BOPP film winding device

A winding device and film technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of film deformation, unfavorable development, high cost, etc., and achieve the effect of avoiding loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

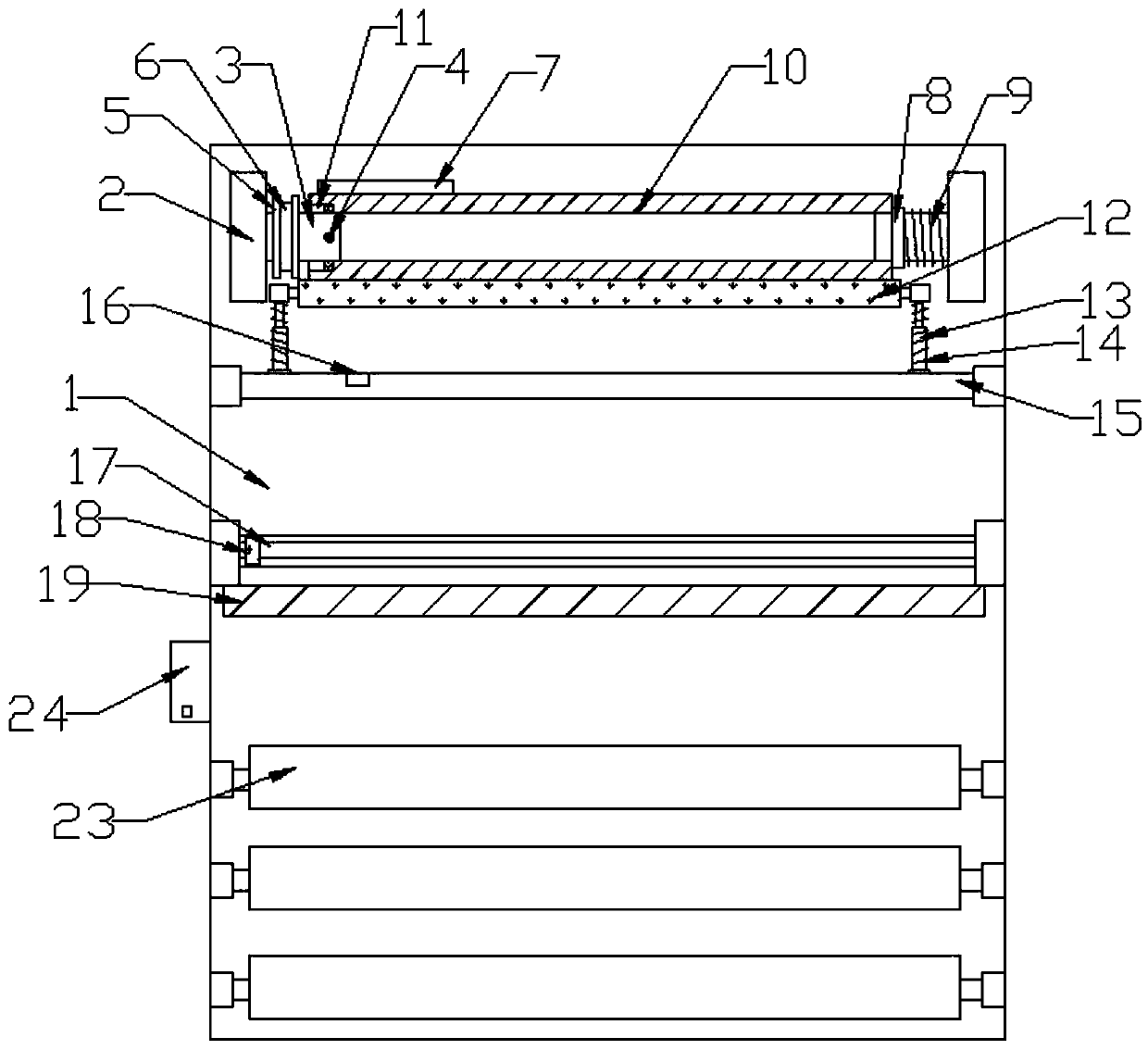

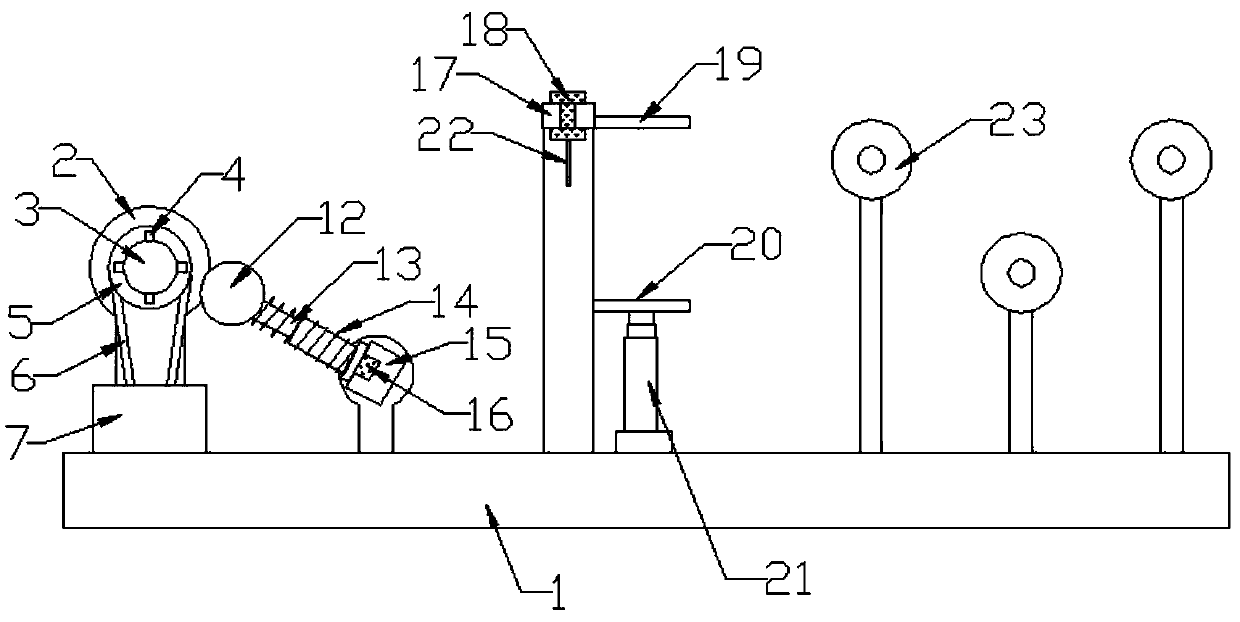

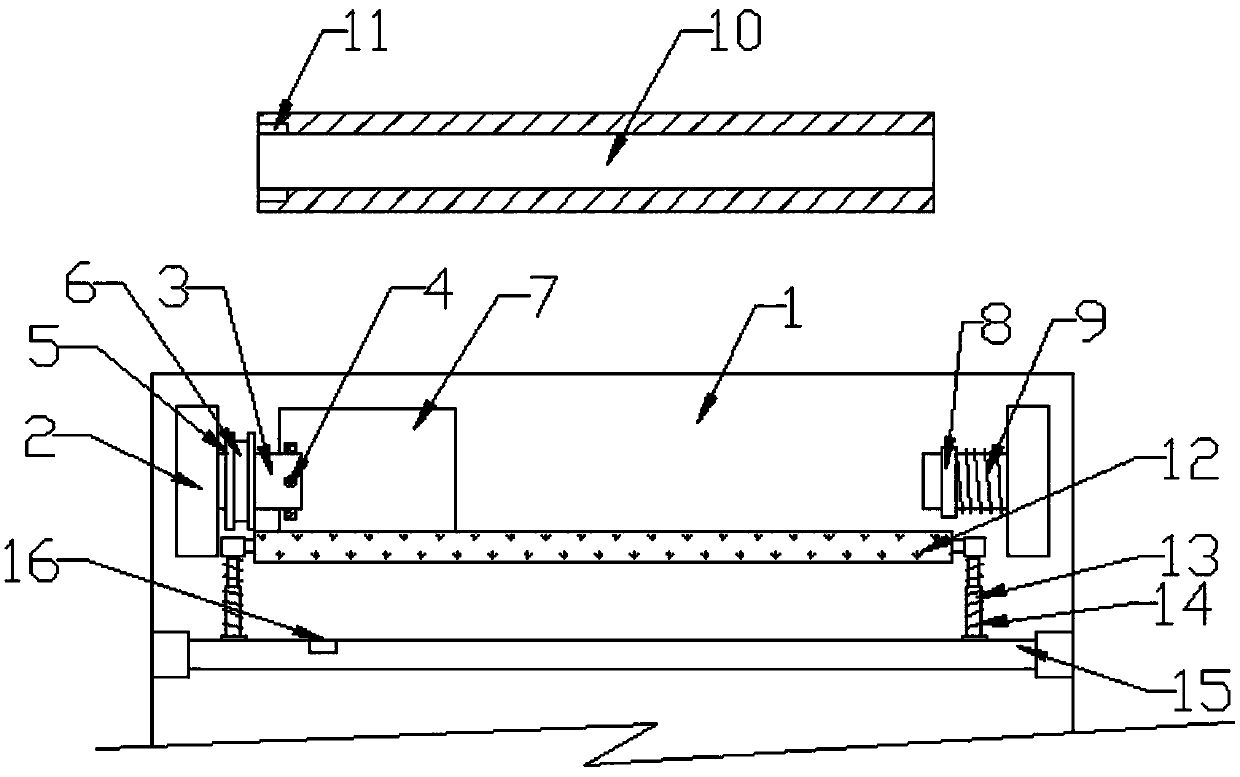

[0030] Such as Figure 1-5 As shown, a BOPP film winding device includes a worktable 1, a support frame 2, a winding mechanism, a pressing structure, a cutting mechanism, a control mechanism, and a receiving roller 23. The winding mechanism includes two fixed shafts 3, two A winding roller 10 is sleeved between the fixed shafts 3, and one of the fixed shafts 3 is connected to a rotating motor 7 through a pulley 5 and a belt 6. The pressing mechanism includes a pressing roller 12, and both ends of the pressing roller 12 are connected with telescopic The telescopic rod 13 of the spring 14 has a cutting mechanism including an electric slide rail 17, a fixed pressing plate 19 and a movable pressing plate 20, and the control mechanism is a control box 24.

[0031] A set of support frames 2 are welded symmetrically on the workbench 1. A set of fixed shafts 3 are installed on the inside of the support frame 2 through bearings. One of the fixed shafts 3 is equipped with a pulley 5, and t...

Embodiment 2

[0033] Such as Figure 1-5 As shown, the pressing roller 12 in the pressing mechanism is tightly attached to the bottom of one side of the winding roller 10. Both ends of the winding roller 12 are also threadedly connected with an inclined telescopic rod 13, and the telescopic rod 13 is sleeved with a telescopic spring 14. Through the elastic force of the telescopic spring 14, the pressure roller 12 is tightly attached to the winding roller 10, the telescopic rod 13 is mounted on the cross bar 15 through a bearing, and the cross rod 15 is welded to the workbench 1 through the support rod.

[0034] The two ends of the pressure roller 12 are respectively equipped with connecting blocks through bearings. The telescopic rod 13 is threadedly connected to the connecting block, and the telescopic rod 13 is also installed on the cross rod 15 through bearings to facilitate the connection between the telescopic rod 13 and the pressure roller 12 Separate, install or replace a telescopic spr...

Embodiment 3

[0037] Such as Figure 1-5 As shown, the electric slide rail 17 in the cutting mechanism is also welded to the worktable 1 through the support frame 2. The electric slide rail 17 is located on the front side of the pressure roller 12, and a matching electric slide 18 is installed on the electric slide rail 17. A cutting knife 22 is installed at the bottom end of the sliding block 18, and the electric sliding block 18 moves back and forth on the electric slide rail 17 to drive the cutting knife 22 to move left and right to cut the BOPP film. The top front side of the support column 2 is also fixed by bolts. The pressure plate 19 is placed under the fixed pressure plate 19 with a movable pressure plate 20. The movable pressure plate 20 is bolted to the piston ends of the two lifting cylinders 21 on the workbench 1, and is used for lifting the lifting cylinder 21 to drive the moving pressure plate 20 to close tightly. At the bottom end of the fixed pressing plate 19, the BOPP film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com