Angle cutter realizing smooth cutting and preventing burrs of end side and implementation method of angle cutter

A kind of technology of hair cutting machine and cutting mechanism, which is used in metal processing machinery parts, clamping, supporting and other directions, and can solve the problems of rough grinding of cutting grooves, fuzzing of saw material broken edges, uncontrollable installation accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

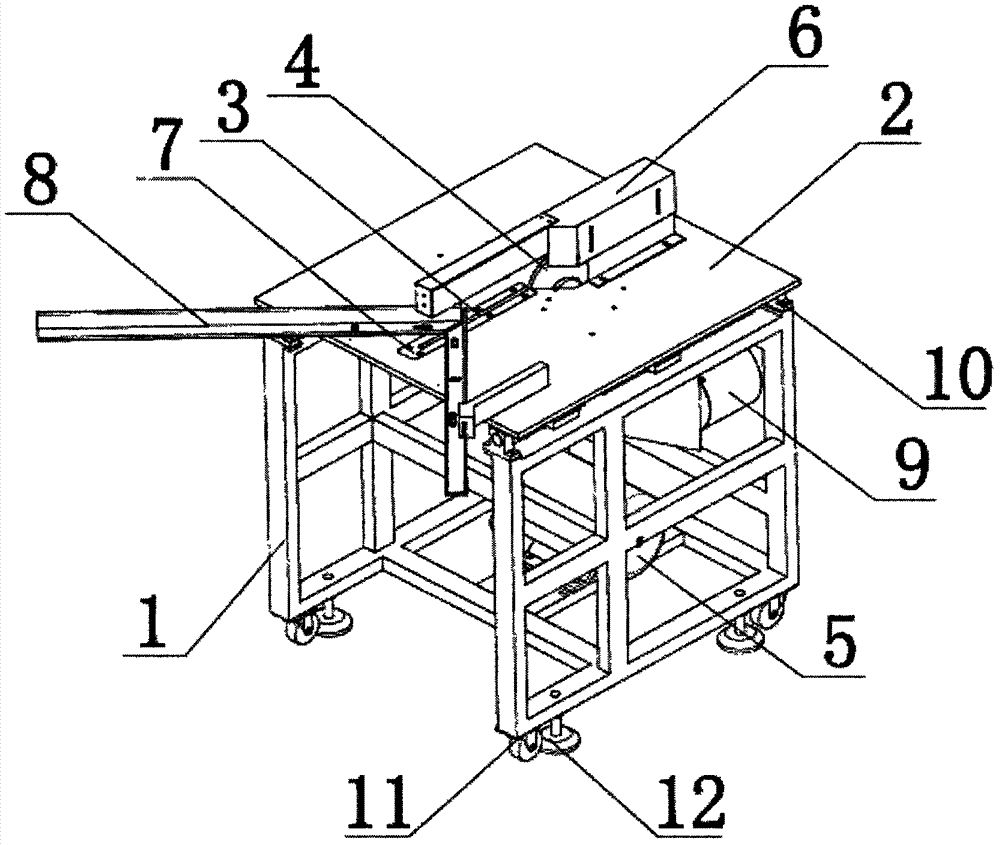

[0020] Embodiment 1: as figure 1 As shown, a cutting flat end edge lint-free chamfering machine and its realization method include a frame 1 on which a board 2 and a cutting mechanism are carried, the cutting mechanism is accommodated in the frame 1, and the platen 2 Arranged on the top of the frame 1, two sets of supporting mechanisms are set on the bottom of the frame 1, one set is four casters 11 set on the four corners of the bottom, and the other set is also four sets of positioning plates set on the four corners of the bottom The fixed support 12.

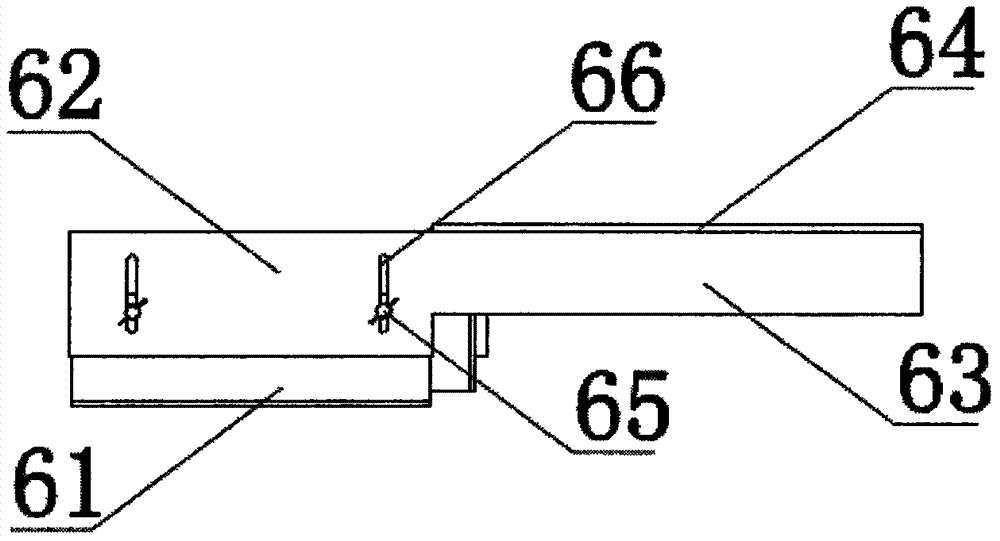

[0021] The cutting mechanism further includes a cutting wheel 4 and a drive motor 5, the cutting wheel 4 is installed on a rotating shaft, the two ends of the rotating shaft are installed in a pair of bearing seats on the frame 1, and one of the ends of the rotating shaft protrudes A driven pulley is sleeved outside its corresponding bearing seat. The driving motor 5 is located directly below the cutter wheel 4. A driving pu...

Embodiment 2

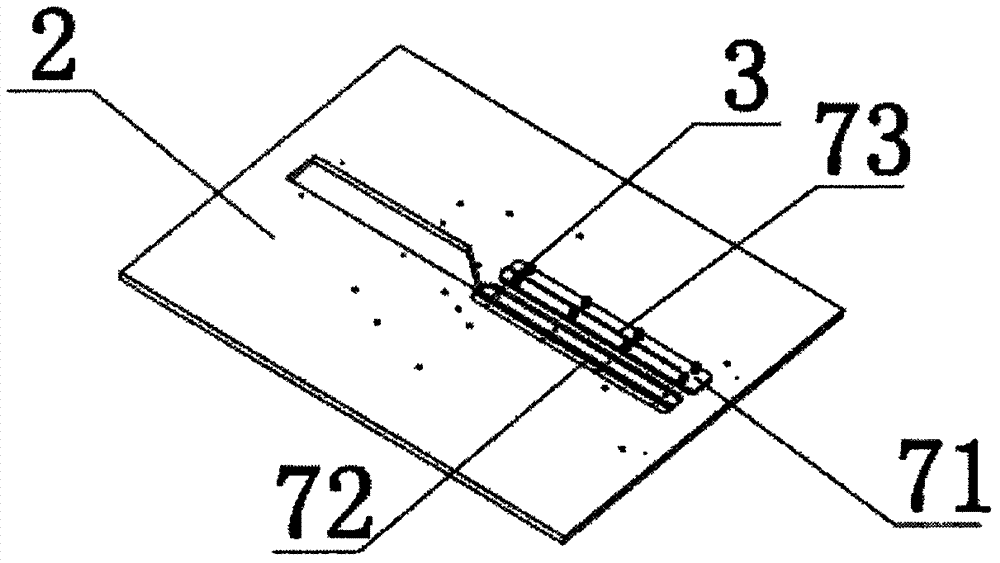

[0031] Embodiment 2: as image 3 As shown, the structure of the end edge lint-free mechanism 7 is also such as: the end of the cutting groove 3 is not arranged with the cutting wheel 4. A step groove 72 with a width greater than its groove width is recessed inwardly, and a brittle inlay is filled in the step groove 72 71 , the exposed end surface of the brittle inlay 71 is flat and flush with the upper end surface of the platen 2 . The fragile inlay 71 is a piece of plastic.

[0032] All the other are with embodiment 1.

[0033] A method for realizing a corner cutting machine that cuts flat ends and lint-free edges. When the corner cutting machine leaves the factory, the platen and the cutting mechanism are immobile and fixed. The cutting wheel passes through one end of the cutting groove, and the other end of the cutting groove penetrates up and down, and Fill with brittle inlays seamlessly and not loose; when the angle cutter is turned on for the first time, the platen and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com