Method for die-cutting foam

A foam and die-cutting technology, which is applied in metal processing and other directions, can solve the problems of weak adhesion between the protective film glue and the release film, unqualified products, and affecting subsequent processes, so as to avoid the separation and arching of the protective film and foam , Improve the effect of not easy to discharge waste and ensure the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

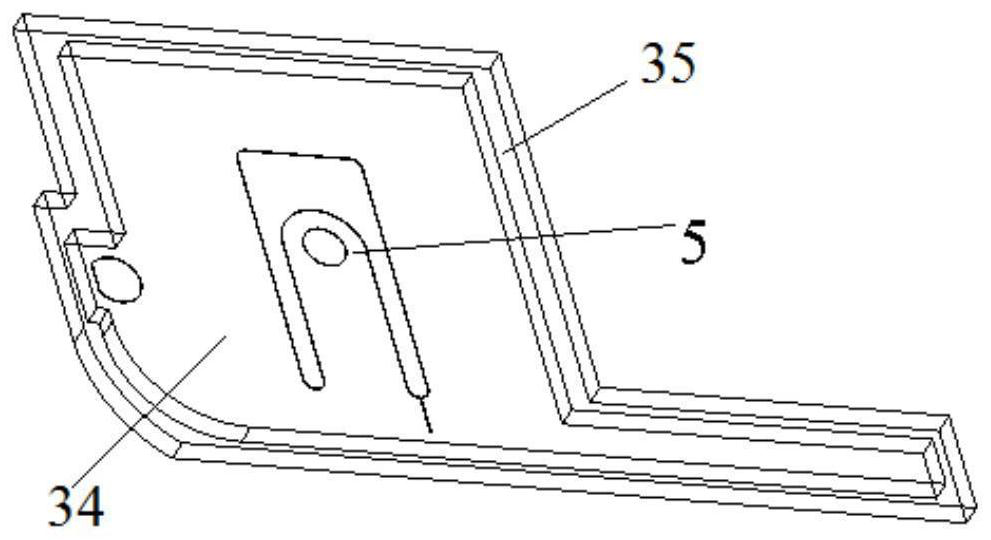

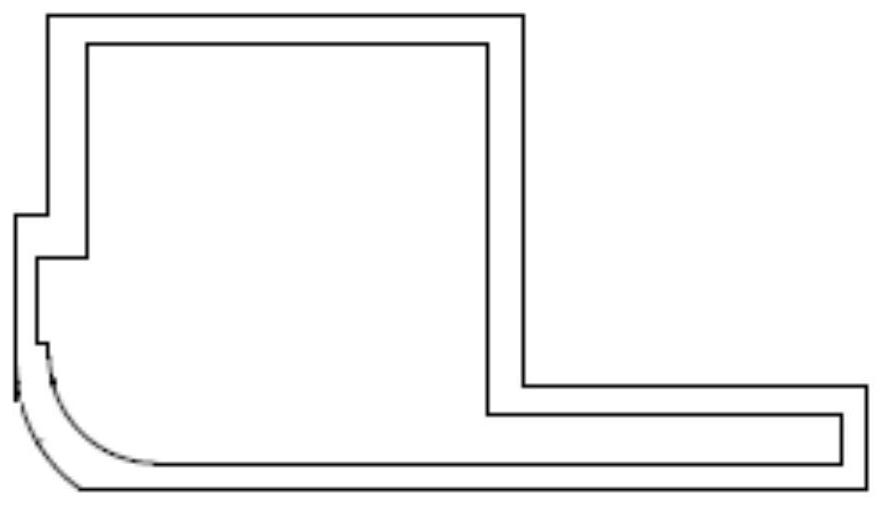

[0039] The product that the die-cutting method of present embodiment produces is as figure 1 and figure 2 As shown, this product is made up of protective film 34 and product main material 35, and product main material 35 is glue and foam. The foam is a frame-like structure hollowed out in the middle, including an inner frame and an outer frame. The size of the outer frame is greater than that of the inner frame, and the distance between the outer frame and the inner frame is 1 mm. The protective film 31 is provided with a protective film handle 5 .

[0040] The method for die-cutting foam of the present embodiment may further comprise the steps:

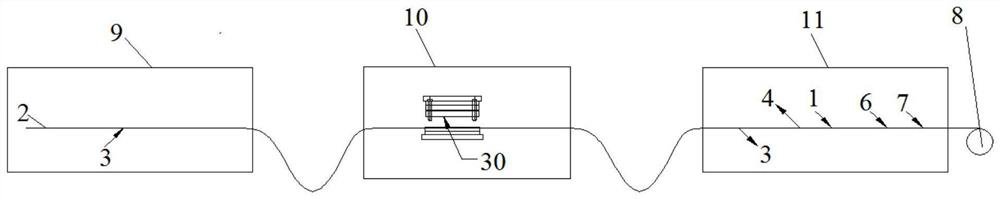

[0041] one die cut

[0042] This step is in order to process the surface structure of the protective film on the product, and punch out structures such as the protective film handle 5 and the positioning hole on the protective film; the specific method is as follows: image 3 As shown, the first winding roller 8 is used to drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com