Production system of hollow special-shaped double-faced adhesive tape die-cutting part

A production system and double-sided adhesive technology, applied in the direction of adhesive products, layered products, films/sheets without carriers, etc., can solve the problems of product quality decline, product displacement of hollow die-cut parts, etc. Waste, the effect of reducing size defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

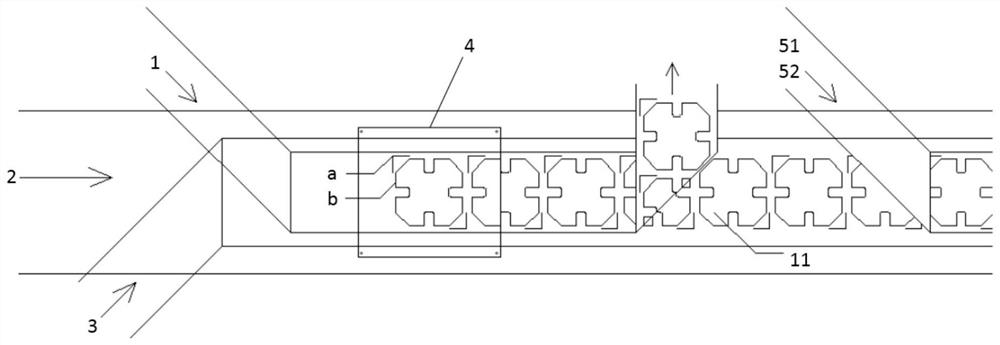

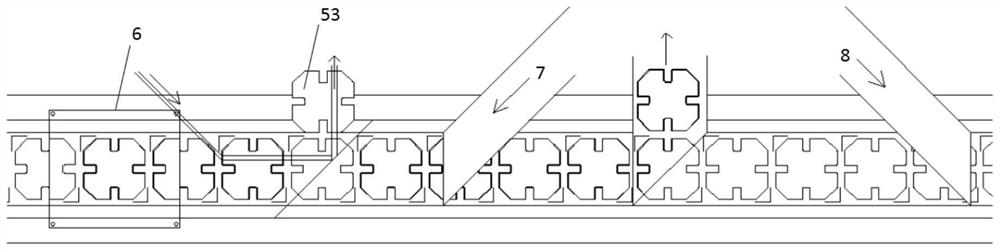

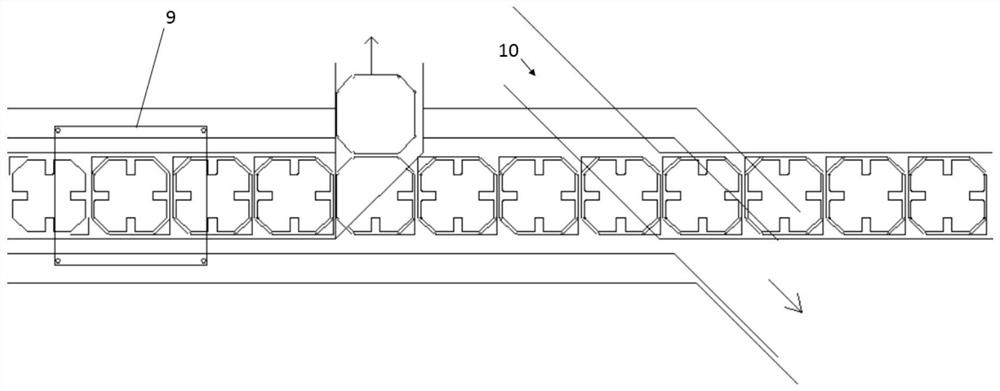

[0048] A production system for hollowed-out special-shaped double-sided adhesive die-cut pieces, such as Figure 1-4 , the system includes a laminating unit before punching, a die-cutting unit before punching, a laminating unit before punching two, die-cutting machine 6 for two punches, a waste discharge unit for two punches, a die-cutting unit for three punches and a receiving unit for die-cut pieces; Laminating unit includes handle release film discharge roller, low-viscosity protective film discharge roller and low-viscosity bottom film discharge roller, handle release film discharge roller unwinds handle release film 2, low-viscosity protection The film unwinding roller unwinds the low-viscosity protective film 1, and the low-viscosity bottom film unwinds the low-viscosity bottom film 3. After the laminating unit before punching, the low-viscosity protection film 1 and the low-viscosity bottom film 3 respectively Attached above and below the release film 2 of the handle; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com