Positive control type wool warp tension system

A tension system and control technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of inability to achieve high-quality and high-speed weaving of towels, lack of coordination, and large motion inertia of swing parts, so as to achieve stable tension and avoid Efficacy of brushed, high loop quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

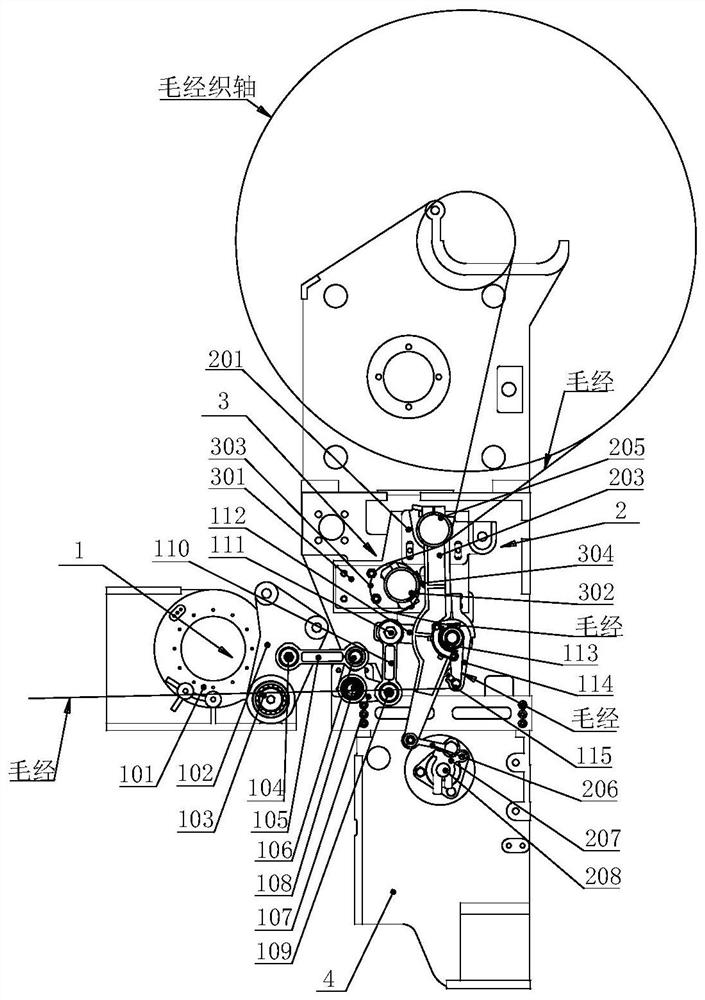

[0041] The present invention is described in detail below in conjunction with accompanying drawing:

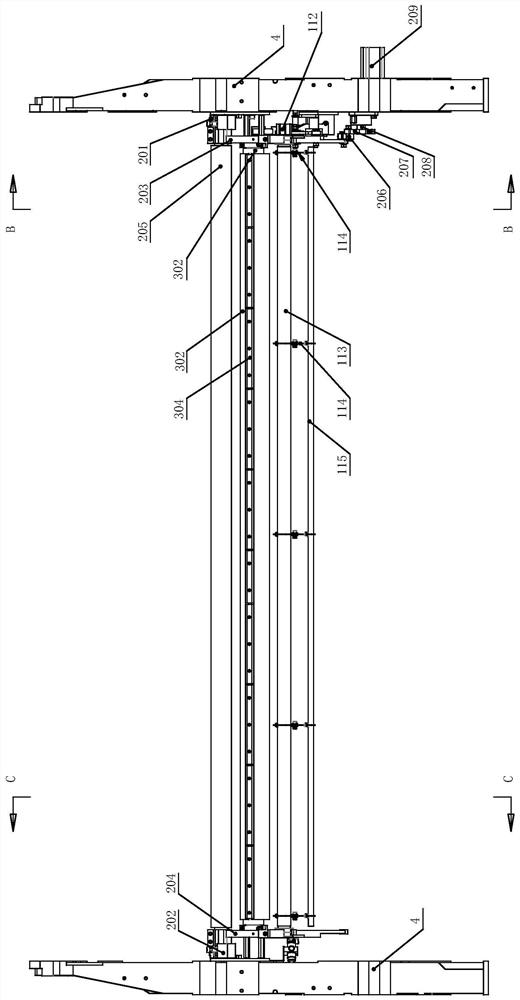

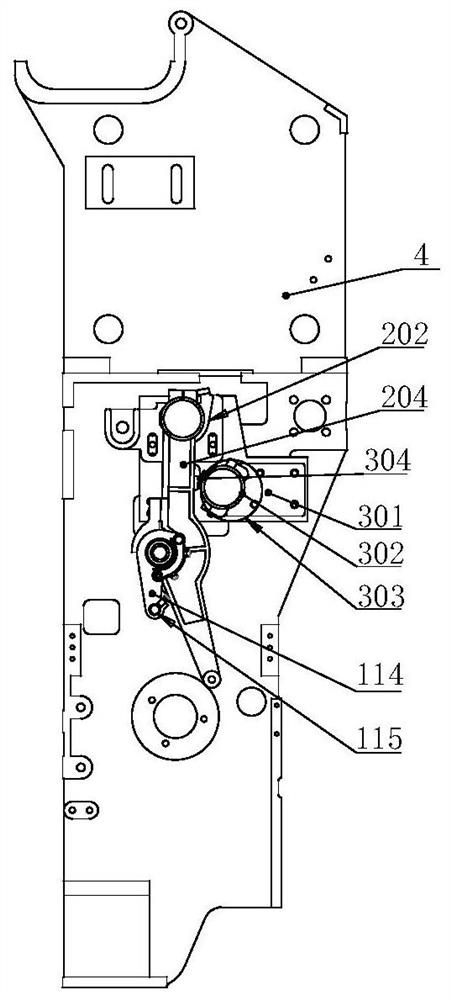

[0042] combine Figure 1 to Figure 5 , a positively controlled hair warp tension system, comprising a wallboard 4, a cloth movement active follower 1, a hair warp tension active control device 2 and a hair warp tension buffer device 3, the wallboard 4 has two, two wall The boards 4 are arranged opposite to each other from left to right.

[0043] The wool warp tension active control device 2 includes a support pendulum shaft 205, a tension rocker arm 203 and a rocker arm drive mechanism. The support pendulum shaft 205 is a hollow shaft with a circular section, and the support pendulum shaft 205 is horizontally arranged on two wallboards 4 Between them, the two ends thereof respectively pass through a rocker arm support 201 to rotate with the corresponding side wall panel 4. They are respectively rotatably connected with the corresponding rocker arm support 201 through a beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com