Non-stop waste discharge device for label production

A waste discharge device and label technology, which is applied in metal processing and other fields, can solve the problems of large waste edges and affect production efficiency, and achieve the effects of saving time, convenient cleaning, and improving waste discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

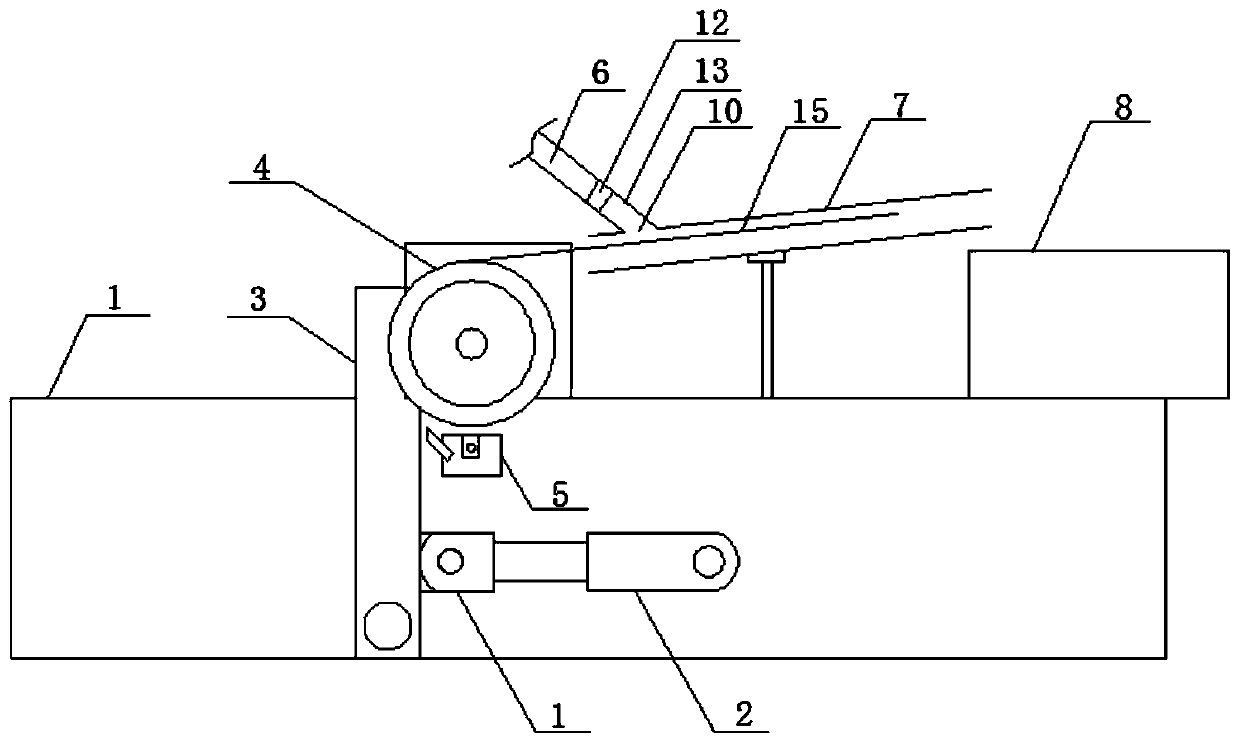

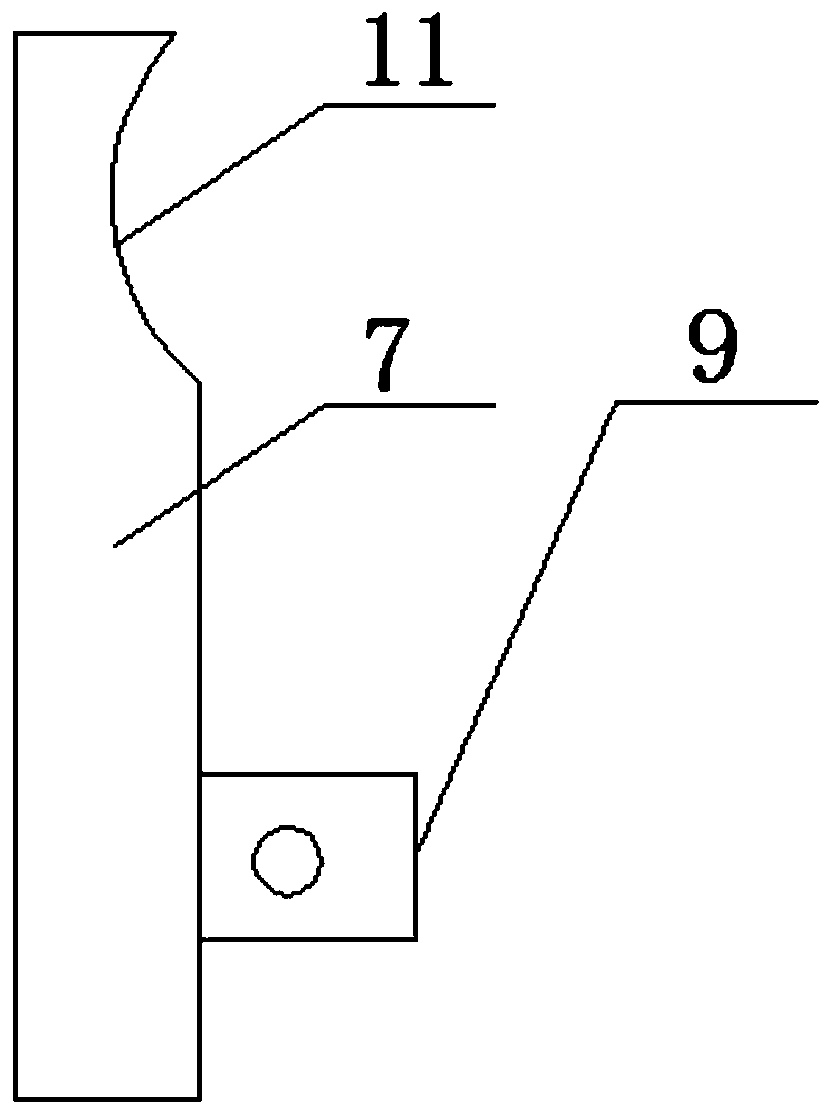

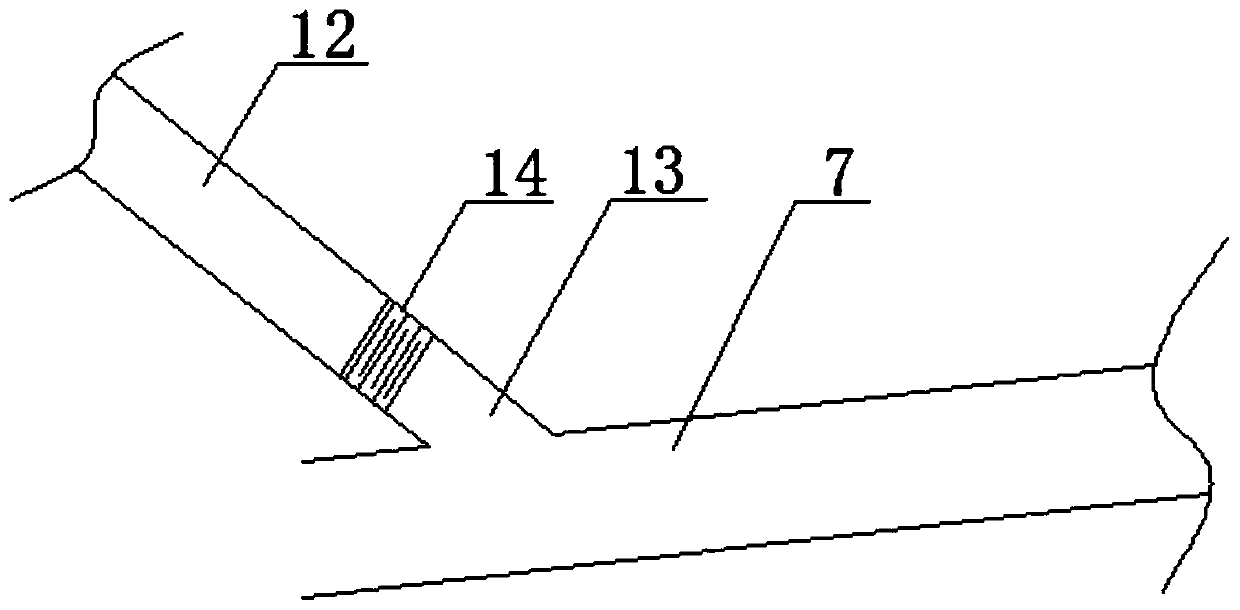

[0026] Embodiment 1: as figure 1 As shown, the waste edge 15 enters between the lower right side of the traction roller 4 and the scraper 5, and is gently pressed by the pressing groove 11 of the pressure rod 3 on the left side of the traction roller 4, and the traction roller 4 rotates clockwise. Drive the waste edge 15 to enter the guide channel 7, and then enter the recovery box 8 from the guide channel 7. At the same time, the entrance of the guide channel 7 is also provided with a blower, which can provide the driving force for the waste edge 15 to enter the recovery box 8, and accelerate the recovery process. Waste edge 15 is blown in the recovery box 8 from guide passage 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com