A kind of cushioning, dust-proof foam and its production process

A technology of dust-proof foam and production process, applied in the fields of buffer and dust-proof foam, can solve the problems of poor sealing and shock-absorbing effect, and achieve the effects of reducing wool, good sealing and shock-absorbing effect, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

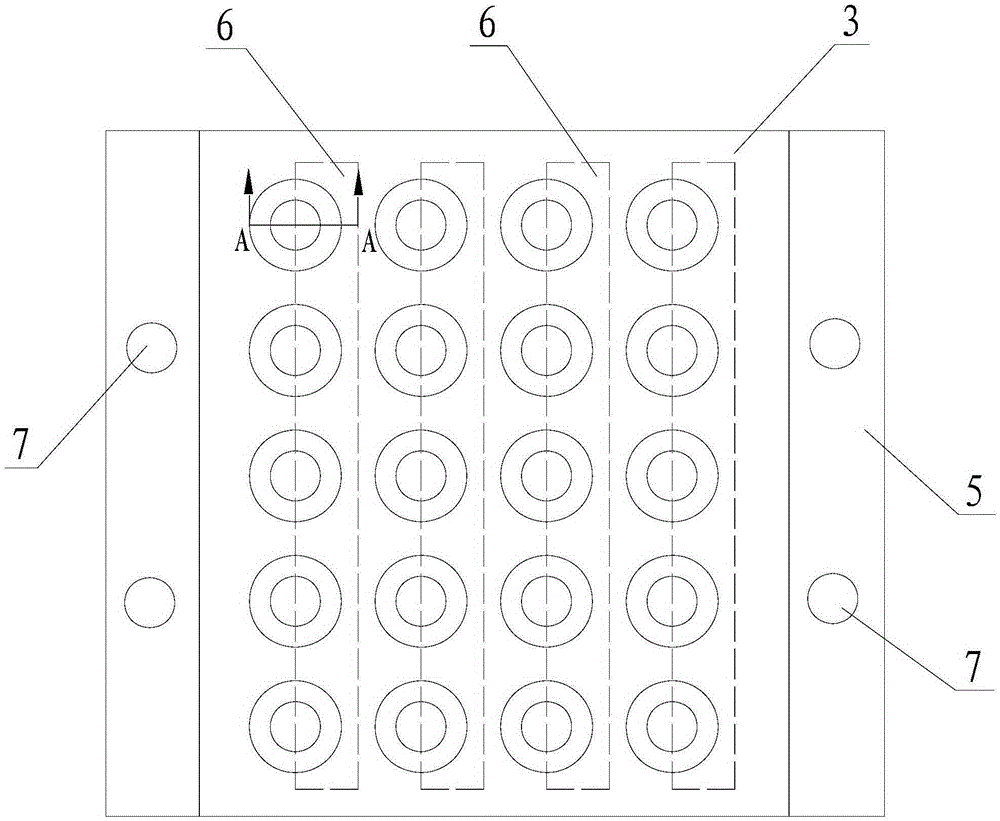

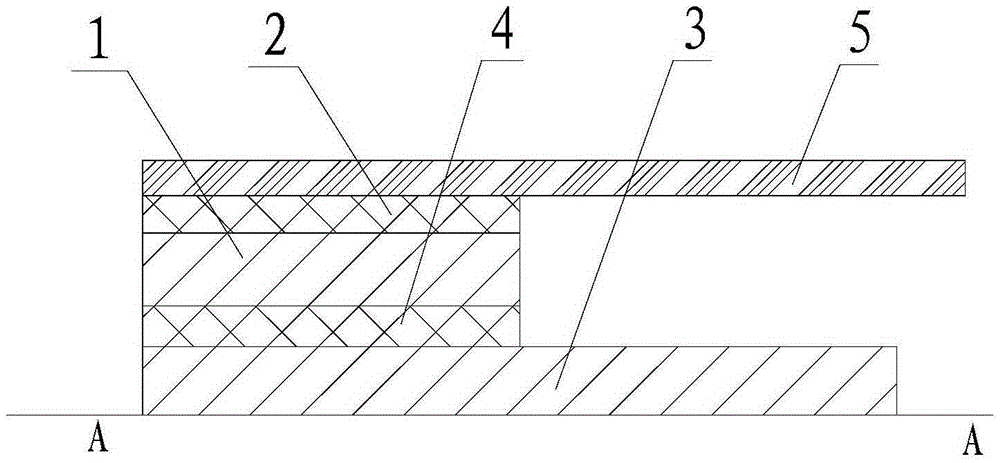

[0023] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] see Figure 1-2 As shown, the above-mentioned cushioning and dustproof foam is used for shock absorption, sealing, waterproof, and dustproof between the camera and the shell cover. The foam includes a semicircular first foam layer 1, pasted on the The second adhesive layer 4 on one side surface of the first foam layer 1, the circular second foam layer 3 pasted on the first foam layer 1 through the second adhesive layer 4, the second adhesive layer 3 through the first adhesive layer 2 the release layer 5 pasted on the surface of the other side of the first foam layer 1, of course, the release layer 5 can also be pasted on the other side of the second foam layer 3, the first foam layer 1 and The inner rings of the second foam layer 3 have the same diameter and are arranged concentrically. In this embodiment, the outer diameters of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com