Device and method for dipping of copper wire winding of automobile generator stator

A technology of automobile generator and stator copper wire, which is applied to electromechanical devices, manufacturing motor generators, and electric components, etc., can solve the problems of increased cleaning difficulty, increased energy consumption, low heat conduction efficiency, etc., and achieves a uniform and beautiful surface of the sticky paint layer. , The efficiency of heat conduction is improved, and the effect of increasing the space of the dipping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further explained below in conjunction with the drawings and embodiments, but the following content is not intended to limit the protection scope of the present invention.

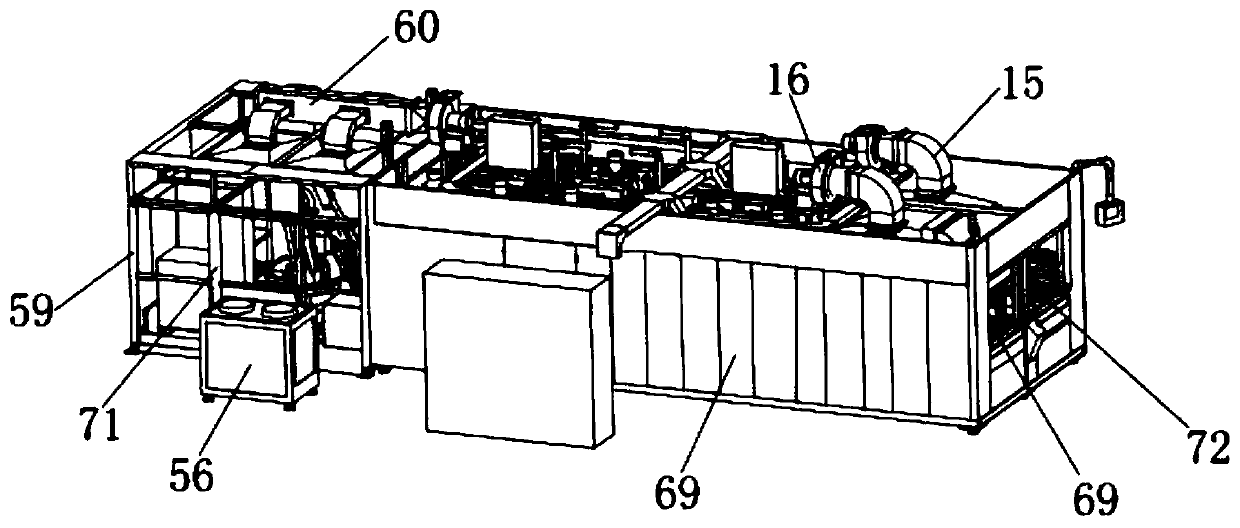

[0035] This embodiment provides a device for impregnating the copper wire winding of the stator of an automobile generator, such as figure 1 As shown, it includes a preheating transmission mechanism, an integral structural frame 70 containing a high-temperature furnace, a paint dipping device 71, a gel after dipping paint and a curing transmission mechanism 72; the preheating transmission mechanism 69 before dipping paint and the gel after dipping paint The solidification transmission mechanism is assembled together through the integral structure frame 70 containing the high temperature furnace side by side, and the dipping device 71 is connected to the integral structure frame 70 containing the high temperature furnace;

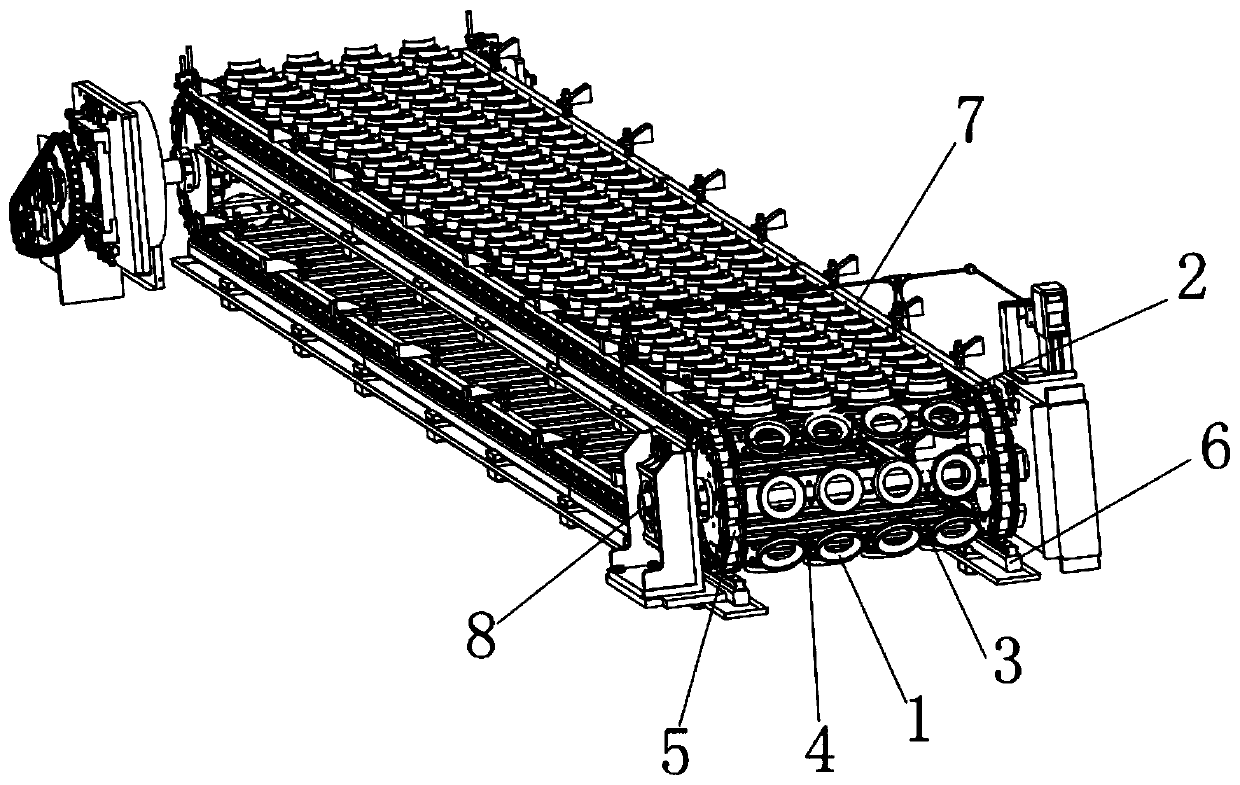

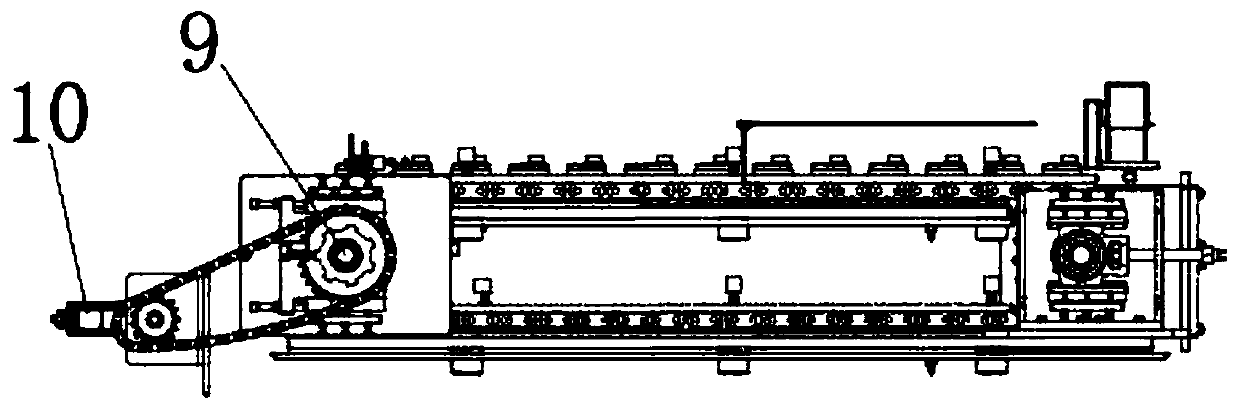

[0036] like figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com