Rapid high-precision distribution device with breaking device

A high-precision and fast technology, applied in the field of mechanical devices, which can solve the problems of uneven feeding flow rate, limited metering accuracy, and serious wear of spiral blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

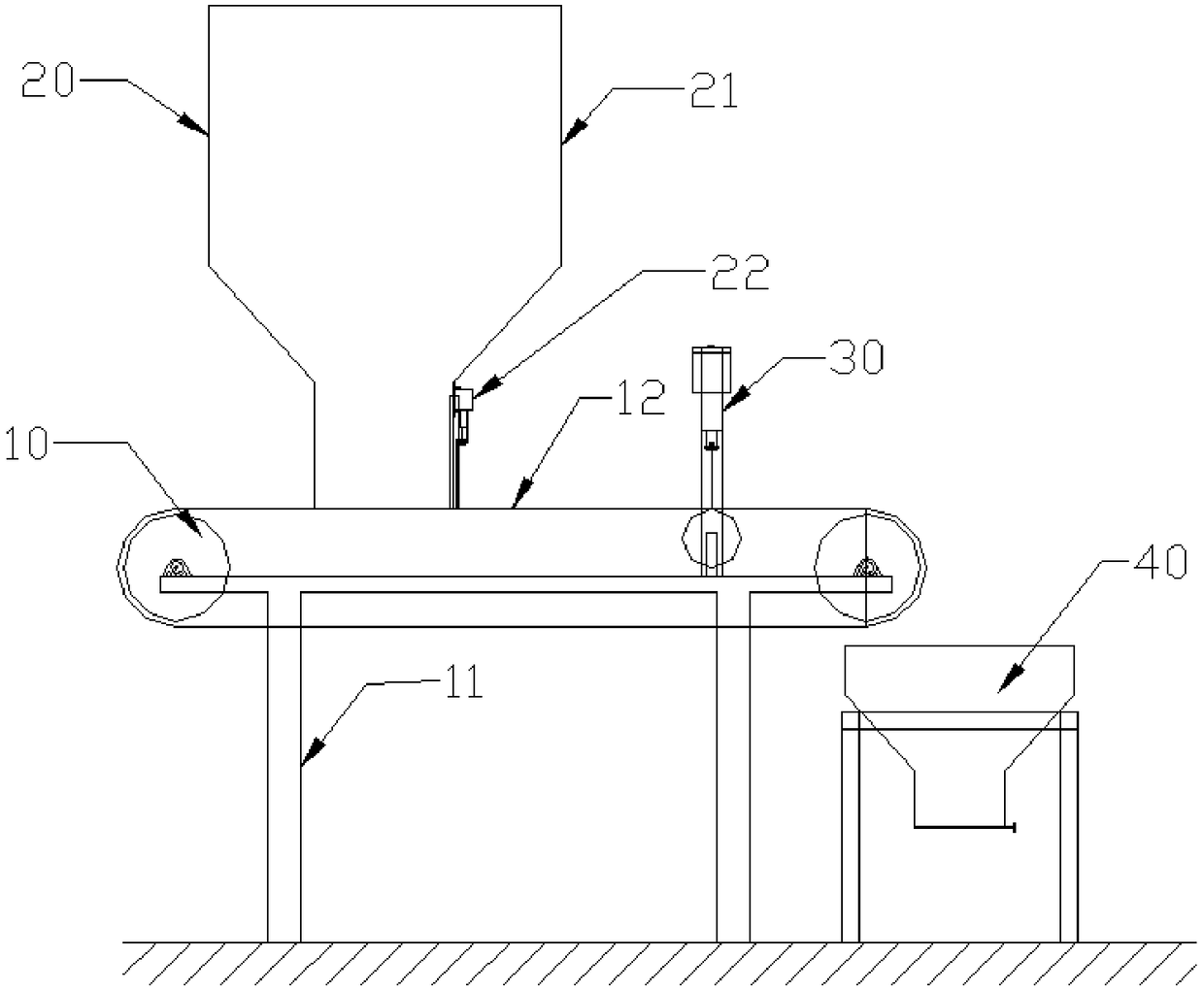

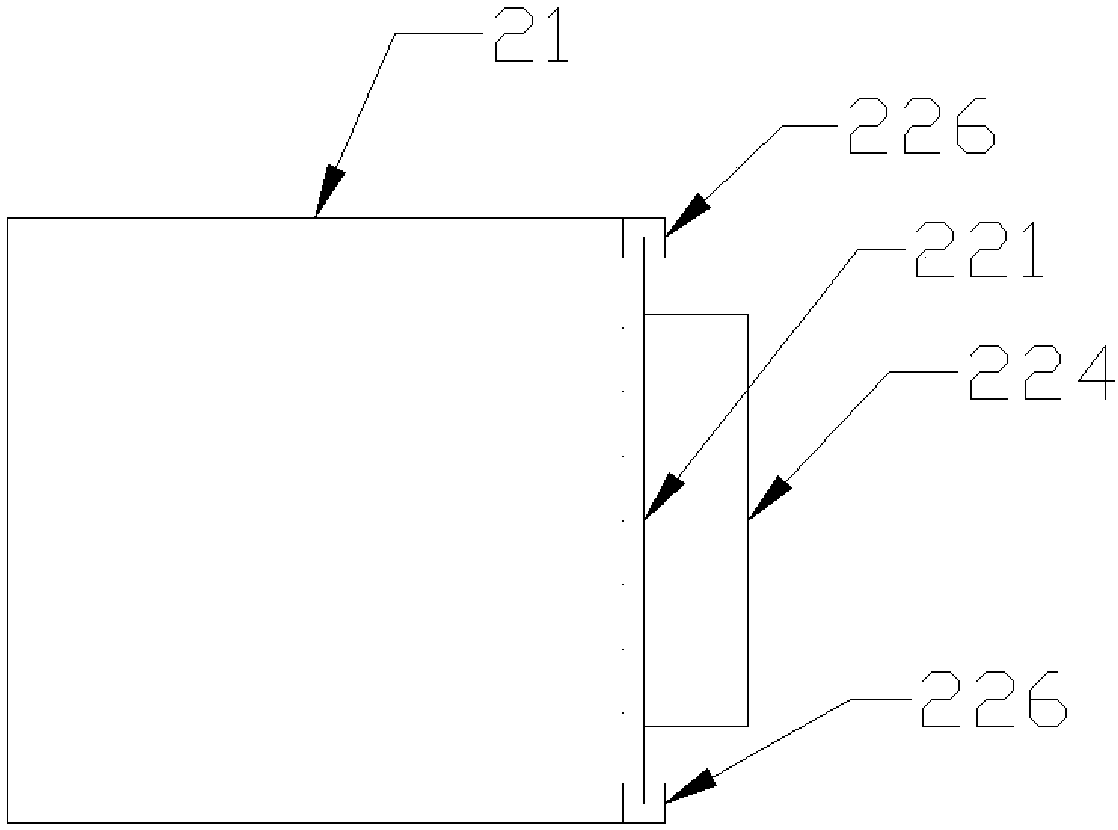

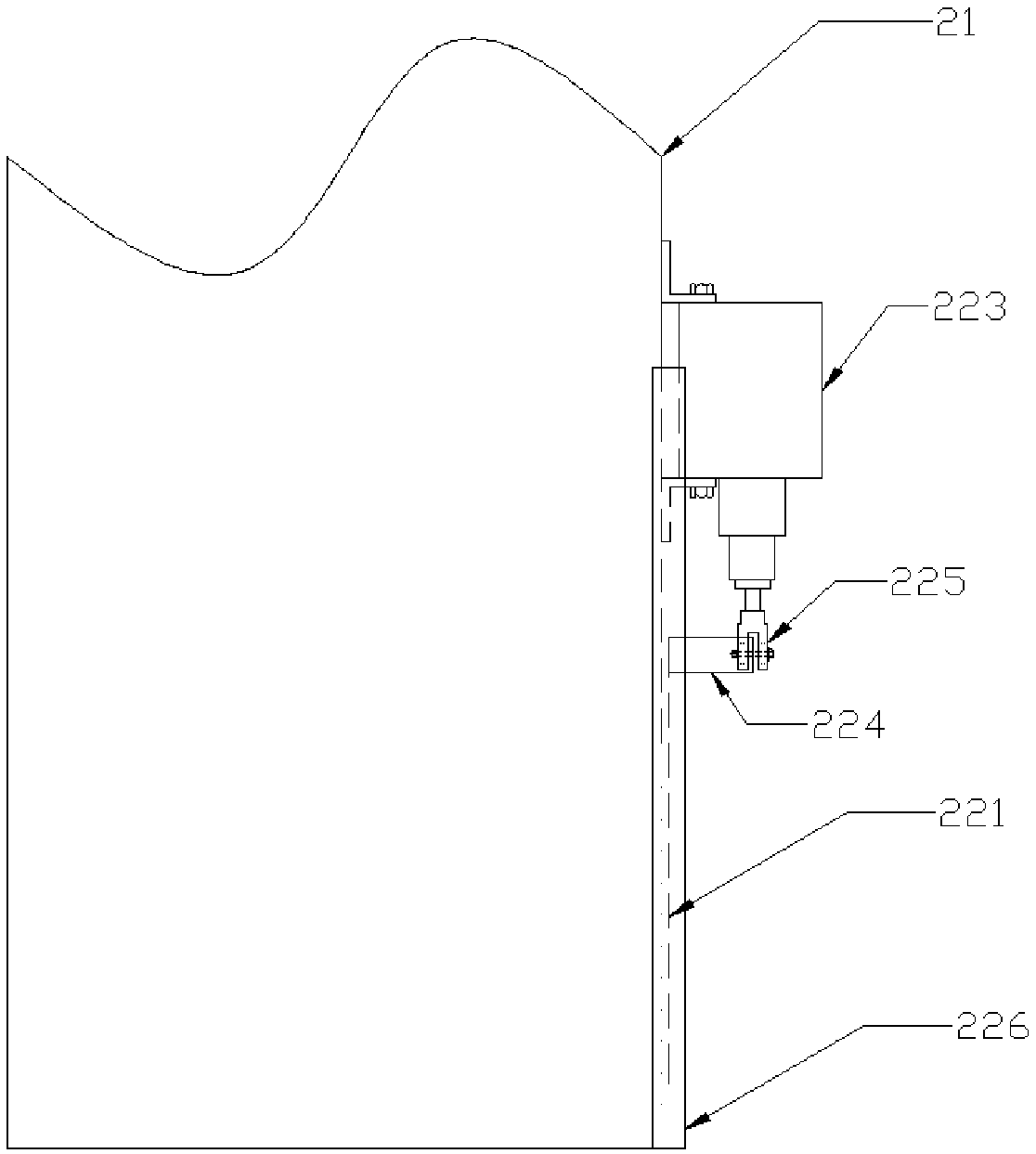

[0106] figure 1 It is a schematic structural diagram of an embodiment of a fast and high-precision batching device of the present invention.

[0107] Such as figure 1 As shown, the fast and high-precision batching device includes: a belt conveyor 10, a silo 20, a stopper 30, a weighing hopper 40, and a control system.

[0108] The belt conveyor 10 is a belt conveyor, which is installed horizontally or inclined upward or downward according to the actual application. It is used for conveying materials. It is an existing technology and includes: a conveyor bracket 11, a conveyor belt 12, a drive motor, and a speed regulation Device.

[0109] The conveying bracket 11 is used to support the conveying belt 12 and other mechanisms, and a supporting roller is installed on the conveying bracket 11.

[0110] The conveyor belt 12 is arranged horizontally or inclined upward according to actual needs; the conveyor belt 12 includes one of a rubber belt, a braided belt, a plastic belt, a nylon bel...

Embodiment example 2

[0160] The difference between this embodiment and the first embodiment is that the fast and high-precision batching device of the second embodiment further includes a cleaning device 45.

[0161] Such as Picture 10 with Picture 11 As shown, the cleaning device 45 includes: a cleaning device bracket 451 and a scraper 452; the cleaning device bracket 451 is fixedly arranged with the conveying bracket 11; the cleaning device 45 is used to scrape off the material attached to the surface of the conveyor belt 12 to clean the conveyor belt 12. The function of the surface; the cleaning device 45 is located on the socket 421, and the scraped material falls into the socket 421 to prevent the material from falling out.

[0162] The scraper 452 is fixedly arranged in cooperation with the cleaning device bracket 451; 452 is preferably fixedly connected by bolts.

[0163] The end of the scraper 452 in contact with the conveyor belt 12 is the scraping part; the scraping part is in contact with th...

Embodiment example 3

[0169] Picture 12 It is a schematic structural diagram of another embodiment of a fast and high-precision batching device of the present invention.

[0170] Figure 13 Yes Picture 12 The schematic perspective view of the breaker device of the illustrated embodiment.

[0171] The difference between this embodiment and the first embodiment or the second embodiment is that the third embodiment further includes a breaker 50.

[0172] The breaker device 50 includes a breaker main body 51 and a breaker drive mechanism; the breaker drive mechanism is used to drive the movement of the breaker main body 51; the breaker drive mechanism includes the breaker power device and the breaker drive mechanism .

[0173] The main body 51 of the breaker device is a three-dimensional skeleton structure, preferably a steel frame structure; the main body 51 of the breaker device is formed by a rod or sheet in a fixed connection, and the shape of the outer contour of the connection is with the silo main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com