Patents

Literature

36results about How to "Avoid fluffing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extremely soft non-woven fabric and production process thereof

PendingCN108532130AImprove rednessHigh tensile strengthFilament forming substance formingPattern makingSmooth surfacePolypropylene

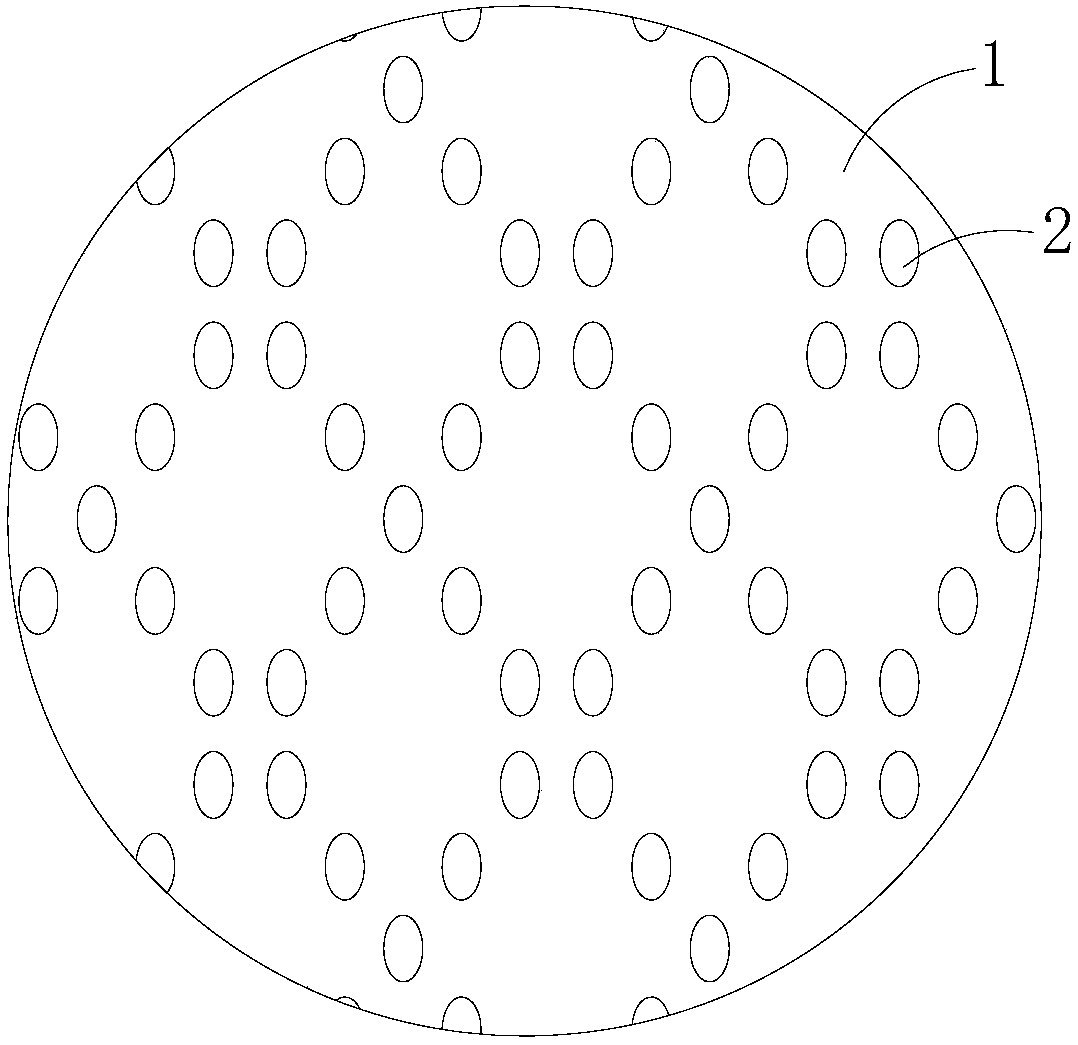

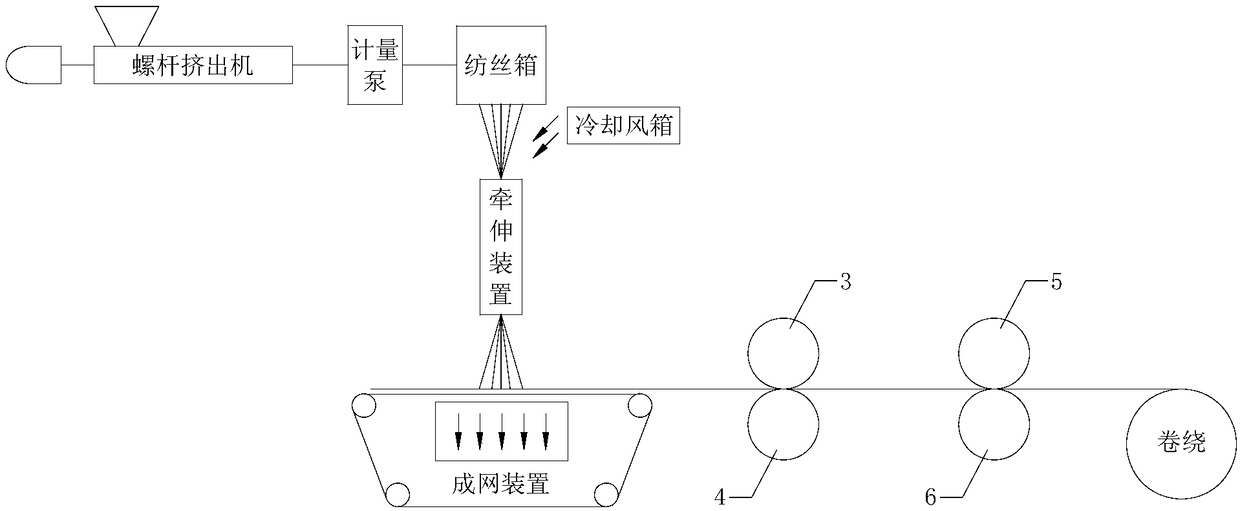

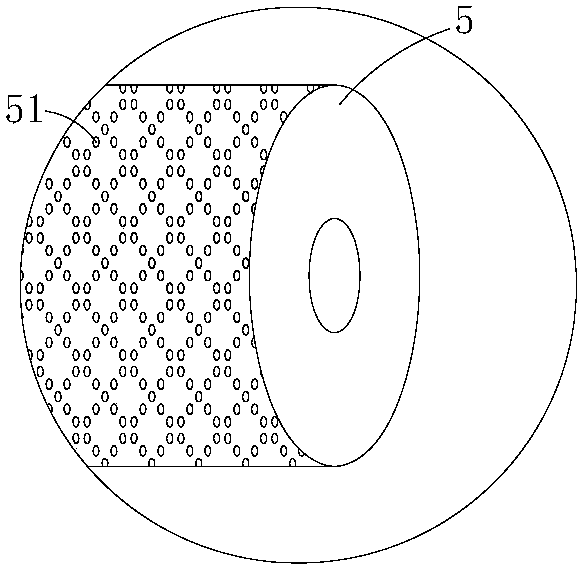

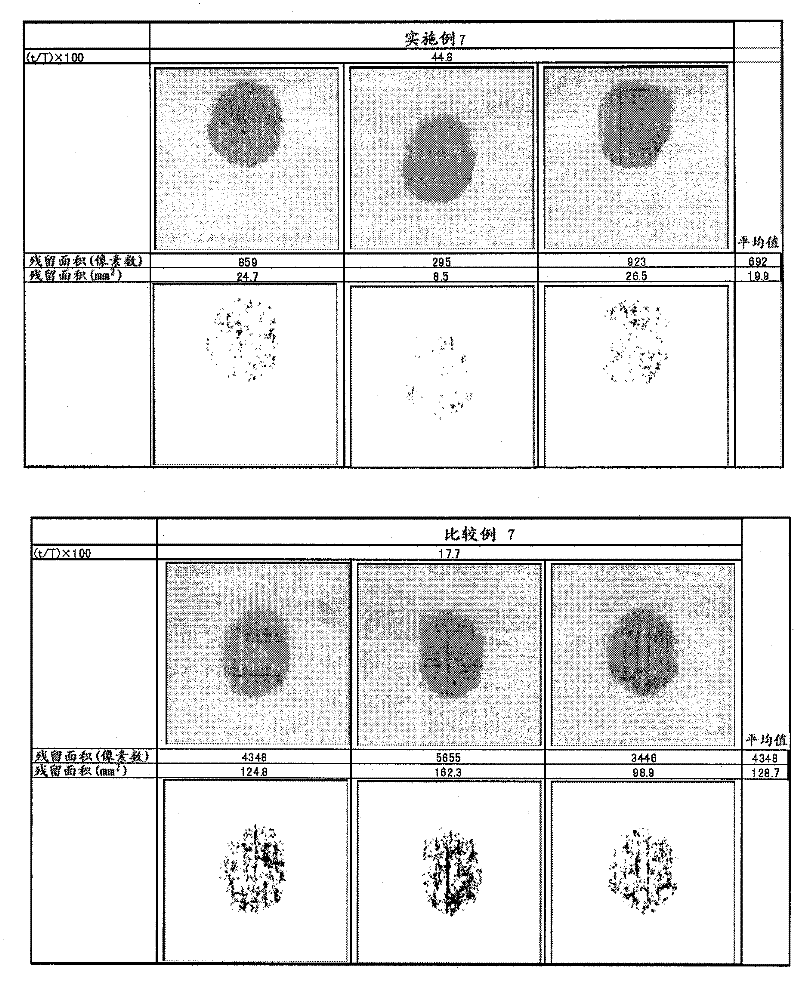

The invention discloses an extremely soft non-woven fabric. The non-woven fabric comprises a milky white extremely soft spun-bonding non-woven fabric, and the milky white extremely soft spun-bonding non-woven fabric is densely covered with rolling points. The non-woven fabric can be better applied to a diaper base film and a waistline, the milky white extremely soft spun-bonding non-woven fabric blended by a propylene-based elastic material, a milky white master batch, a soft master batch and polypropylene is adopted, the softness is better than ordinary products, the problems of redness and swelling, itching and the like caused by friction between the skin and a non-woven fabric are solved, the non-woven fabric has an effective protective effect, the milky white extremely soft spun-bonding non-woven fabric is densely covered with the rolling points in diamond arrangement, the tensile strength of the non-woven fabric is improved, the fluffing phenomenon can be prevented, and the non-woven fabric has smooth surface and is softer during use.

Owner:ZHEJIANG KEDEBANG NONWOVEN CLOTH

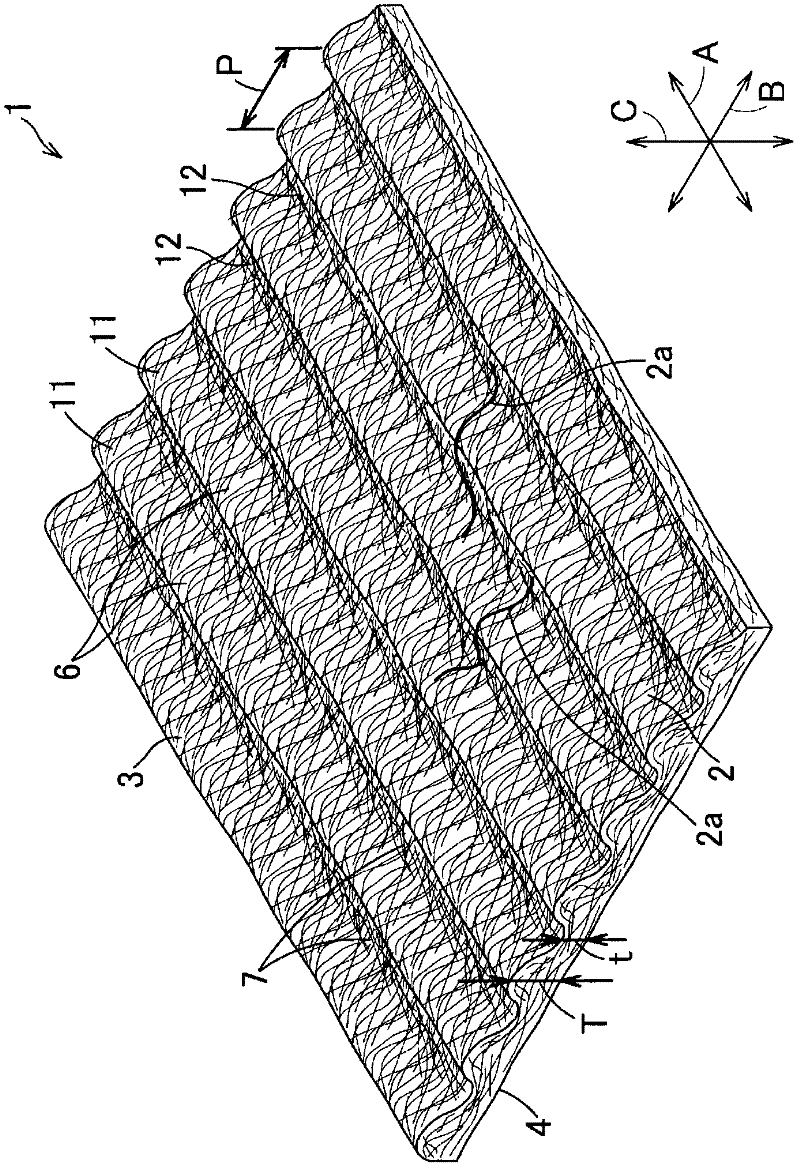

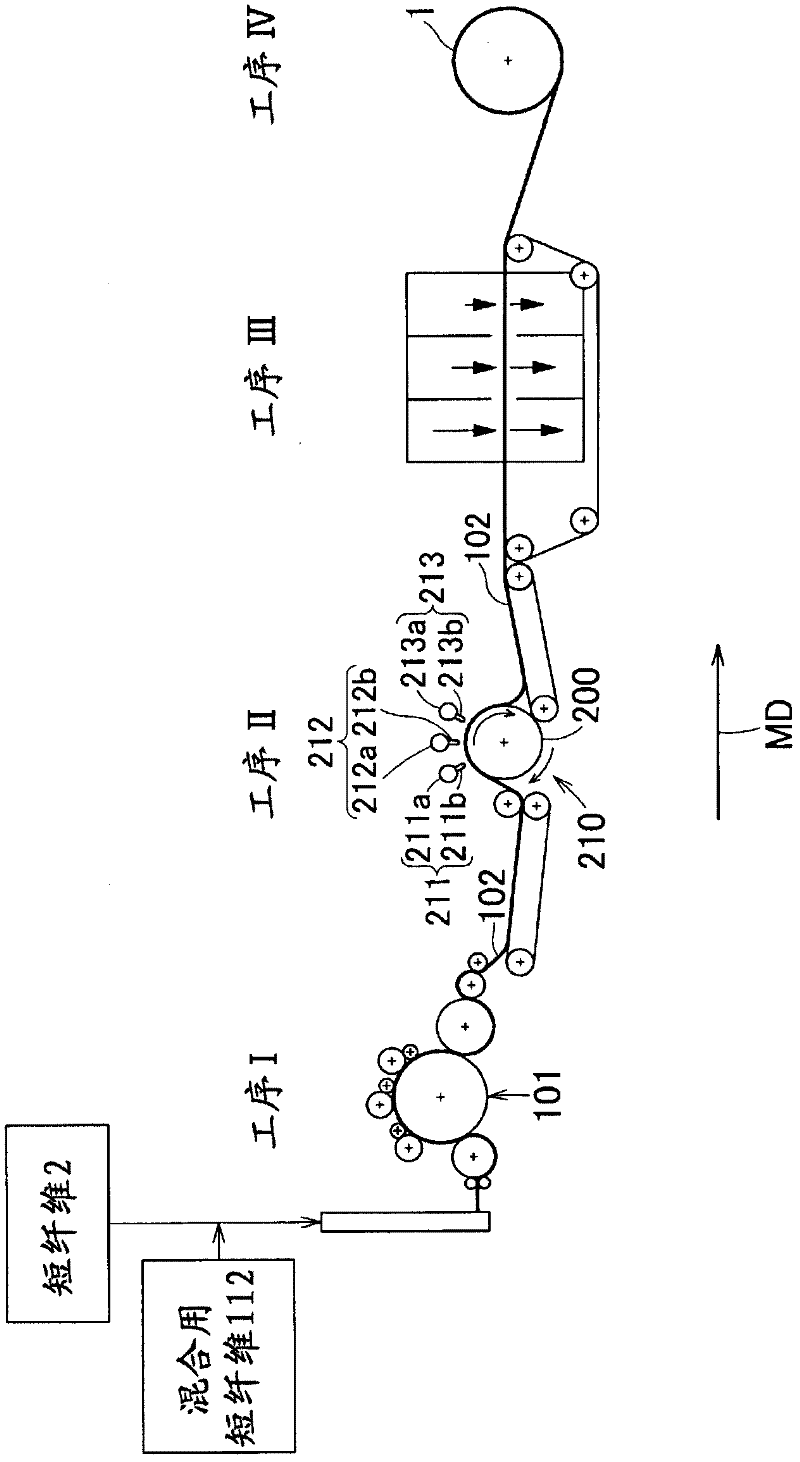

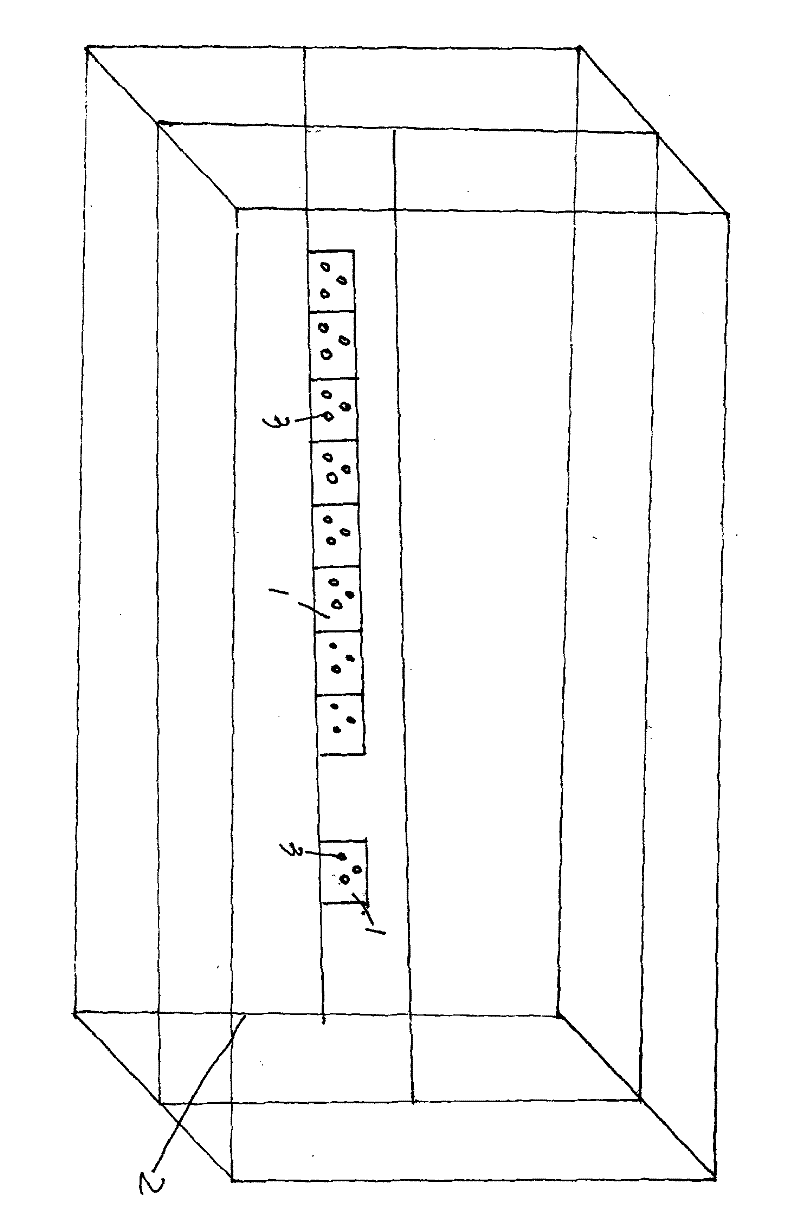

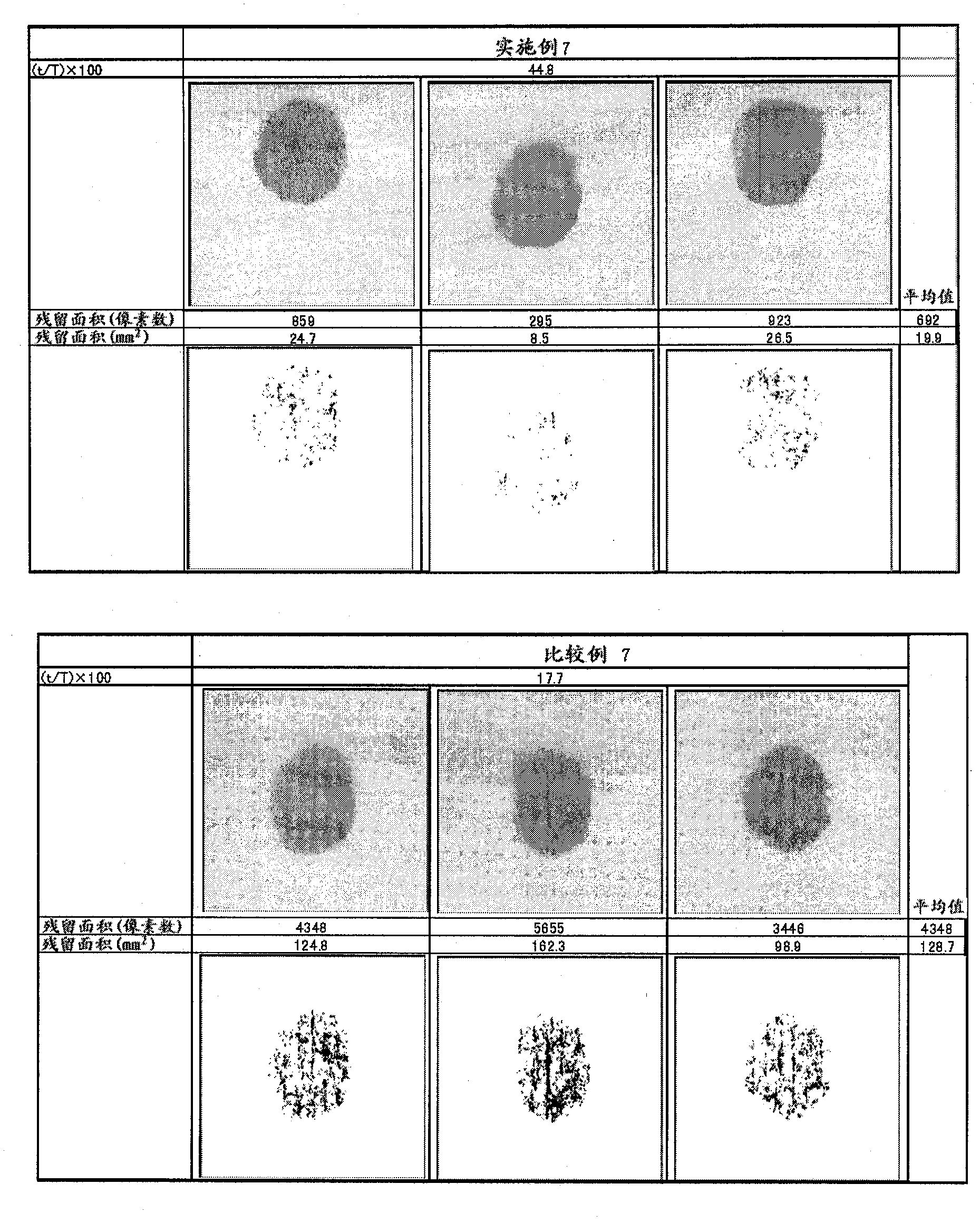

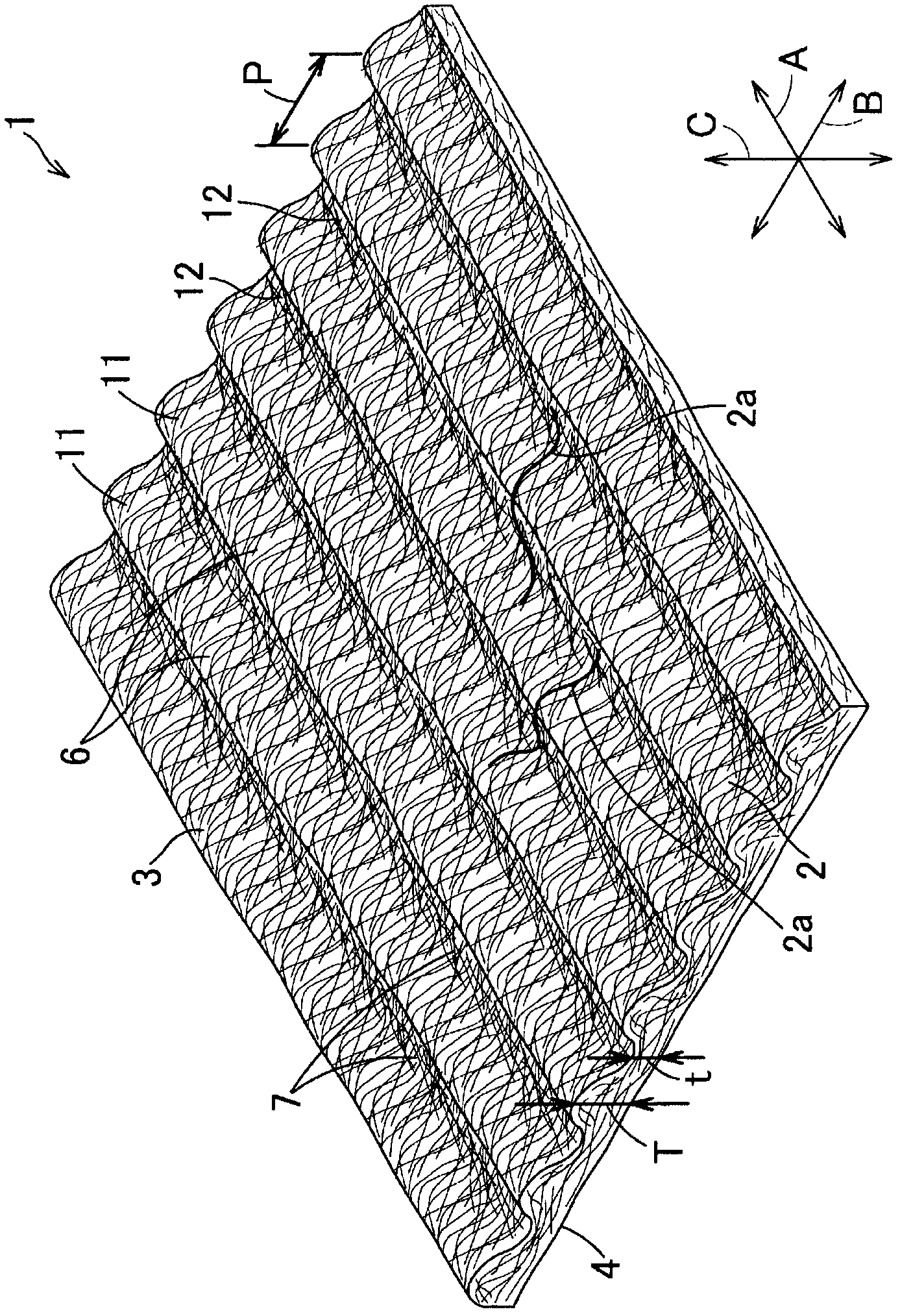

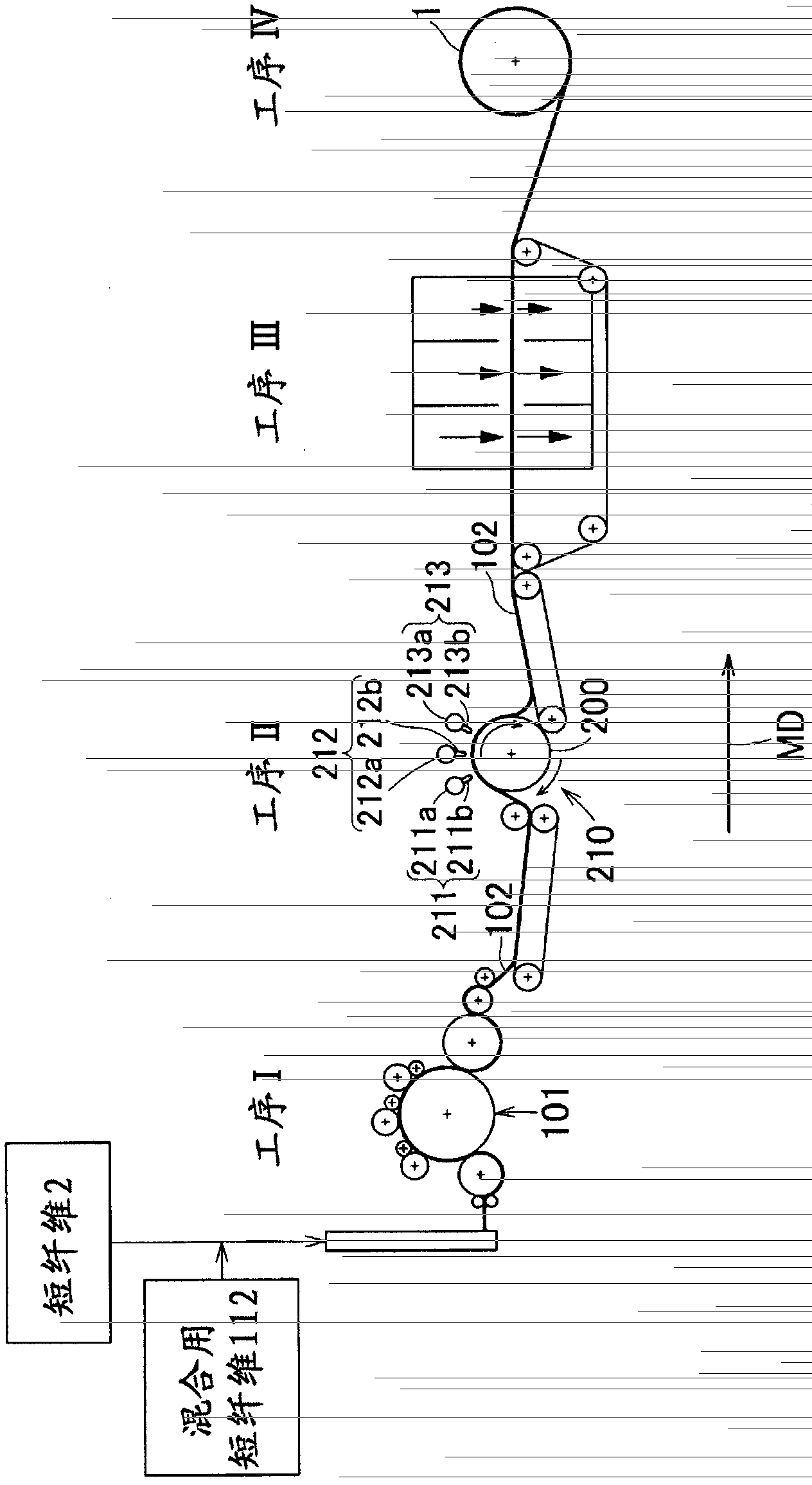

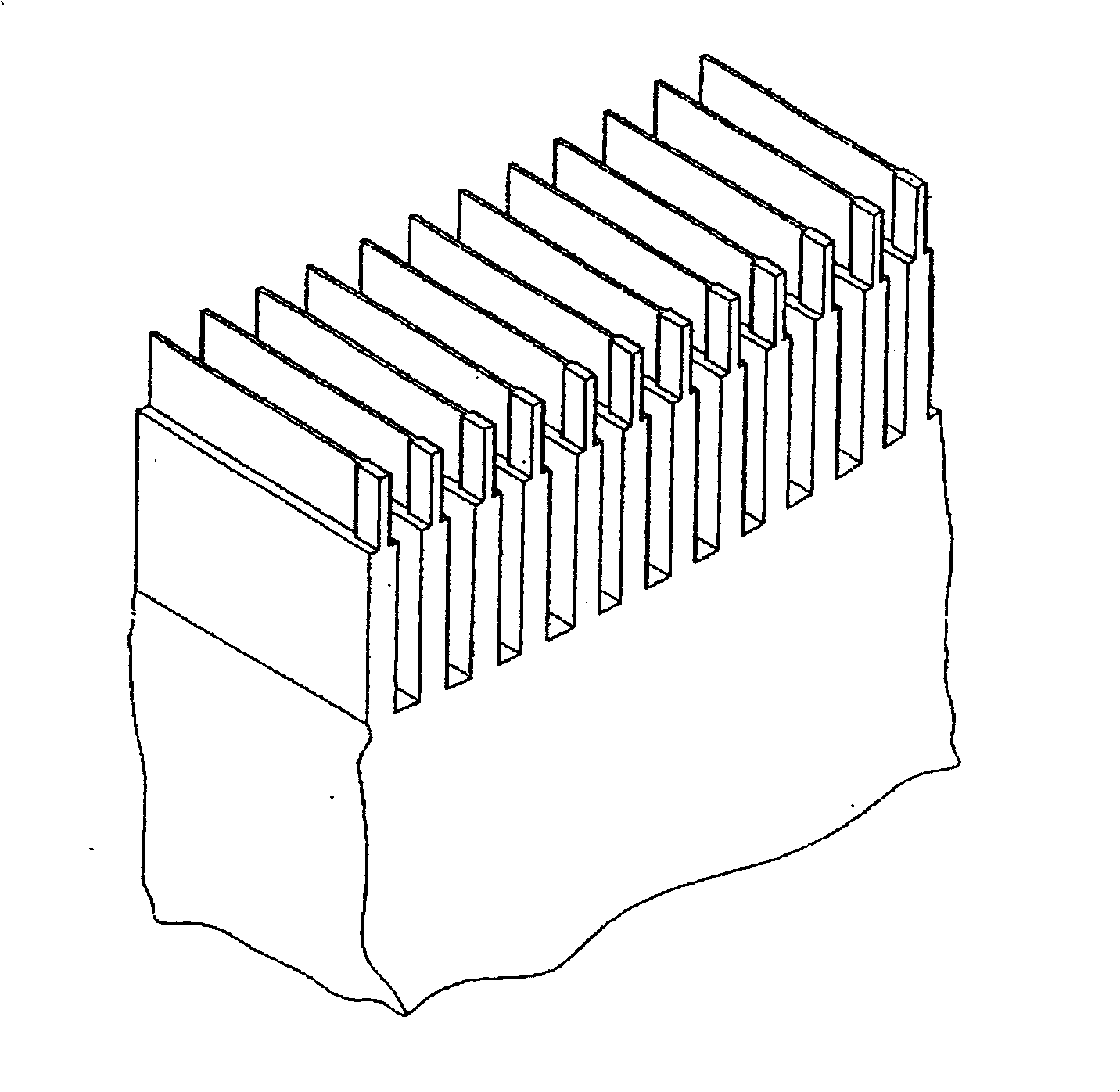

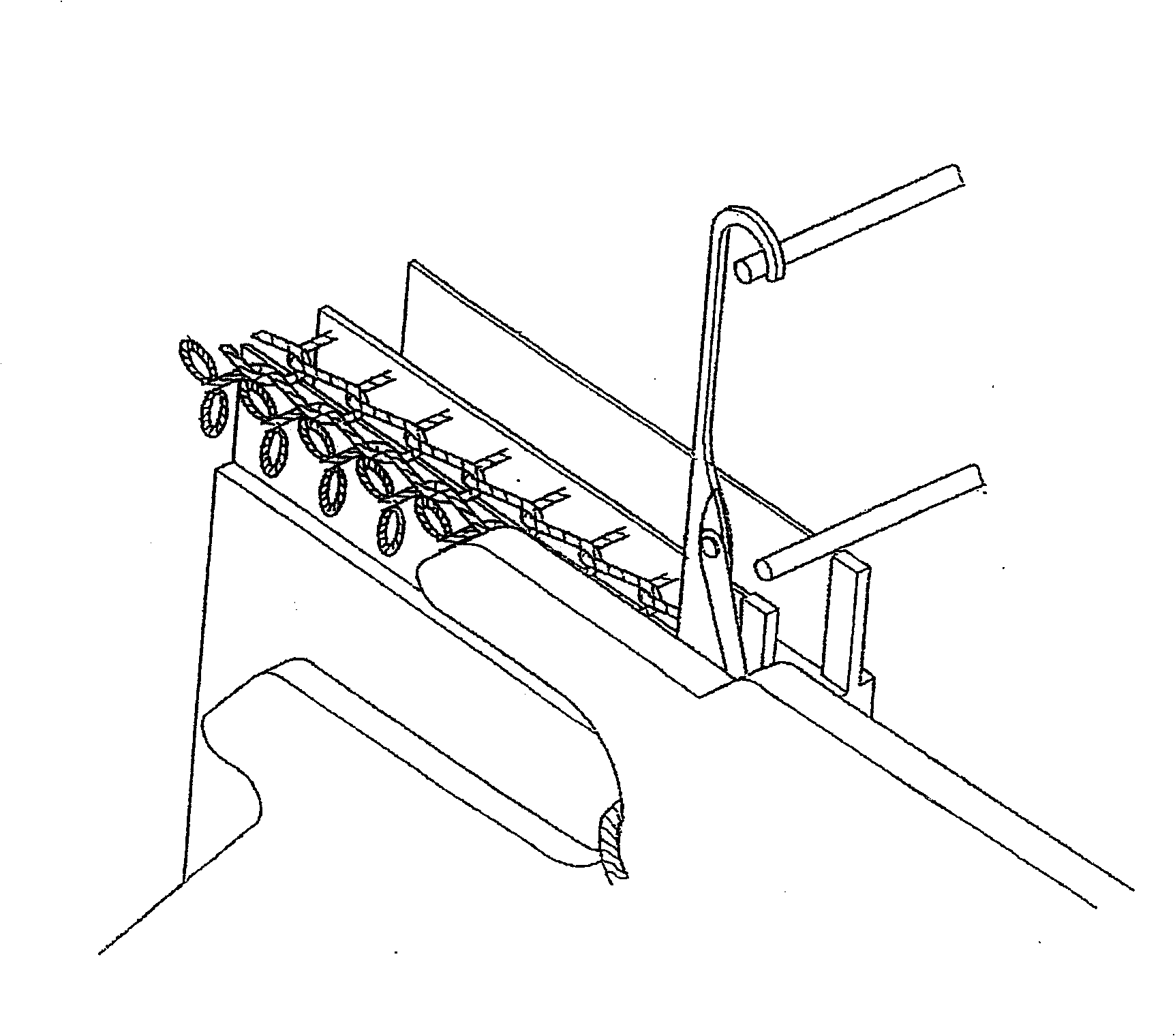

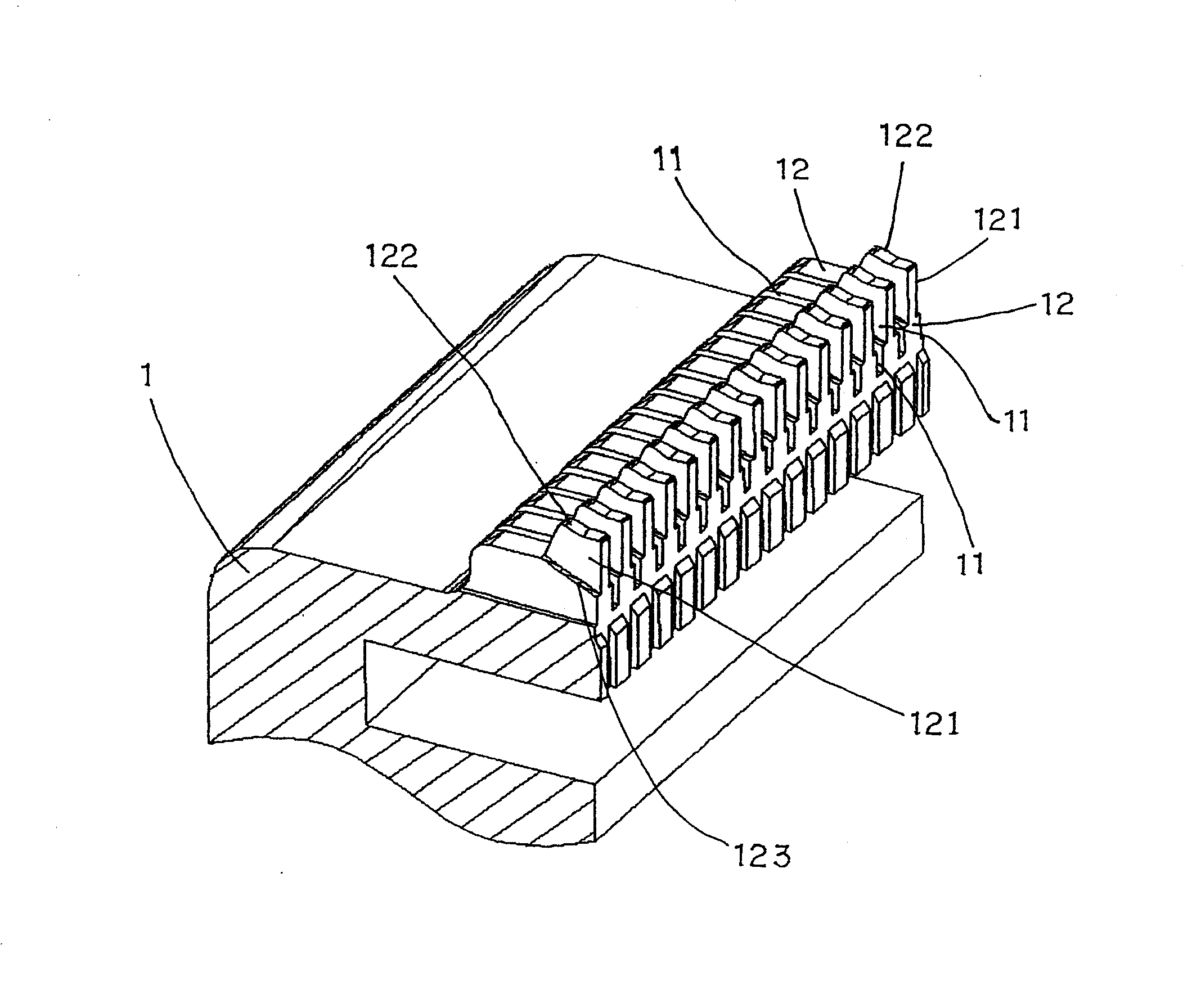

Liquid-permeable nonwoven fibrous fabric

ActiveCN102482817AThrough highAvoid fluffingLayered productsAbsorbent padsNonwoven fabricSynthetic resin

A liquid-permeable nonwoven fibrous fabric which permits a viscous bodily fluid to pass therethrough. The liquid-permeable nonwoven fibrous fabric (1) comprises staple fibers (2) formed from a thermoplastic synthetic resin and disposed in the state of being fusion-bonded to one another. The front surface (3) thereof has ridges (6) and grooves (7), the ridges (6) and the grooves (7) extending in parallel with one another in the lengthwise direction (A) and being alternately arranged in the crosswise direction (B). The proportion of the height (t) from the back surface (4) of the nonwoven fibrous fabric (1) to the bottom (12) of each groove (7) to the height (T) from the back surface (4) to the top (11) of each ridge (6) is in the range of 40-55%. The front surface (3) includes fibers (2a) which are staple fibers (2) each extending between adjacent grooves (7) through the ridge (6) and which have been fusion-bonded to other staple fibers (2) in each of the grooves (7).

Owner:UNI CHARM CORP

Cotton blended spinning elastic knitted underwear face fabric and processing technique thereof

InactiveCN101148801AStress reliefImprove the finishWeft knittingBiochemical fibre treatmentYarnPolymer science

The elastic knitted underwear fabric of blended cotton fiber and viscose fiber is woven with the materials including cotton fiber in 72-77 wt%, superfine viscose fiber in 19-25 wt% and elastic polyurethane fiber in 3-7 wt%, and through the technological process including frame spinning with cotton fiber and superfine viscose fiber to obtain 40S combed blended cotton-viscose yarn, yarn steaming, knitting the blended cotton-viscose yarn and elastic polyurethane fiber in a single-sided large circular weaving machine to obtain the underwear fabric, and final polishing to eliminate hairs biologically with enzyme. The elastic knitted underwear fabric has improved fluffing and balling up performance, smooth surface, fully handling and high wearability.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

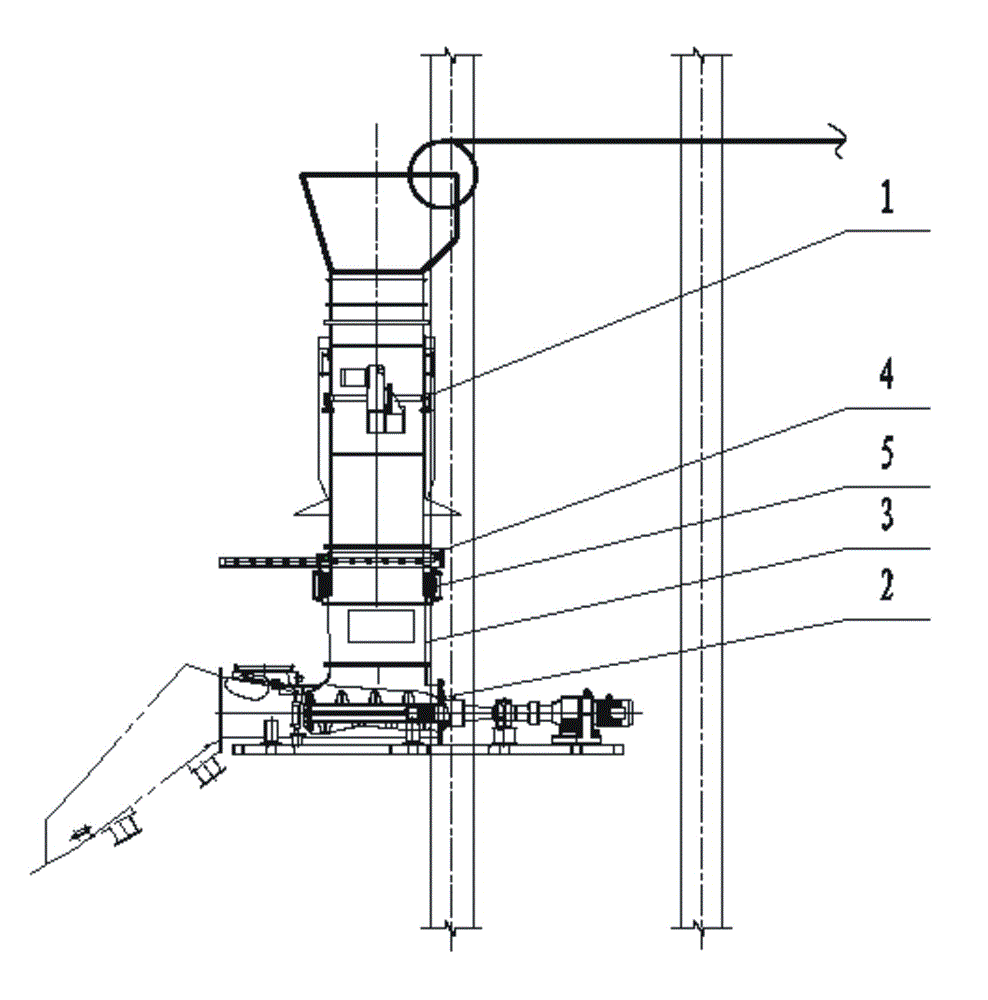

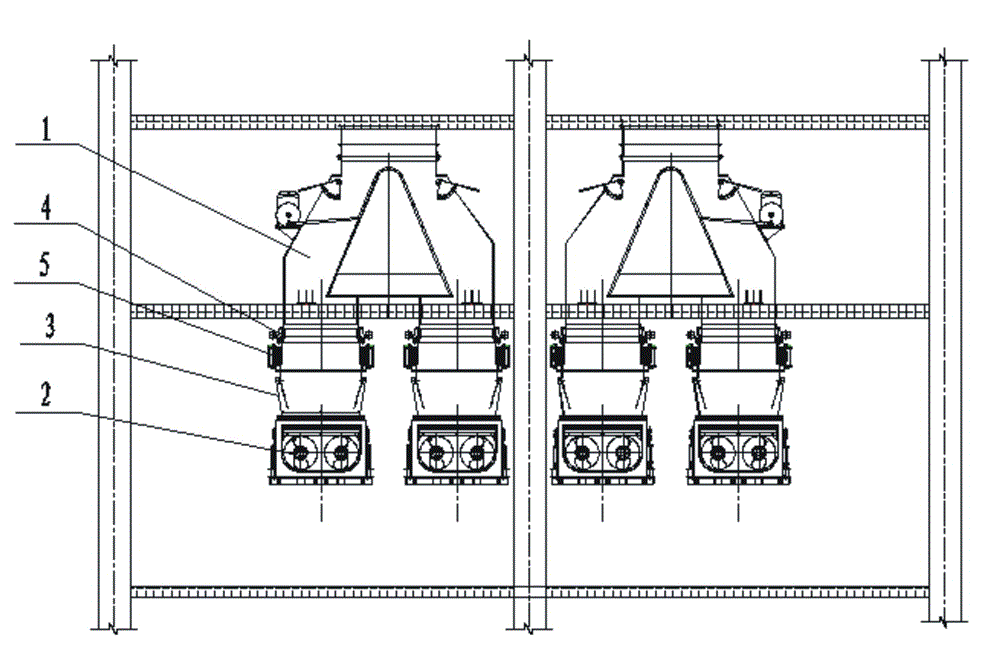

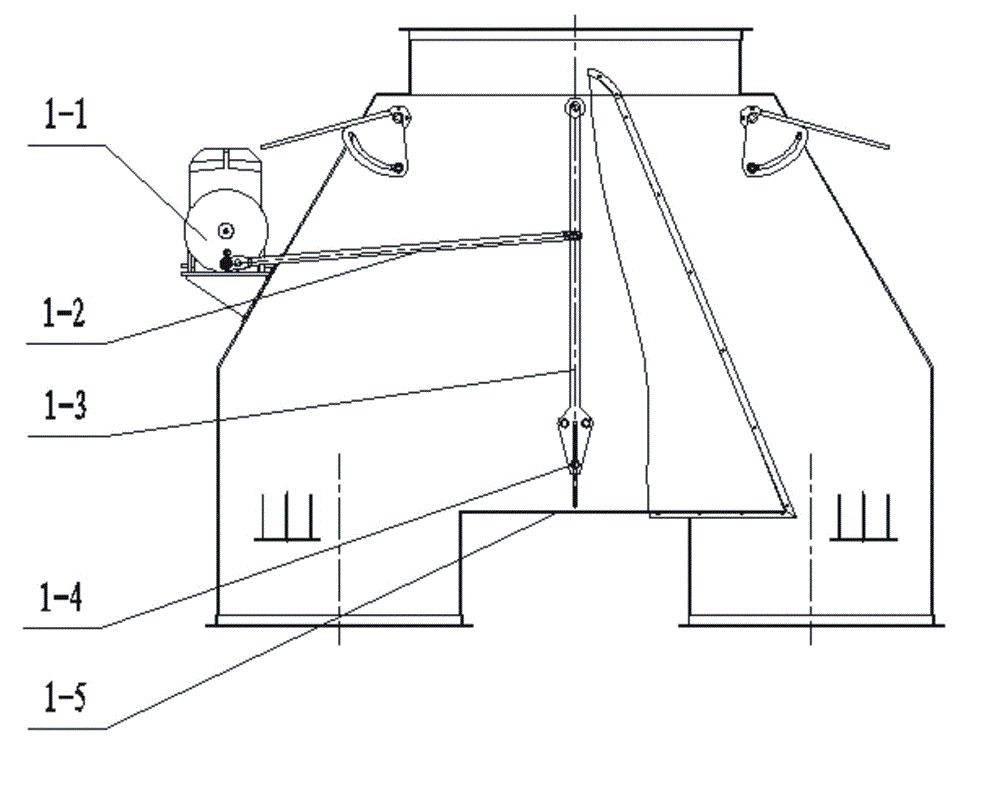

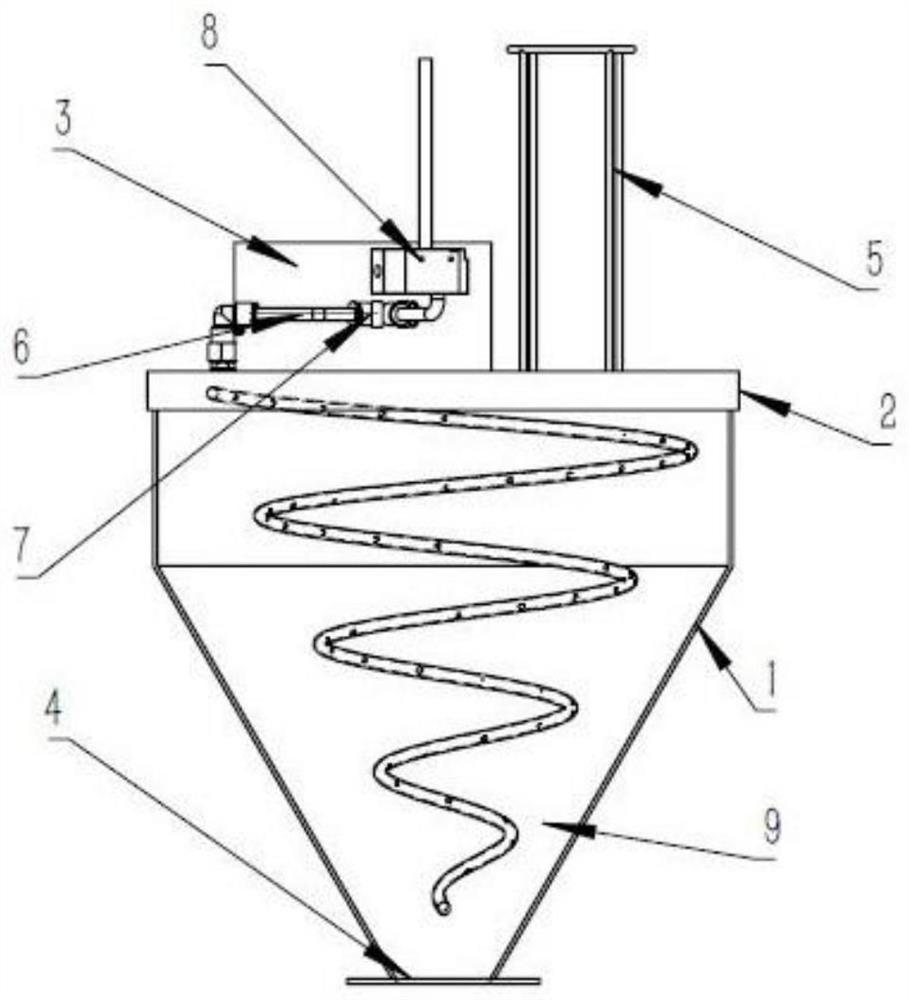

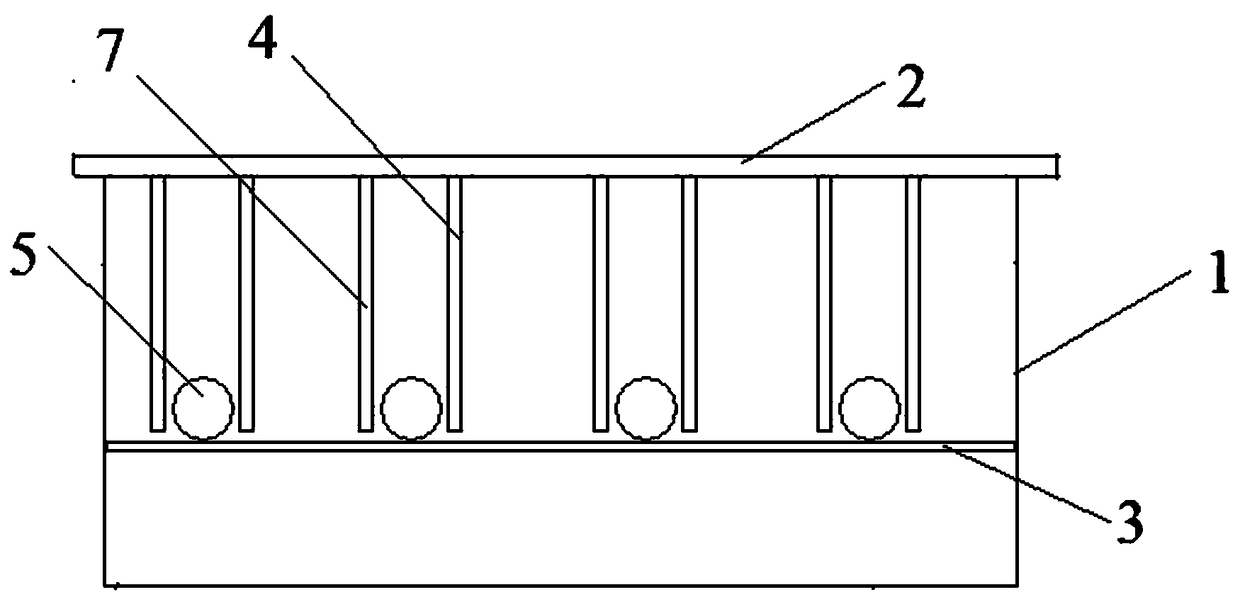

Furnace-free front storage bin feeding device for biomass power plant

InactiveCN102913935ALower the altitudePrevent bridgingFluidized bed combustionLump/pulverulent fuel feeder/distributionFailure ratePower station

The invention relates to a furnace-free front storage bin feeding device for a biomass power plant. The blanking is directly performed by employing a charging belt, a charging belt corresponds to a distributor, a distributor is provided with two discharge openings; the discharge openings of each distributor are butted with a spiral feeding device through a blanking pipe; and four spiral feeding devices respectively corresponds to four feeding holes of a corresponding boiler. The device is easy, convenient and high in adaptability, the transfer link is reduced, the failure rate of the system is reduced, the height of the charging belt is reduced, the bridging and bulking phenomena in the traditional stokehole storage bin are avoided, the floor area is saved, and the cost is saved; and meanwhile, the device has good practical using effect of various biomass fuels, the stability, reliability and the safety of equipment operation in a feeding system are improved, and the device can be widely applied to various boilers for biomass power generation, and are particularly applied to circulating fluidized bed boilers.

Owner:武汉丰盈能源技术工程有限公司

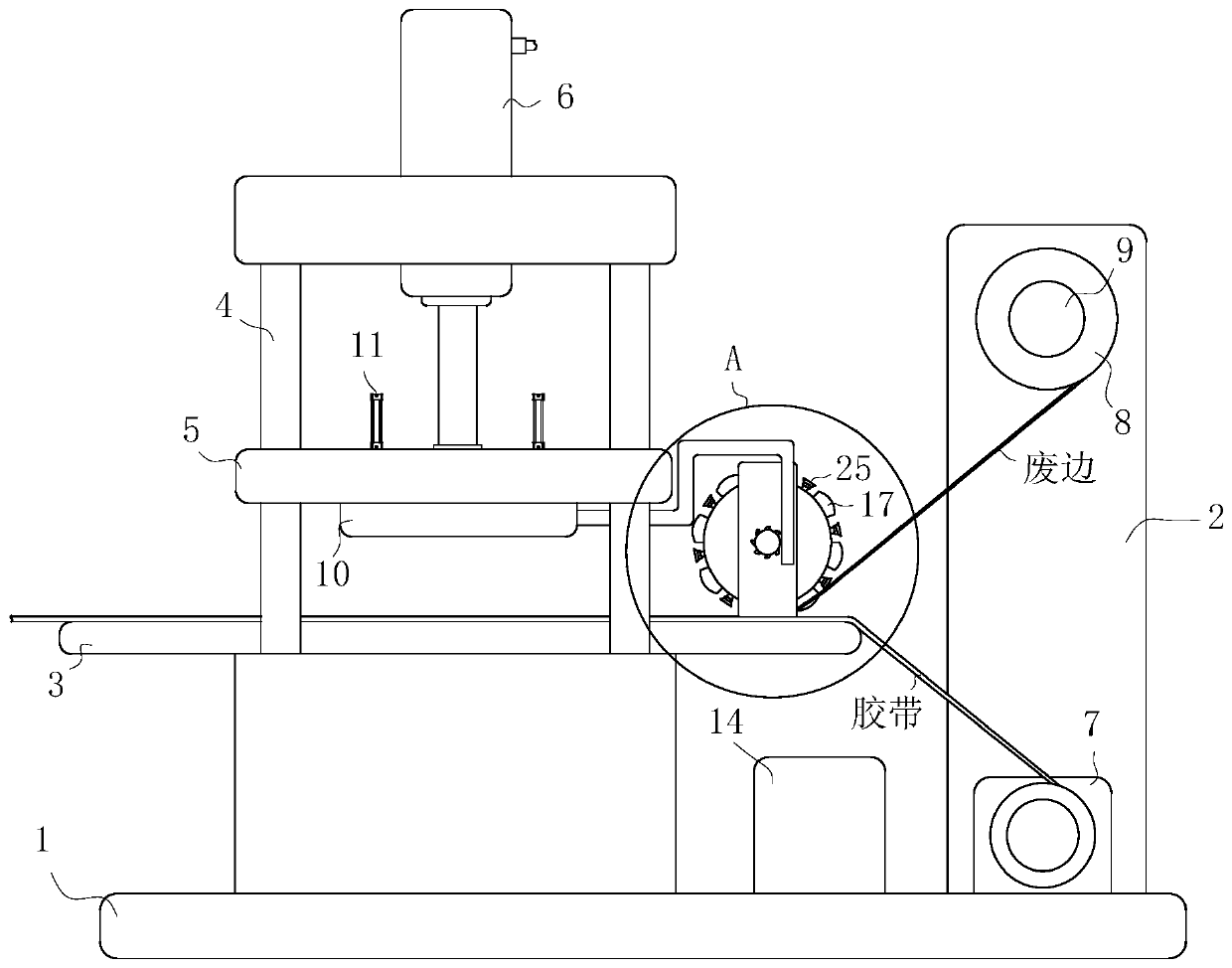

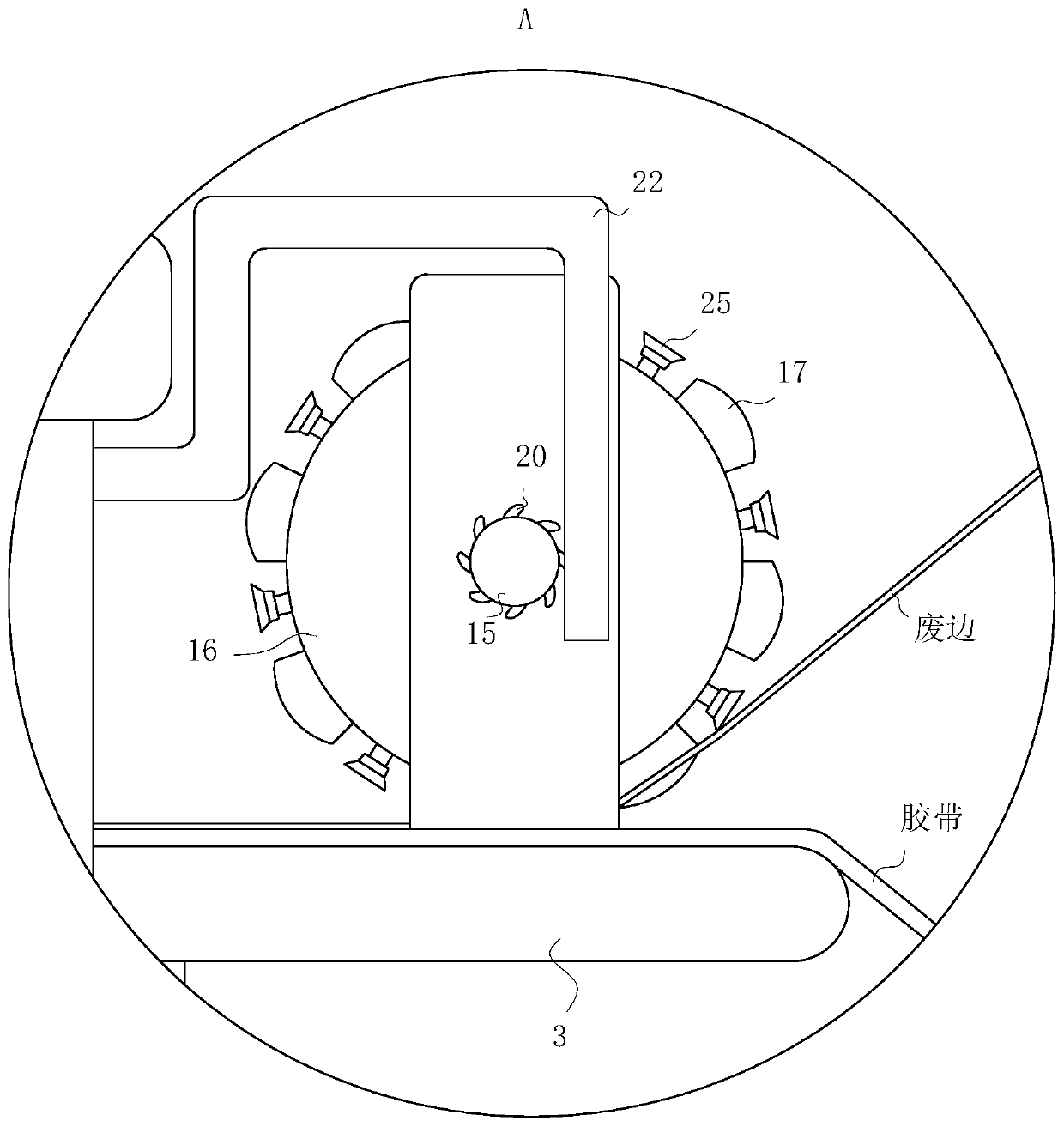

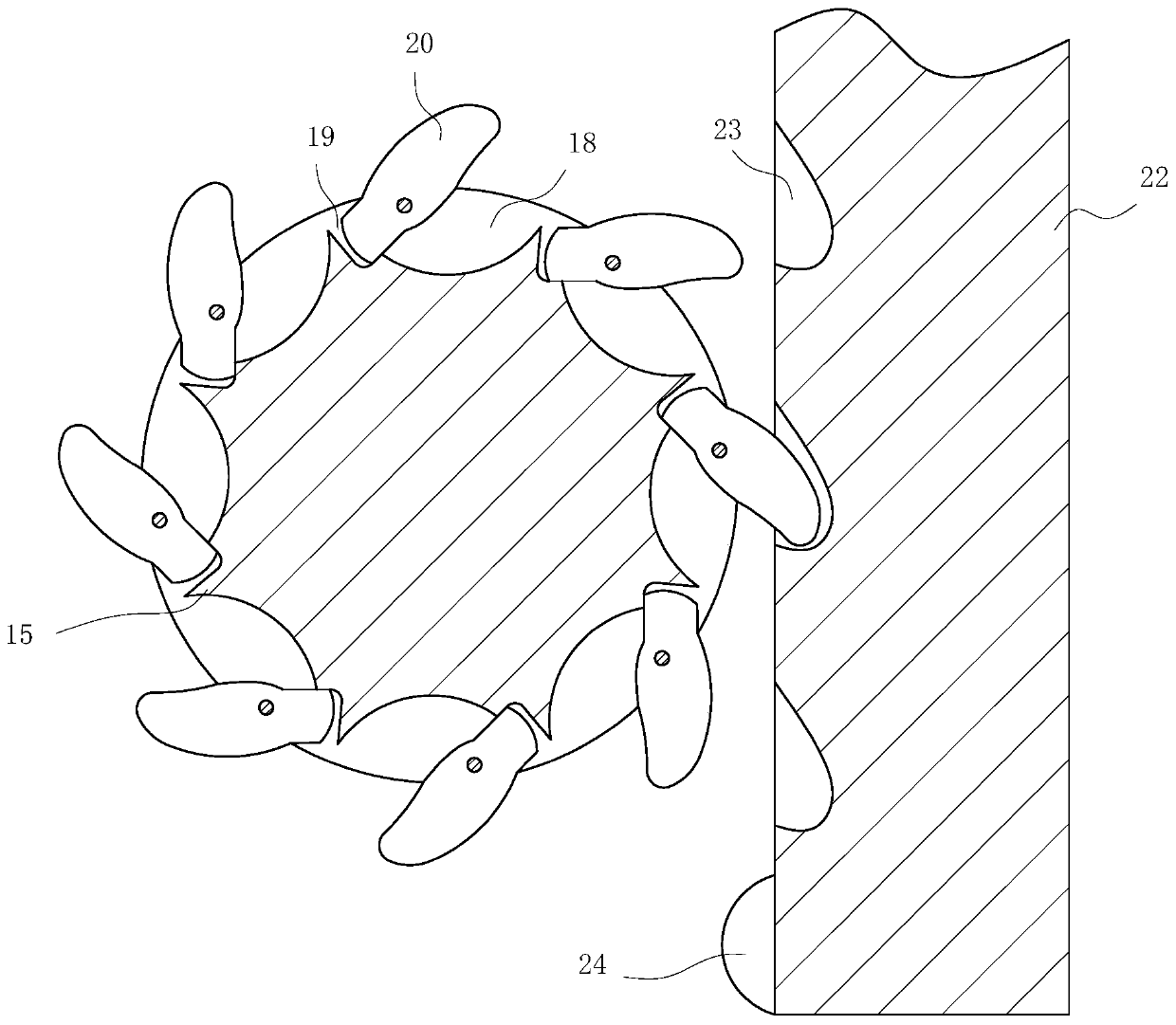

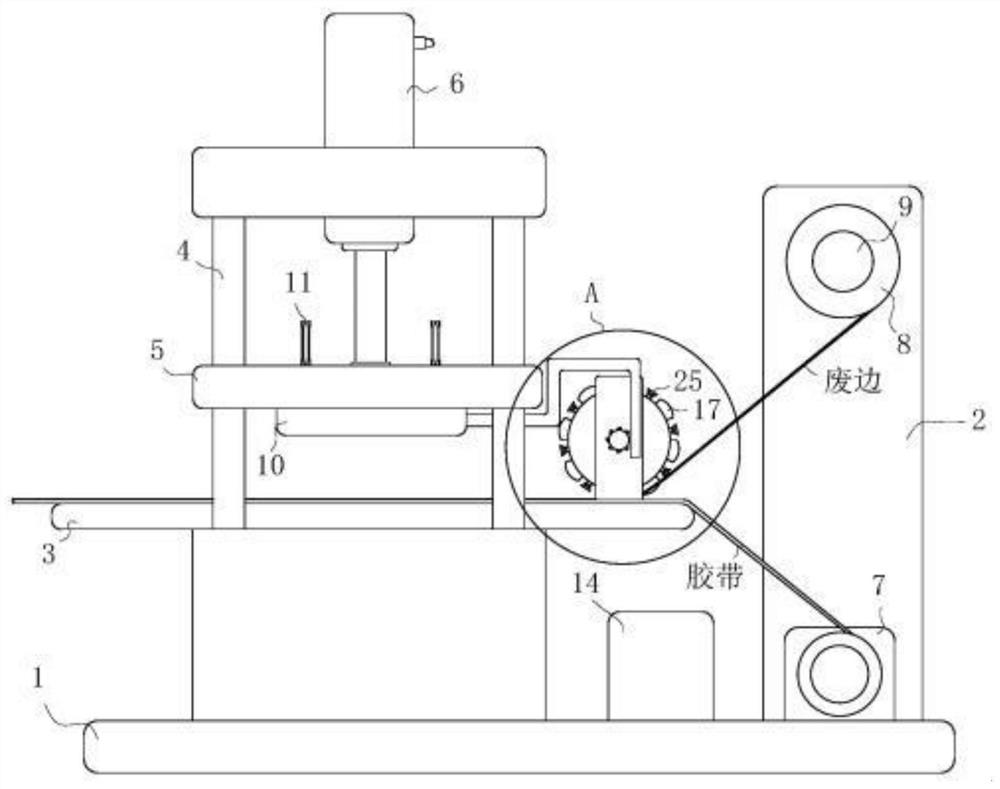

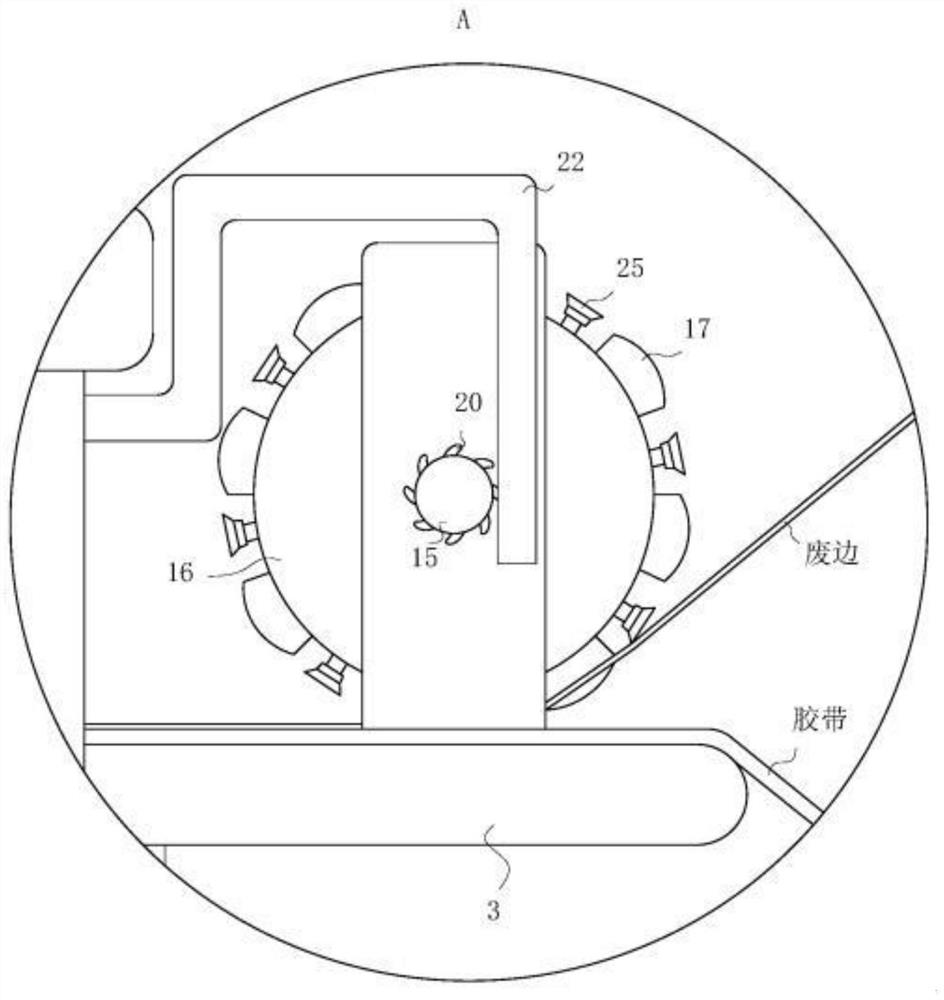

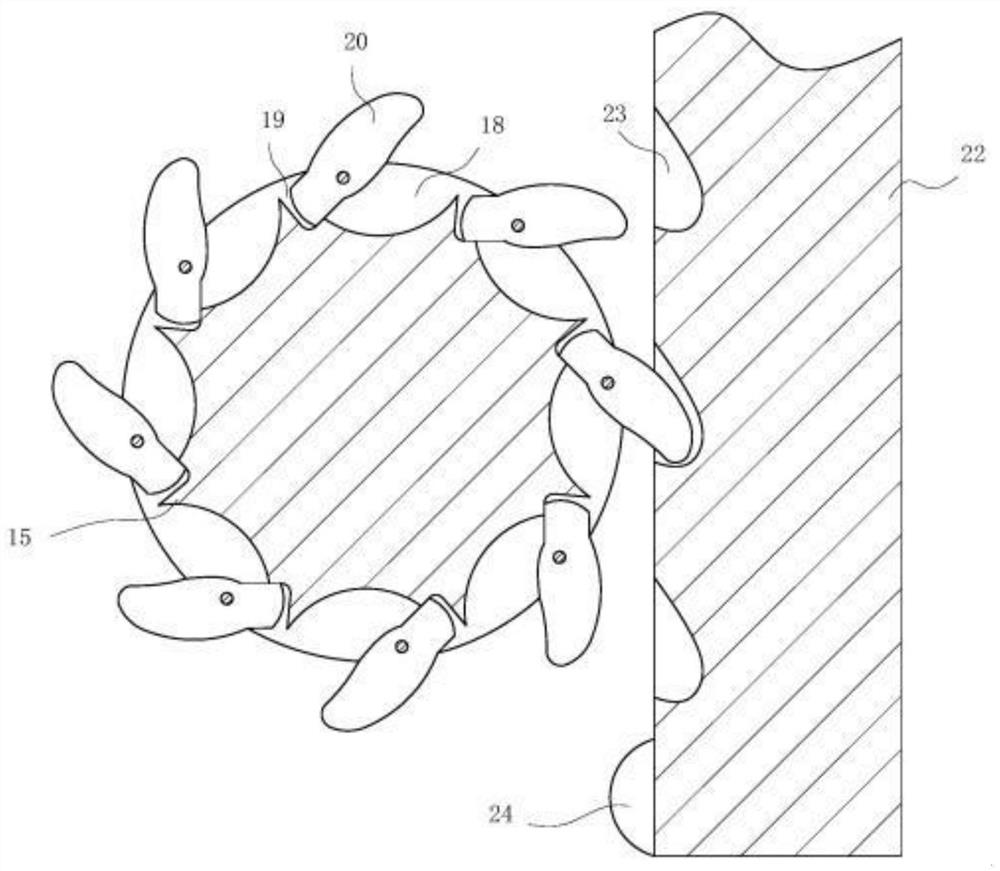

Die cutting device for adhesive tape processing

ActiveCN111037641AImprove waste discharge efficiencyReduce the possibilityMetal working apparatusPhysicsElectric machinery

The invention belongs to the technical field of adhesive tape processing, and particularly relates to a die cutting device for adhesive tape processing. The die cutting device comprises a bottom plate, wherein a hydraulic machine and a mounting plate are fixed at the top end of the bottom plate; the hydraulic machine comprises a workbench, a guide rod, a movable cross beam and a hydraulic cylinder; a first driving motor and a second driving motor are fixed on the side wall of the mounting plate; rotating rollers are fixed at the output shaft ends of the first driving motor and the second driving motor; the rotating rollers are used for winding an adhesive tape and a waste edge correspondingly; and more than two die cutting knives are fixed at the bottom end of the movable cross beam. According to the die cutting device, the adhesive tape is pressed through the arrangement of a pressing plate, so that the adhesive tape cannot be broken during die cutting, and the phenomenon that the cutedge of the adhesive tape is fluffed is avoided; and a limiting block is arranged to protect a product, so that the product cannot be taken up when being separated from the waste edge, and the wastedischarge efficiency of the adhesive tape is improved.

Owner:安徽灿宇光电科技有限公司

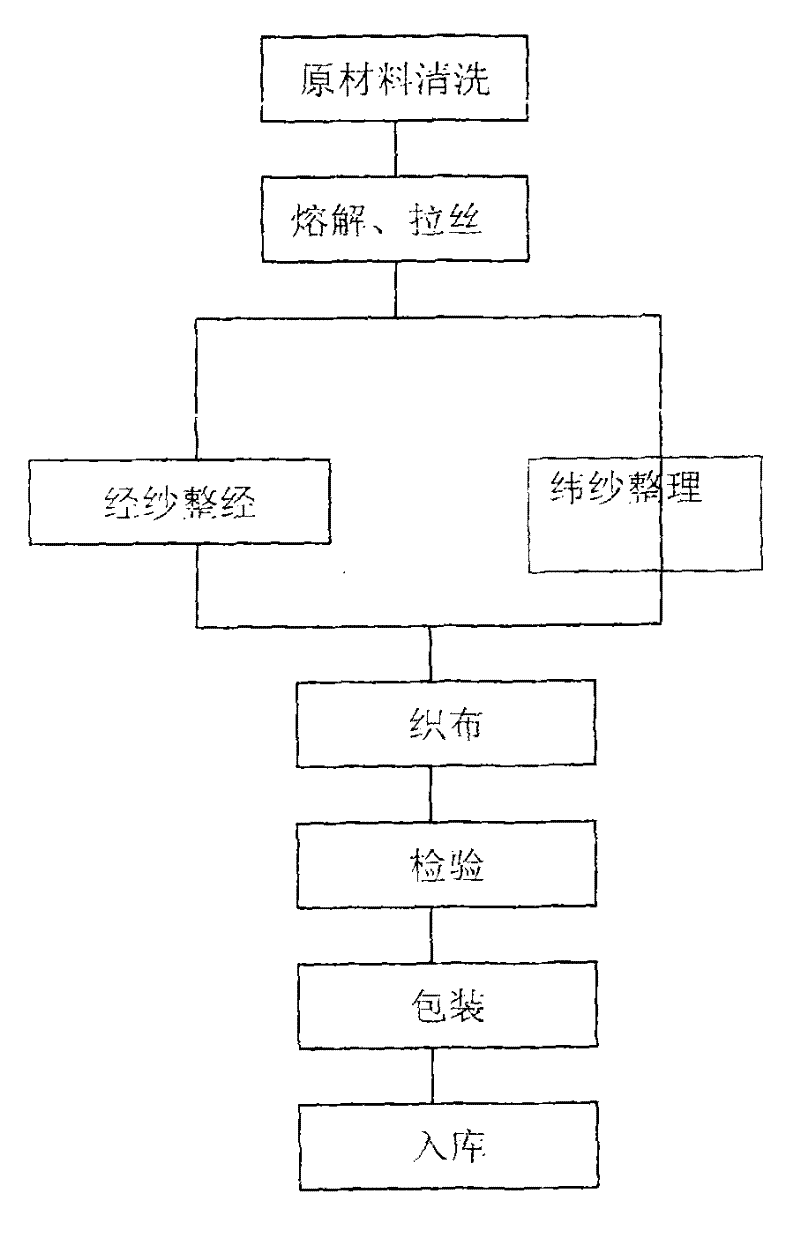

Glass fiber weaving process and special equipment thereof

InactiveCN101748546AAvoid wear and tearAvoid harmLoomsOther manufacturing equipments/toolsFiberGlass fiber

The invention discloses a glass fiber weaving process and special equipment thereof. The technological process is finished through procedures of cleaning, melting, wire drawing, warp yarn warping, weft yarn finishing, weaving, check and warehousing on raw materials. The special equipment is a warping tensioner and a weft yarn introduction device. When the process is adopted to manufacture a glass fabric, procedures of unwinding and twisting are removed from a finishing process of weft yarns, and a stranding procedure is removed from a finishing process of weft yarns so as to enable glass precursor fibers not to generate friction with equipment of unwinding, twisting and stranding, avoid abrasion and hurt to the glass precursor fibers, guarantee the tensile strength of the glass precursor fibers, enhance the product quality and the production efficiency and save the energy consumption and the product cost.

Owner:黄新春

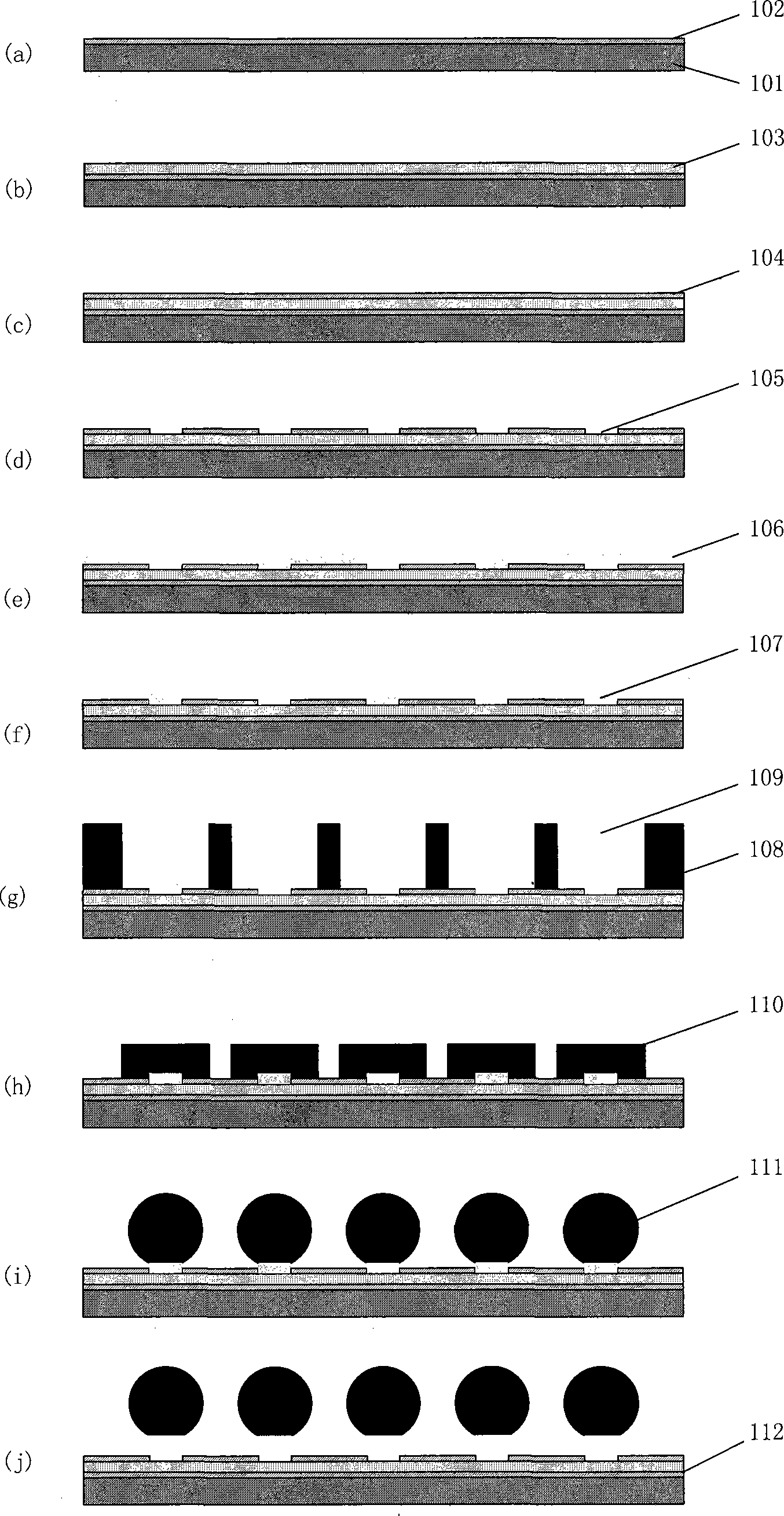

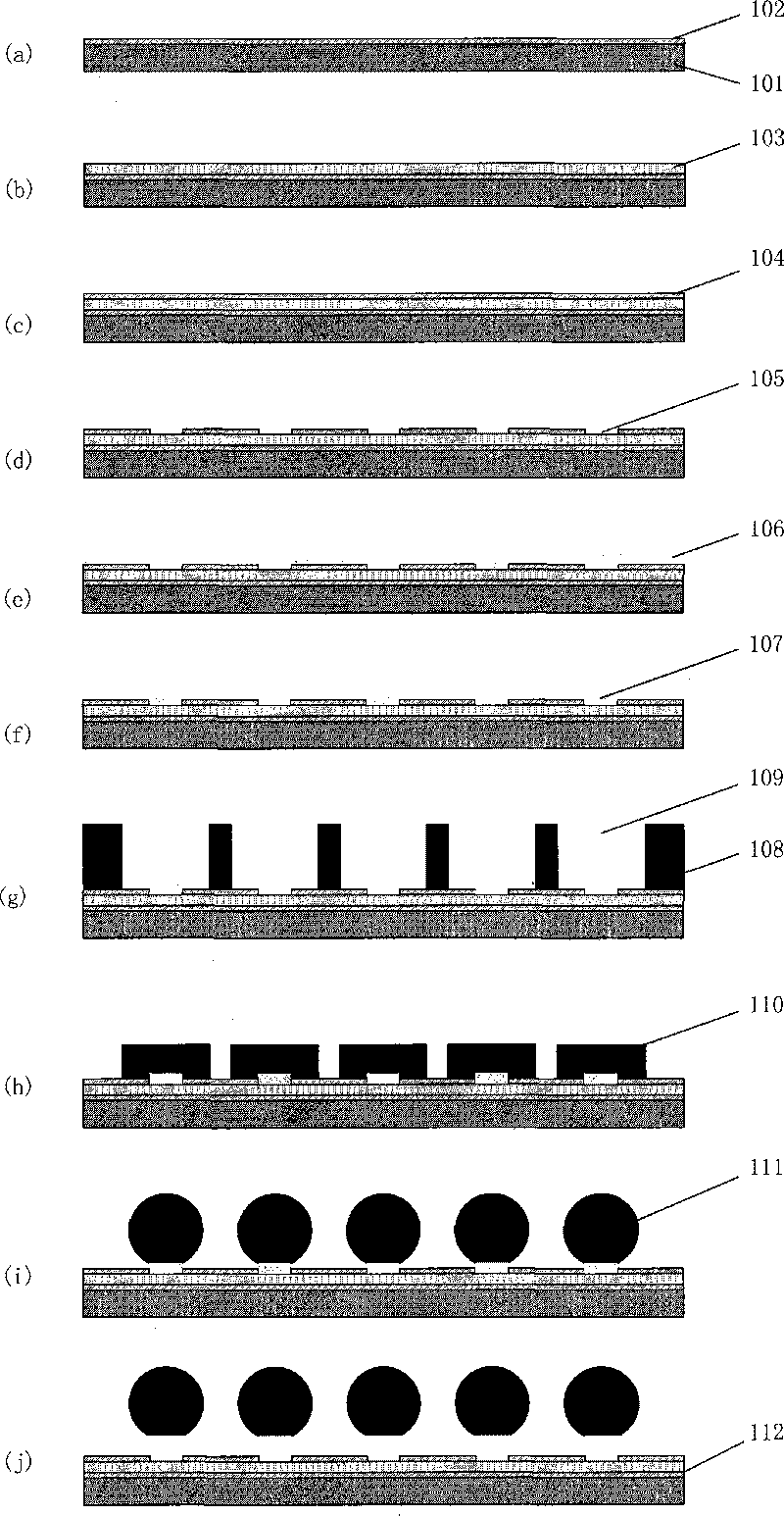

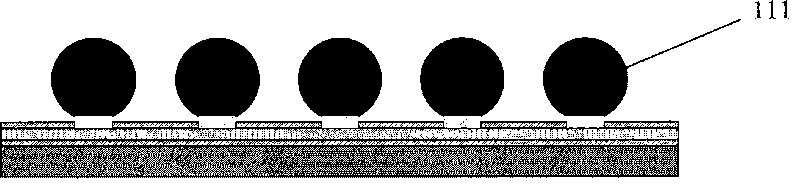

Method for producing tiny soldered balls with repeatedly-usable substrates

InactiveCN101246828ANarrow particle size distributionPrevent surface oxidationSolid-state devicesSemiconductor/solid-state device manufacturingResistSputtering

The invention relates to a method for manufacturing a small solder ball, in which a substrate is reusable. The invention is characterized in: firstly, the reusable substrate is prepared by means of IC manufacture process: a silicon wafer is used as a base, a metal conducting layer is sputtered from the front after heat oxidation treatment; secondly, the small solder ball is manufactured on the reusable substrate: a metal sacrificial layer is sputtered on the substrate to cover the opening of the conducting layer, thick photosensitive resist is coated and an electroplating window is photoetched, then solder is electroplated, the thick photosensitive resist is removed after electroplating, the solder is reflowed to form a solder ball, thereafter the metal sacrificial layer is corroded to be removed, so that the solder ball can drop off completely from the reusable substrate, and finally the solder ball is collected. According to the invention, the manufacturing procedure is simple and consumes small energy, the process has good controllability, the bottleneck of low productivity is overcome; the manufactured solder ball has smooth surface, good sphericity and uniform size, with the smallest grain diameter being 0.15mm.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

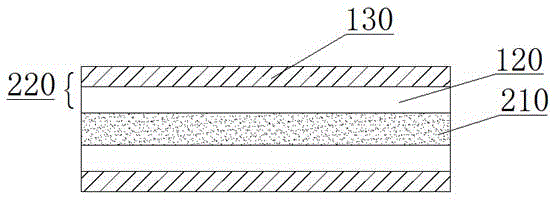

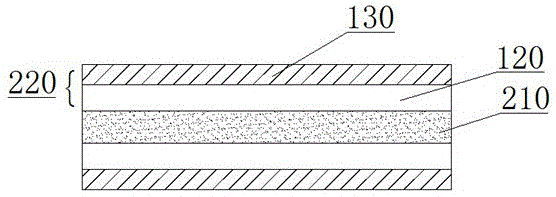

Making method of anti-static lamination type support pad for protecting LCD panel

ActiveCN104589769AReduce pollutionReduce incidenceSynthetic resin layered productsLaminationForeign matterPolyolefin

The invention relates to a making method of an anti-static lamination type support pad for protecting an LCD panel. According to the making method, a polyolefin film of an anti-static layer is at least formed on one surface or two surfaces of a polyolefin or polyurethane foam sheet by virtue of lamination. The lamination type support pad made by using the making method can be used as a panel lamination type support pad which is used for preventing the surface from being scraped, polluted and impacted and is especially sensitive to static electricity when a liquid crystal display panel is stored and conveyed, and can be used for effectively preventing the edge of the lamination type support pad from fluffing, further effectively reducing the dust generation rate and preventing foreign matters from permeating between the lamination type support pads.

Owner:纳诺化学技术株式会社 +2

Angle cutter realizing smooth cutting and preventing burrs of end side and implementation method of angle cutter

ActiveCN106984867AAvoid fluffingSolve the installation accuracyPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses an angle cutter realizing smooth cutting and preventing burrs of an end side and an implementation method of the angle cutter. The angle cutter comprises a bedplate; the bedplate is provided with a cutting slot; the cutting slot is used for a cutting knife wheel to pass through and is arranged along a rectilinear direction; inside the cutting slot, one end provided with no cutting knife wheel is filled with a fragile insert; and an exposed end face of the fragile insert is smooth and is flush with the upper end face of the bedplate. The main concept of the angle cutters still starts with elimination of a clearance between the cutting knife wheel and the cutting slot to make sure that a sawed material is always supported and burrs caused by inertial rupture in a cutting process can be prevented, so the first problem to be solved is installation precision; however, the angle cutter disclosed by the invention steers clear of the installation precision problem, the cutting slot and the cutting knife wheel still have the clearance, but the cutting slot is filled with the fragile insert, and the final actual movement direction of the cutting knife wheel is generated by cutting when being started for the first time, so the cutting knife wheel has no clearance with the clearance at the fragile insert.

Owner:SHENZHEN JINRONGKE TECH CO LTD

Meal replacement powder capable of breeding hair, blacking hair, tonifying kidney and nourishing qi and blood and preparation method thereof

InactiveCN107095133AGood tonic effectRetain nutrientsFood freezingMetabolism disorderLiver and kidneyChemical composition

The invention relates to meal replacement powder capable of breeding hair, blacking hair, tonifying kidney and nourishing qi and blood and a preparation method thereof. The meal replacement powder is prepared from multiple raw materials, such as black glutinous rice, black soybeans, black sesame, dried black mulberries and black dates, and a finished product is prepared by frying the raw materials, crushing or grinding the raw materials into to-be-mixed materials of different particle sizes separately and mixing the materials. The meal replacement powder can be taken for a long period of time, is free of a pigment, a preservative or a chemical component, integrates multiple nutrients, and has multiple functions of breeding hair, blacking hair, nourishing qi and blood, nourishing the liver and kidney, improving the human immunity and resistance and alleviating various chronic diseases.

Owner:王建新

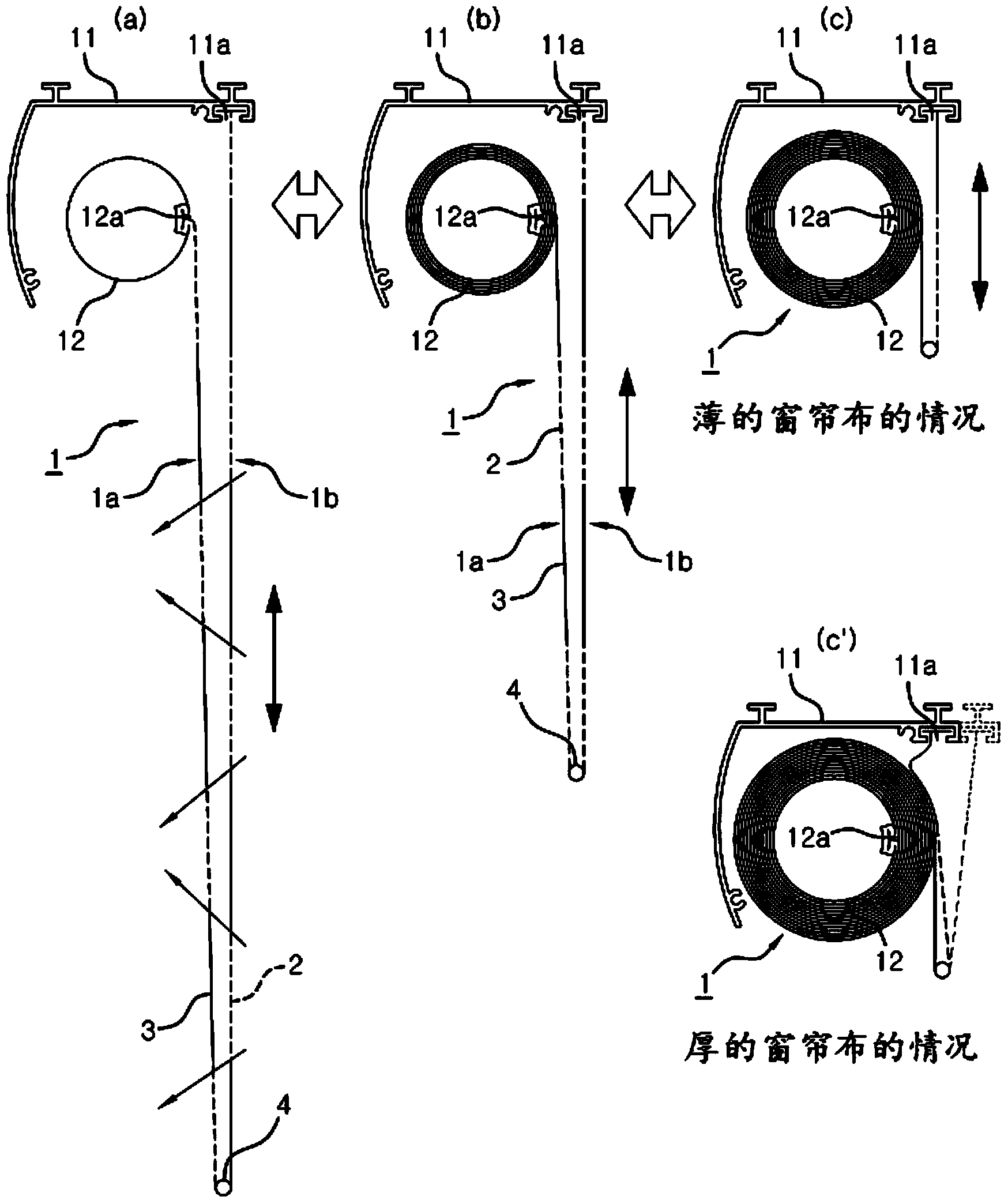

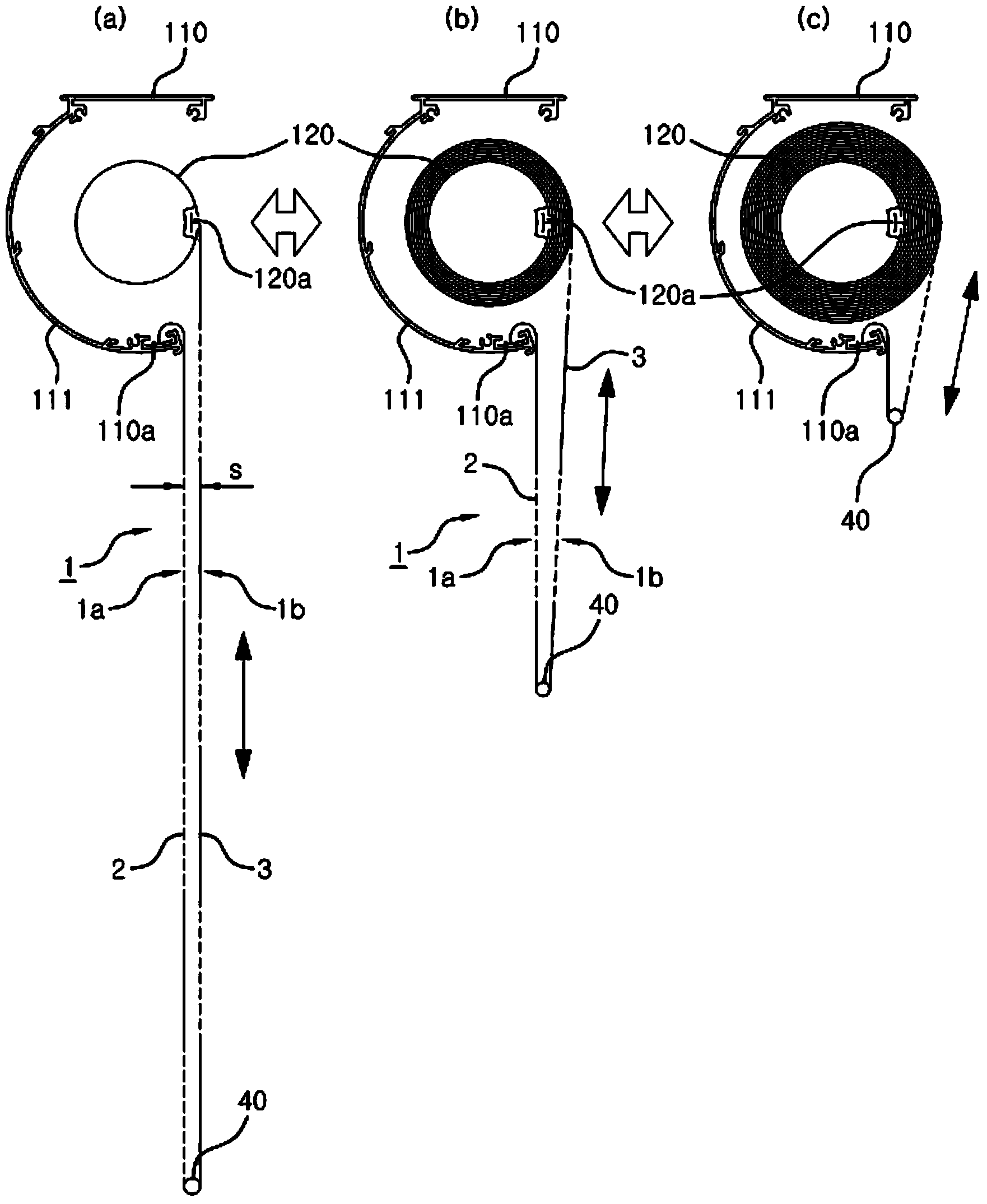

Roll blind

InactiveCN103806822AReduce frictionAvoid fluffingLight protection screensLight controlMechanical engineering

The invention relates to a roll blind which comprises the components of: a head guide rail (110) which is fixedly arranged on a window frame; a winding rod (120) which is arranged on the head guide rail (110) and can rotate; one piece of curtain cloth (1) of which the ends are respectively combined with the head guide rail (110) and the winding rod (120); a loading part (40) which is arranged below the window cloth (1) and sustains rotation of a natural guide and tension state of the curtain cloth (1) in movement of the curtain cloth; and a driving part (130) which controls driving of the winding rod (120). The roll blind of the invention is characterized in that: the head guide rail (110) forms a front part (111) in a manner that packaging the winding rod (120) below the winding rod (120) through a central position; a distance (s) between the front part (111) at one end of the fixed curtain cloth (1) and the winding rod (120) at the other end of the fixed curtain cloth (1) is same with the distance (s) between a front curtain sheet and a back curtain sheet (1a,1b) of the curtain cloth (1) that lifts through the loading part (40), so that sunlight cannot penetrate when the curtain cloth (1) is put down for insulating the sunlight.

Owner:WINPLUS

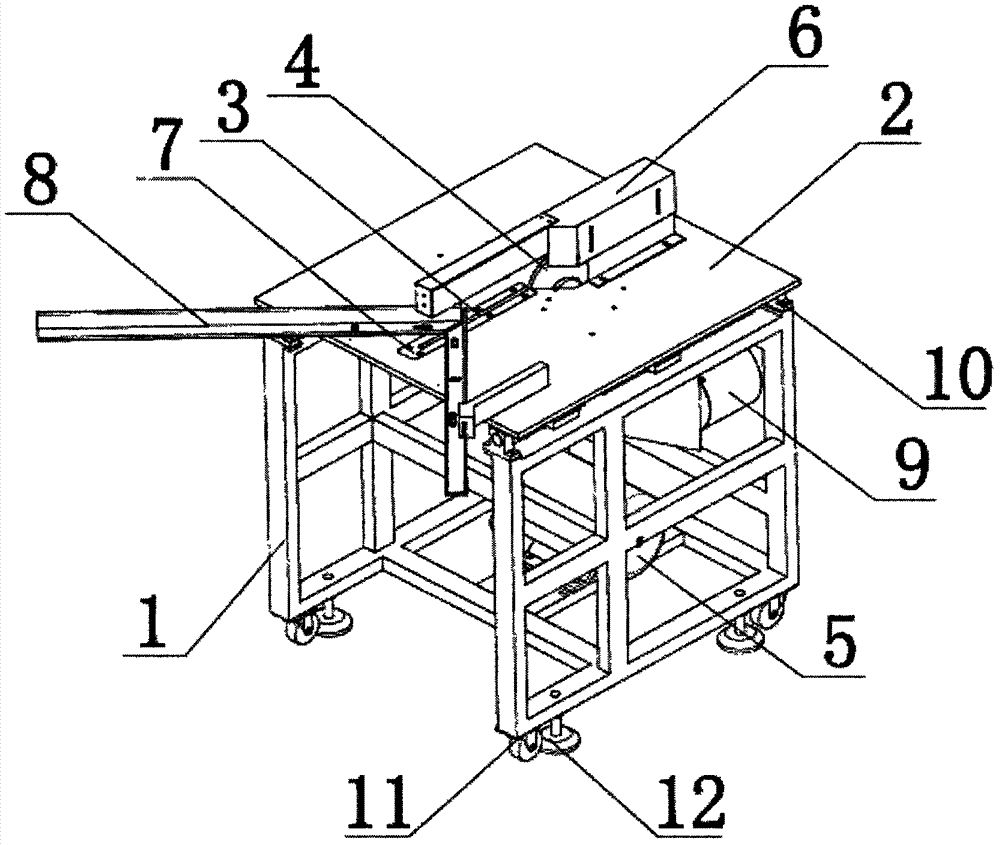

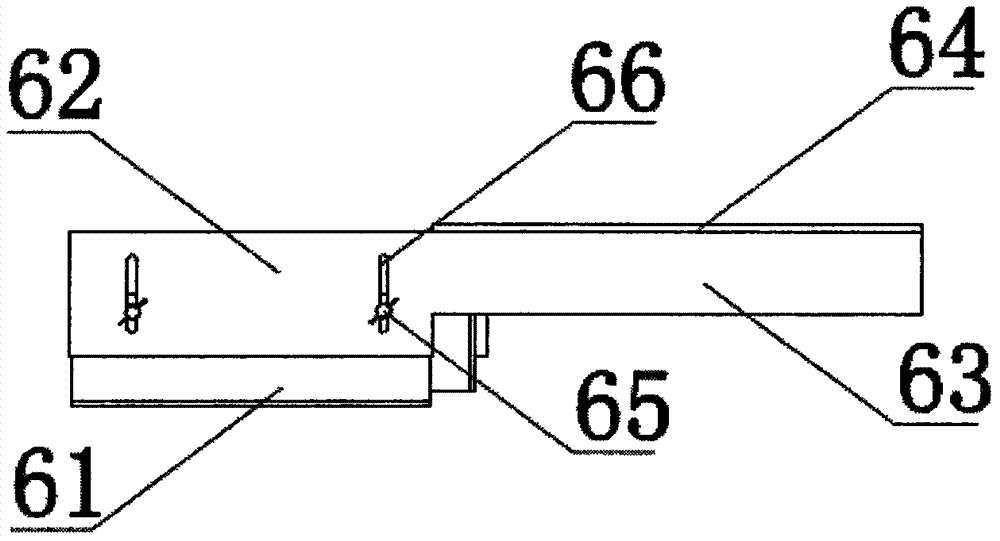

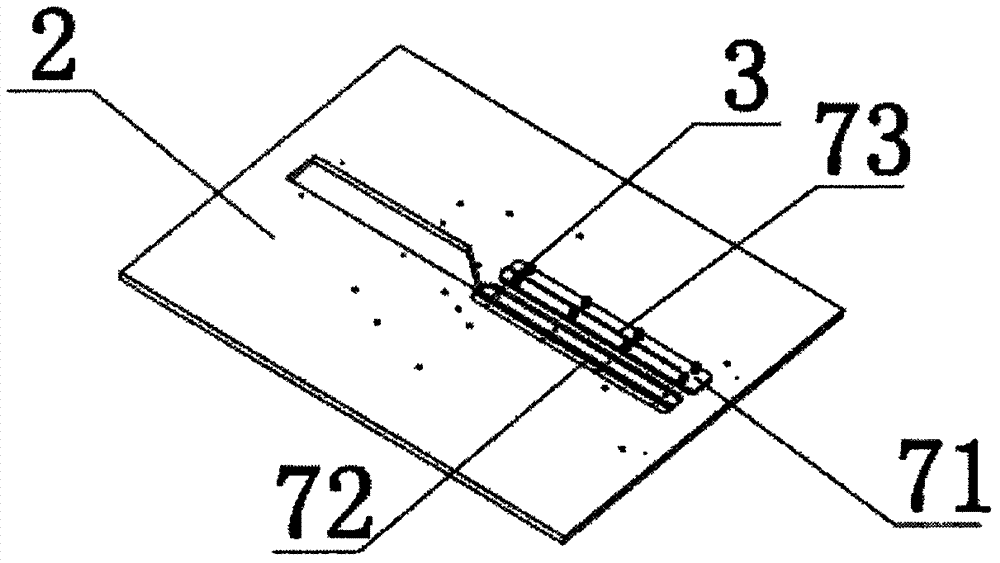

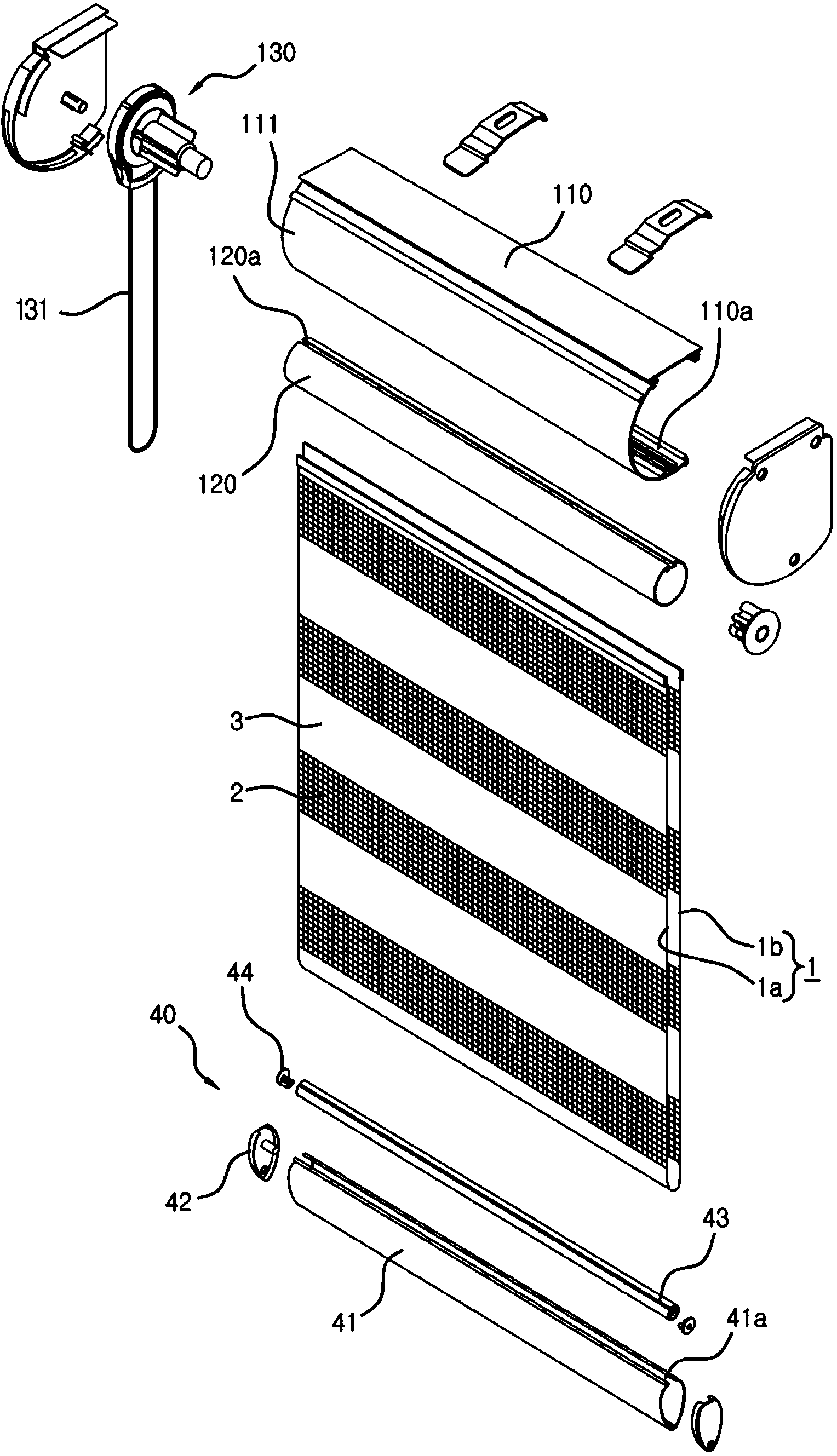

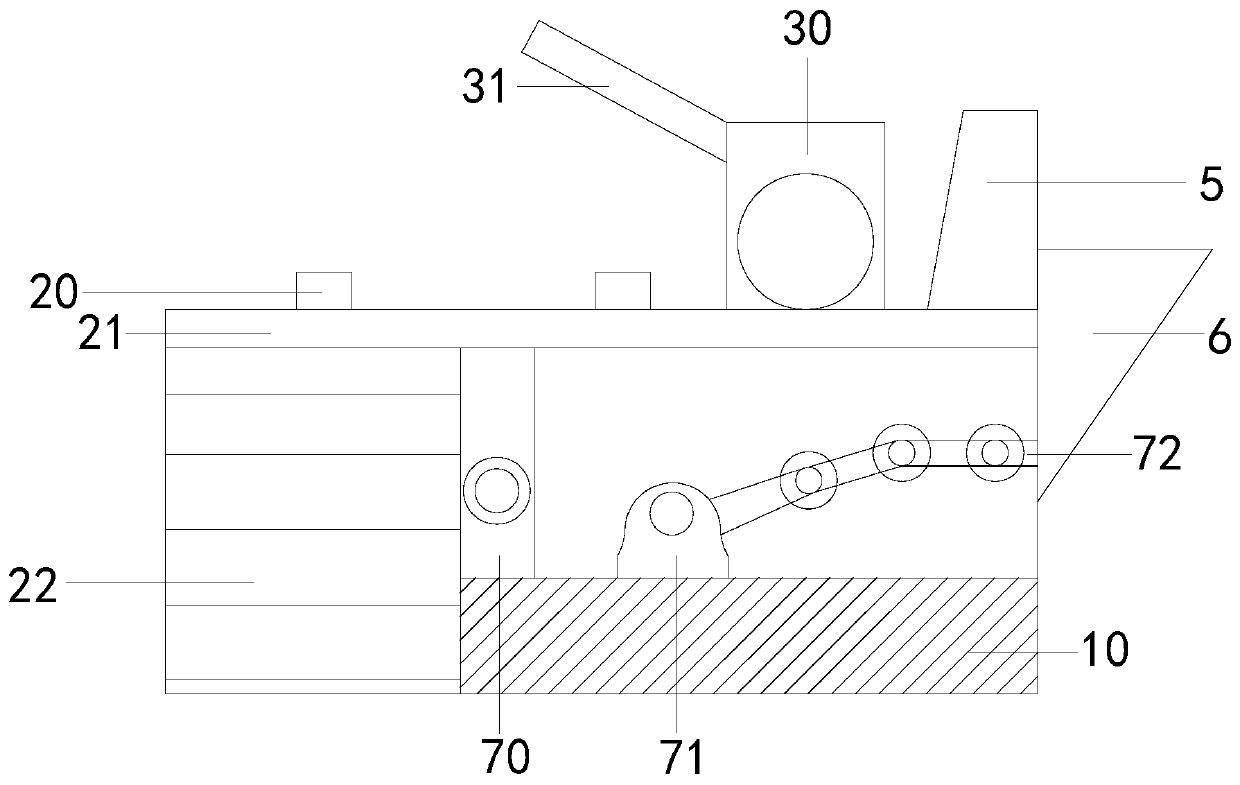

Rapid high-precision distribution device with breaking device

PendingCN108557289AControl precisionControl the output speedLarge containersConveyor partsSolid particleEngineering

The invention discloses a rapid high-precision distribution device. The rapid high-precision distribution device comprises a belt-type conveying device, a material cabin, a material blocking device, aweighing hopper, and a control system. The material cabin is cooperatively installed above a conveying belt, and the bottom thereof is slightly higher than the conveying belt. The material cabin is used for storing a material, and comprises a material cabin body and a cabin door. The material blocking device is cooperatively and fixedly installed with the conveying belt, positioned above the conveying belt, and perpendicular to the conveying belt. The material cabin is positioned behind a moving direction of the conveying belt. The weighing hopper is cooperatively installed below the tail endof the conveying belt. The control system is used for receiving data of the weighing hopper, calculating, and controlling the work of the belt-type conveying device, the cabin door and the material blocking device. The device is capable of realizing rapid-speed feeding, intermediate-speed feeding, slow-speed feeding, and accurate feeding; high in feeding precision, rapid in speed, and suitable for solid particles, powder, and an adhesion mixture; and small in repetitive control precision deviation without a loose material.

Owner:郑州鼎源自动化科技有限公司

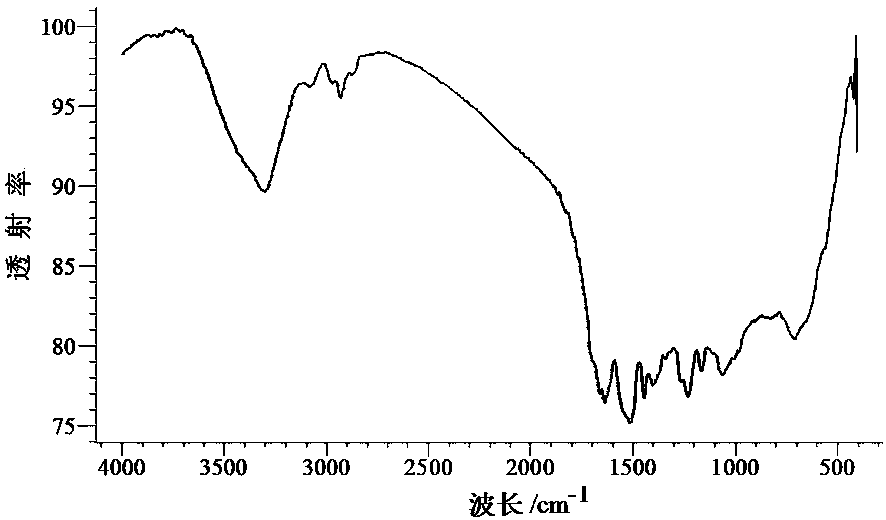

Wormwood antibacterial yarn processing method

InactiveCN110938883AIncrease contentImprove stabilityArtificial thread manufacturing machinesArtificial filaments from viscoseYarnSpinning

The invention discloses a wormwood antibacterial yarn processing method. The processing method comprises the following steps of preparing a wormwood antibacterial dispersion liquid, then preparing a slurry, then preparing a spinning viscose glue, next, preparing wormwood antibacterial fibers, and finally carrying out sizing to obtain a finished product. The processing method not only can improve the stability of the sterilization effect, but also has the advantages of low production cost, high sterilization effect, convenience in production and high toughness.

Owner:ZHEJIANG HUINONGSI KNITTING UNDERWEAR

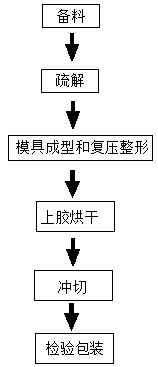

High-fidelity loudspeaker cone and production process thereof

PendingCN110080034AHigh elastic rateGuaranteed StrengthElectrical transducersWater-repelling agents additionMaterials preparationGlass fiber

The invention discloses a high-fidelity loudspeaker cone and a production process thereof. The cone comprises components in parts by weight as follows: 30-45 parts of sisal pulp, 10-25 parts of flax pulp, 5-15 parts of fluff pulp and 0.5-2 parts of carbon fiber powder. The cone production process comprises following steps: S1), material preparation: the sisal pulp, flax pulp and fluff pulp are taken out in the weight ratio, lumps and impurities are removed, dust cleaning treatment is performed, and soaking is respectively performed for 30-50 min. According to the high-fidelity loudspeaker coneand the production process cone thereof, mixed pulp of the sisal pulp, flax pulp and fluff pulp is used as a main material of the cone to provide rigidity and toughness of the cone, so that the elasticity of the cone is improved; the carbon fiber, bulletproof fiber and glass fiber are used as compound ingredients to ensure the strength of the cone, so that the stability of the paper cone is improved; the edge of the cone is soaked with glue, solder alloy is used for attaching to avoid flaking, the elasticity and fatigue resistance of cone are improved, and the tone of a loudspeaker is better.

Owner:广州市建桥音响配件有限公司

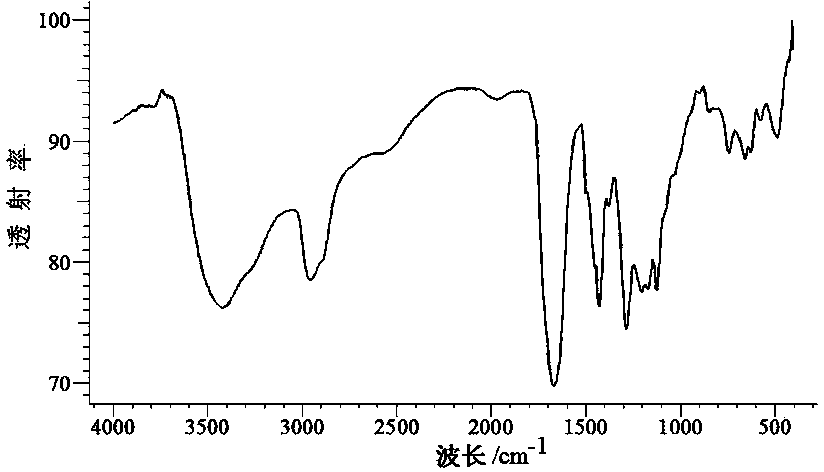

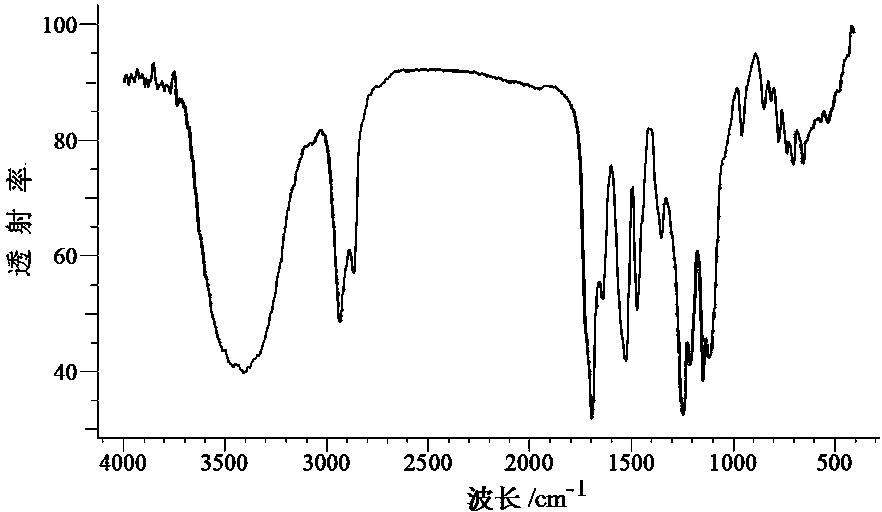

Method for preparing functional protein fiber

The invention discloses a method for preparing functional protein fiber. The method comprises the following steps: firstly, dipping the fiber into a finishing solution; then dewatering and drying the dipped fiber; finally baking or microwave-processing the dried fiber to obtain the functional fiber, wherein the finishing solution is prepared from the following four ingredients in percentage by weight: 5-15 percent of preshrinking aqueous solution, 5-20 percent of vinyl monomer, 0.15-1.6 percent of initiator and the rest of water. The functional protein fiber prepared by the method has a good soil release performance and good washing fastness and the hand feeling of subsequent fabrics is not influenced. The processing method has low production cost and stronger operability and is suitable for industrial application.

Owner:常州喜莱维纺织科技有限公司

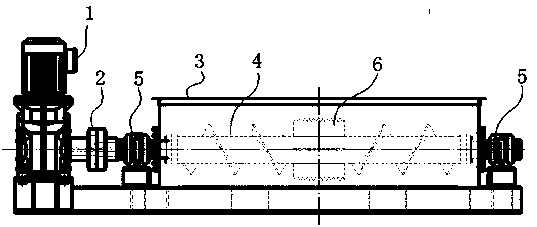

Drier screw conveying device for biomass power generation

The invention discloses a drier screw conveying device for biomass power generation. The drier screw conveying device comprises a drive device, a coupler, a shell, a screw body and bearing pedestals. The screw body is arranged in the shell, and the bearing pedestals are connected to the two ends of the screw body; the coupler is connected with the bearing pedestals and driven by the drive device. The drier screw conveying device for biomass power generation has the advantages that the phenomenon of material fluffing in the feeding process can be effectively prevented through even rotation of shifting plates; rotation of the shifting plates enables the materials to be spread evenly, so the phenomenon of uneven material feeding is avoided; the drier screw conveying device for biomass power generation has good practicality and is capable of bringing excellent economic benefits and social effects.

Owner:ZHAOYANG PNEUAMTIC HYDRAULIC MECHANICAL EQUIP JIANGSU

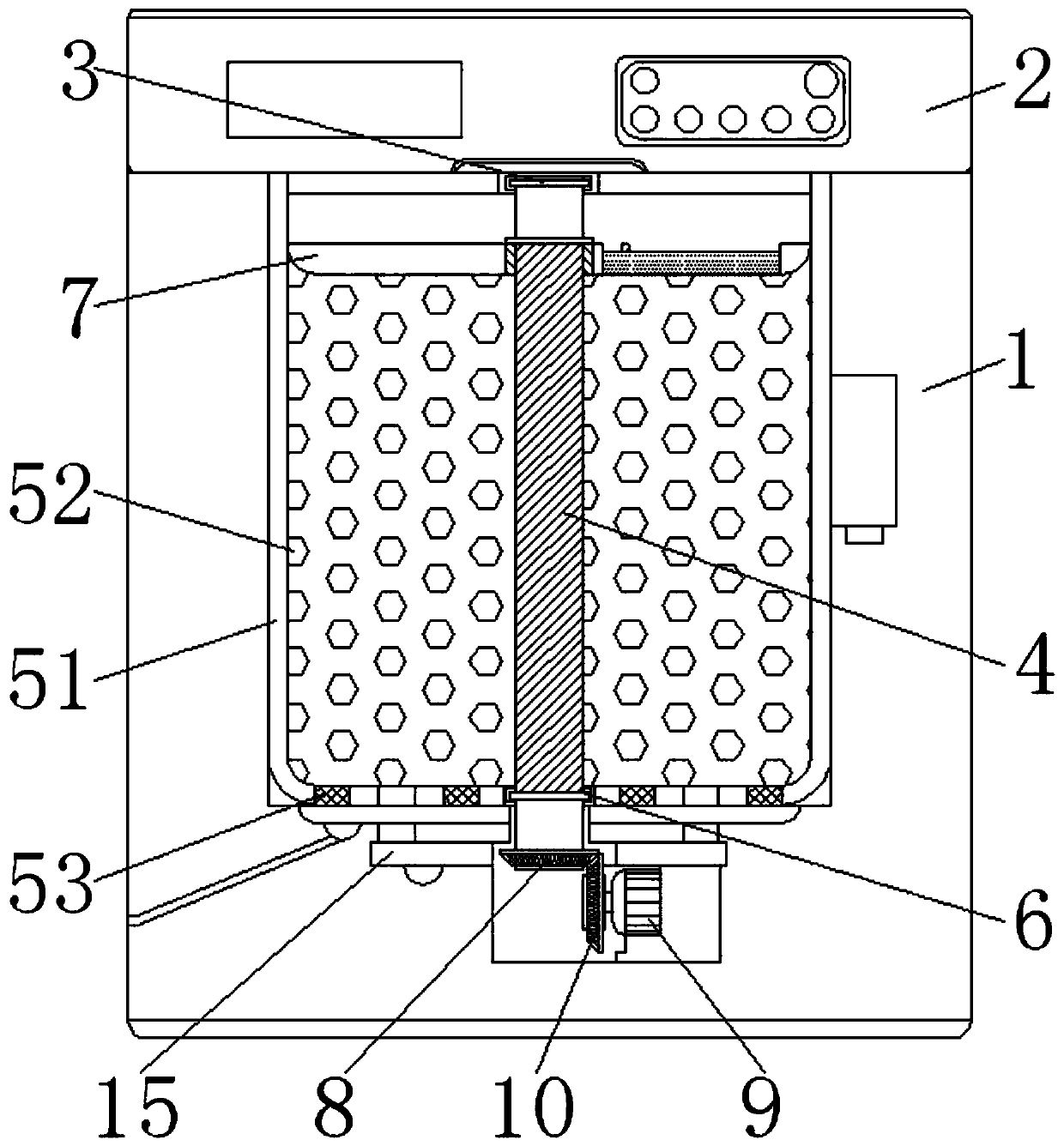

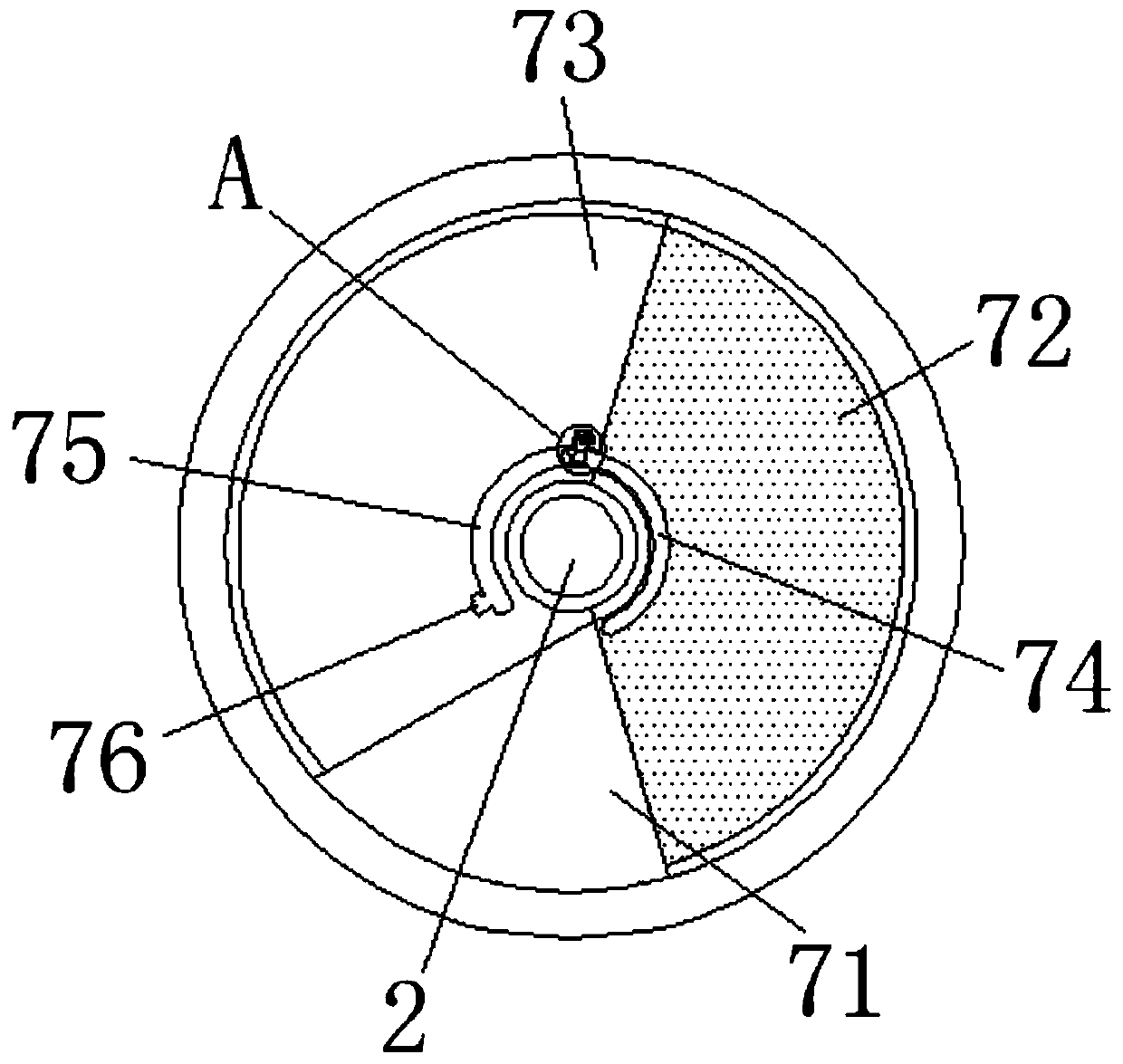

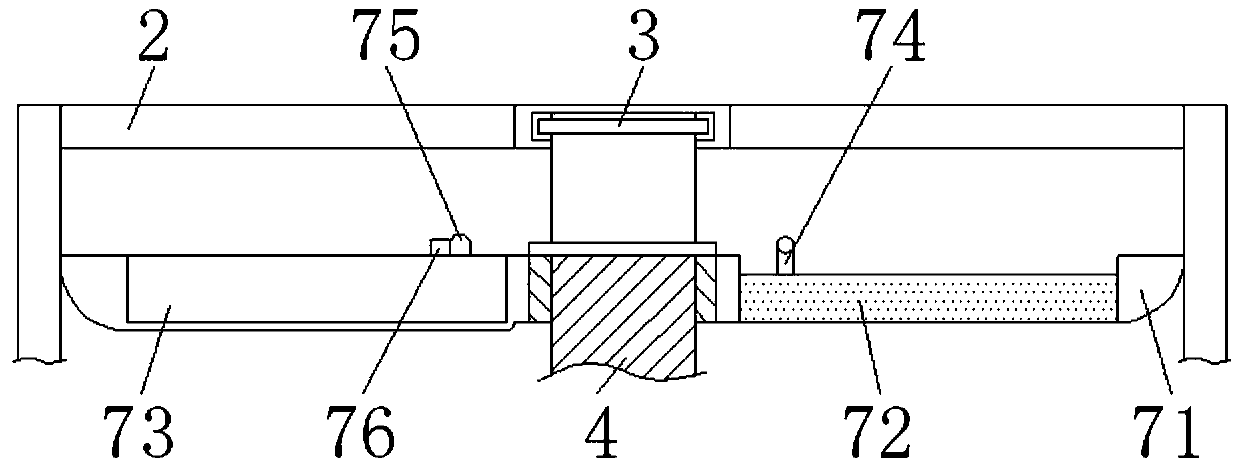

Textile cleaning equipment

InactiveCN110924009AEasy to dryMaintain overall shapeLiquid/gas/vapor removal by squeezingWoven fabricManufacturing engineering

The invention relates to the technical field of cleaning of textiles, and discloses textile cleaning equipment. The textile cleaning equipment comprises a body; a protective cover is movably sleeved at the top of the body; a cleaning mechanism is movably sleeved at the bottom of the inner cavity of the body; a driving device is fixedly installed inside the body; the top end of the driving device penetrates through the body and extends to the bottom of the inner cavity of the body; the bottom end of the driving device is in contact with the bottom of the cleaning mechanism; and a spacing ring is movably sleeved at the top of the body. According to the textile cleaning equipment provided by the invention, through the cooperation between a threaded rod, a smoothing mechanism, a driven bevel gear, a servo motor and a drive bevel gear, the filtering of cleaned textiles is facilitated; because the smoothing mechanism is pressed down slowly, the phenomenon that the textiles are knotted due tothe centrifugal force is avoided, even the phenomenon of surfaces fluffing of textile fabrics is avoided, thus a worker is facilitated to take out the cleaned textiles, the cleaned textiles are conveniently aired, the integral shape of clothes is kept, and the clothes are not easy to deform.

Owner:桐乡市衣涟皮草有限公司

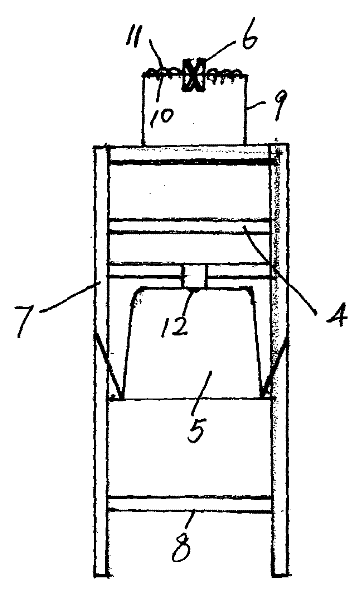

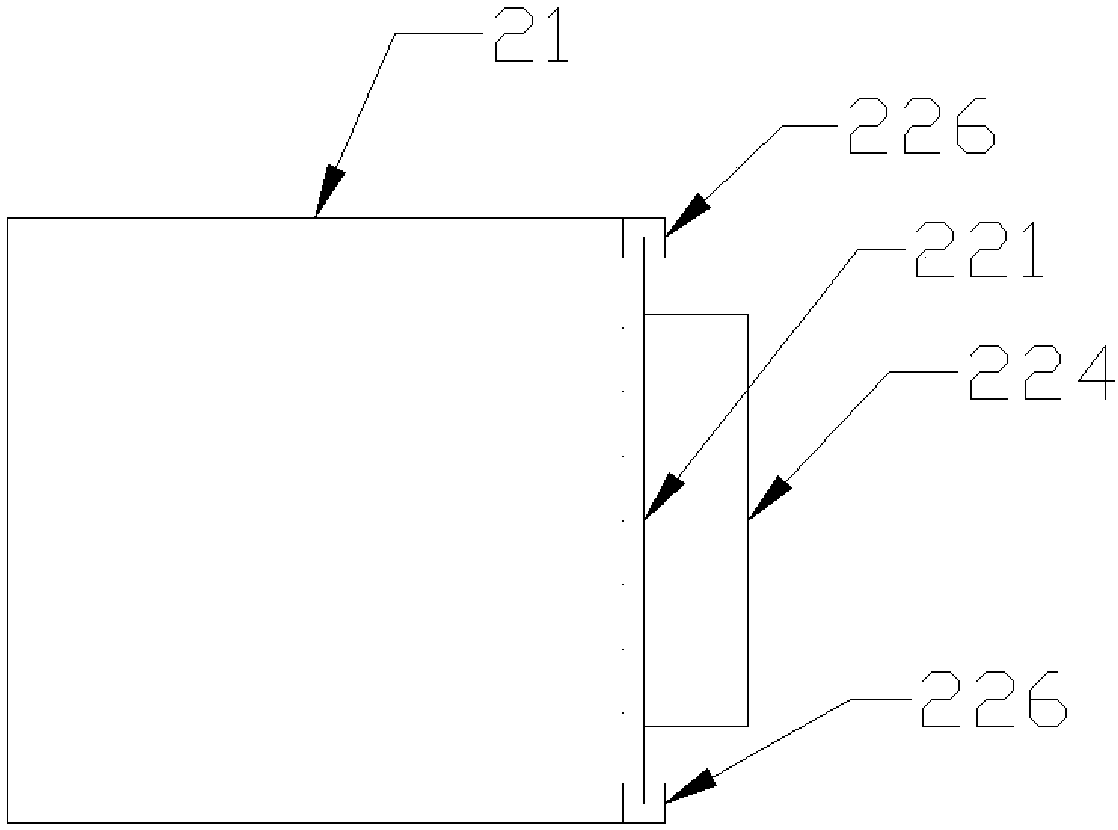

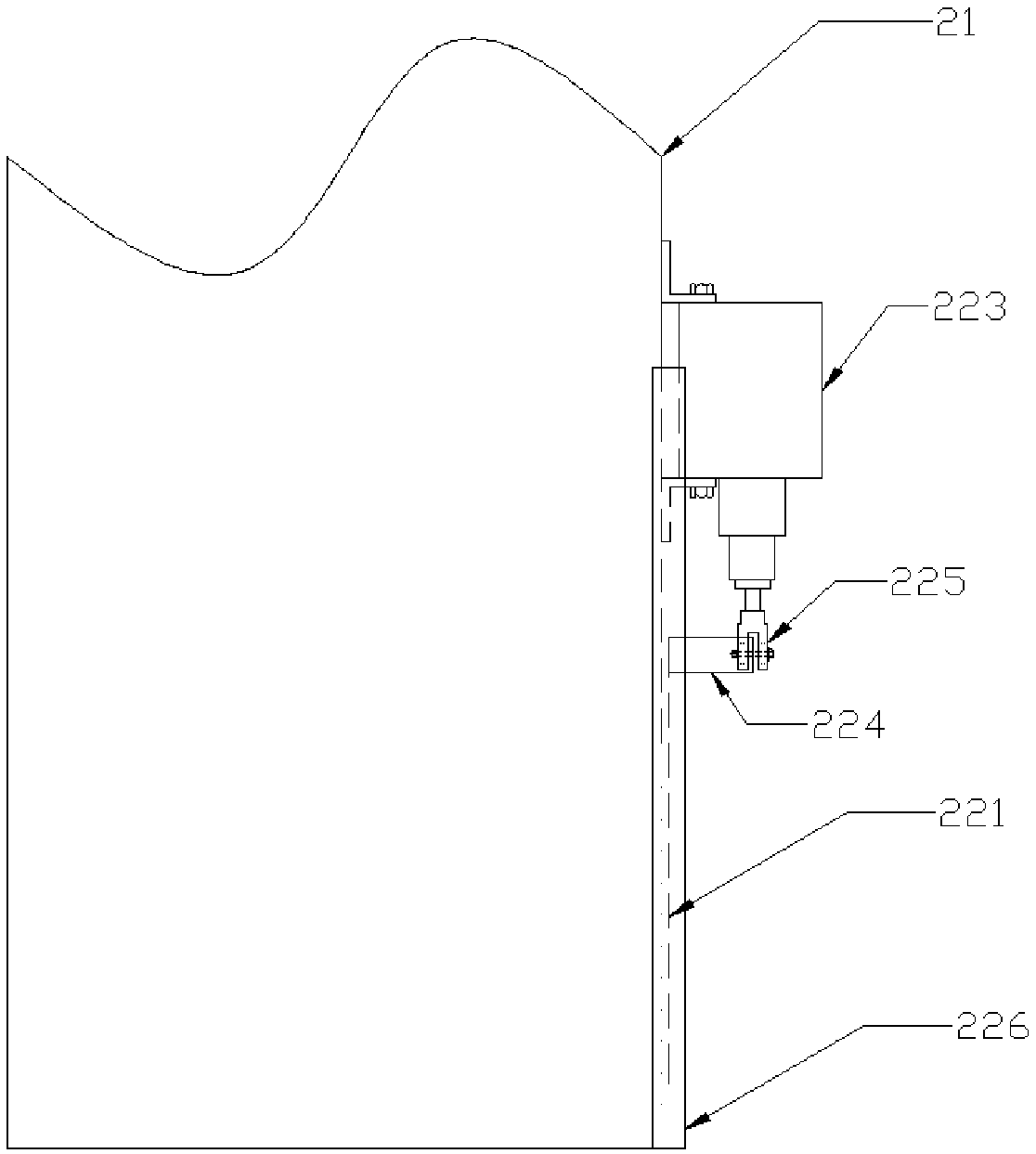

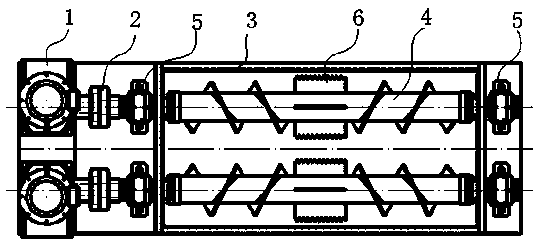

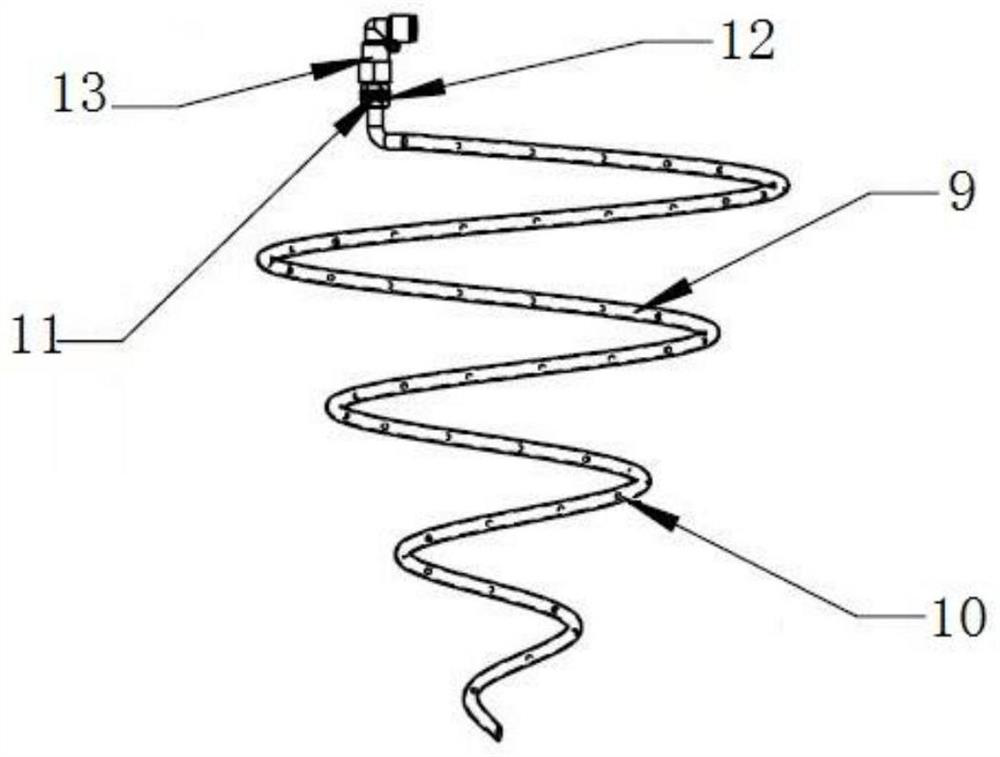

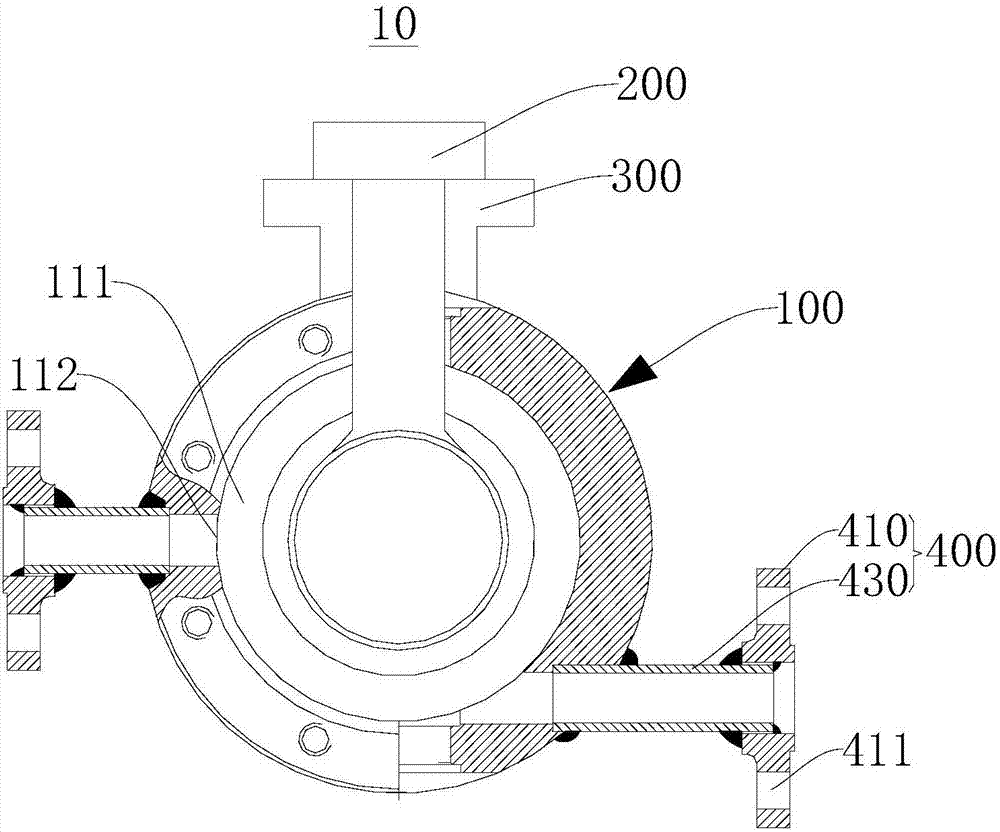

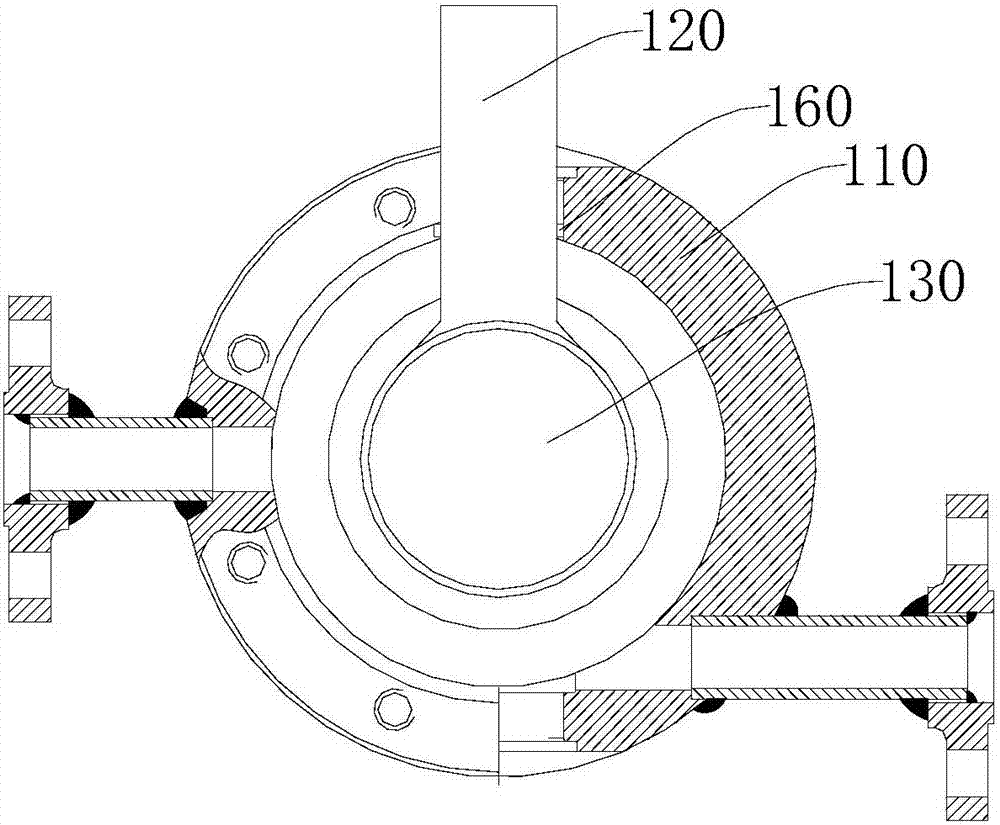

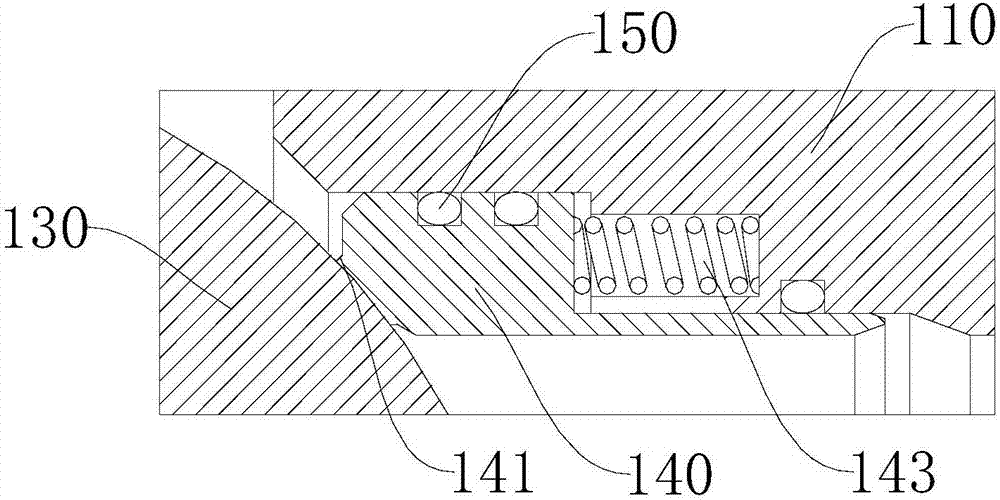

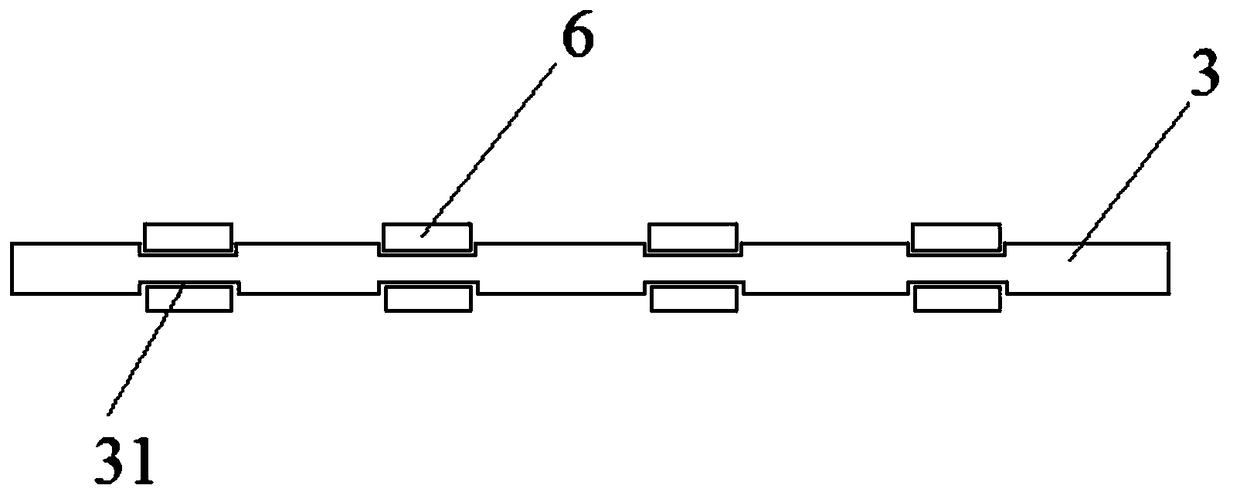

Intermittent automatic feeding material bin with material fluffing prevention function

InactiveCN113619941AAvoid fluffingContinuous and stable feedingLarge containersProcess engineeringCaking

The invention discloses an intermittent automatic feeding material bin with a material fluffing prevention function. The intermittent automatic feeding material bin comprises a material bin body, a material bin cover, a feeding port and a discharging port, an air blowing pipeline is arranged in the material bin body, the air blowing pipeline is installed on the material bin cover in a suspended manner, a front end port of the air blowing pipeline is connected with an external air source through an air inlet pipeline, an electromagnetic valve is installed on the air inlet pipeline, a lower end port of the air blowing pipeline is closed, meanwhile, air outlet holes are distributed in the air blowing pipeline, and a breathing port used for exhausting air is further formed in the material bin cover. According to the intermittent automatic feeding material bin, compressed air is introduced from the upper portion of the air blowing pipeline, compressed and caked powder at the bottom of the feeding material bin is blown away under the action of wind force generated when the compressed air is blown out through the air outlet holes, the situation that the compressed and caked powder is fluffy at the bottom of the material bin is prevented, the aims of feeding materials in time and reducing material compaction and caking are achieved, the risk of material breakage is reduced, and the production efficiency is improved.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

Full-coating sweeping anti-lock abrasion resisting ball valve

PendingCN107178644AImprove seismic strengthIncreased torsional strengthPlug valvesCleaning using gasesActuatorMaterials science

The invention discloses a full-coating sweeping anti-lock abrasion resisting ball valve, and relates to the technical field of ball valve cleaning. The full-coating sweeping anti-lock abrasion resisting ball valve comprises a ball valve component, an executer, a receiving disc and two adapter flanges. A switch ball is arranged in a containing cavity and connected with a valve rod. The valve rod stretches out of the containing cavity and is connected with the executer. The executer is connected with the receiving disc. The receiving disc is arranged on a valve body and connected with the valve body through a mortise assembly. Two sweeping holes communicate with the containing cavity. Compared with ball valves in the prior art, according to the provided full-coating sweeping anti-lock abrasion resisting ball valve, due to the adoption of the mortise assembly connected between the receiving disc and the valve body and the valve body communicating with the adapter flanges through the sweeping holes, the situation that in the frequent valve rod opening and closing process, components are shaken loosely can be avoided; and deposited materials in the containing cavity can be cleaned, the switch ball is prevented from being locked, practicability is high, and cost performance is high.

Owner:SICHUAN SUKE FLUID CONTROL EQUIP CO LTD

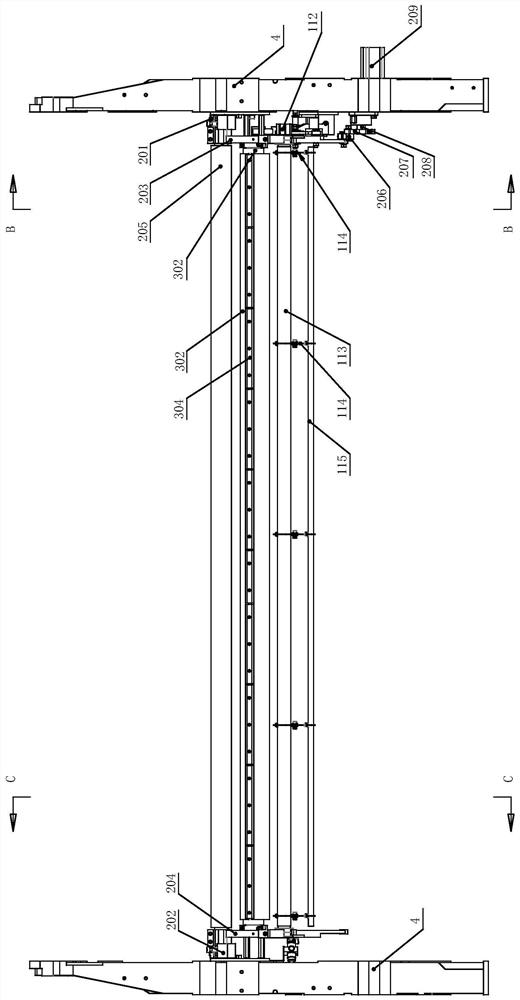

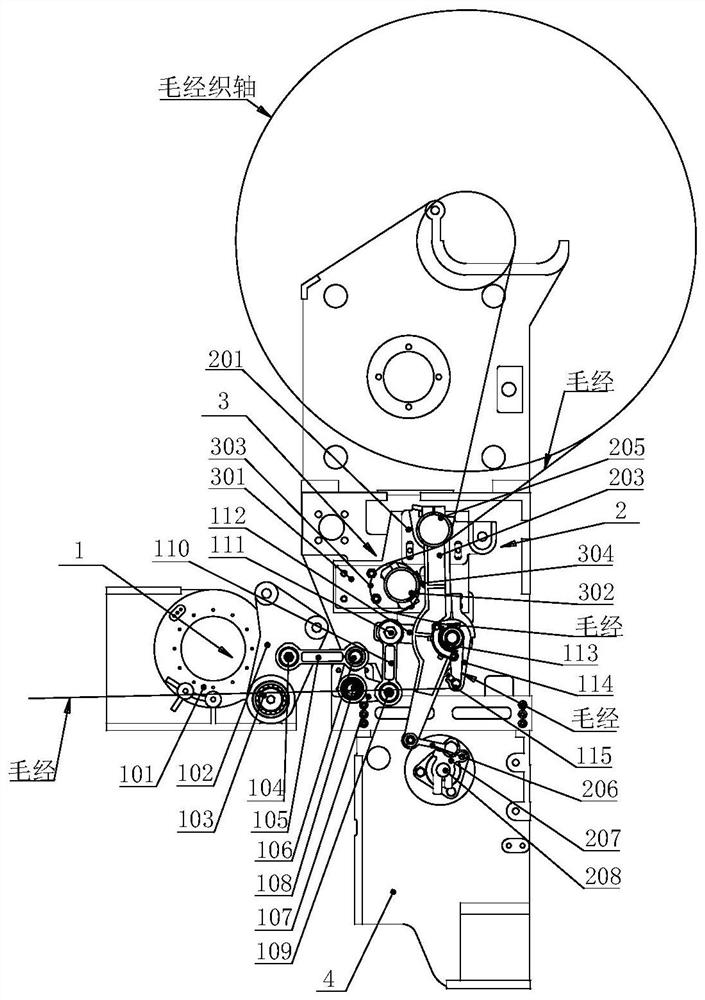

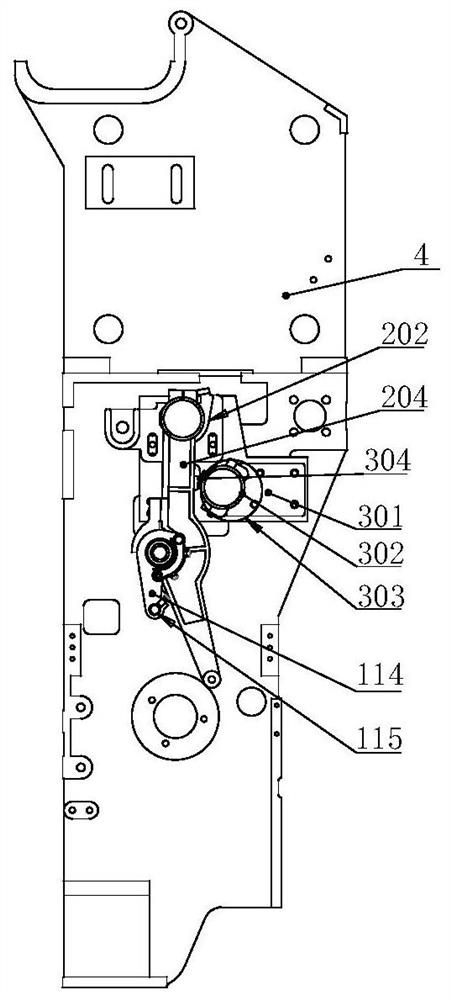

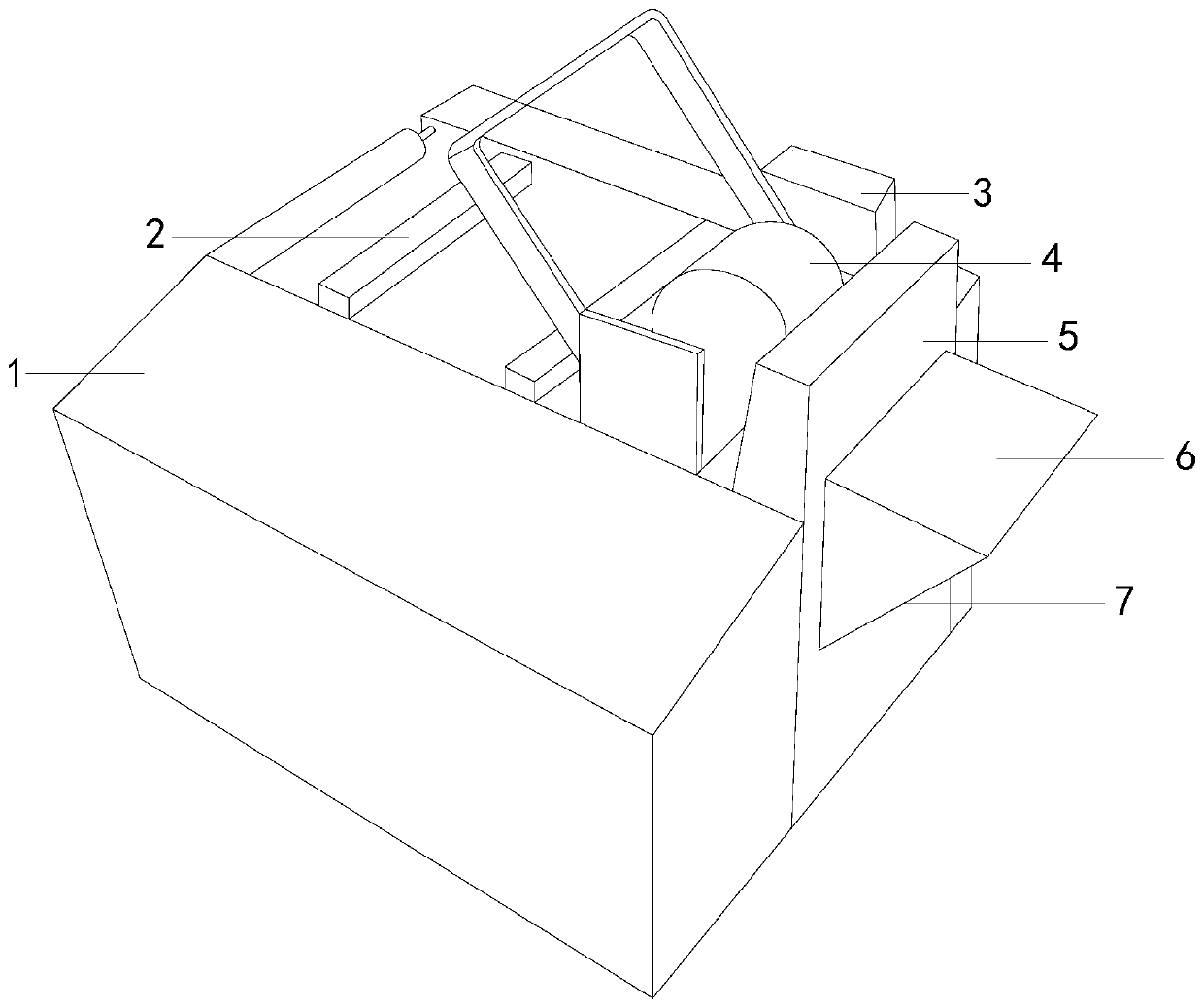

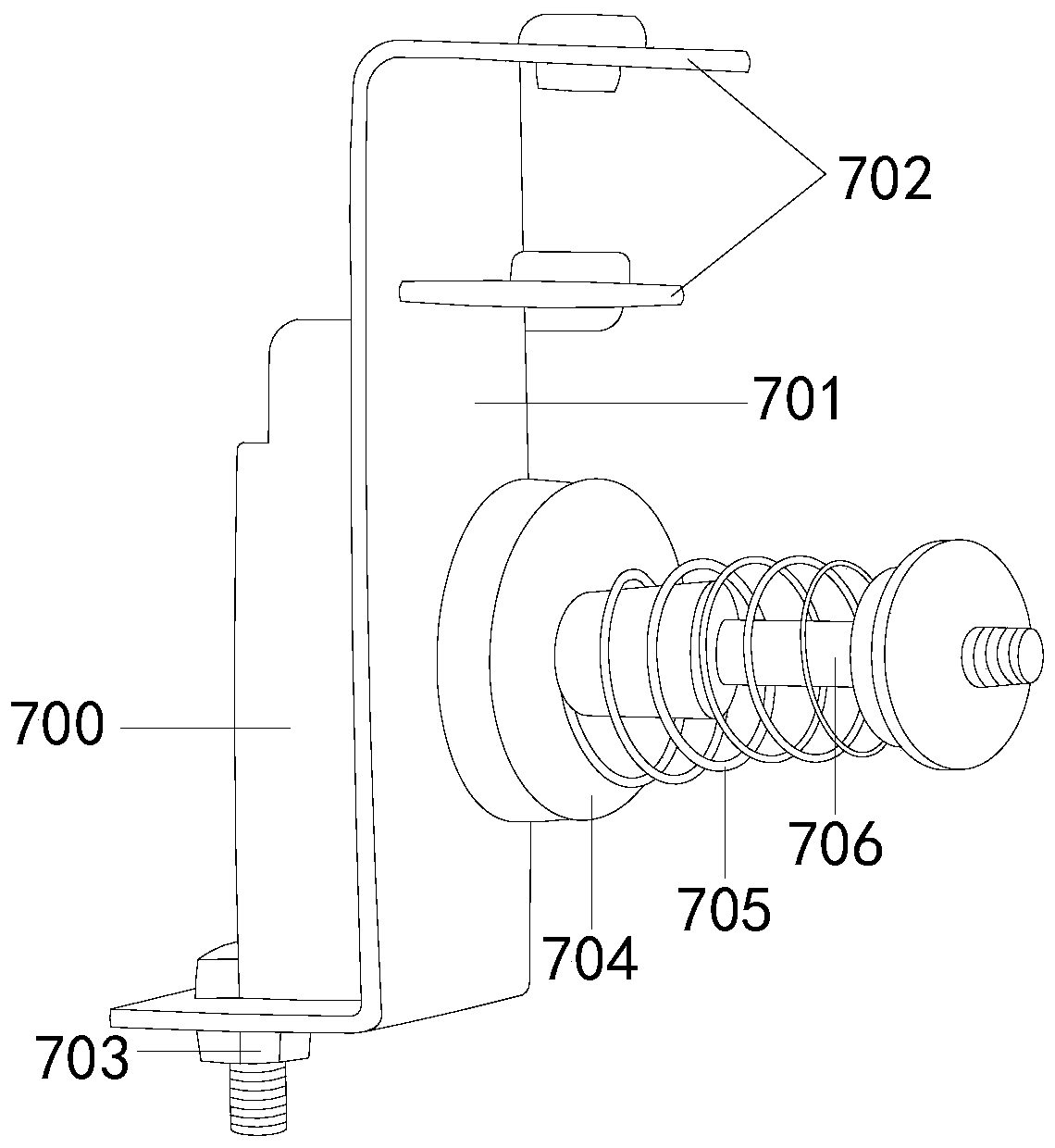

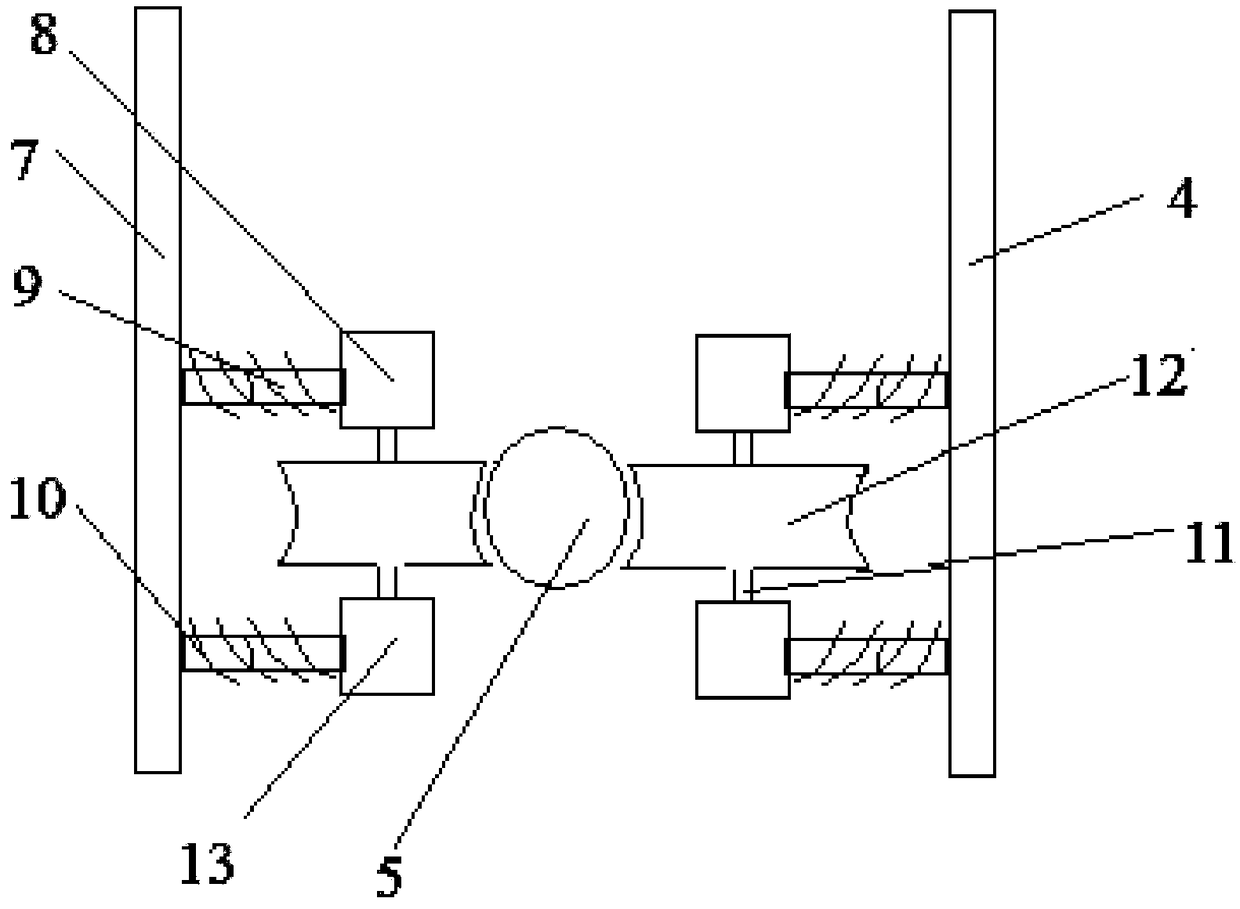

Positive control type wool warp tension system

The invention discloses a positive control type wool warp tension system. The system comprises two wall boards, a distribution positive following device, a wool warp tension active control device anda wool warp tension buffer device, wherein the wool warp tension active control device comprises a supporting swing shaft, tension rocker arms and a rocker arm driving mechanism, the supporting swingshaft is arranged between the two wall boards, the two tension rocker arms are symmetrically arranged at the two ends of the supporting swing shaft left and right, the rocker arm driving mechanism isconnected with the lower end of the left tension rocker arm, the distribution active following device comprises a tension adjusting mechanism and a connecting rod transmission mechanism, the tension adjusting mechanism is arranged on the two tension rocker arms and comprises a tension swing shaft and a swing rod, one end of the connecting rod transmission mechanism is arranged on the left side wall board through a fuzzing support, and the other end is fixedly connected with the corresponding end of the tension swing shaft. According to the system, active control over the wool warp tension is more accurate, the requirements for the wool warp tension in various states are met, the tension is stable in the weaving process, coordination is better, and high-quality and high-speed towel weavingis achieved.

Owner:青岛天一红旗特种织机科技有限公司

Automatic woven tape processing device

The invention discloses an automatic woven tape processing device. The device structurally comprises a main device body, a conveying roller, a gripper, a motor, a radiator, a hopper protection board and a weft grinding and cutting mechanism. The device has the advantages that the weft grinding and cutting mechanism is searched and developed, a conventional steel wire end cutting mode is changed into an alloy cutting piece cutting mode, compared with steel wire ends, the cutting surfaces of cutting pieces are smoother, there are no burrs on the cross sections, and the situation that fibers on the surface of a woven tape are carried upwards to cause a fluffing phenomenon cannot occur at the cut-off moment; through shaping and bundling of a weft rectifier, the disordered weft process is unified and standardized; moreover, in order to effectively solve the problem of the weft fluffing phenomenon caused by the loss of the cutting pieces after long-time work, the weft grinding and cutting mechanism is provided with a weft cutter, the running kinetic energy of the device can be utilized for grinding and cutting the cutting pieces, the deterioration parts and cracks on the cutting pieces disappear, and the weft fluffing phenomenon of the woven tape due to the loss of the cutting pieces is avoided.

Owner:张美容

Method for producing tiny soldered balls with repeatedly-usable substrates

InactiveCN101246828BNarrow particle size distributionPrevent surface oxidationSolid-state devicesSemiconductor/solid-state device manufacturingResistSputtering

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Cotton blended spinning elastic knitted underwear face fabric and processing technique thereof

The invention relates to a processing technique for elastic knitted underwear fabric of blended cotton fiber and viscose fiber, which is characterized in that ring spinning with cotton fiber and superfine viscose fiber to obtain 40S combed blended cotton-viscose yarn, yarn steaming, knitting the blended cotton-viscose yarn and elastic polyurethane fiber in a single-sided large circular weaving machine to obtain the underwear fabric, and final polishing to eliminate hairs biologically with enzyme. The elastic knitted underwear fabric has improved fluffing and balling up performance, smooth surface, fully handling and high wearability.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

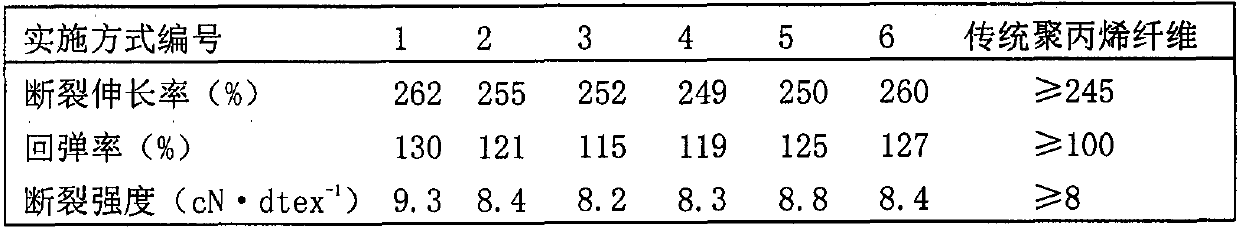

Method for preparing high-strength polypropylene fibers

PendingCN110747519AIncrease temperatureGuaranteed StrengthSpinning head liquid feederGrip property fibresBreaking strengthPolymer science

The invention discloses a method for preparing high-strength polypropylene fibers, which comprises the steps of adding polypropylene pellets into a hopper of a spinning machine, and extruding througha spinneret at 230 DEG C, with a water tank having a length of 1.2 m and a water temperature of 70 DEG C and being 8 cm right below the spinneret; subjecting a melt stream sprayed from the spinneret to first-step water cooling in the water tank before second-step annular air cooling at the temperature of 30 DEG C; applying a softening agent to the polypropylene fibers subjected to two-step cooling, winding the obtained fibers on a first roller five times which has the roller temperature of 65 DEG C and the rotating speed of 180 m / min, and winding on a second roller eight times which has the roller temperature of 85 DEG C and the rotating speed of 800 m / min to obtain the polypropylene fibers. The method has the advantages that the elongation at break of the polypropylene fibers can be increased to greater than 249%, the resilience is greater than 115%, the breaking strength is greater than 8.2 cN.dtex<-1>, and the method is suitable for manufacturing high-strength polypropylene fibers.

Owner:QIQIHAR UNIVERSITY

Method for making antistatic laminated support pad for protecting LCD panel

ActiveCN104589769BReduce pollutionReduce incidenceSynthetic resin layered productsLaminationForeign matterGeneration rate

The invention relates to a making method of an anti-static lamination type support pad for protecting an LCD panel. According to the making method, a polyolefin film of an anti-static layer is at least formed on one surface or two surfaces of a polyolefin or polyurethane foam sheet by virtue of lamination. The lamination type support pad made by using the making method can be used as a panel lamination type support pad which is used for preventing the surface from being scraped, polluted and impacted and is especially sensitive to static electricity when a liquid crystal display panel is stored and conveyed, and can be used for effectively preventing the edge of the lamination type support pad from fluffing, further effectively reducing the dust generation rate and preventing foreign matters from permeating between the lamination type support pads.

Owner:纳诺化学技术株式会社 +2

Liquid-permeable nonwoven fibrous fabric

ActiveCN102482817BThrough highAvoid fluffingLayered productsAbsorbent padsEngineeringNonwoven fabric

Owner:UNI CHARM CORP

Needle cylinder mechanism of two-sided terry circular knitting machine

The invention discloses a needle cylinder mechanism of a double-side terry circular knitting machine. The upper end of a front space part section in a needle cylinder sinker slot is provided with a relative high and thin projection part, a higher flange is arranged at the rear end upper edge of the projection part, and the bottom of the projection part is an inclined plane extending downwards andforwards; the slot width of a narrower sinker slot at the lower end of the needle cylinder can only accommodate access of the sinker; the projection part at the front end upper edge of the space partis thin so as to cause the slot forming the front sinker section to have a wider upper end and a narrower lower end. The needle cylinder can help cause the terry at the face side and the back side ofknitted fabrics to have the same length, prevent broken terry yarn and fluffiness, cause cotton flock produced in the knitting operation to easily drop, and produce no stockpiling and blockage.

Owner:洪荣豪

A cable bridge that is easily pulled

InactiveCN109066507AAvoid fluffingReduce frictionElectrical apparatusCable trayPetroleum engineering

Owner:镇江苏电电气有限公司

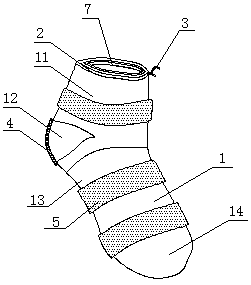

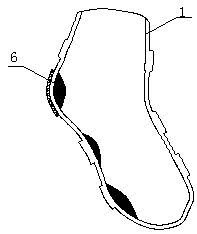

Pilling-resistant woolen sock

InactiveCN108936844AAvoid fluffingReduces the chance of fluffingPanty-hoseHosieryEngineeringSilica gel

The present invention discloses a pilling-resistant woolen sock. The pilling-resistant woolen sock comprises a sock body, wherein the sock body comprises a sock leg part, a heel part, a sole part anda forefoot part; the forefoot part is located below the sole part, the heel part is located on the upper bottom face of the sole part, the sock leg part is located above the heel part, and the middlesof the outer surfaces of the sock leg part, heel part, sole part and forefoot part are fixedly provided with silica gel rings respectively. The pilling-resistant woolen sock has the advantages that heel silica gel and the silica gel rings are arranged, so that the heel is the position where the foot applies the maximum force when a person wears the sock, the foot steps on the heel part, so that the heel silica gel tightly fits a shoe sole, therefore, the friction force between the heel silica gel and the shoe sole is larger, and the fuzziness phenomenon caused by sliding of the sock is avoided; the silica gel rings are in contact with a shoe, so that the friction between the sock body and the shoe is reduced, thereby reducing the fuzziness probability of the sock, and the silica gel ringsreduce the contact area between the sock and the shoe, thereby further reducing the fuzziness probability of the sock body.

Owner:沈建清

Die-cutting equipment for tape processing

ActiveCN111037641BAvoid fluffingImprove waste discharge efficiencyMetal working apparatusHydraulic cylinderAdhesive belt

The invention belongs to the technical field of adhesive tape processing, and particularly relates to a die cutting device for adhesive tape processing. The die cutting device comprises a bottom plate, wherein a hydraulic machine and a mounting plate are fixed at the top end of the bottom plate; the hydraulic machine comprises a workbench, a guide rod, a movable cross beam and a hydraulic cylinder; a first driving motor and a second driving motor are fixed on the side wall of the mounting plate; rotating rollers are fixed at the output shaft ends of the first driving motor and the second driving motor; the rotating rollers are used for winding an adhesive tape and a waste edge correspondingly; and more than two die cutting knives are fixed at the bottom end of the movable cross beam. According to the die cutting device, the adhesive tape is pressed through the arrangement of a pressing plate, so that the adhesive tape cannot be broken during die cutting, and the phenomenon that the cutedge of the adhesive tape is fluffed is avoided; and a limiting block is arranged to protect a product, so that the product cannot be taken up when being separated from the waste edge, and the wastedischarge efficiency of the adhesive tape is improved.

Owner:安徽灿宇光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com