Waste discharging device used on slitting machine

A technology of waste discharge device and slitting machine, which is applied in the direction of metal processing, etc., can solve the problems of being stuck in the slitting machine, affecting the 5S on site, and equipment downtime, etc., and achieves the effect of simple device structure and high waste discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

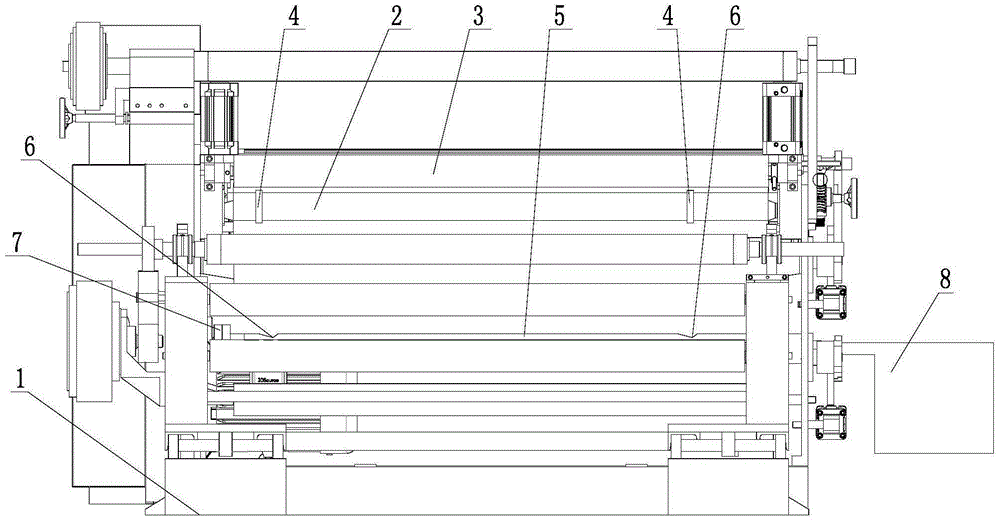

[0014] see figure 1 As shown, the above-mentioned waste discharge device for a slitting machine includes a frame 1, a first guide roller 2 and a second material guide roller 2 which are arranged on the frame 1 and rotate around the direction of its axis respectively. Two material guide rollers 3 , a gap for conveying materials is formed between the first material guide roller 2 and the second material guide roller 3 , and the first material guide roller 2 is located below the second material guide roller 3 . In this embodiment, the material is a release film. Both ends of the first material guide roller 2 are provided with cutters 4 for cutting irregular edges of the release film, and the release film is divided into strips by the cutter 4 . The waste discharge device includes a waste discharge pipe 5 provided on the frame 1, an inlet 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com