Drier screw conveying device for biomass power generation

A screw conveying device, biomass power generation technology, applied in the direction of conveyor objects, transportation and packaging, packaging, etc., can solve the problems of easy filling of the shell, uneven distribution of feeding materials, and difficulty in dredging, so as to prevent material filling, Good practicability, the effect of solving the phenomenon of uneven feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

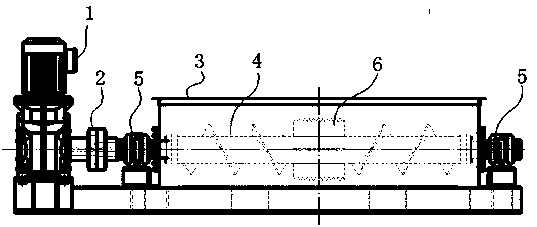

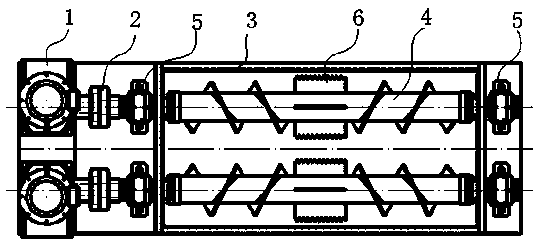

[0014] Such as figure 1 and figure 2 As shown, the feeding device for the biomass power generation silo includes a driving device 1, a coupling 2, a housing 3, a spiral body 4 and a bearing seat 5; the driving device 1 is connected to the coupling 2, and the coupling 2 is connected to the bearing Seat 5 links to each other, and bearing seat 5 links to each other with spiral body 4, and spiral body 4 can have two, is located in the shell 3 symmetrically and parallelly, all links to each other with bearing seat 5. The driving device 1 is a speed reducer, and is arranged on the side of the housing 1 . Preferably, the feeding device is arranged on the upper part of the tail belt of the belt conveyor.

[0015] When working, when the fuel is sent into the silo of the dry material shed through the transportation equipment, the material spiral will transfer the material fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com