Horizontal bar for ladder type cable trays

A ladder and bridge technology, which is applied in the direction of pipeline supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of poor bearing capacity and weak stability, and achieve increased seismic performance, convenient construction and fixing, and high The effect of quality weld output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

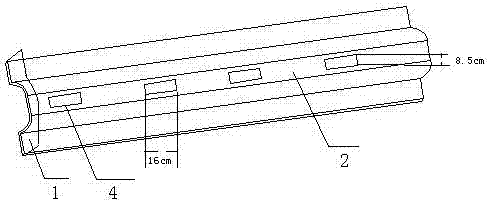

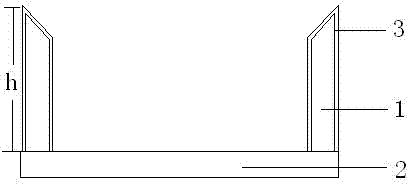

[0016] As shown in the figure, there is a kind of ladder for ladder bridge. The ladder is an integral plate with Ω-shaped longitudinal section, wherein, the two ends of ladder 2 are vertically upwardly provided with baffles 1, and the longitudinal section of baffle 1 is at right angles. Trapezoidal, one end at a right angle is connected to the ladder 2; the height h of the baffle plate 2 is 5-10 cm, and its outer surface is covered with a layer of buffer pad 3, and the thickness of the buffer pad is 2-15 mm. Simultaneously, the bottom surface of the ladder 2 is evenly provided with some installation holes 4, and the length of the installation holes is 16cm, and the width is 8.5cm.

[0017] The beneficial effects of the present invention are:

[0018] 1. Since the longitudinal section of the ladder is an Ω-shaped integral plate, the connection between the ladder side and the ladder is changed from the traditional point contact to the surface contact, which increases the contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com