Method for preparing high-strength polypropylene fibers

A polypropylene fiber and polypropylene technology, applied in the field of spinning, can solve problems such as poor strength of polypropylene fibers, achieve stable cooling conditions, avoid broken wires, and facilitate stretching and traction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

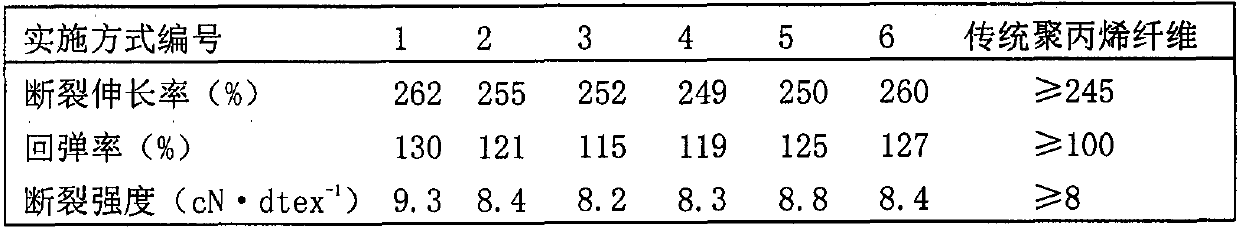

Examples

Embodiment 1

[0018] Put the polypropylene pellets into the hopper of the spinning machine and extrude through the spinneret at 230°C. A water tank is set at a position 8cm directly below the spinneret and between the air cooling device. The length of the water tank is 1.2m, The water temperature is 70°C. After the first step of water cooling is carried out by passing the thin stream of polypropylene melt ejected from the spinneret through the water tank, the second step of annular air cooling is performed on the water-cooled thin stream of polypropylene melt, and the air cooling temperature is 30°C. Apply a softener to the obtained polypropylene fiber after one-step water cooling and two-step air cooling, and wind the fiber obtained by the softener on a roll for 5 turns under the condition that the temperature of the first roll is 65°C, and the speed of the first roll is 180m / min , and then the fiber is wound on the second roll for 8 turns under the condition that the temperature of the se...

Embodiment 2

[0021] In this embodiment, the temperature of the spinneret is 235° C., the temperature of the second roll is 85° C., and the rotational speed of the second roll is 800 m / min.

Embodiment 3

[0023] In this embodiment, the temperature of the spinneret is 230° C., the temperature of the second roll is 85° C., and the rotational speed of the second roll is 820 m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com