Manufacturing method of vertical die cutting piece with irregular double-glue area

A production method and irregular technology, applied in metal processing and other directions, can solve problems such as insufficient area, inability to discharge, and poor final products, so as to achieve the effects of increasing production capacity, reducing costs, and avoiding the phenomenon of glue pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

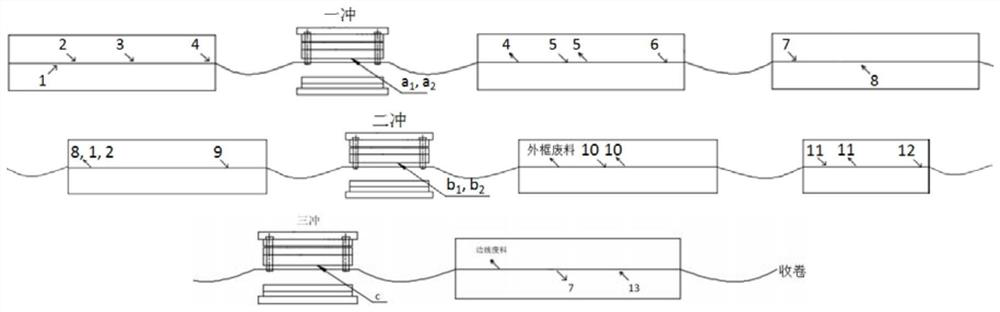

[0043] An irregular double rubber area vertical die-cut method, the die-cut member sequentially comprising a separator 13, a handle film 6, a double-sided adhesive 3 and a tape film 12, such as Figure 9-11 , the method includes the following steps, such as Figure 1 :

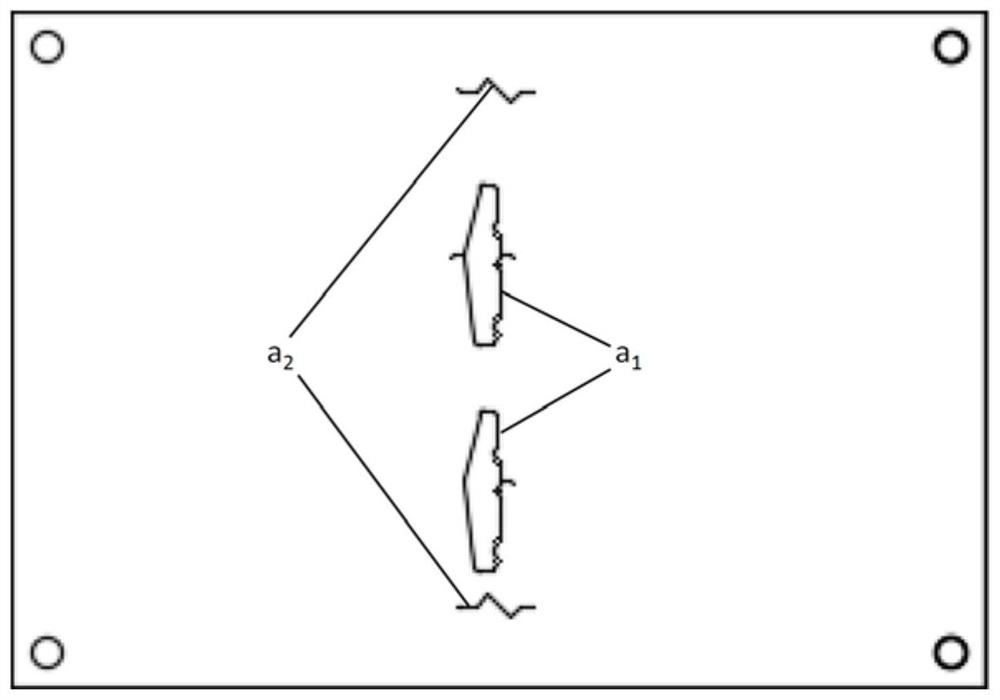

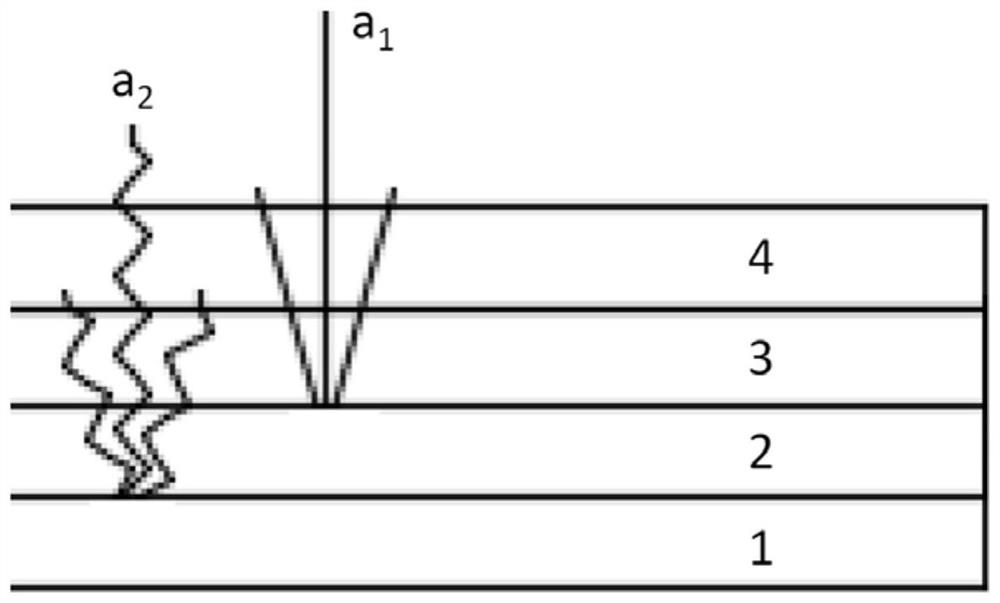

[0044] (1) The lamination of the primary material belt: the bottom film 2, double-sided adhesive 3 and release film 4 are successively glued to the single-sided adhesive 1 to form a first-class material belt; the first-stage die cutting machine is provided with a knife line a that matches the die-cutting pattern 1 and a 2 as Figure 2 , knife line a 1 The punching and cutting level includes release film 4 and double-sided adhesive 3, knife line a, from top to bottom 2 The punching and cutting level includes release film 4, double-sided adhesive 3 and bottom film 2 from top to bottom, such as Figure 3 。 The width of a die-cutting pattern is 120-140% of the width of the double-sided adhesive 3 in the die-cut product,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com