Cloth winding device

A winding device and cloth technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of inconvenient use of winding rollers, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

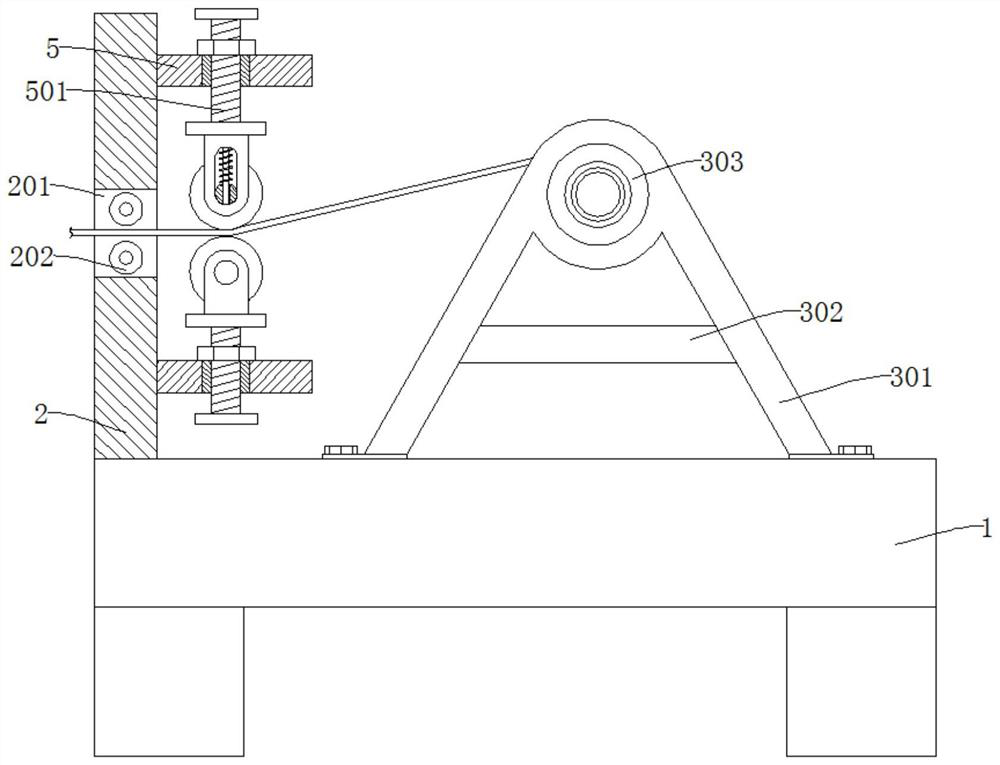

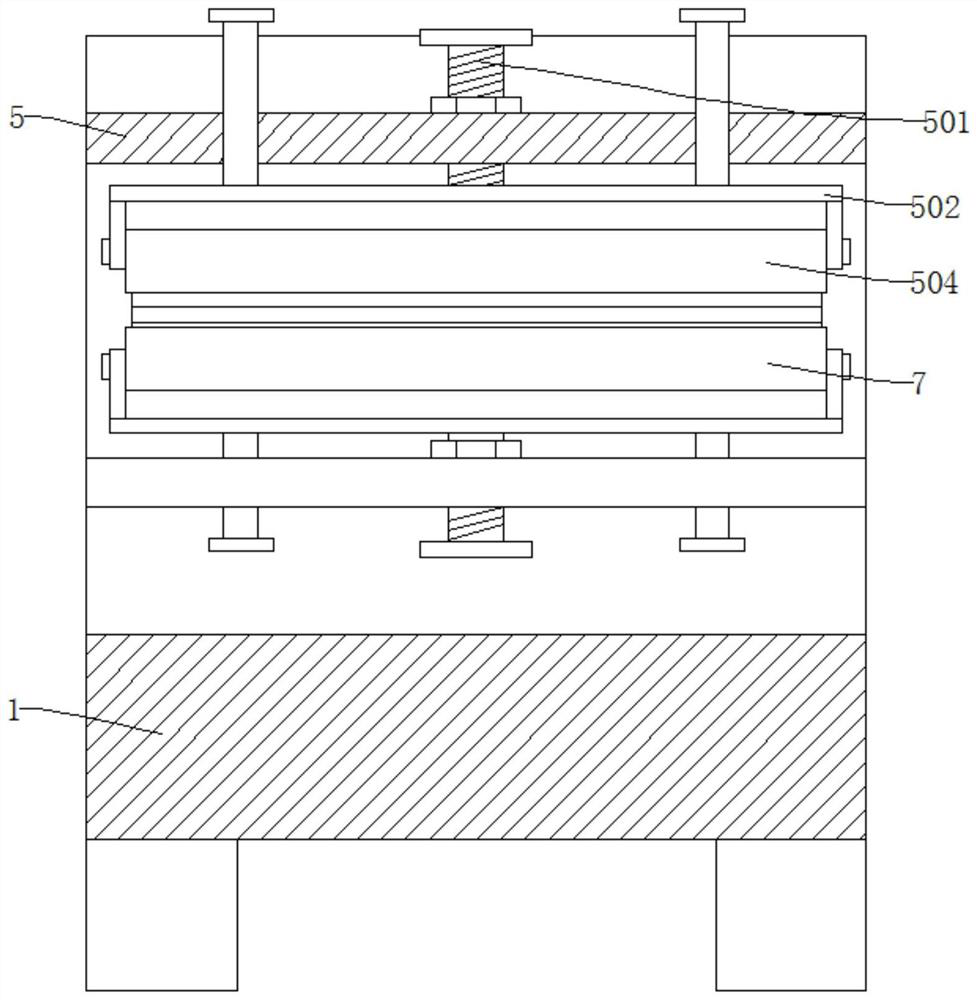

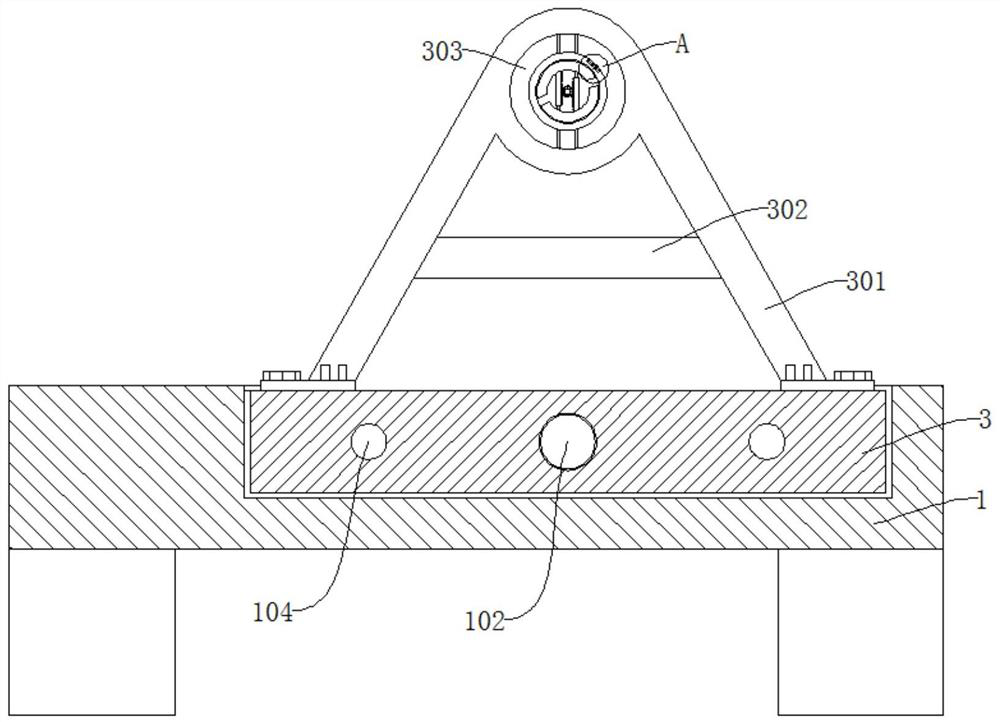

[0036] refer to Figure 1-8 , a cloth winding device, comprising a base 1, the base 1 is provided with a chute 103, and two fixed blocks 3 are slidably connected in the chute 103;

[0037] The top outer walls of the two fixed blocks 3 are all provided with fixed mounts 301, and the top outer walls of the fixed mounts 301 are all rotatably connected with fixed discs 303, and the outer walls of the fixed discs 303 are slidably connected with arc blocks 304, and the outer walls of the arc blocks 304 are connected with Winding roller 4;

[0038] The outer wall of the fixed disk 303 is connected with a first rotating shaft 3031, and the first rotating shaft 3031 is connected to the fixed frame 301 by bearing rotation, and the first rotating shaft 3031 is provided with a fixing member for fixing the arc block 304;

[0039] The top outer wall of the base 1 is also connected with a vertical plate 2, and the outer wall of the vertical plate 2 is fixedly connected with two horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com