Manufacturing method of environment-friendly RFID tag antenna

A technology for RFID tags and manufacturing methods, applied to antennas, antenna parts, antenna supports/installation devices, etc., can solve the problems of heavy metal pollution, high energy consumption, and high cost, and achieve reduced processing difficulty, reduced environmental pollution, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

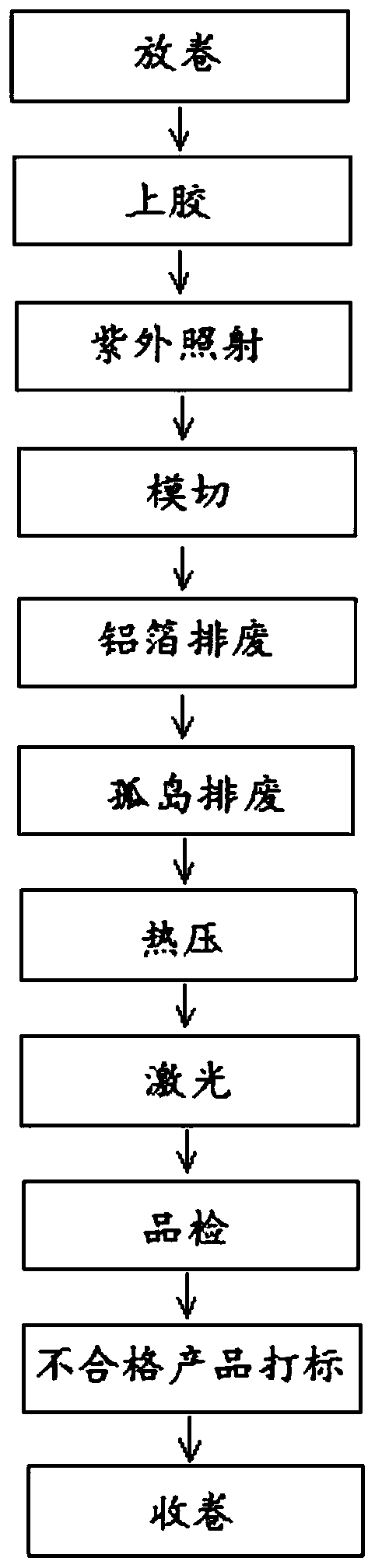

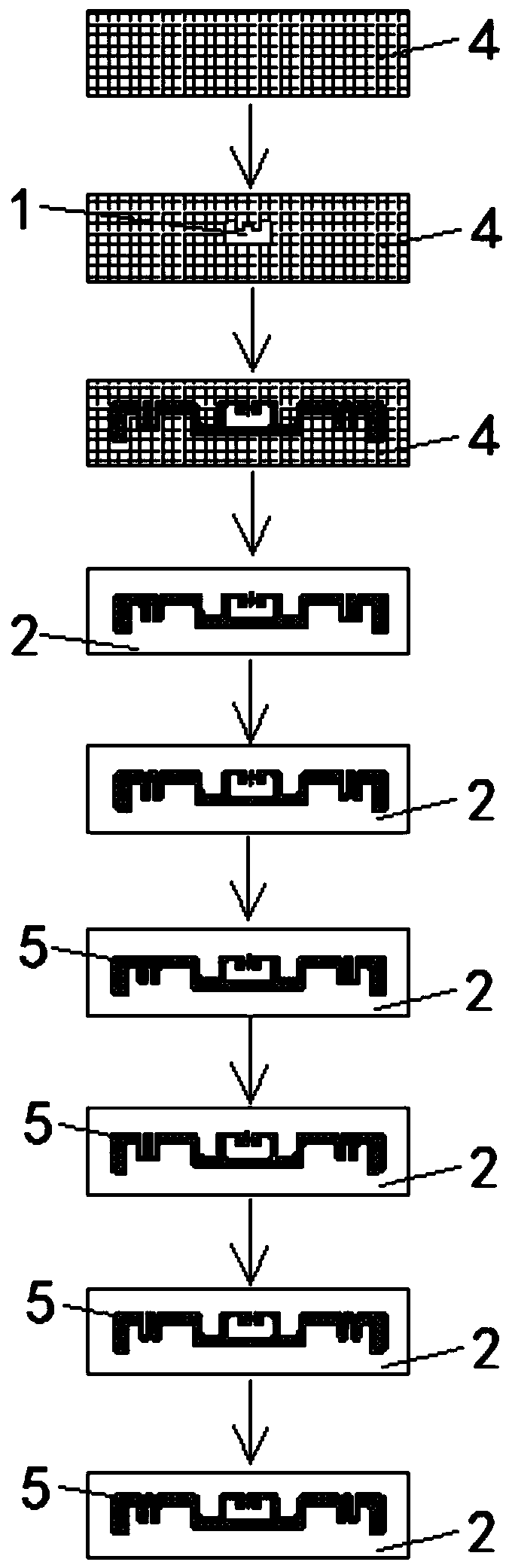

[0057] The present embodiment provides a manufacturing method of an environment-friendly RFID tag antenna, comprising the following steps:

[0058] S1: unwinding process through the unwinding roller;

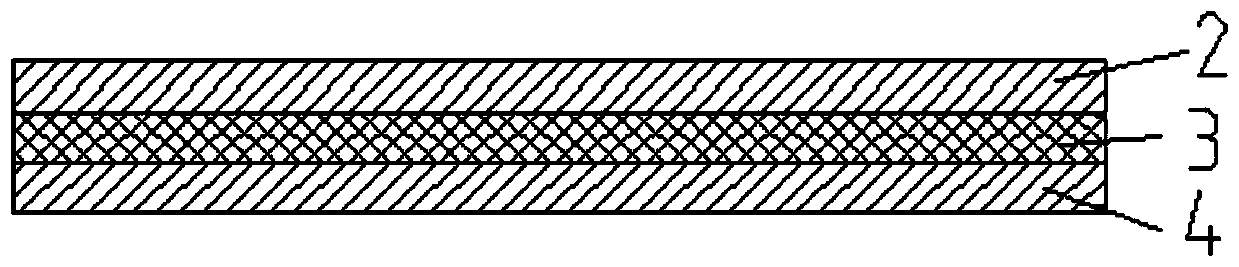

[0059] S2: Apply 10um glue on the isolated island where the raw material is set to form glue layer 1;

[0060] S3: After gluing, irradiate the glue with a UV instrument for 5 seconds to ripen the glue;

[0061] S4: Die-cut the raw material after gluing, and roll up the excess aluminum foil 4 by the waste roll roller to obtain the first waste discharge product; pass the first waste discharge product and the waste discharge product through two pressure rollers Pressing the paper, and then rolling up the waste paper and the glue layer 1 by an island roller to obtain the preliminary product;

[0062] S5: performing hot-pressing treatment on the preliminary product by means of an electromagnetic roller;

[0063] S6: performing laser cutting on the hot-pressed preliminary product by ...

Embodiment 2

[0067] The present embodiment provides a manufacturing method of an environment-friendly RFID tag antenna, comprising the following steps:

[0068] S1: unwinding process through the unwinding roller;

[0069] S2: Apply 15um glue on the isolated island where the raw material is set to form glue layer 1;

[0070] S3: After gluing, irradiate the glue with a UV instrument for 8 seconds to ripen the glue;

[0071] S4: Die-cut the raw material after gluing, and roll up the excess aluminum foil 4 by the waste roll roller to obtain the first waste discharge product; pass the first waste discharge product and the waste discharge product through two pressure rollers Pressing the paper, and then rolling up the waste paper and the glue 1 by an island roller to obtain the preliminary product;

[0072] S5: performing hot-pressing treatment on the preliminary product by means of an electromagnetic roller;

[0073] S6: performing laser cutting on the hot-pressed preliminary product by a la...

Embodiment 3

[0077] The present embodiment provides a manufacturing method of an environment-friendly RFID tag antenna, comprising the following steps:

[0078] S1: unwinding process through the unwinding roller;

[0079] S2: Apply 20um glue on the isolated island where the raw material is set to form glue layer 1;

[0080] S3: After gluing, irradiate the glue with a UV instrument for 10 seconds to ripen the glue;

[0081] S4: Die-cut the raw material after gluing, and roll up the excess aluminum foil 4 by the waste roll roller to obtain the first waste discharge product; pass the first waste discharge product and the waste discharge product through two pressure rollers Pressing the paper, and then rolling up the waste paper and the glue layer 1 by an island roller to obtain the preliminary product;

[0082] S5: performing hot-pressing treatment on the preliminary product by means of an electromagnetic roller;

[0083] S6: performing laser cutting on the hot-pressed preliminary product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com