Automatic waste discharge mold, punching machine and punching method

A technology of automatic rowing and punching machines, which is applied in the direction of manufacturing tools, stone processing tools, working accessories, etc., can solve the problems of production efficiency not meeting customer requirements, obstacles to improving efficiency, and easy jamming on the cutting die, etc. Achieve the effect of improving product qualification rate, high production efficiency, avoiding breakage and material jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict. For the convenience of description, the words "up", "down", "left" and "right" appear in the following text, which only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

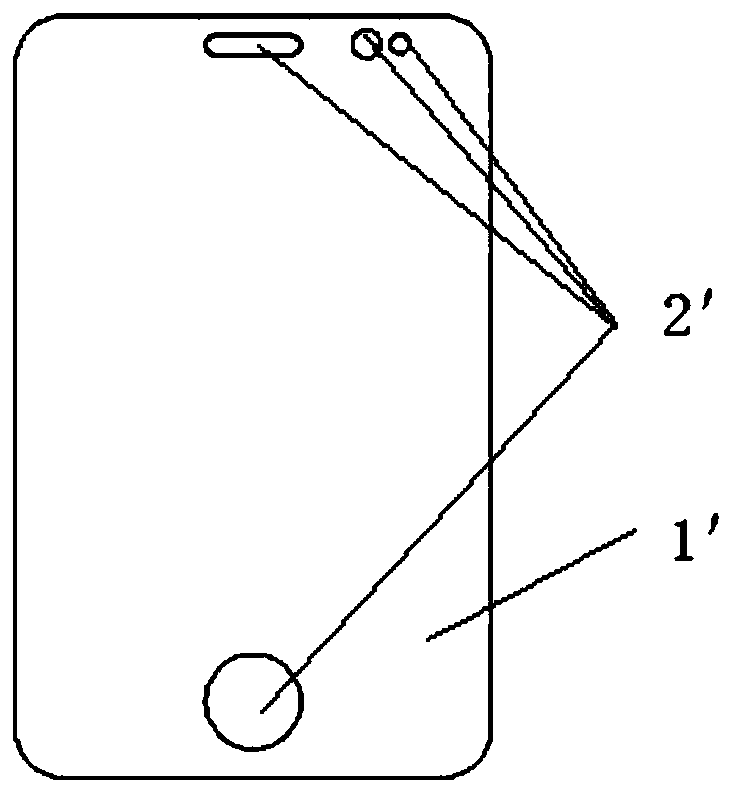

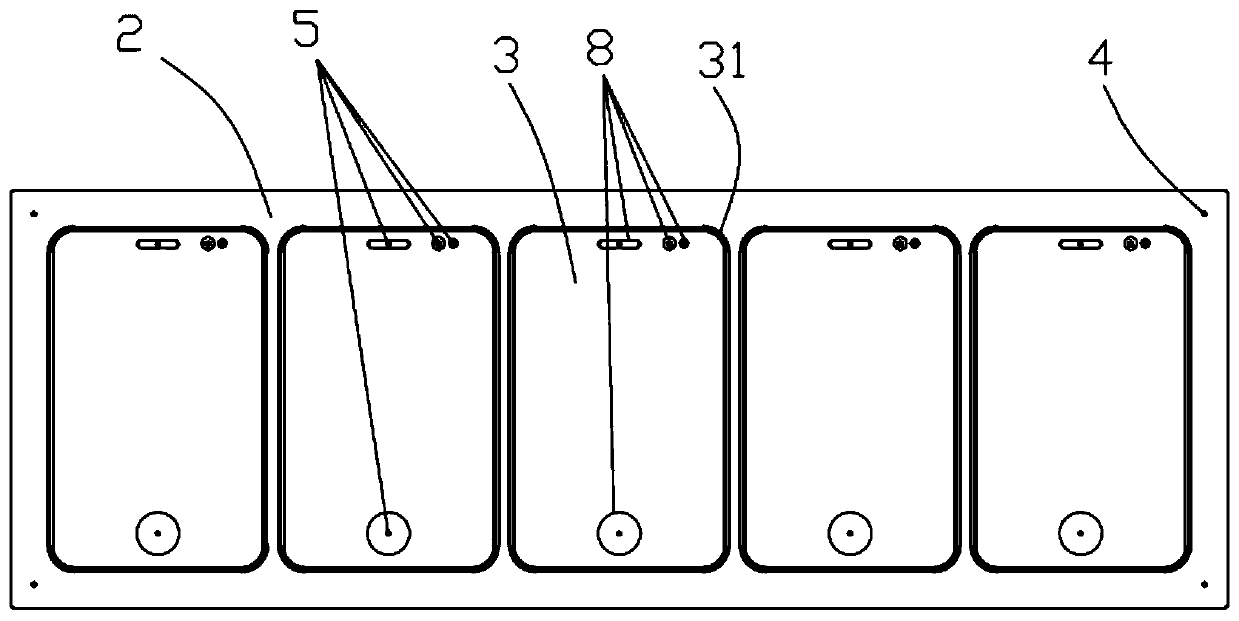

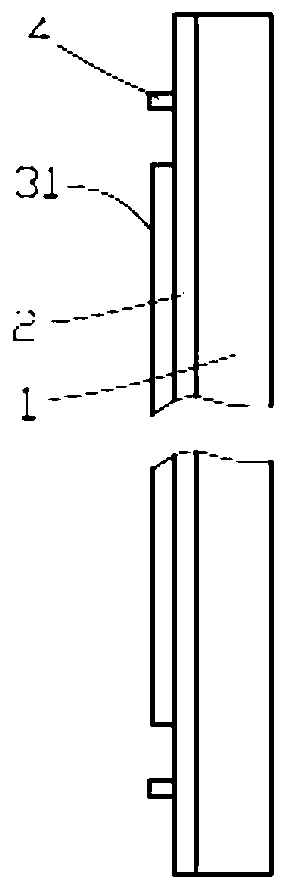

[0035] like Figure 2~5 As shown, an automatic waste discharge mold provided in this embodiment includes a base 1 , a blade 2 , a die hole 3 , a positioning pin 4 and a spring pin 5 .

[0036] The blade 2 is fixed on the base 1, and the base 1 and the blade 2 are rectangular structures. A positioning needle 4 is provided on both sides of the blade 2 at the four corners. A buffer hole 6 for installing the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com