Method for preparing functional protein fiber

A technology of functional protein and protein fiber is applied in the field of preparation of functional protein fiber, which can solve the problems of insufficient resistance to household washing, added value of hard textiles, and hard hand feeling of textiles, so as to solve the problems of poor washing fastness and improve the The effect of easy decontamination and soft touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of the pre-condensed aqueous solution: 20Kg acrylic acid, 15Kg N-vinyl-2-pyrrolidone and 65Kg water were added to the reaction kettle, heated to 60℃ while stirring, and then 1.75Kg potassium persulfate was added and reacted for 5 hours. An acrylic acid / N-vinyl-2-pyrrolidone pre-condensed aqueous solution with a mass concentration of 35% was obtained.

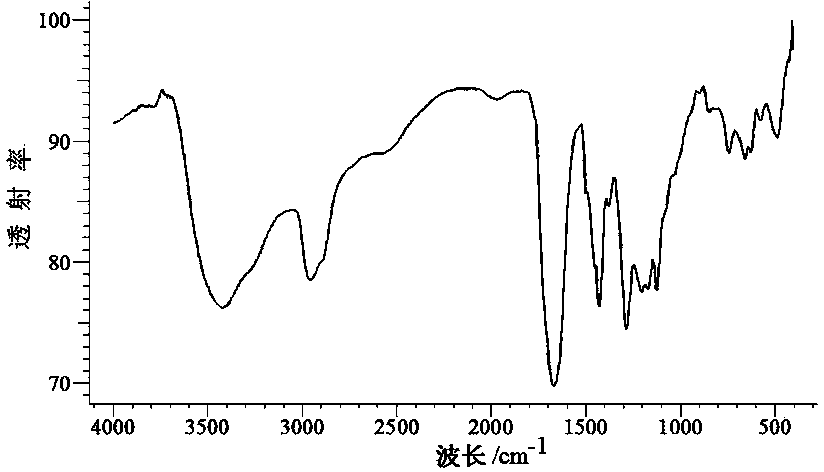

[0039] Attached figure 1 Is the infrared spectrum of the pre-shrinked body in the aqueous solution of the above-mentioned pre-shrinked body. figure 1 It can be seen that the pre-condensate is a polyacrylic acid / pyrrolidone polymer.

Embodiment 2

[0041] The preparation of the pre-condensed aqueous solution: 15Kg of methacrylic acid, 19Kg of acrylamide and 66Kg of water were added to the reactor, and the temperature was raised to 70℃ while stirring, and then 1.70Kg of potassium persulfate was added and reacted for 4 hours to obtain the mass concentration It is a 34% methacrylic acid / acrylamide pre-condensed aqueous solution.

Embodiment 3

[0043] Preparation of pre-condensed aqueous solution: 15Kg acrylic acid, 15Kg N-vinyl-2-pyrrolidone, 10Kg acrylamide and 60Kg water were added to the reaction kettle, heated to 80°C while stirring, and then 2.40Kg potassium persulfate was added, reaction 3 After hours, an acrylic acid / N-vinyl-2-pyrrolidone / acrylamide pre-condensed aqueous solution with a mass concentration of 40% was prepared.

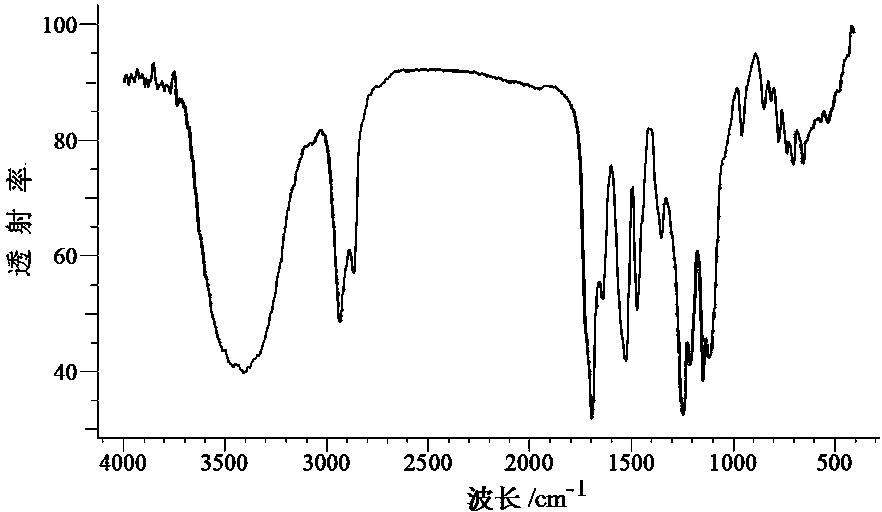

[0044] Attached figure 2 Is the infrared spectrum of the pre-shrinked body in the aqueous solution of the above-mentioned pre-shrinked body. figure 2 It can be seen that the pre-condensate is a polyacrylic acid / pyrrolidone / acrylamide polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com