Intermittent automatic feeding material bin with material fluffing prevention function

An automatic feeding, intermittent technology, used in containers, packaging, transportation and packaging, etc., can solve problems affecting production efficiency and product quality, affecting continuous and stable feeding, and unstable production lines, so as to improve production efficiency and improve product quality. Product quality, reliable effect, guaranteed effect of continuity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to express the technical solution of the present invention more clearly, a detailed description will be given in conjunction with specific embodiments, which are only used to explain the invention and not limit the present invention.

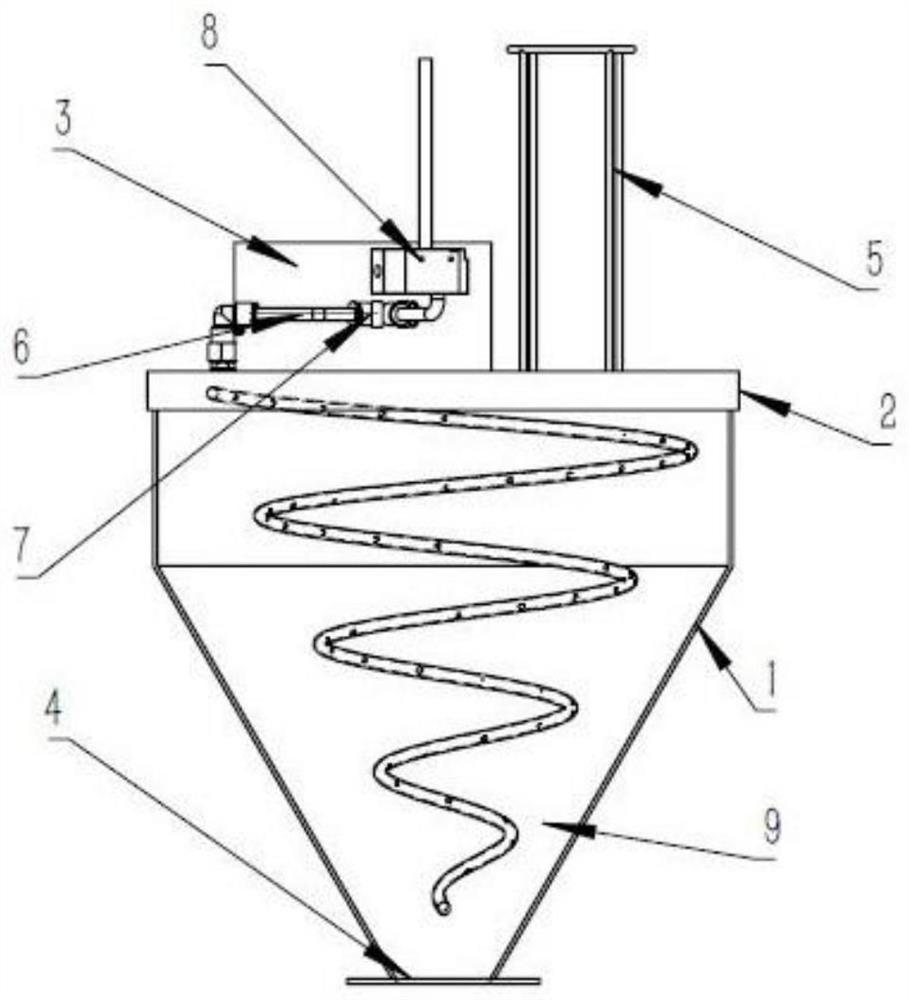

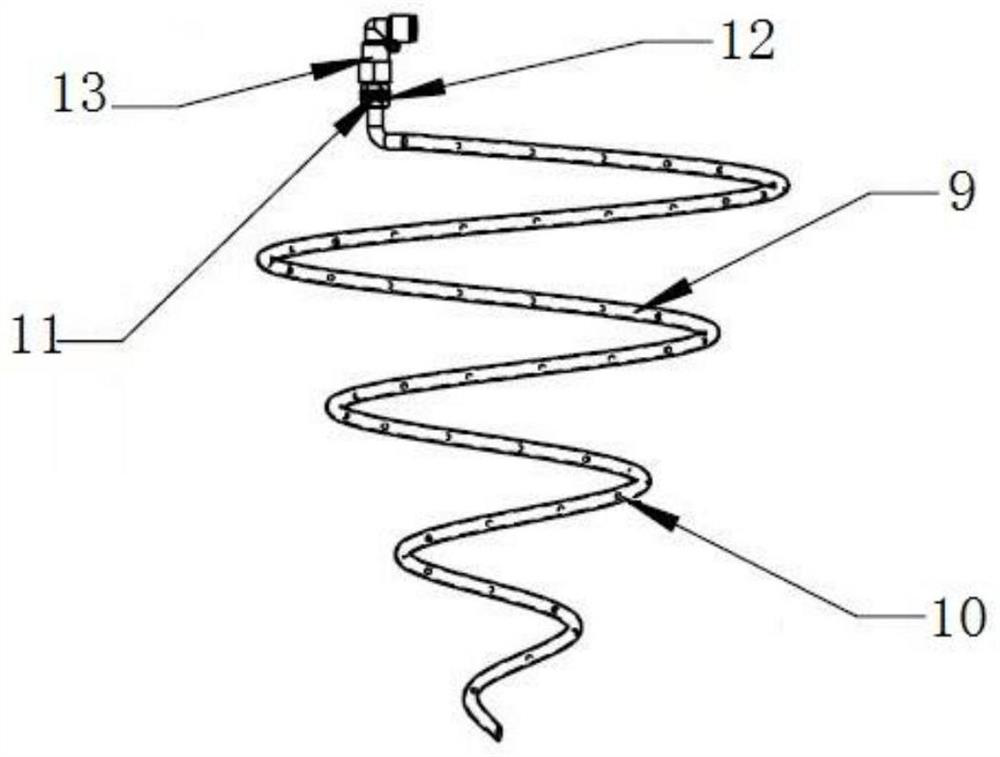

[0020] see Figure 1-2 , an embodiment provided by the present invention: an intermittent automatic feeding silo with the function of preventing tent materials, comprising a silo 1, a silo cover 2, a feed port 3 and a discharge port 4, the silo 1 is provided with a blowing pipeline 9, and the blowing pipeline 9 is suspended and installed on the silo cover 2, and the front port of the blowing pipeline 9 is connected to an external air source through an air intake pipeline, and a solenoid valve 8 is installed on the air intake pipeline. , the lower port of the air blowing pipe 9 is closed, and the air blowing pipe 9 is provided with outlet holes 10, and the silo cover 2 is also provided with a breathing port 5 for exhaust.

[0021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com