Method for producing tiny soldered balls with repeatedly-usable substrates

A manufacturing method and substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as poor process controllability, easy introduction of various impurities, ineffective control of droplet size and continuous growth, etc. , to reduce production costs, avoid surface oxidation, wire drawing or fluffing, and avoid chipping, burrs and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

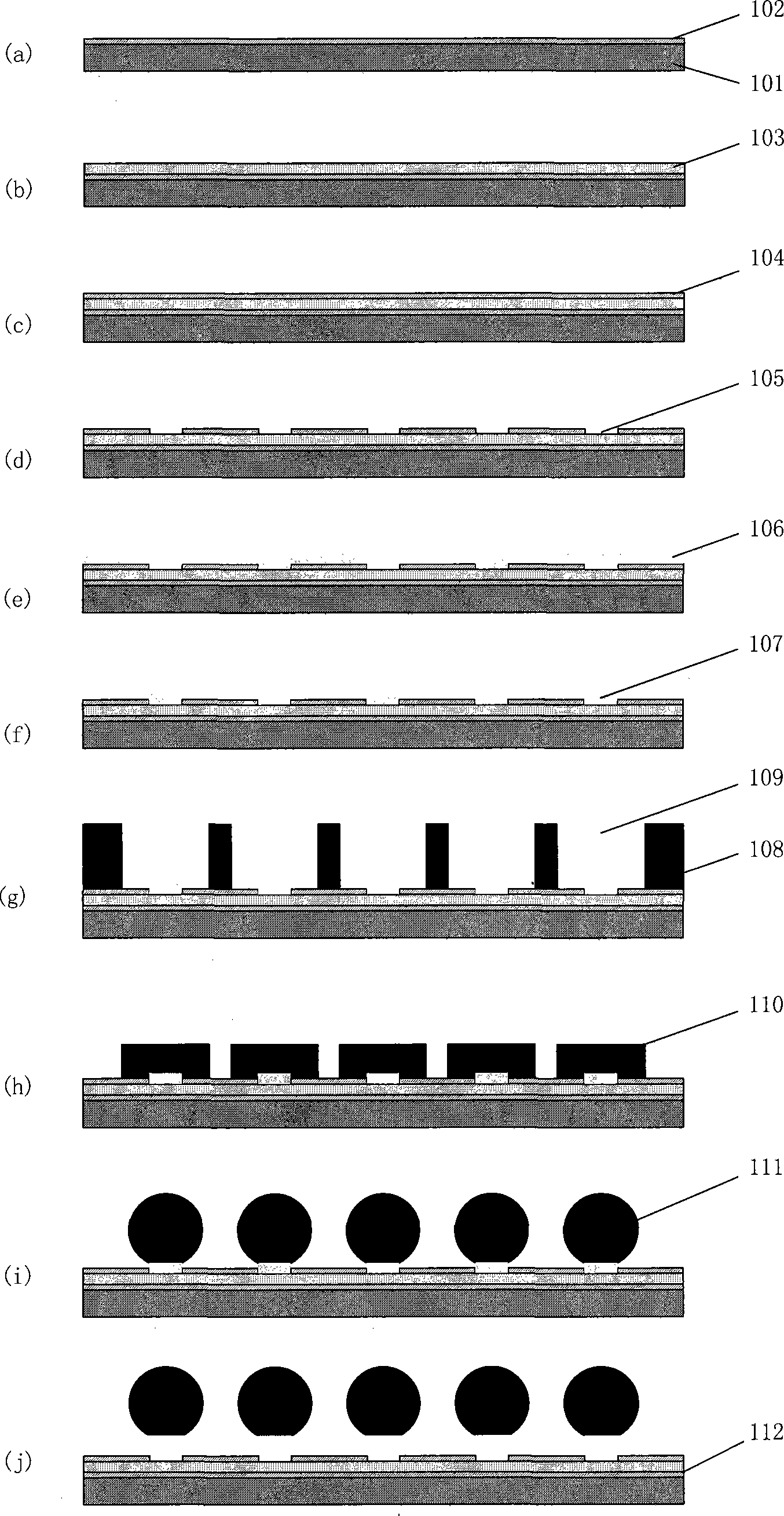

[0025] The preparation process flow of a typical micro solder ball includes the following steps:

[0026] 1. Using IC manufacturing process to prepare reusable substrates

[0027] (1) First, clean the single-side polished N-type (100) silicon wafer, and then perform thermal oxidation treatment, and the thickness of the silicon dioxide oxide layer 102 is about 0.3 microns;

[0028] (2) Vacuum sputtering metal conductive layer TiW and Au 103, the thickness is about 0.05 microns and 0.2 microns, respectively; the adhesion between the silicon dioxide layer and Au is poor, so TiW is used as the metal adhesion layer on the silicon dioxide , The three layers of metal are all sputtered sequentially in the same vacuum chamber;

[0029] (3) Then deposit a layer of barrier layer SiO on the conductive layer by plasma enhanced chemical vapor deposition (PECVD) method 2 Or Si 3 O 4 104, the thickness is about 0.1 micrometers; the circular barrier layer opening is etched by positive photoresist ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com