A method for preparing a patterned sapphire substrate for gan growth

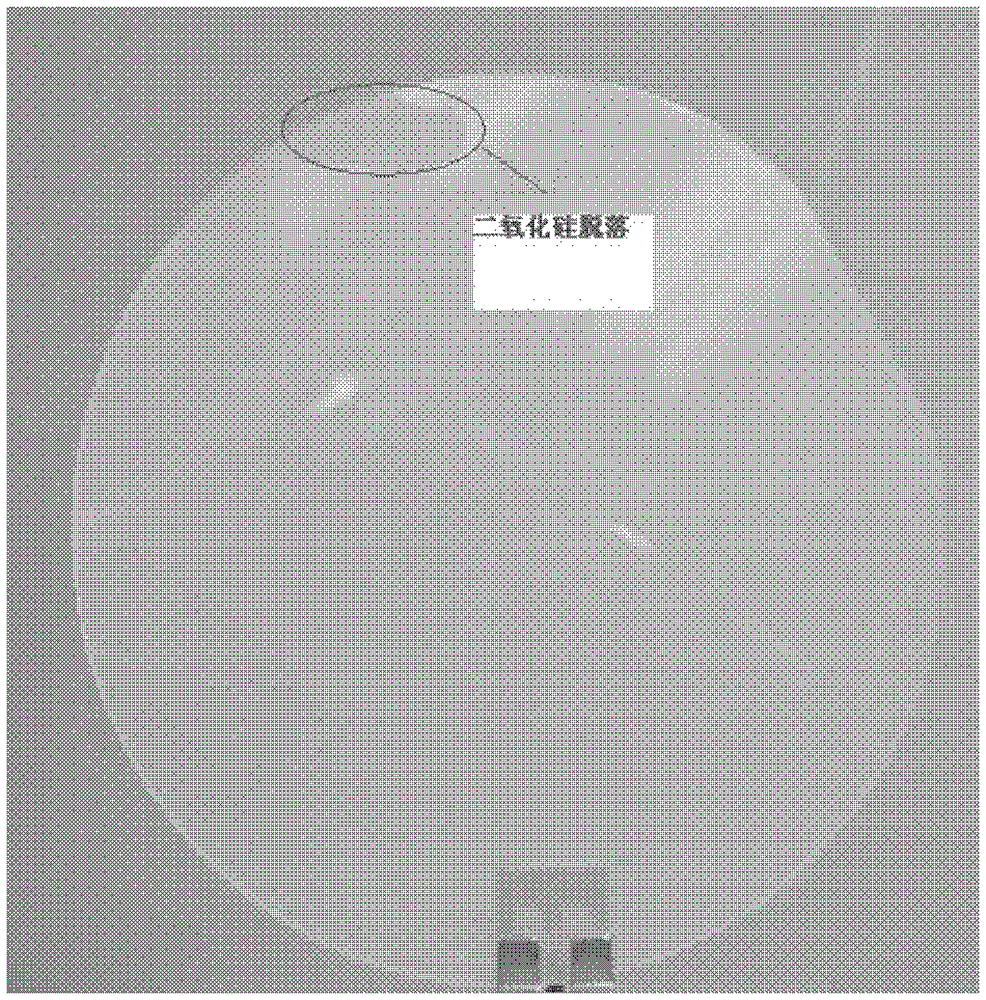

A patterned sapphire and sapphire substrate technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as uneven corrosion, silicon dioxide shedding, pinholes and imprints, so as to avoid local shedding and reduce dislocations Density, the effect of avoiding uneven corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Embodiment, preparation patterned sapphire substrate II (through pretreatment)

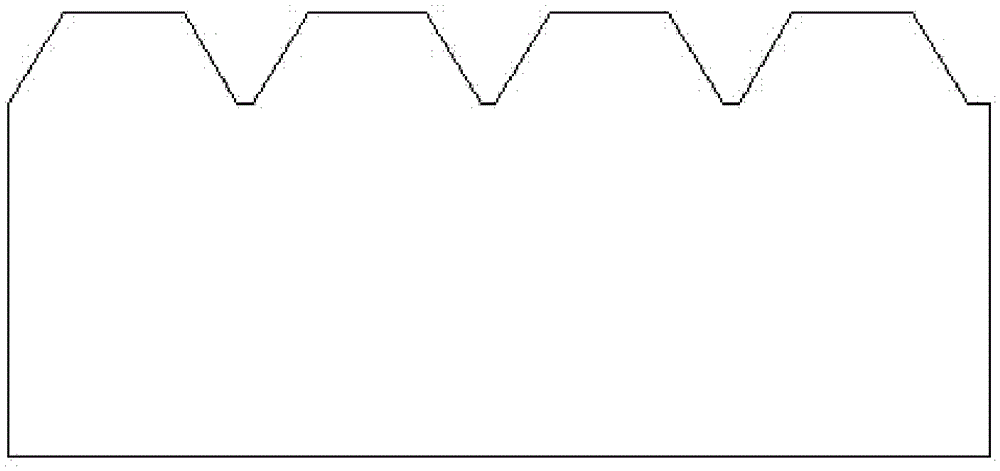

[0039] A silicon dioxide mask layer with a thickness of 0.1-1.0 μm is prepared on the C-plane sapphire by using plasma enhanced chemical vapor deposition (PECVD).

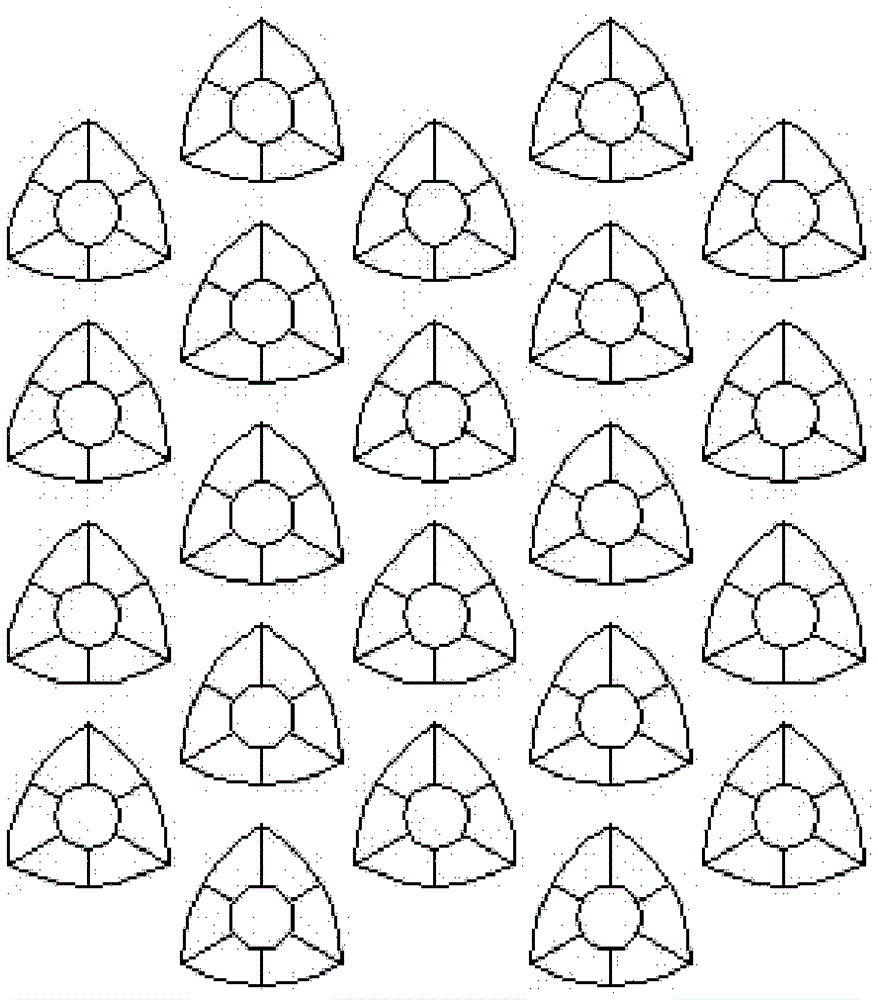

[0040] Using photolithography technology, on the silicon dioxide mask layer, periodically arranged cylindrical photoresist mask patterns with a thickness of 1.0-3.0 μm and a bottom diameter of 2.0-4.0 μm are carved. The pitch is 0.5-1.0 μm.

[0041] Put the substrate into a special buffer solution, soak it at 23-50°C for 30s, let the buffer fully wet the substrate, then take out the substrate (do not need to dry it), the concentration of the special buffer solution is: It is obtained by mixing 40% hydrofluoric acid solution and water at a volume ratio of 10:1 to 20:1.

[0042] Then put the pretreated substrate into a mixture of hydrofluoric acid solution and water with a volume ratio of 1:6 and a concentration of 40%, etch at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com