Needle cylinder mechanism of two-sided terry circular knitting machine

A technology of circular knitting machine and double-sided wool, which is used in weft knitting, circular knitting machines with separate action needles, knitting, etc. First-class problems, to avoid the breakage and fluffing of the terry yarn, and the effect of easily falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

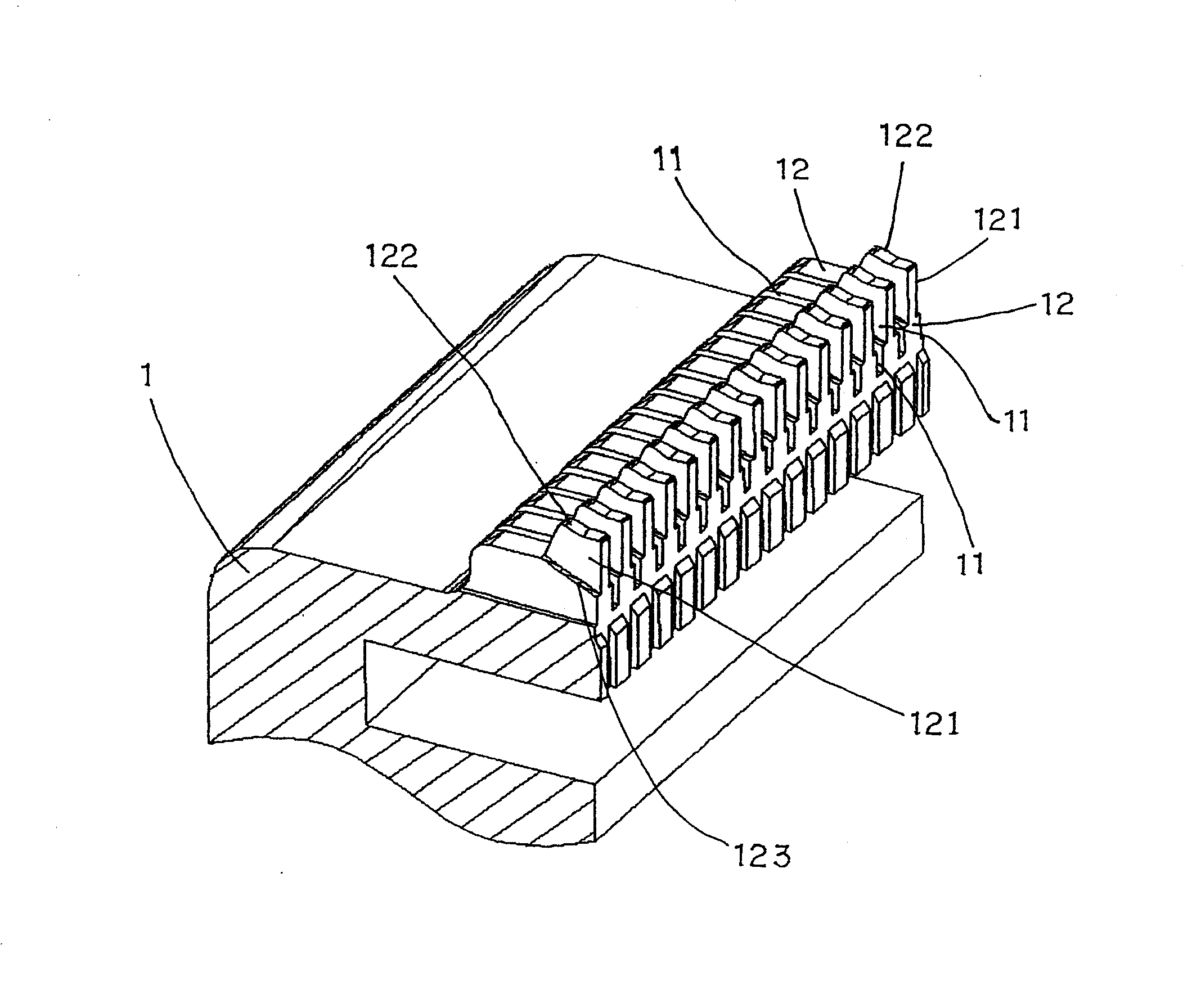

[0021] See image 3 , Figure 4 , The present invention is mainly provided at the upper end of the front section of the spacer 12 between the syringe 1 sinogram slot 11, a protrusion 121 that is higher and thinner than the spacer, so that the upper end of the sinogram slot 11 of the syringe 1 The shape is wide and narrow at the lower end, while the sinker slot 11 in the rear section continues the sinker slot 11 at the lower end of the front section. The lower end of the syringe 1 is narrower than the slot width of the sinker slot 11 and can only accommodate The gram piece 2 enters, the upper edge of the rear end of the protrusion 121 is a flange 122 protruding upward along the protrusion 121, and at the bottom of the protrusion 121, a slope 123 extending downward and forward is provided.

[0022] By means of the aforementioned structure and shape of the needle cylinder 1, when knitting materials, the narrower sinker slot 11 at the lower end of the needle cylinder 1 can make the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com