Automatic rejected cup discharging device

An automatic discharge and screening device technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of labor and low efficiency, and achieve the effect of high waste discharge efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following descriptions are only preferred embodiments of the present invention, and do not limit the protection scope of the present invention. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

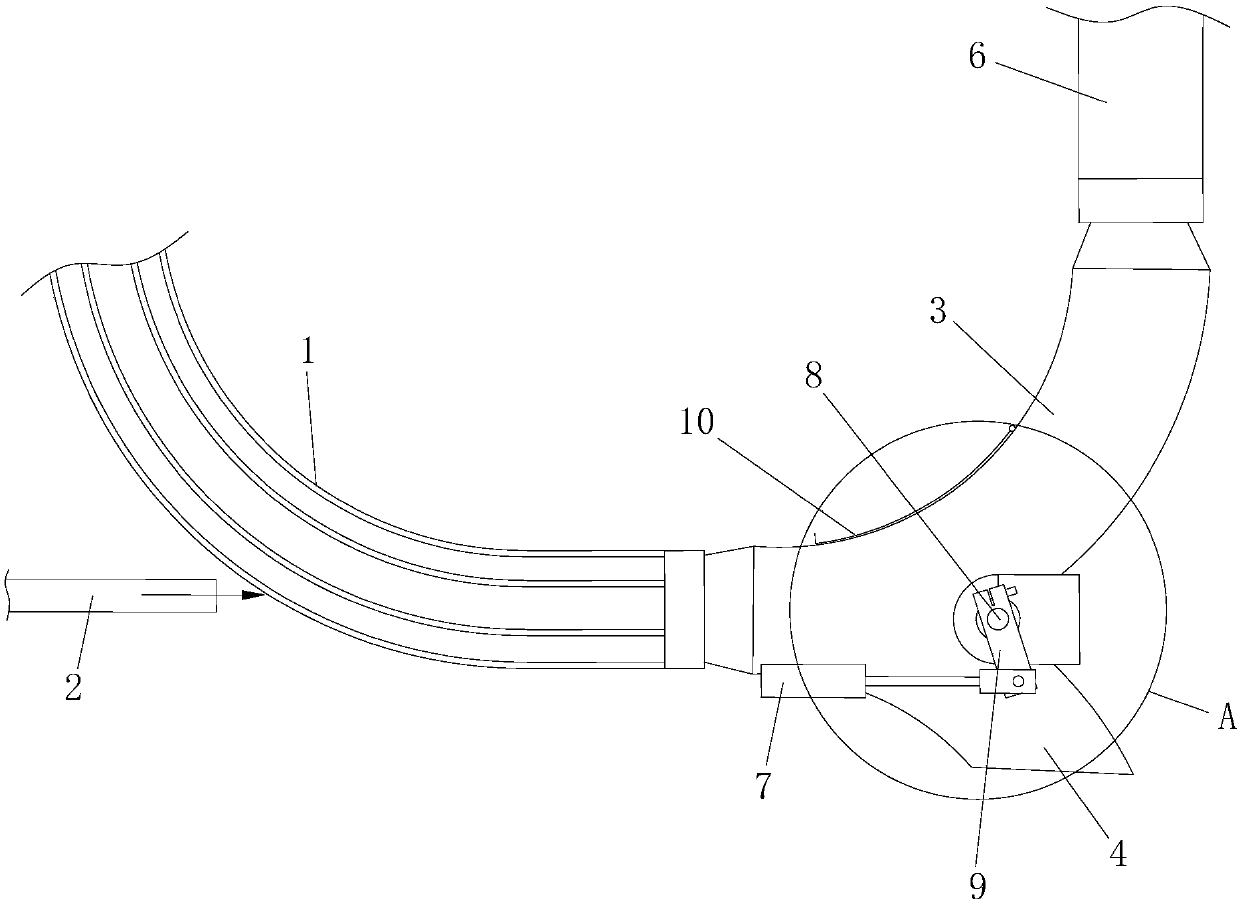

[0019] Examples, see Figure 1 to Figure 3 Shown: an automatic cup discharge device, including an introduction pipe 1, a screening device, a detection probe (not shown in the drawings) and a controller (not shown in the drawings),

[0020] The pipe wall of the introduction pipe 1 is hollowed out, and the paper cups manufactured on the paper cup manufacturing equipment can freely fall into the introduction pipe 1. An air pipe 2 is arranged on the left side of the introduction pipe 1, and the air outlet of the air pipe 2 can push the introduction pipe 1. The paper cup inside moves quickly to the right;

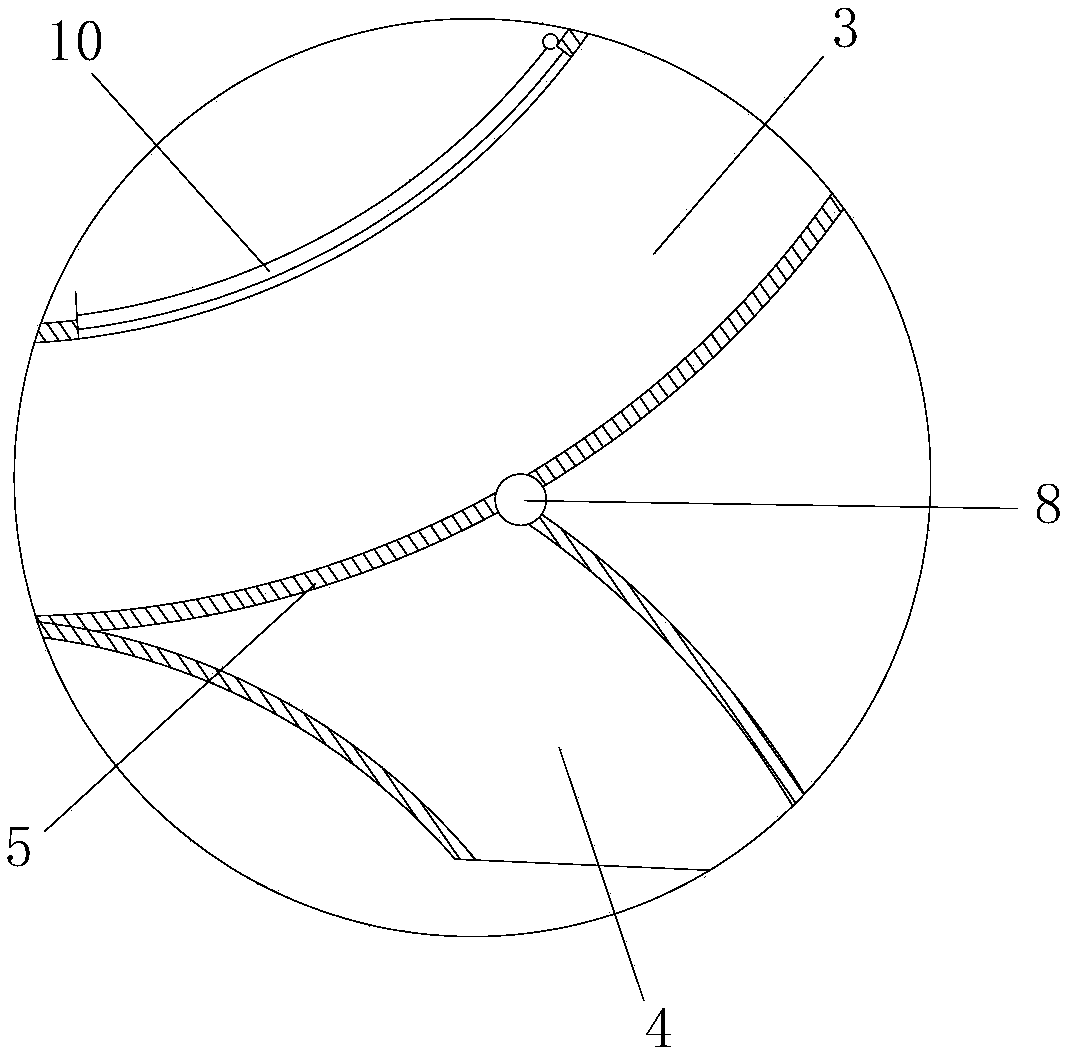

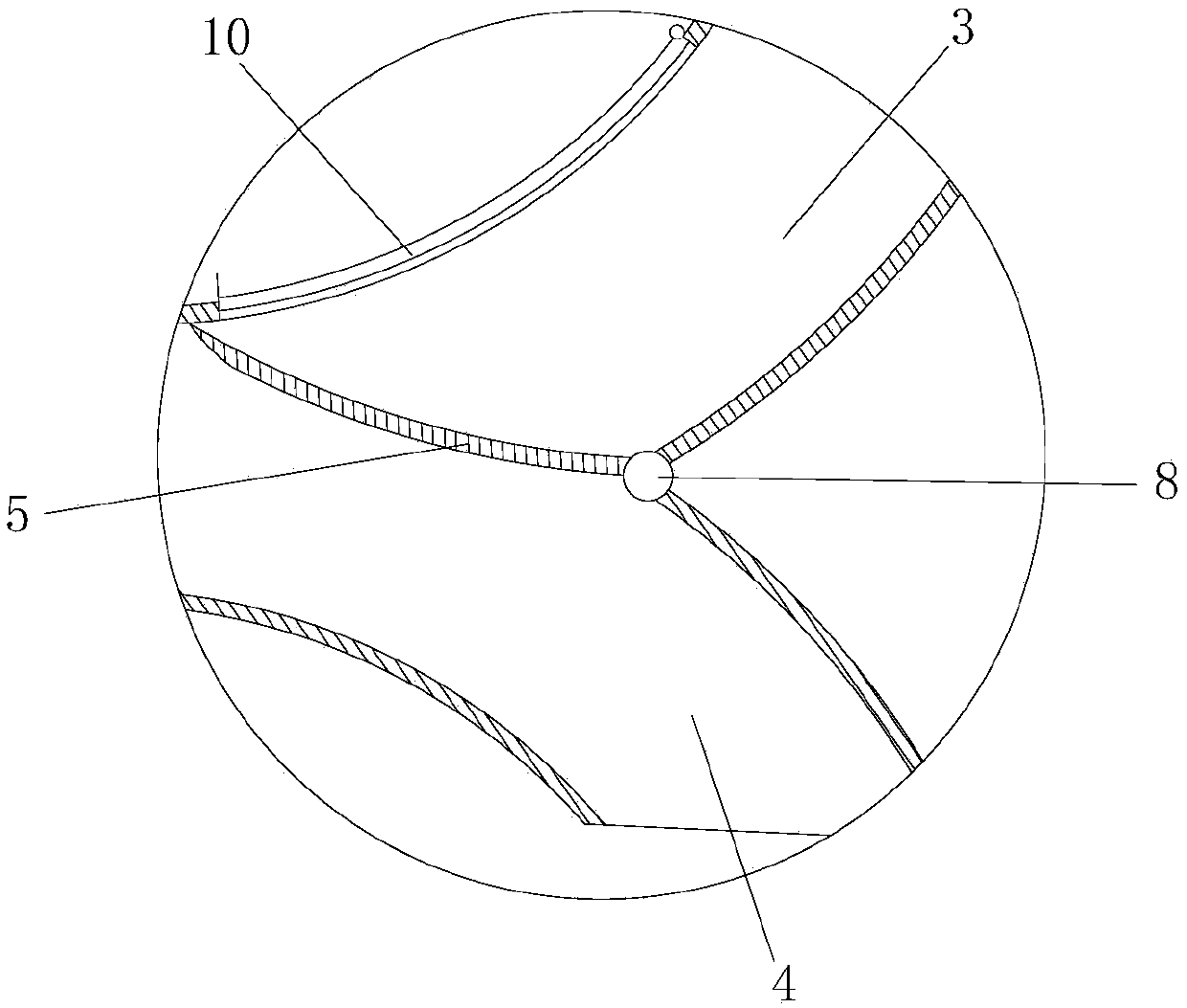

[0021] The screening device includes a finished product passage pipe 3, the lower side of the finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com