Full-coating sweeping anti-lock abrasion resisting ball valve

A technology of wear-resistant balls and coatings, applied to valve details, valve devices, valve housing structures, etc., can solve problems such as sealing surface and flow channel erosion, ball valve failure, increased maintenance costs, etc., to improve shock resistance and torsion resistance Strength, prevention of failure to work, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

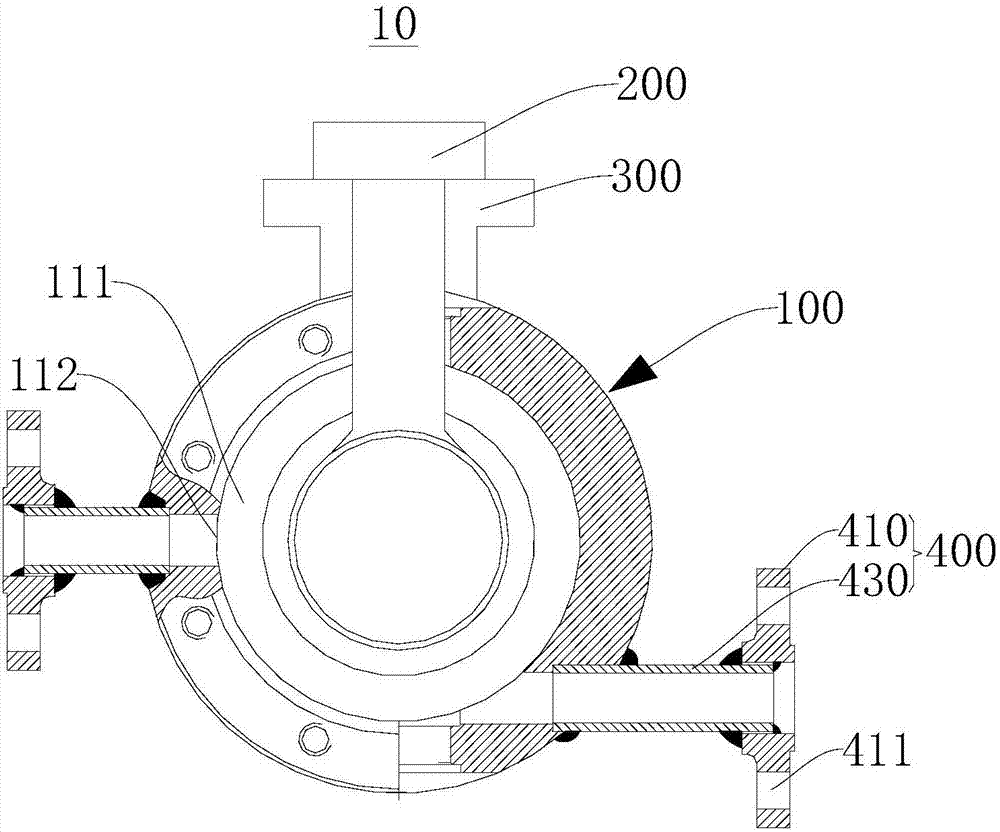

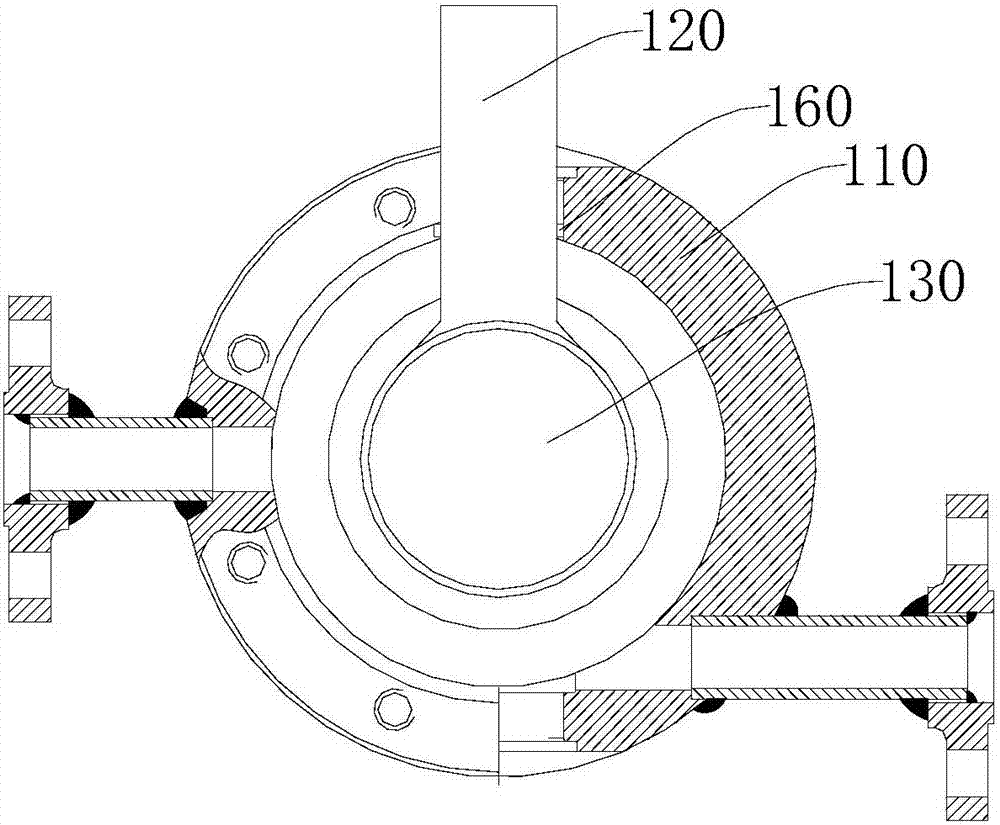

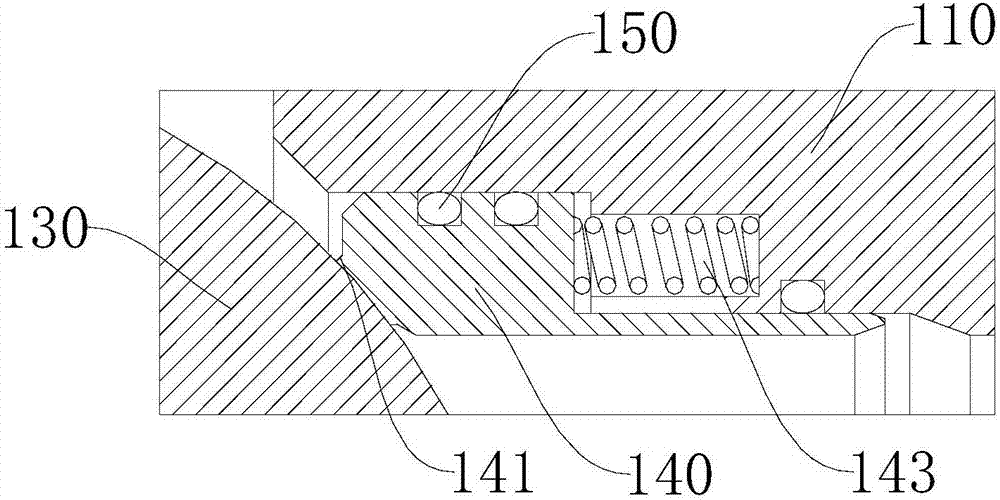

[0032] Please refer to figure 1 , the embodiment of the present invention provides a full-coated anti-lock wear-resistant ball valve 10 with purge, which is used to control the circulation or closure of materials. Its structure is simple, it can clean up the silted material in the body cavity, prevent the valve ball from being locked and cause it to fail to work, and can increase the shock resistance and torsional strength, with strong practicability and high cost performance.

[0033] The full-coated belt purging anti-lock wear-resistant ball valve 10 is applied to a discharge device (not shown in the figure), and the discharge device includes a fully-coated belt purge anti-lock wear-resistant ball valve 10, electronic control equipment (not shown in the figure) ) and two purging devices (not shown). The full-coated anti-lock wear-resistant ball valve 10 with purge is connected with the purge equipment through the electronic control equipment, and the purge equipment is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com