Flame-retardant clothing and preparation process thereof

A preparation process and technology of flame retardant fabrics, applied in the field of textile products, can solve the problems of human injury, poor air permeability, easy oily kitchen clothes, etc., and achieve the effects of improving flexibility, good heat resistance, and ensuring cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

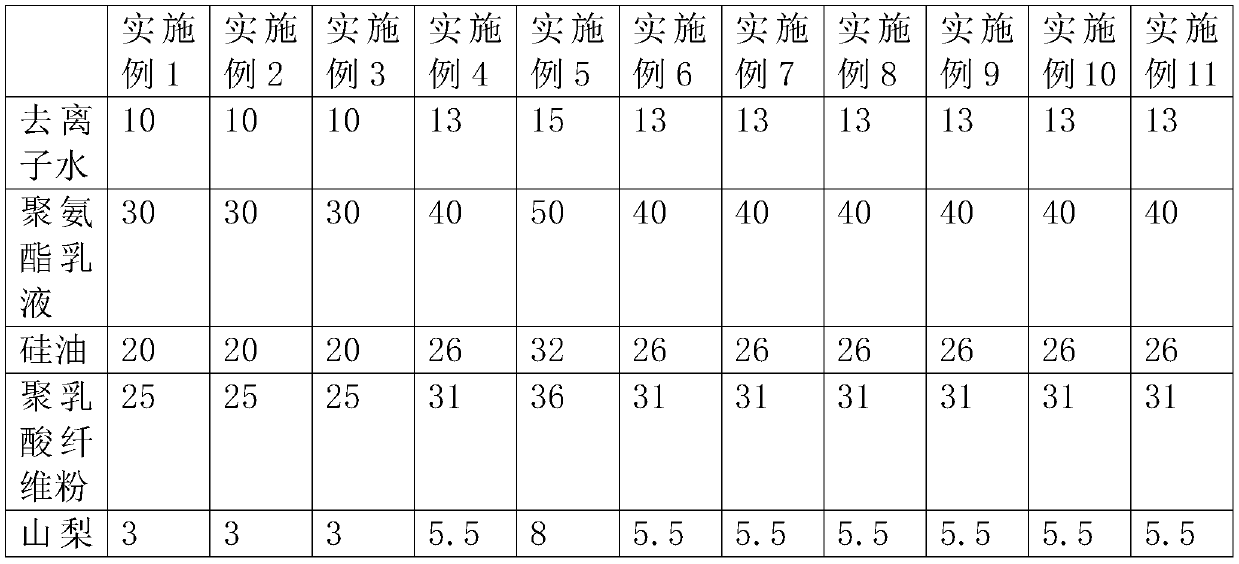

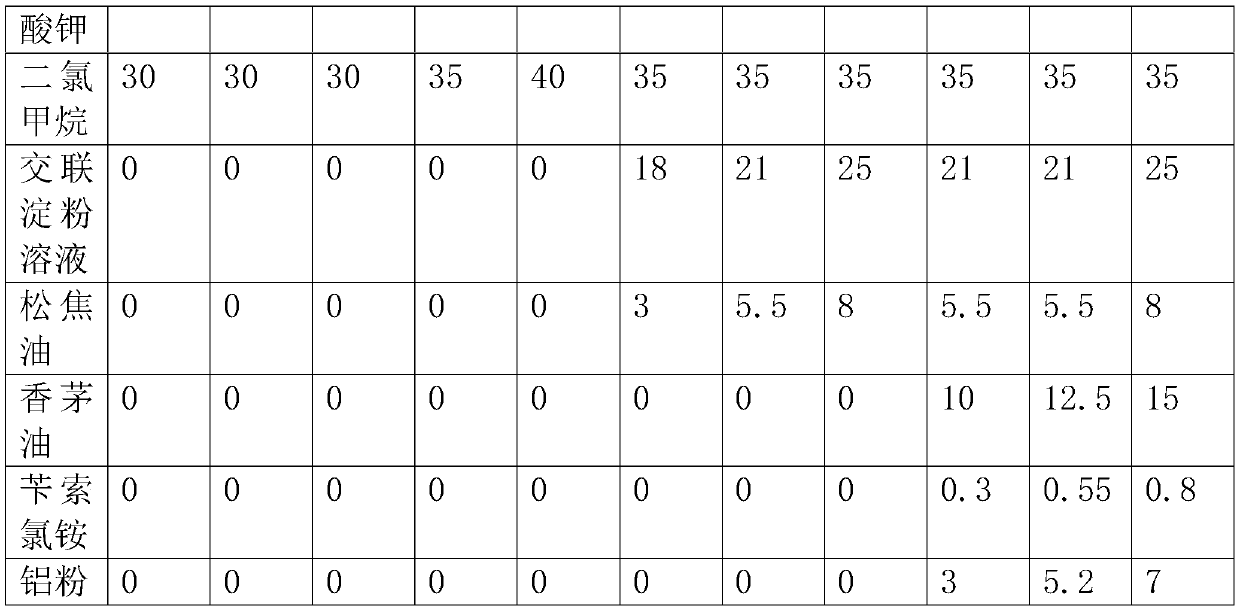

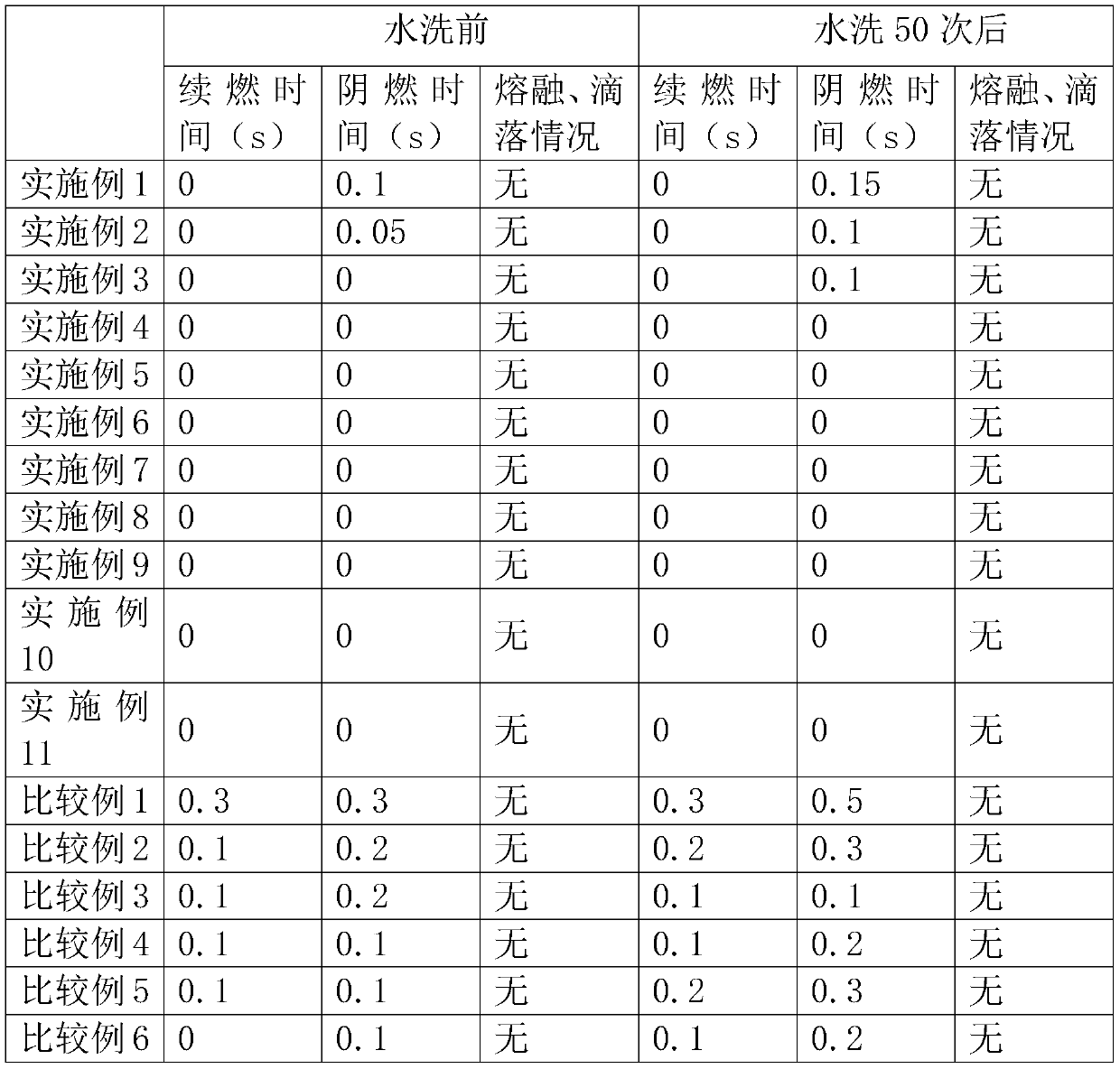

Examples

Embodiment 1

[0063] A preparation process for flame retardant clothing, comprising the following steps:

[0064] S1. Pretreatment: Soak the flame-retardant fabric in clean water at a temperature of 25°C, then add ethanol to the clean water, wash the flame-retardant fabric, beat it, and finally centrifugally dehydrate to obtain a clean flame-retardant fabric.

[0065] In this embodiment, the weight ratio of ethanol to water is: 0.5:5.

[0066] The flame-retardant fabric in step S1 is made by weaving polyester fiber, flame-retardant acrylic fiber, flame-retardant vinylon and flame-retardant nylon.

[0067] In this embodiment, the polyester fiber in the flame-retardant fabric of step S1 is a vermiculite-modified polyester fiber, and the preparation method of the vermiculite-modified polyester fiber is as follows:

[0068] (1) Grind 10 parts by mass of vermiculite to a particle size of 325 meshes, mix evenly with 57 parts by mass of polyester masterbatch, heat to 300° C. to melt, and keep war...

Embodiment 2

[0098] The difference with embodiment 1 is:

[0099] A preparation process for flame retardant clothing, comprising the following steps:

[0100] S1. Pretreatment: Soak the flame-retardant fabric in clean water at a temperature of 28°C, then add ethanol to the clean water, wash the flame-retardant fabric, beat it, and finally centrifugally dehydrate to obtain a clean flame-retardant fabric.

[0101] In this embodiment, the weight ratio of ethanol to water is: 0.6:5.

[0102] The flame-retardant fabric of the flame-retardant fabric in step S1 is made of polyester fiber, flame-retardant acrylic fiber, flame-retardant vinylon and flame-retardant nylon mixed weaving.

[0103] In the present embodiment, the polyester fiber in step S1 is a vermiculite modified polyester fiber, and the preparation method of the vermiculite modified polyester fiber is as follows:

[0104] (1) Grind 13 parts by mass of vermiculite to a particle size of 325 meshes, mix evenly with 70 parts by mass of ...

Embodiment 3

[0133] The difference with embodiment 1 is:

[0134] A preparation process for flame retardant clothing, comprising the following steps:

[0135] S1. Pretreatment: Soak the flame-retardant fabric in clear water at a temperature of 30°C, then add ethanol to the clean water, wash the flame-retardant fabric, beat it, and finally centrifugally dehydrate to obtain a clean flame-retardant fabric.

[0136] In this embodiment, the weight ratio of ethanol to water is 0.8:5.

[0137] The flame-retardant fabric in step S1 is made by weaving polyester fiber, flame-retardant acrylic fiber, flame-retardant vinylon and flame-retardant nylon.

[0138] In this embodiment, the polyester fiber of the flame-retardant fabric in step S1 is a vermiculite-modified polyester fiber, and the preparation method of the vermiculite-modified polyester fiber is as follows:

[0139] (1) Grind 15 parts by mass of vermiculite to a particle size of 325 meshes, mix evenly with 85 parts by mass of polyester mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com