A die-cutting process of flat plate knife removal

A cutting die and process technology, which is applied in the field of die-cutting die-cutting process of flat plate, can solve the problems of lowering, die-cutting frame is easy to produce embossing, etc., and achieve the effect of avoiding crushing and improving process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

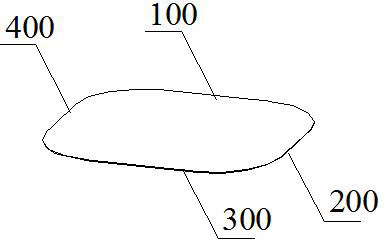

[0020] Example 1 takes figure 1 The protective film product of the shape shown is taken as an example to illustrate the technical solution of the present invention. The protective film product shown in Example 1 is in the shape of a square as a whole and the corners of the square are smoothly transitioned. According to the line characteristics and process requirements of the protective film product frame, the protective film The product frame is divided into four knife lines clockwise along the line trend: upper knife line 100, right knife line 200, lower knife line 300 and left knife line 400; according to customer requirements, the level between two adjacent protective film products Spacing a0=6mm, vertical spacing b0=5mm;

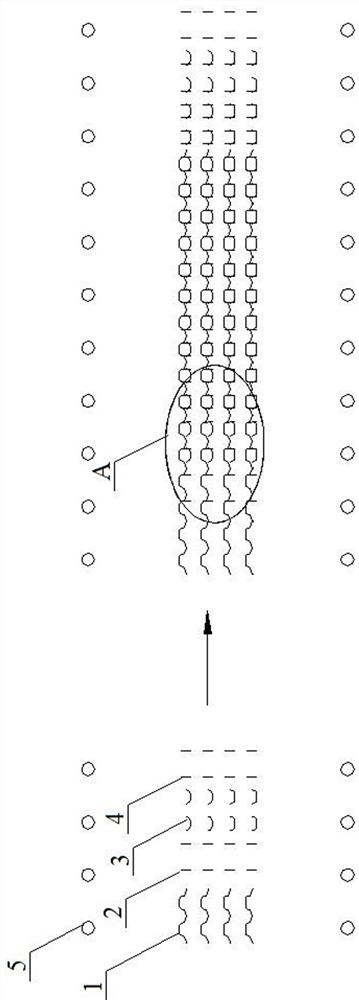

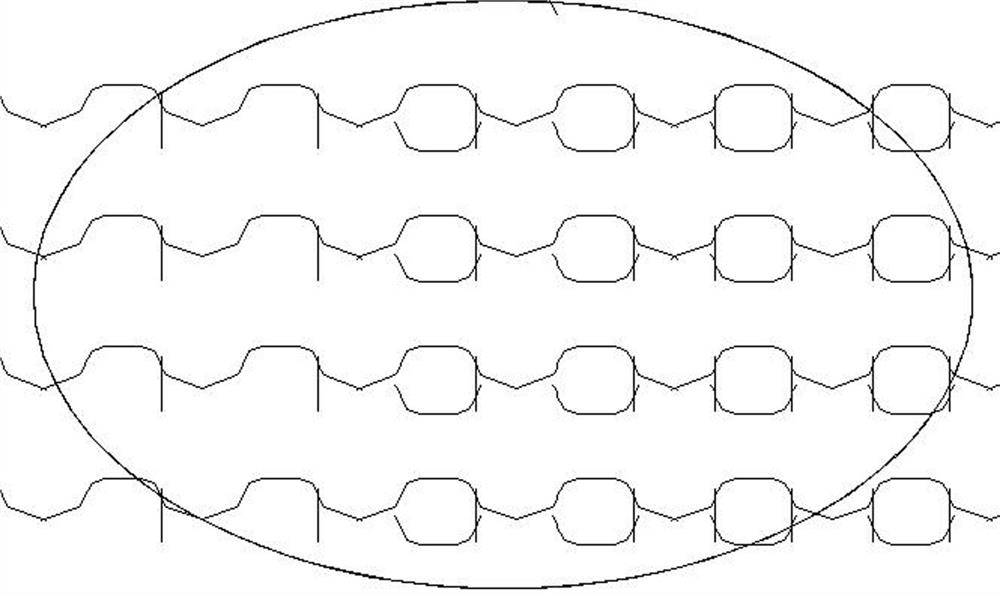

[0021] Flat knife die-cutting process for the production of the above protective film products, such as figure 2 and 3 As shown, correspondingly, the knife mold for die-cutting the protective film product is provided with four blades for cutting the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com