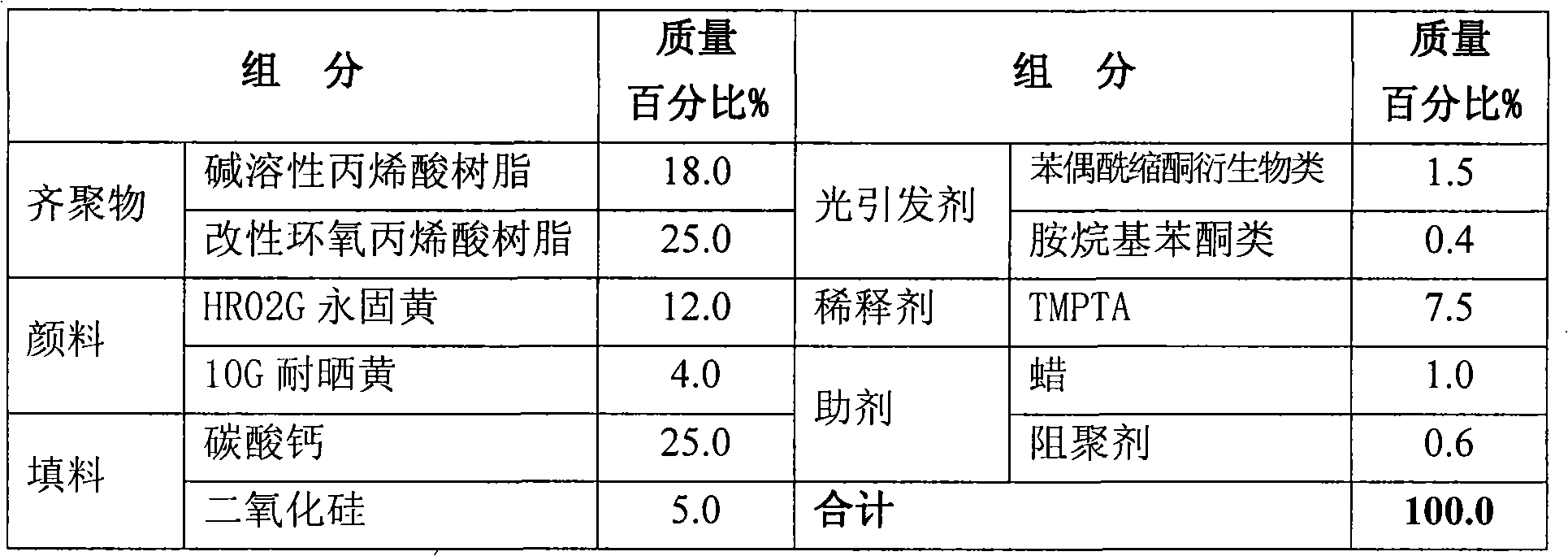

[0054] The component mass percent of yellow UV curable gravure printing ink is as shown in table 3:

[0055] Oligomer 43.0%

[0056] Photoinitiator 1.9%

[0057] Pigment 16.0%

[0058] Thinner 7.5%

[0059] Auxiliary 1.6%

[0060] Filler 30.0%

[0061]Among them, the oligomer includes alkali-soluble acrylic resin and 25% modified epoxy acrylic resin in mass percent respectively accounting for the sum of all components of 18%; Acyl ketal derivatives photoinitiator, 0.4% amino alkyl phenone photoinitiator; pigments include HR02G permanent yellow and 4% 10G light fast yellow that account for the sum of all components in mass percentage; filler It includes 5% of silicon dioxide and 25% of calcium carbonate in the sum of all components by mass percentage; the auxiliary agent includes 1.0% of wax and 0.8% of polymerization inhibitor in the sum of all components in mass percentage.

[0062] The component mass percent of table 3 yellow UV curable gravure printing ink

[0063] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com