Adhesive sticker die-cutting machine with constant temperature waste discharge function

A technology of constant temperature and rubber mold, which is applied in metal processing and other directions, can solve the problem of low reliability of die-cutting waste discharge, and achieve the effect of improving waste discharge efficiency, improving waste discharge reliability, and facilitating waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

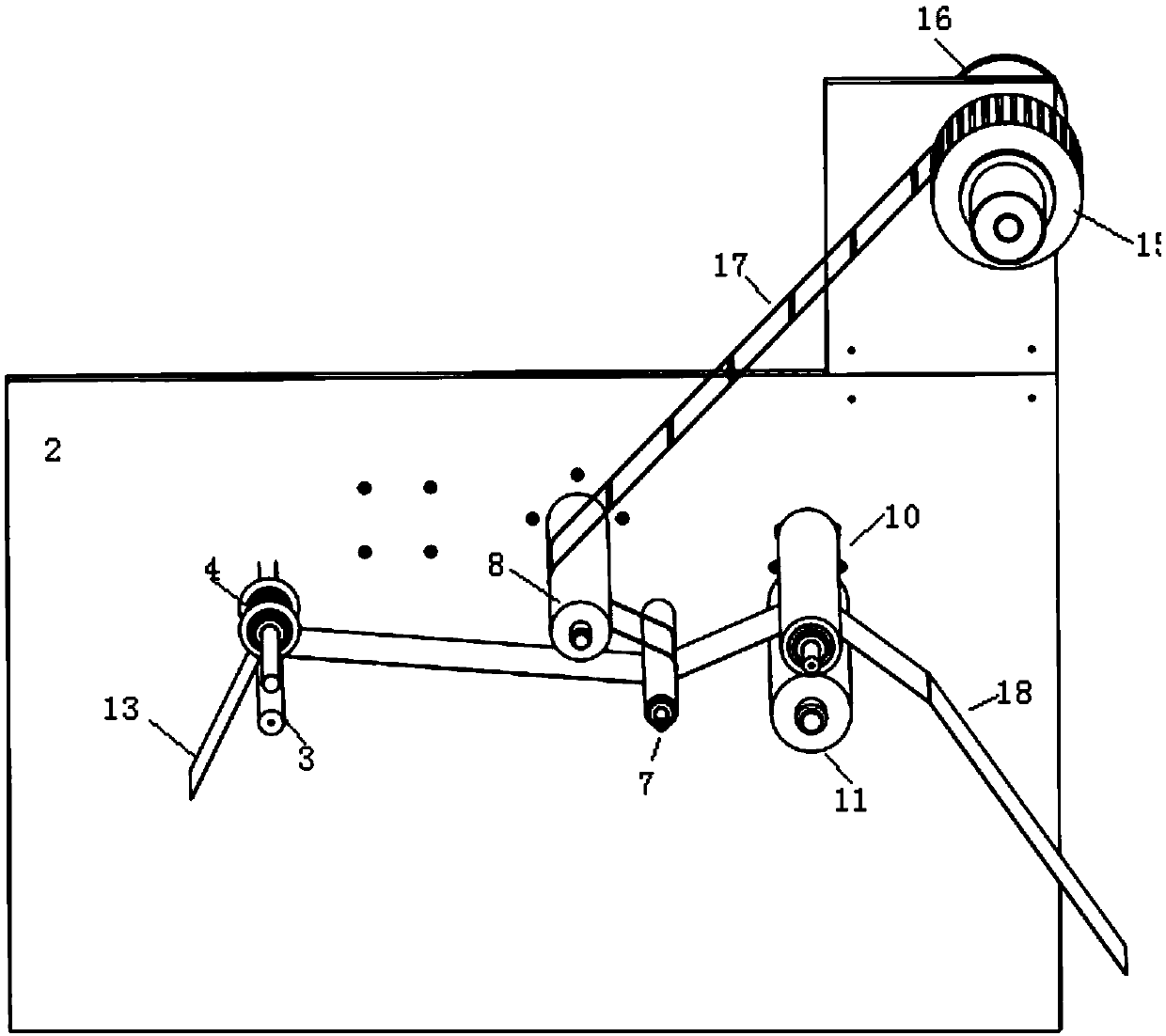

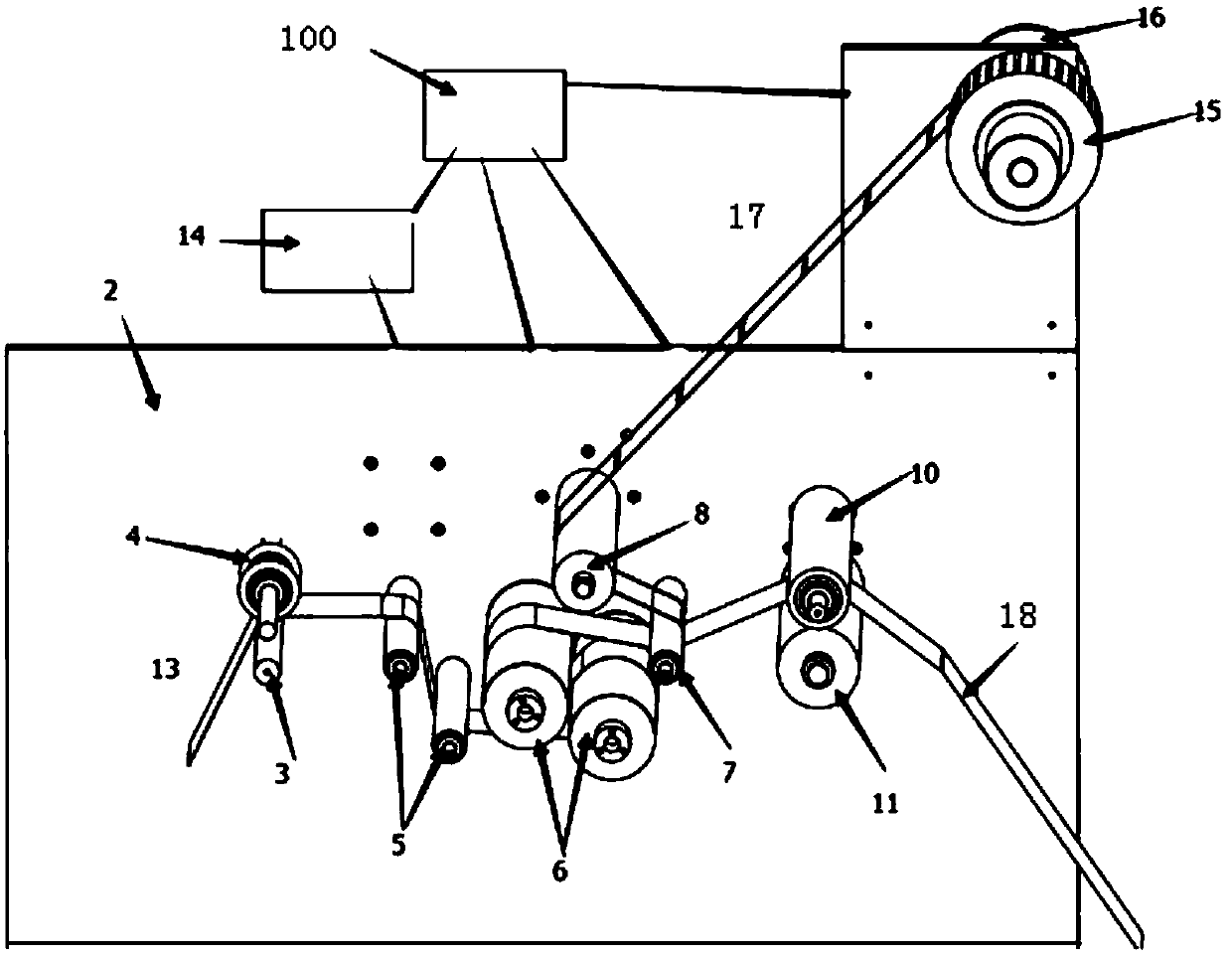

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

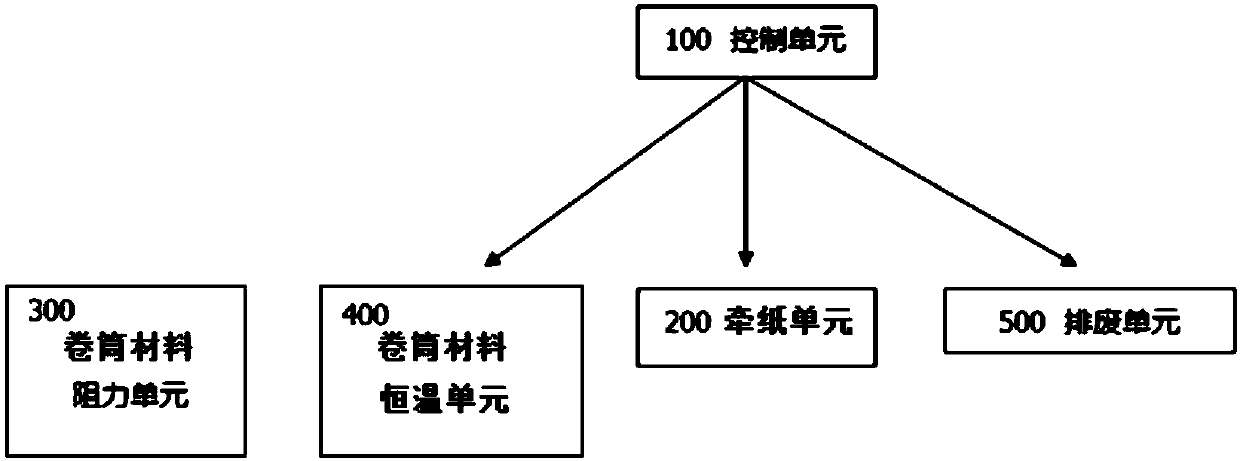

[0019] A self-adhesive die-cutting machine with constant temperature waste discharge proposed by the present invention includes a support plate 2 on which a paper pulling unit 200, a roll material resistance unit 300 and a waste discharge unit 500 are installed. Both the paper pulling unit 200 and the waste discharge unit 500 are connected with a control unit 100; figure 1 and image 3 shown.

[0020] Such as image 3 and Figure 4 As shown, the paper pulling unit 200 in the present invention includes a traction motor 12 controlled by the control unit 100, a traction roller 11 driven by the traction motor 12, and a traction pinch roller 10 matched with the traction rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com