Steel wire rope winding device

A technology of winding device and steel wire rope, which is applied in the direction of winch device and spring mechanism, etc., can solve the problems of high labor intensity, low safety factor, large length, diameter and weight of steel wire rope, etc., so as to reduce labor intensity and improve work efficiency. Efficiency, promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

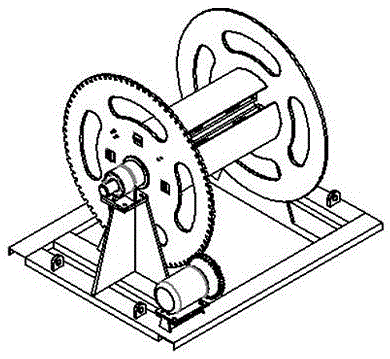

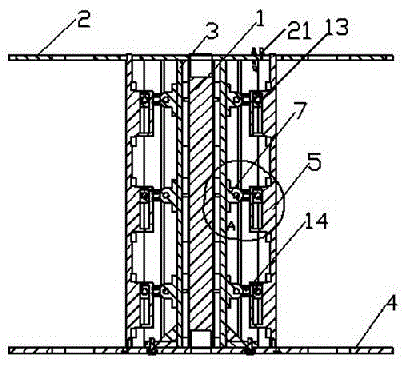

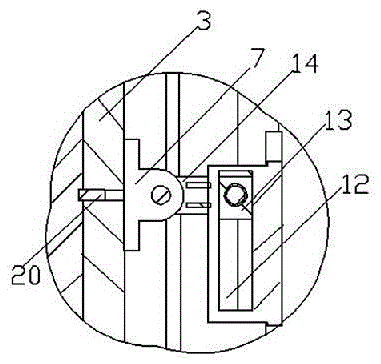

[0026] figure 1 It is shown that the present invention includes a reel device, a reel fixing device, a support and a driving device; Figure 2 to Figure 5It is shown that the reel device includes a mandrel 1, a gear 2 whose side circle center is vertically fixed to one end of the mandrel 1, four rectangular connecting plates 3 of the same size arranged equidistantly along the circumference of the mandrel 1, side plates 4 and connecting plates 3 four sector plates 5 with the same length and equal size; both ends of the mandrel 1 are provided with blind holes along its length direction; the side of the gear 2 is provided with a through hole 6 in the thickness direction and a mounting hole on the same circumference, in the mounting hole Assemble the U-shaped rope clamp 21 through the connecting bolt, which is used to fix the head of the wire rope on the reel device; the rectangular connecting plate 3 is parallel to the mandrel 1, and one of its short sides is fixed to the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com