High-performance adhesive tape without stimulation to human sense organs

A high-performance, sensory technology, used in adhesives, film/flake adhesives, etc., can solve problems such as human irritation, and achieve the effects of extending service life, reducing light transmission, and enhancing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

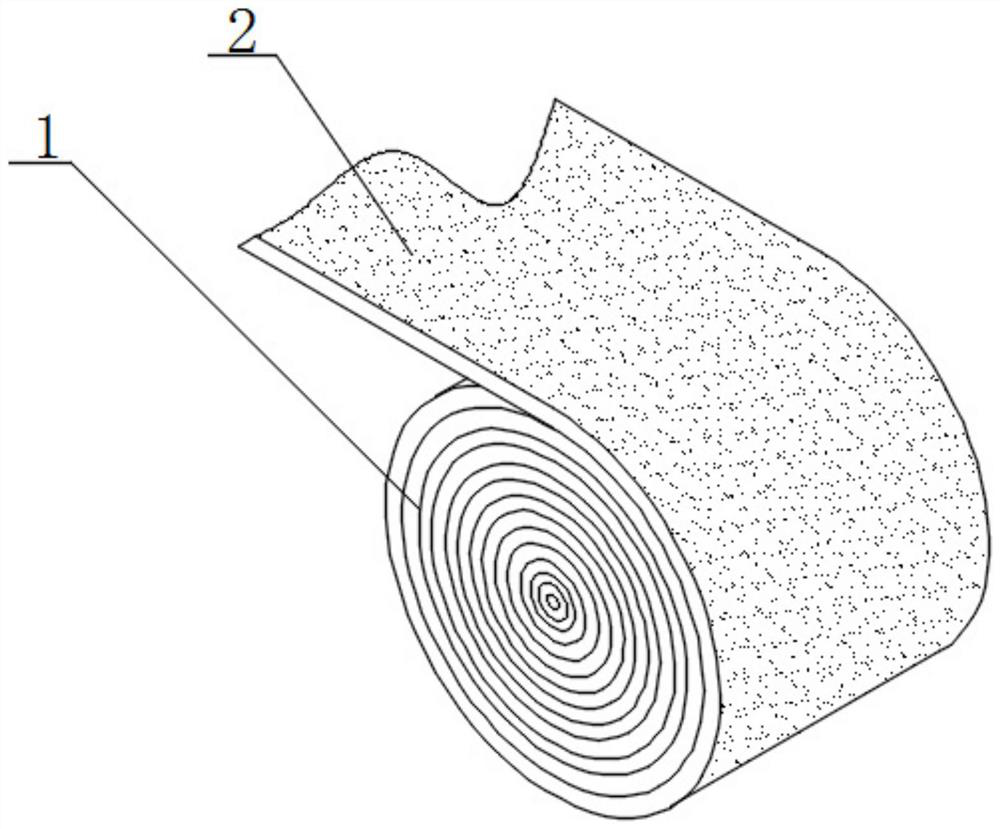

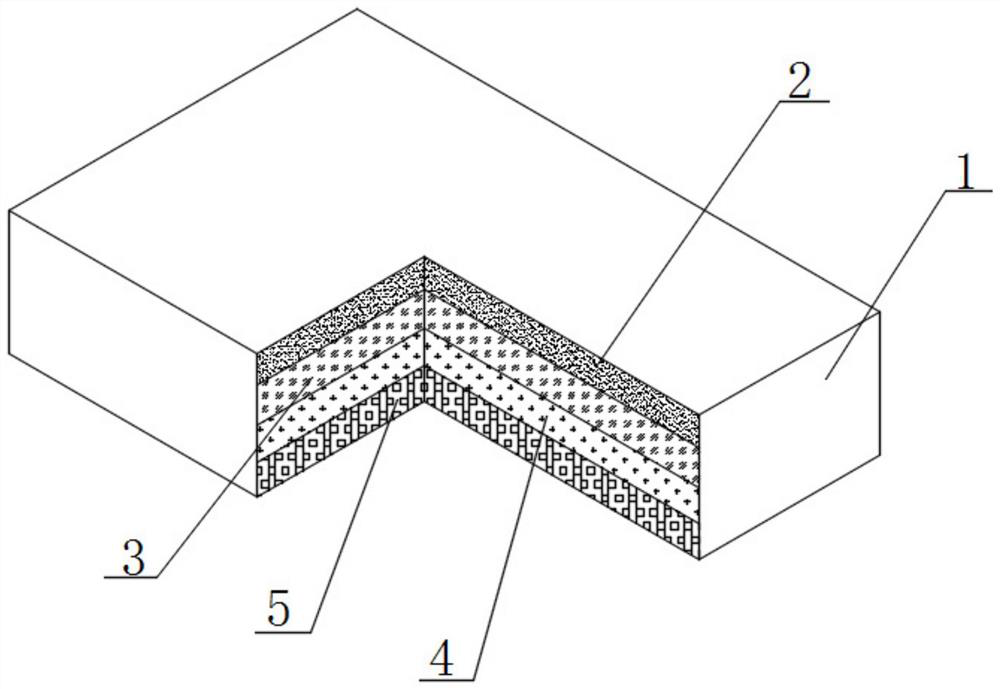

[0023] Example 1: See figure 1 and figure 2 , a kind of non-irritating human sensory high-performance adhesive tape, comprising a main body 1, an anti-slip layer 2 is installed on the inner top wall of the main body 1, a shielding layer 3 is installed on the bottom of the anti-skid layer 2, and a shielding layer 3 is installed on the bottom of the shielding layer 3 There is a tough layer 4, the bottom of the tough layer 4 is equipped with an adhesive layer 5, the anti-slip layer 2 can effectively prevent the relative sliding between the fingers and the adhesive tape, and the shielding layer 3 can reduce sunlight, so that the adhesive layer 5 at the bottom It will not be exposed to sunlight, the toughness layer 4 can increase the toughness of the adhesive tape, making it less likely to break, and the adhesive layer 5 can facilitate the adhesive tape to bond objects.

Embodiment 2

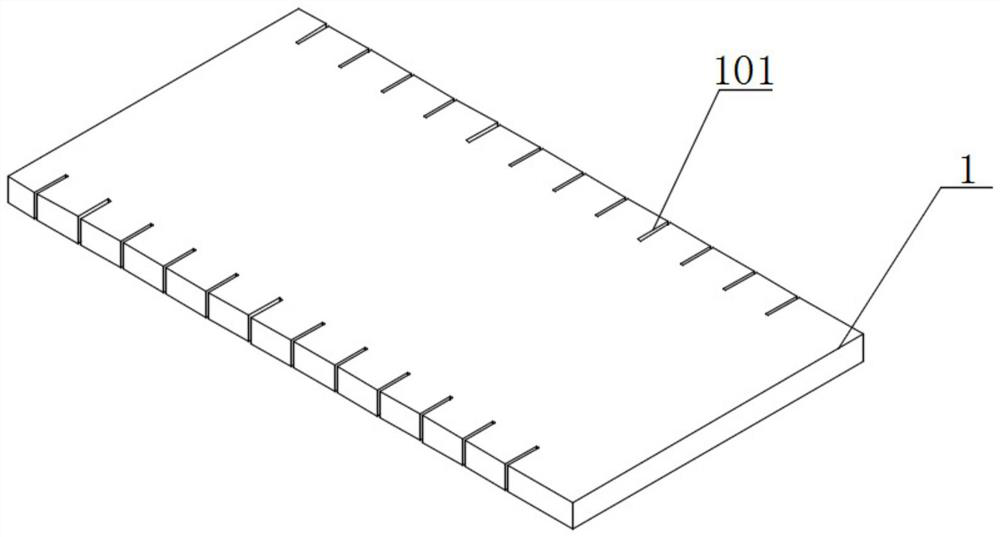

[0024] Example 2: see image 3 , a high-performance adhesive tape that does not stimulate human senses. The outer walls of both sides of the main body 1 are provided with tear seams 101. First, when the staff uses the adhesive tape, the adhesive tape is stretched, and then the adhesive tape is pasted on the items to be bonded. At this time, the adhesive tape needs to be cut off. Generally, a knife is used to cut off the adhesive tape. The existence of the tear seam 101 can help the staff to tear off the adhesive tape quickly. The staff can clamp the two ends of the tear seam 101 with both hands, one in front of the other Finally, the adhesive tape is torn, and due to the existence of the tearing seam 101, the adhesive tape can be broken quickly, which is convenient for the staff to use and speeds up the work.

Embodiment 3

[0025] Example 3: See Figure 4 , a high-performance adhesive tape that does not stimulate human senses, the outer wall of the anti-skid layer 2 is provided with a plurality of anti-skid patterns 201, the outer wall of the anti-skid layer 2 is equipped with frosted sheets 202, and the outer wall of the shielding layer 3 is equipped with a plurality of shielding sheets 301, a dark sheet 302 is installed on the outer wall of the shielding layer 3, a toughness strip 402 is installed on the outer wall of the toughness layer 4, a polyurethane layer 401 is installed on the outer wall of the toughness layer 4, and an anaerobic strip 401 is installed on the outer wall of the adhesive layer 5. Adhesive layer 501, when the staff holds the adhesive tape, the finger part is in contact with the outer wall of the anti-skid layer 2, and the anti-skid pattern 201 can be closely attached to the finger part of the staff to prevent relative sliding and enhance the anti-skid effect. Secondly, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com