Chopped false proof paper products and method for manufacturing and using the same

A manufacturing method and technology for paper products, applied in the improved field of "a fragile anti-counterfeiting paper product, which can solve the problems of counterfeiting, inability to open the surface, and unstable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

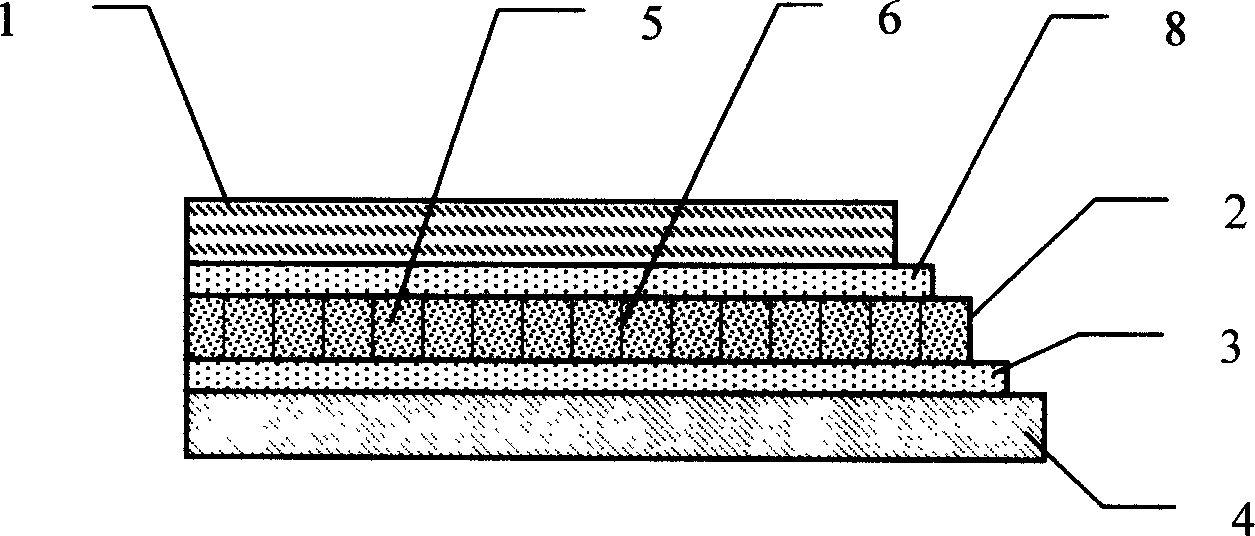

[0029] Such as figure 1 , figure 2 As shown, a kind of broken self-adhesive anti-counterfeiting label is processed.

[0030] In the first step, choose 60 g / m 2 Textured anti-counterfeiting paper (such as the black textured paper produced and used by the Oriental International Anti-counterfeiting Center) as the transfer layer (2).

[0031] The second step is to coat 50 g / m on the back of the textured anti-counterfeiting paper 2 The self-adhesive layer (3), to ensure the adhesive force of the self-adhesive layer (8) ≥ 14N / 25mm, and compound with 95 g / m 2 layers of glassine release paper (4).

[0032] The third step is to print the product brand, product serial number, query telephone number, query website and other content on the transfer layer (2), and then record the anti-counterfeiting information such as texture and digital on it into the anti-counterfeiting database. Then print 8 g / m on the front side of the textured anti-counterfeiting paper 2 UV ink (a small amount...

Embodiment 2

[0037] Such as figure 1 , Figure 4 As shown, process a 30mm×20mm self-adhesive laser anti-counterfeiting label that has been broken.

[0038] In the first step, choose 30 g / m 2 The PET laser aluminized film is used as the transfer layer (2), and the anti-counterfeiting feature information such as product brand is embossed on the laser aluminized film (2).

[0039] In the second step, apply 50 g / m on the back of the laser aluminized film (2) 2 The self-adhesive layer (3), to ensure the adhesive force of the self-adhesive layer (8) ≥ 14N / 25mm, and compound with 95 g / m 2 layers of glassine release paper (4).

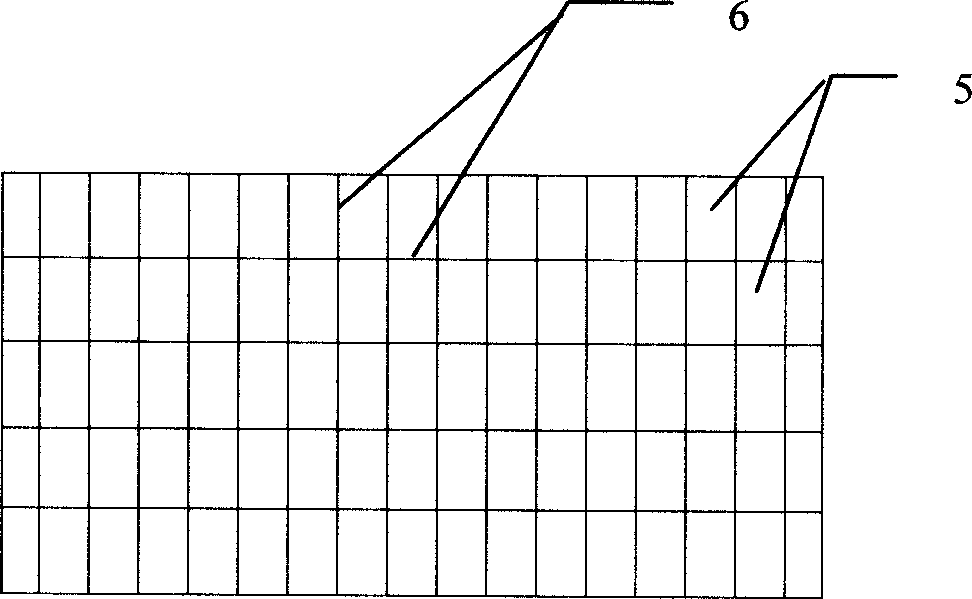

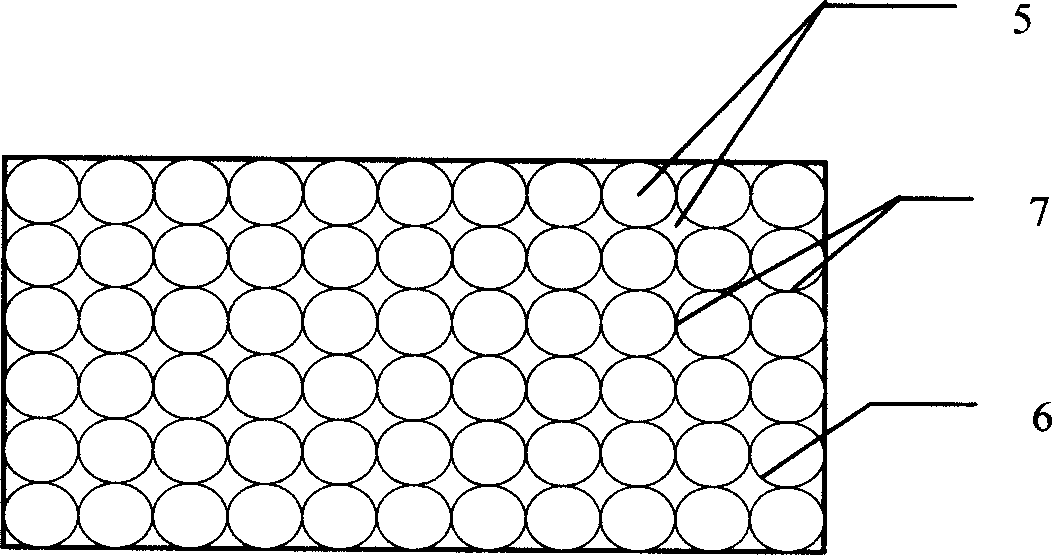

[0040] In the third step, according to the die-cutting process of self-adhesive labels, in a local area (9) of 30mm×20mm, a rectangular array die-cutting knife of 5mm×5mm is produced, and then the die-cutting knives are cut one by one on the die-cutting machine. The laser aluminized film (2) label is die-cut into rectangular discrete small units (5) of 5mm×5mm each. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com