Trademark production process capable of conveniently discharging wastes

A production process and trademark technology, applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of difficult overall cleaning of waste materials, gaps in the bottom plate, and affecting the effect of die-cutting, etc., to achieve automatic waste discharge, improve Effects on Waste Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments.

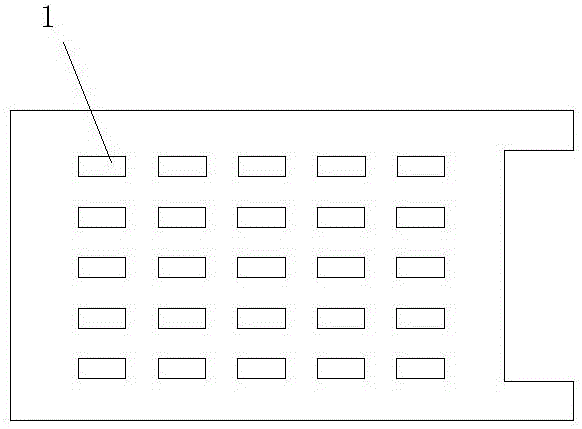

[0016] Such as figure 1 As shown, a plurality of small holes 1 need to be cut out on the surface of the product. The invention provides a trademark production process that is convenient for waste discharge, including the following steps: (1) dispensing glue, dispensing glue on the back of the waste area of the product; 2) Laminating, covering the back of the product with release paper, so that the waste area is pasted with the non-release surface of the release paper; (3) Cutting, cutting the product to separate the waste area from the product, and During the cutting process, the half-cut cutting process is adopted to ensure that the release paper on the back of the product is not cut; (4) waste discharge, take away the cut products, and paste the cut waste on the release paper On paper, waste can be discharged by recycling the release paper.

[0017] By dispensing glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com