A kind of cutting method without base material double-sided adhesive tape

A technology with double-sided adhesive and no base material, which is applied in chemical instruments and methods, lamination auxiliary operations, metal processing, etc. It can solve problems such as poor reverse release, poor deformation, and impact on product production capacity, so as to prevent reverse release Defective, product quality assurance, and product quality improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

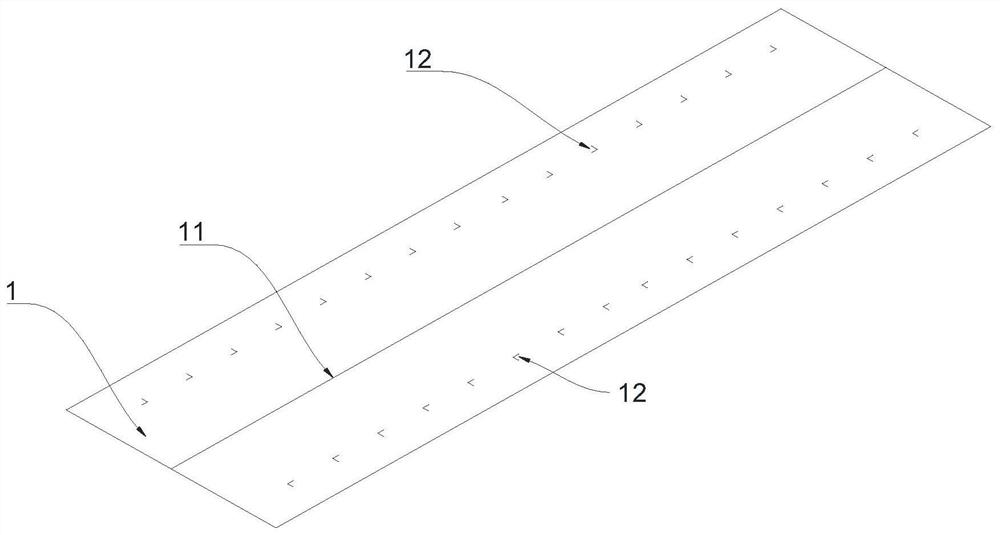

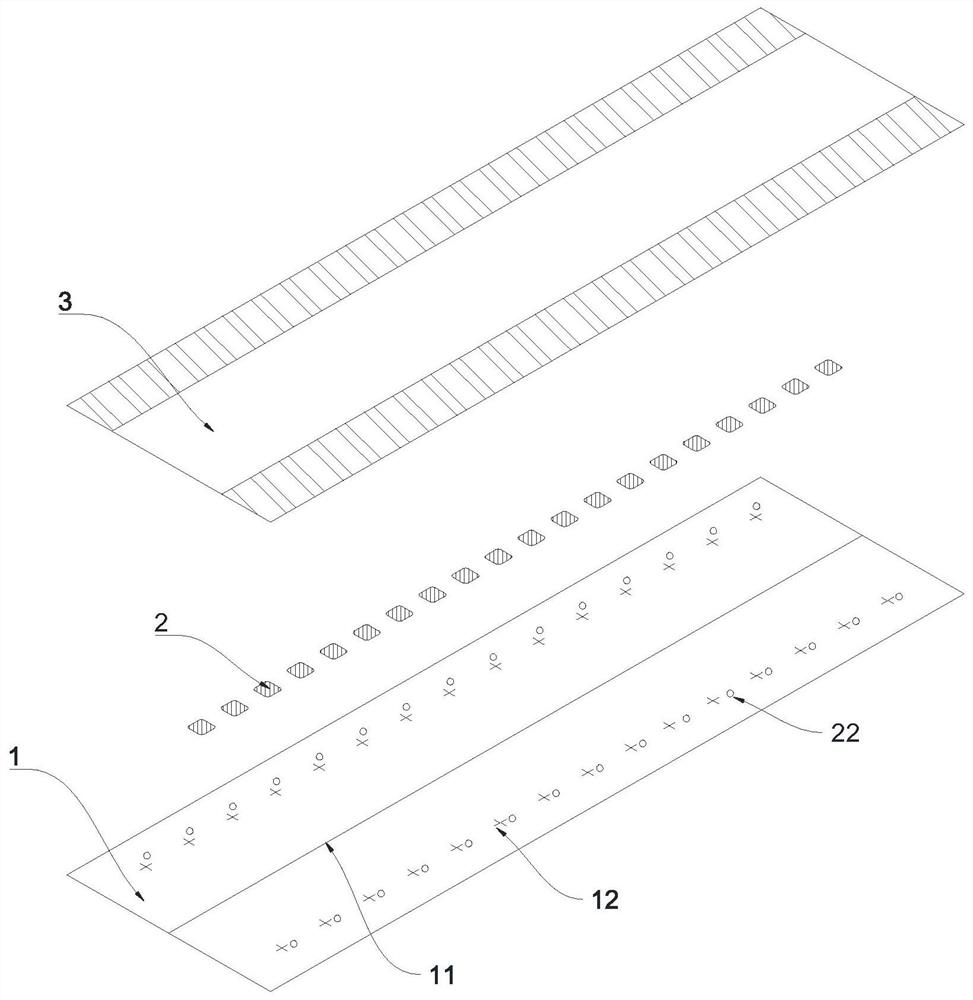

[0024] Figure 1 ~ Figure 4 Schematically shows a cutting method of double-sided adhesive tape without base material according to the present invention. The method includes the following steps:

[0025] S1. Round knife process

[0026] Provide a silicone protective film with a thickness of 0.05mm as the backing film 1, and divide the backing film 1 into a central product area extending along the length direction and product areas on both sides. Use a round knife to cut the backing film 1 in the center along the product area in the middle, leaving a straight gap 11 on the backing film 1 . The blade of the round knife is a single blade, and the tangent should be small. While cutting with a round knife, a half-cross positioning mark 12 is made on the non-product area of the backing film 1, and the resulting backing film 1 after cutting is as follows: figure 1 shown.

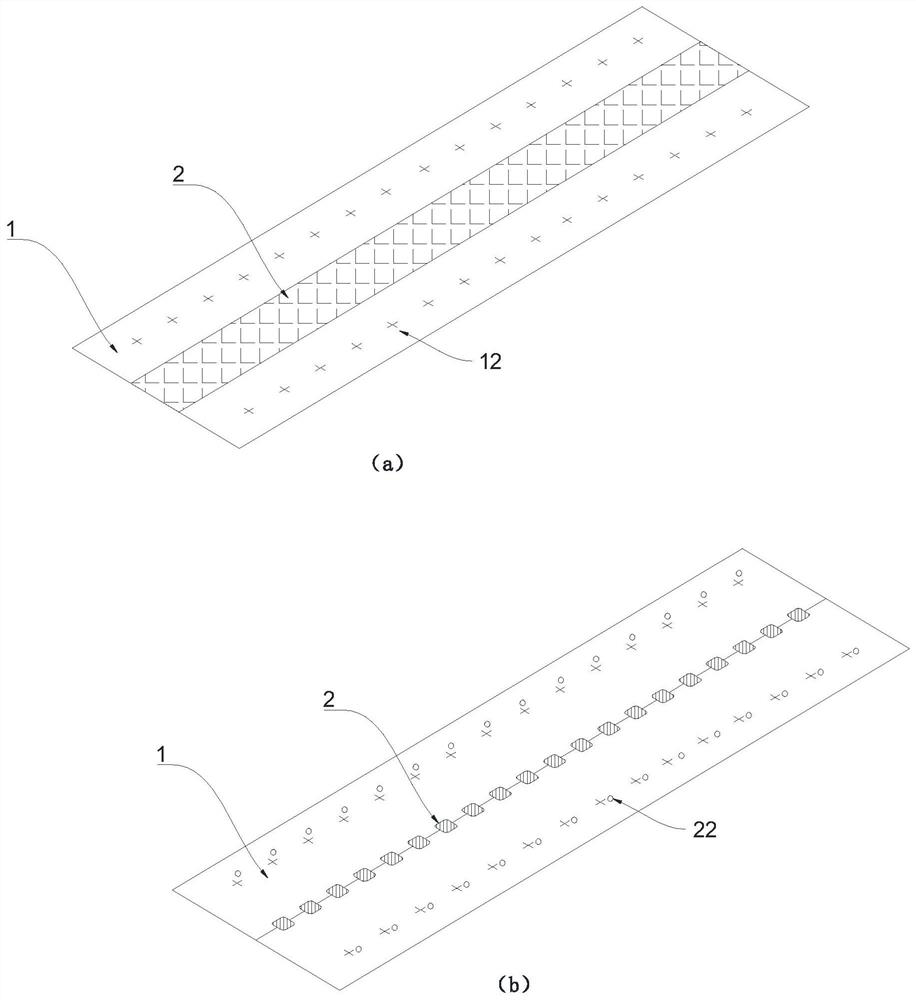

[0027] S2. Round knife sleeve cutting

[0028] Taking the half-cross positioning mark 12 in step S1 as a ...

Embodiment 2

[0038] This embodiment provides a method for cutting double-sided adhesive tape 2 without a base material according to the present invention. The difference between this method and Example 1 is that the thickness of the silica gel protective film selected in step S1 is 0.075 mm. The thickness of the foam used in step S2 and step S3 is 1.2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com