Patents

Literature

92results about How to "Meet the production process needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

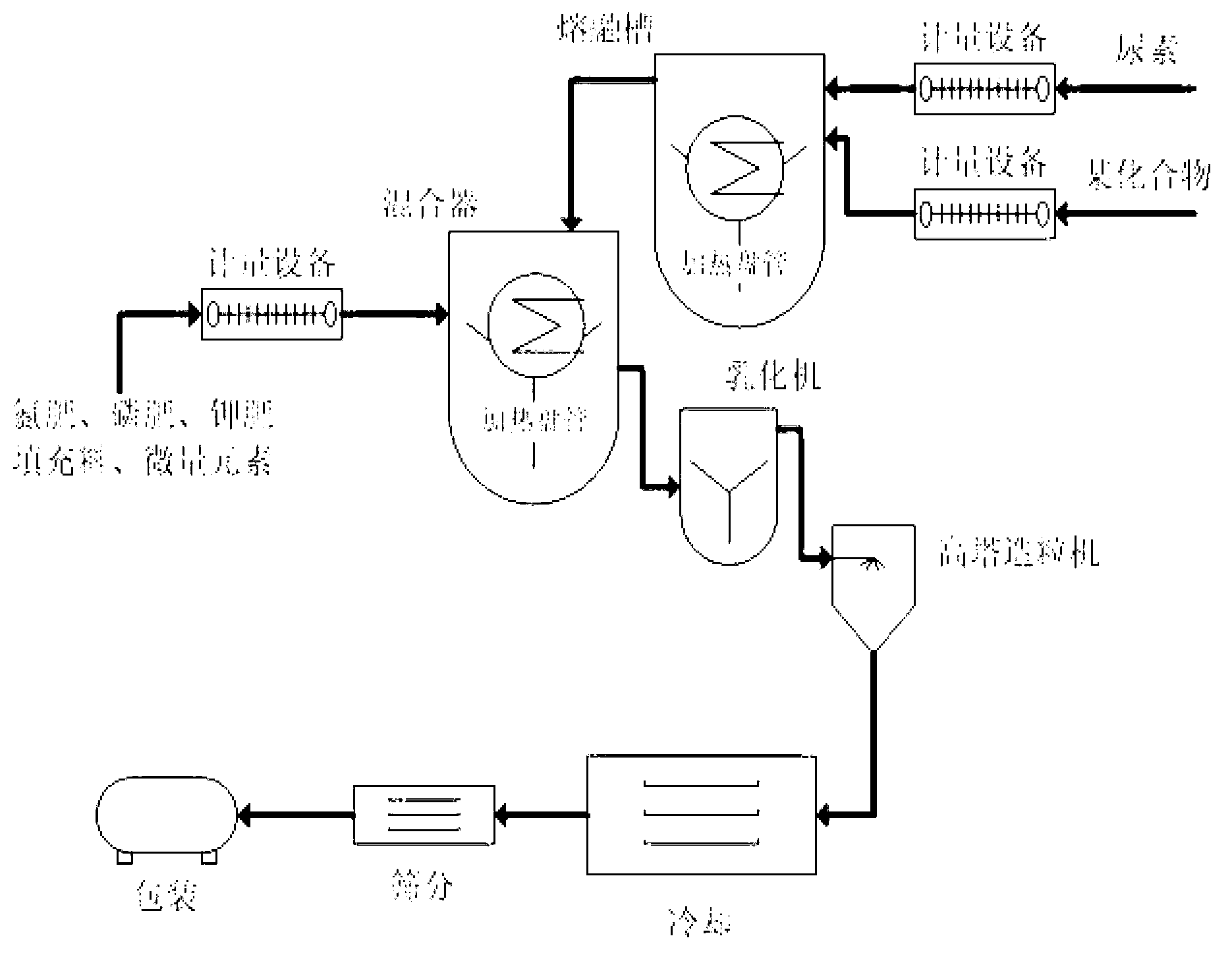

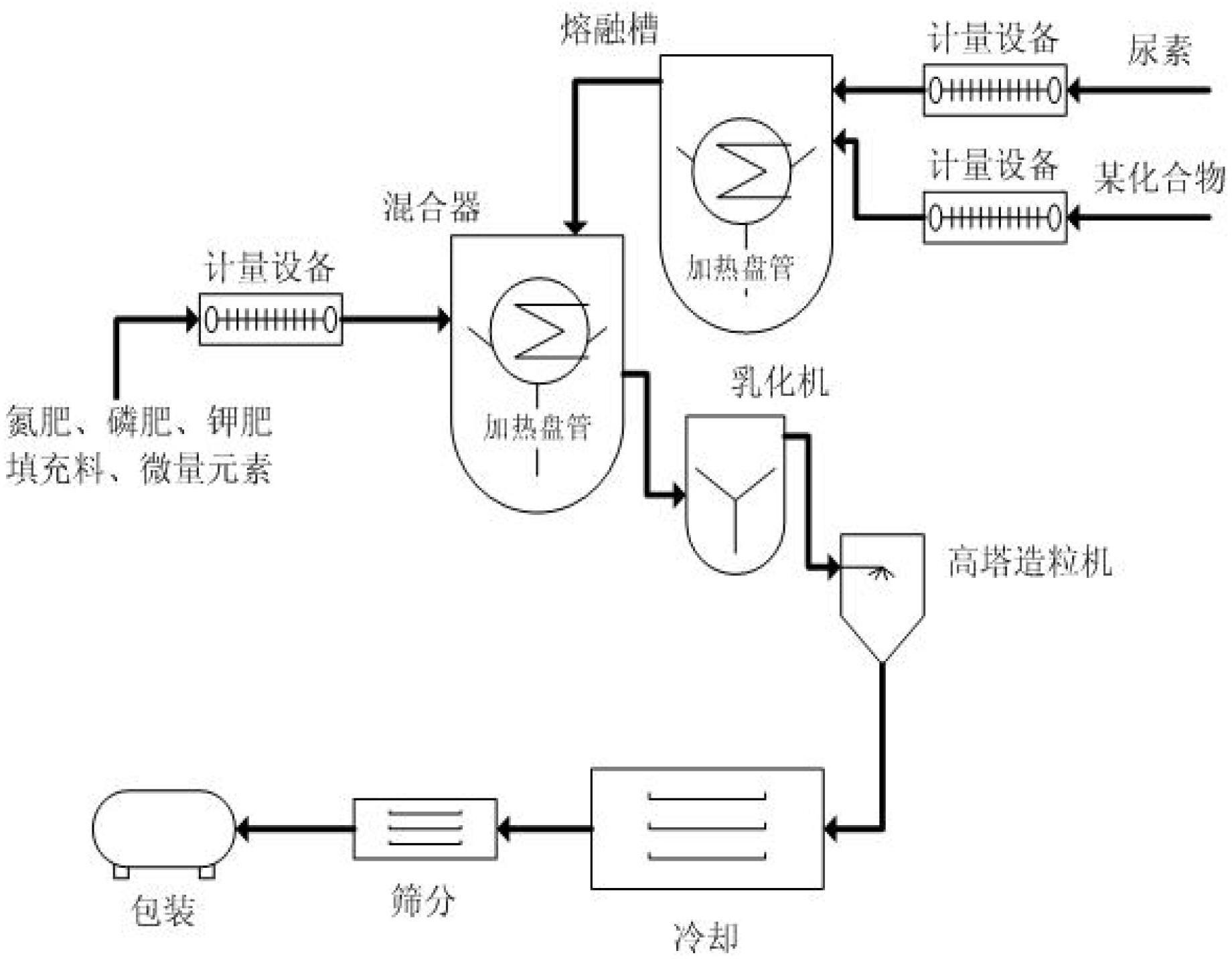

Method for controlling content of biuret in compound fertilizers for melt granulation in prilling tower

InactiveCN102701846AReduce generationReduce production energy consumptionUrea compound fertilisersFertilizer mixturesMelting tankPrill

The invention provides a method for controlling the content of biuret in compound fertilizers for melt granulation in a prilling tower. A low melting point mixture is formed by urea and compounds in a melting tank, and is melted completely at the temperature ranging from 104 to 114 DEG C; nitrogen fertilizers, phosphate fertilizers, potash fertilizers, fillers and trace elements are used for melting urine and production compound fertilizers and are added in a mixer according to product demand ratios, are premixed rapidly under the temperature condition ranging from 90 to 110 DEG C, then are mixed through a slurry emulsifying machine at a high speed so as to form emulsified slurry, and then are processed through the procedures such as granulation, cooling sieving and the like in the prilling tower so as to produce the granular compound fertilizers with low content of biuret; in addition, the content of biuret in the compound fertilizers that are produced by adopting the method is less than 0.6 percent, the quality is safe, and fertilizer damages cannot be caused. The method belongs to a novel environment-friendly production method with low consumption, which can produce the granular compound fertilizers on the basis of urea-based prilling tower melt granulation technology.

Owner:徐州市芭田生态有限公司

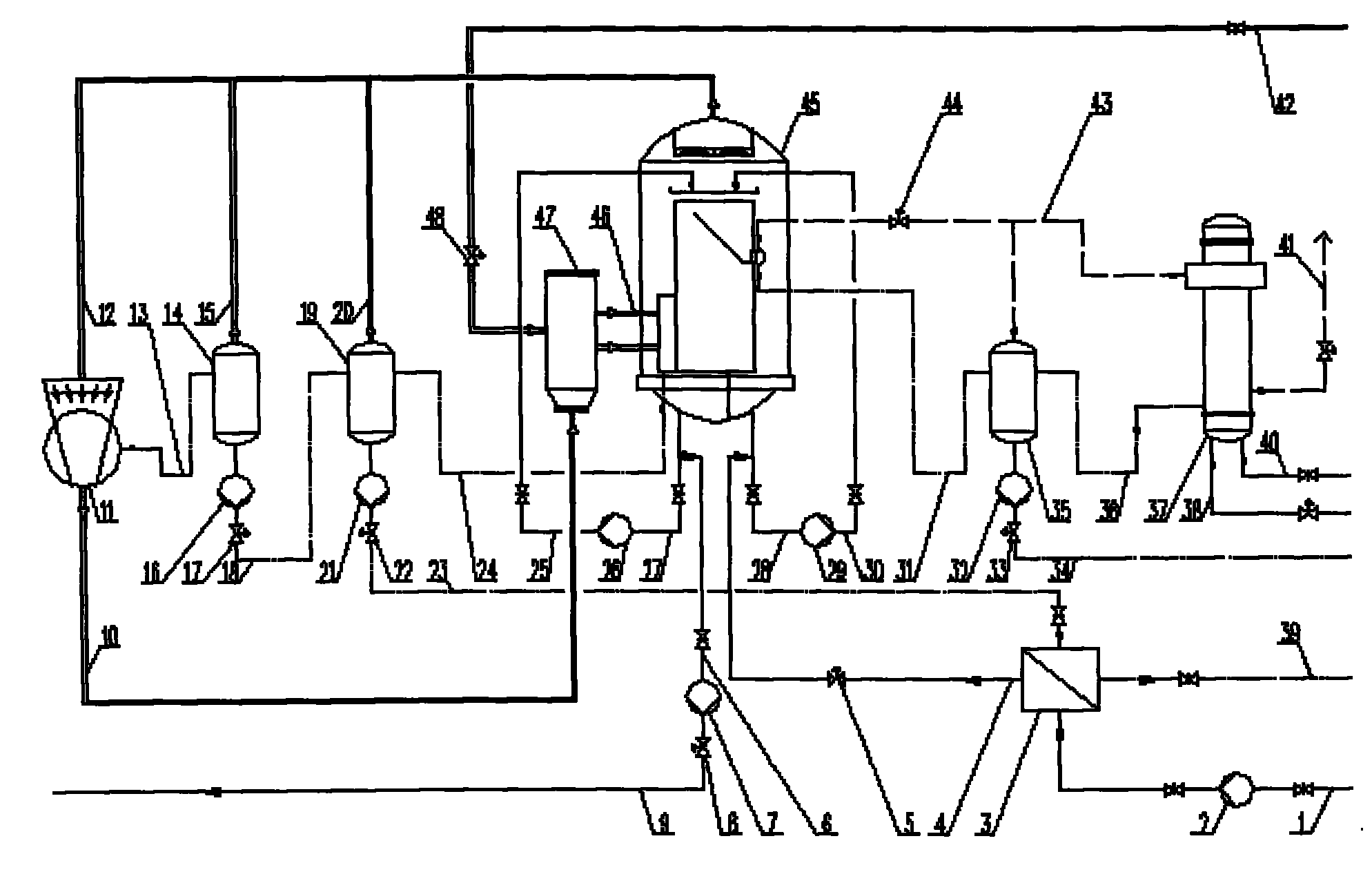

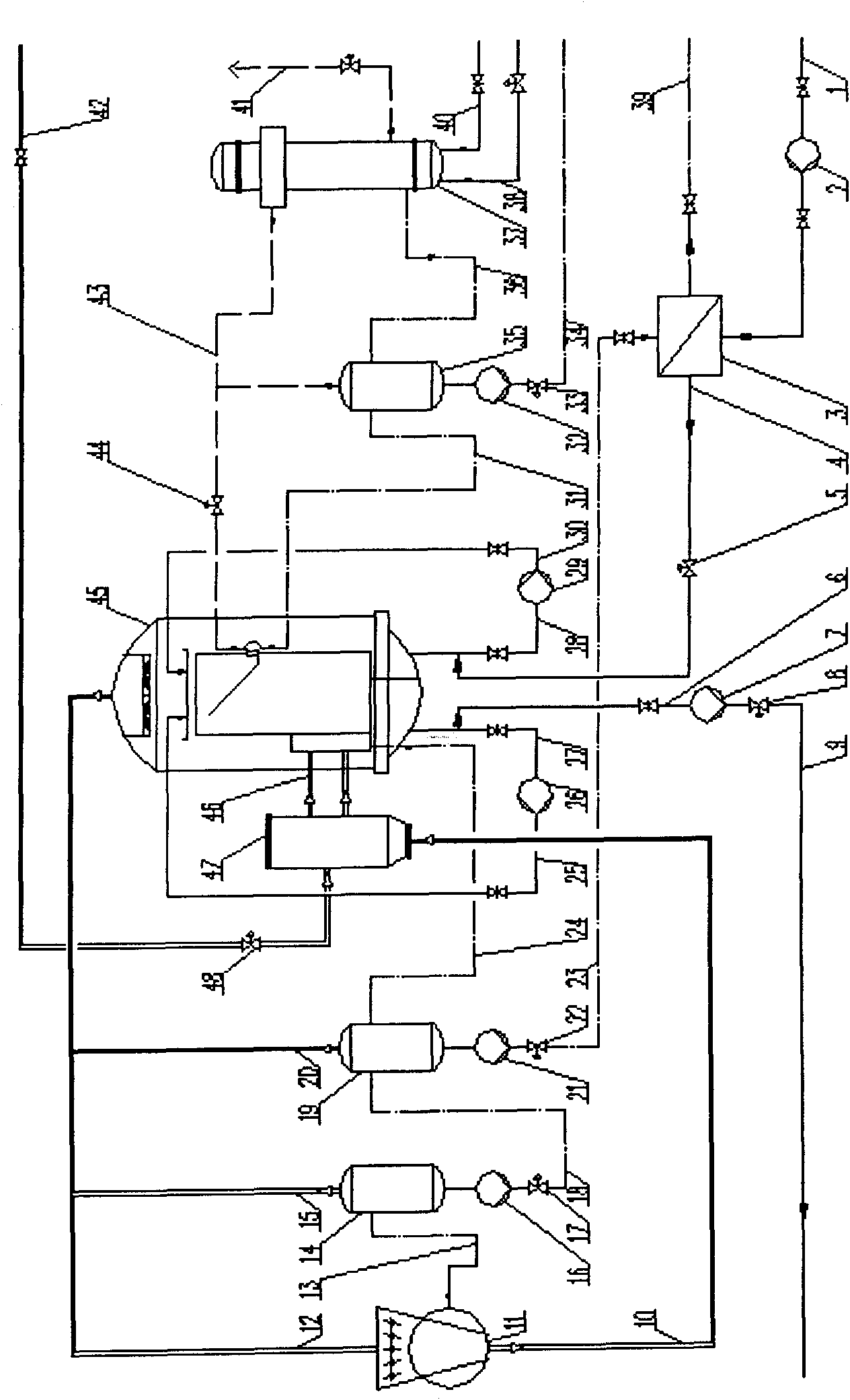

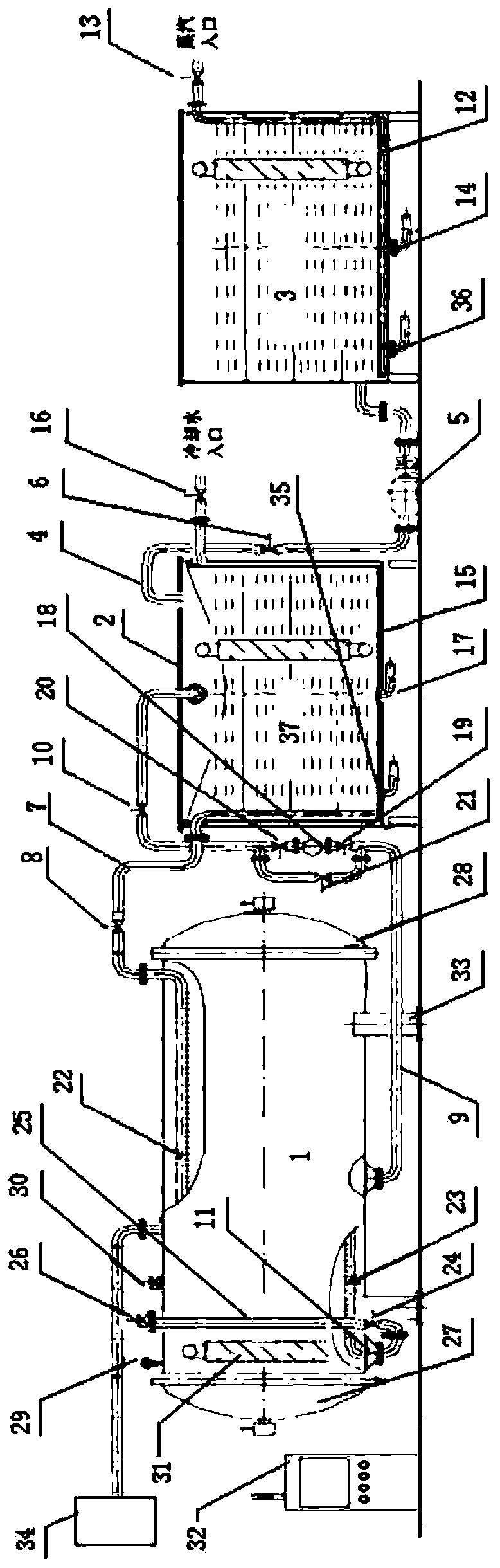

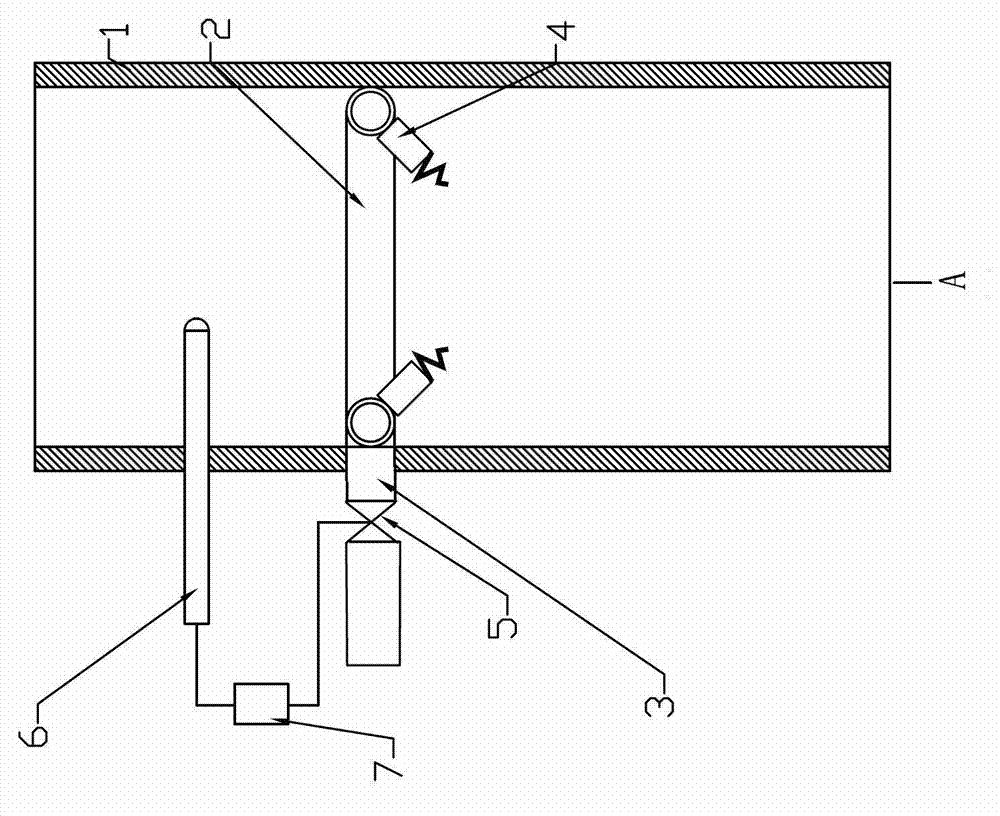

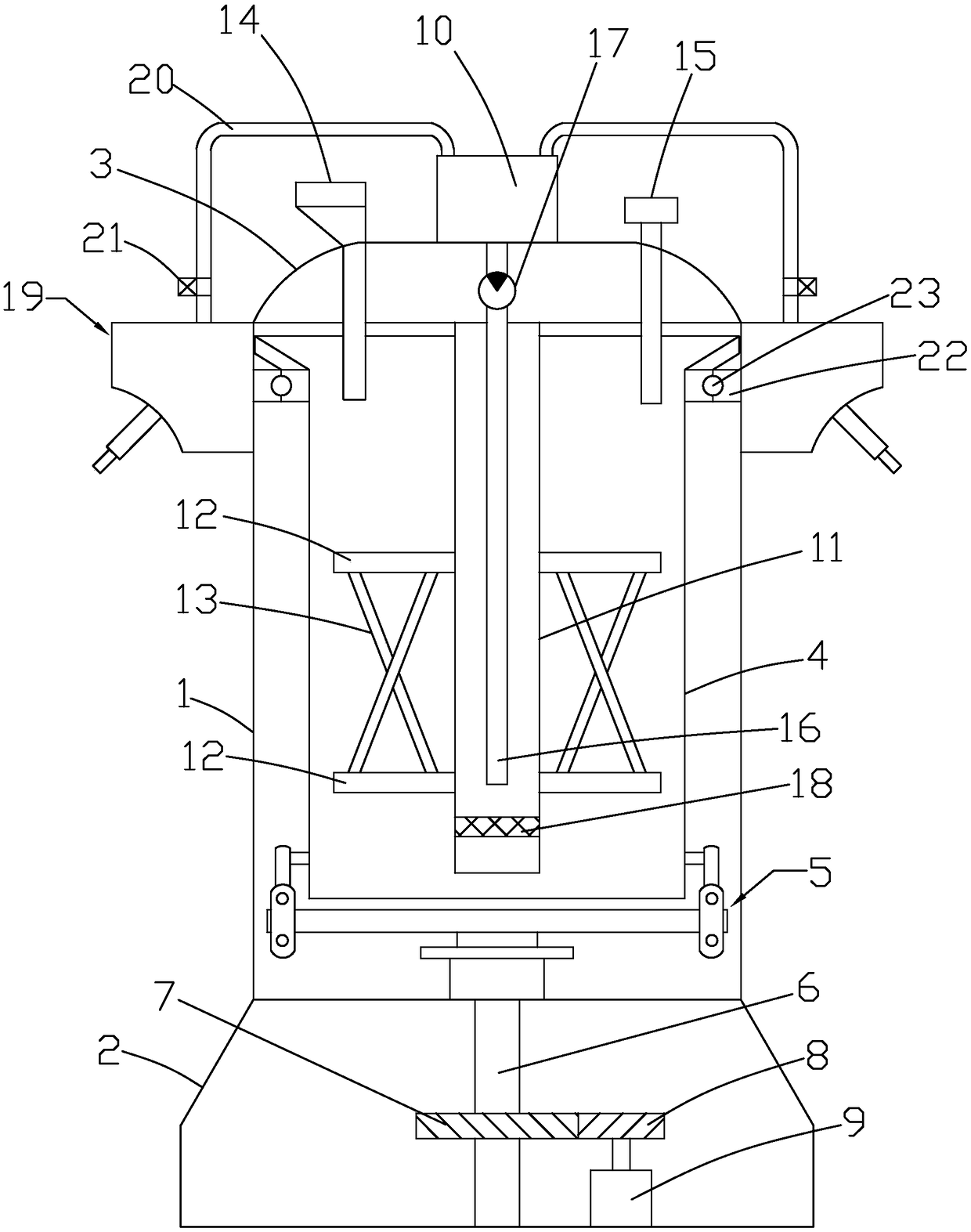

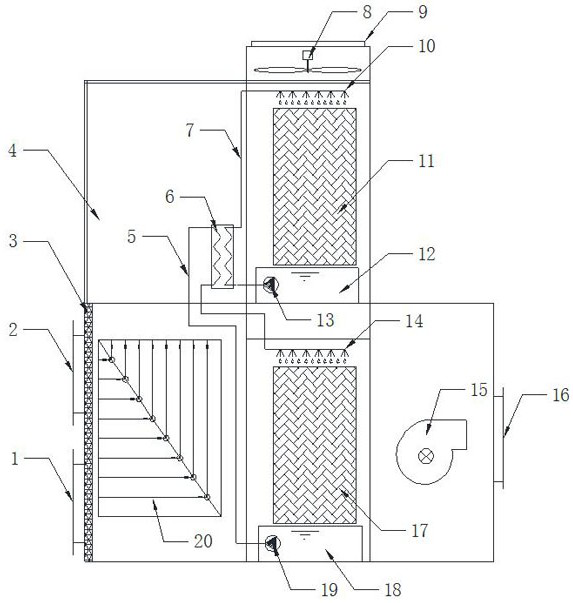

Circulation evaporator

InactiveCN101811743ANon-deterministicLower evaporation temperatureWater/sewage treatment by heatingPapermakingSewage

The invention discloses an evaporator for performing innocent treatment on sewage in industries of papermaking and the like. In an existing device, a secondary steam pipe is connected to an inlet of a compressor; an outlet of the compressor is connected with a steam inlet of a steady head tank; the other steam inlet pipe of the steady head tank is connected with a fresh steam pipe of a boiler; a steam outlet of the steady head tank is connected with a falling-film evaporator which is at least provided with one circulating pipe connected with a circulating pump; an outlet of a stripper plant of the falling-film evaporator is communicated with a non-condensable air pipe and a heavily-polluted condensate water outlet pipe which is communicated with a water inlet of a heavily-polluted condensate water tank; a water outlet of the heavily-polluted condensate water tank is communicated with a heavily-polluted condensate water delivery pipe; and a condensation water outlet pipe of a condenser is communicated with the water inlet of the heavily-polluted condensate water tank.

Owner:兰州节能环保工程有限责任公司 +1

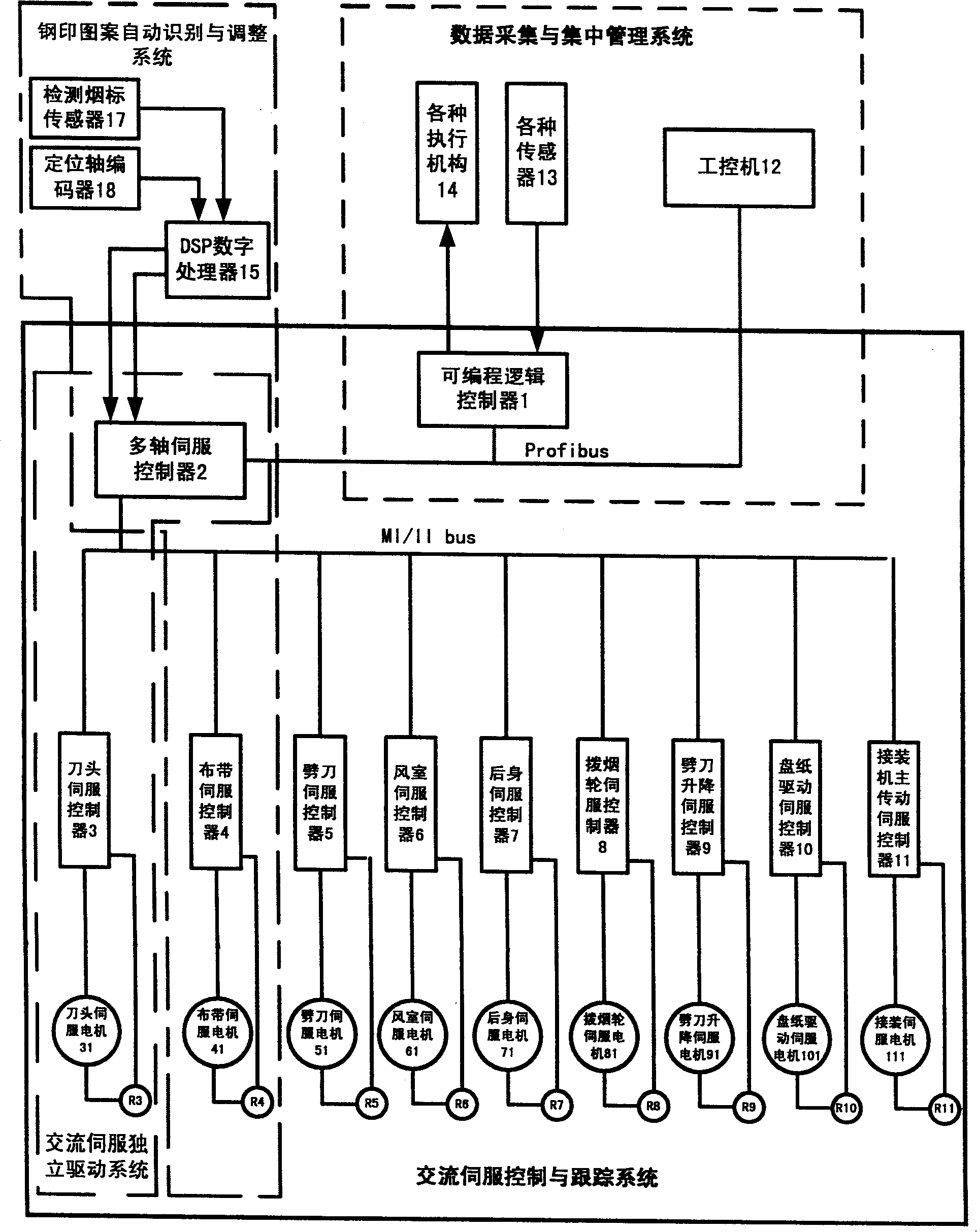

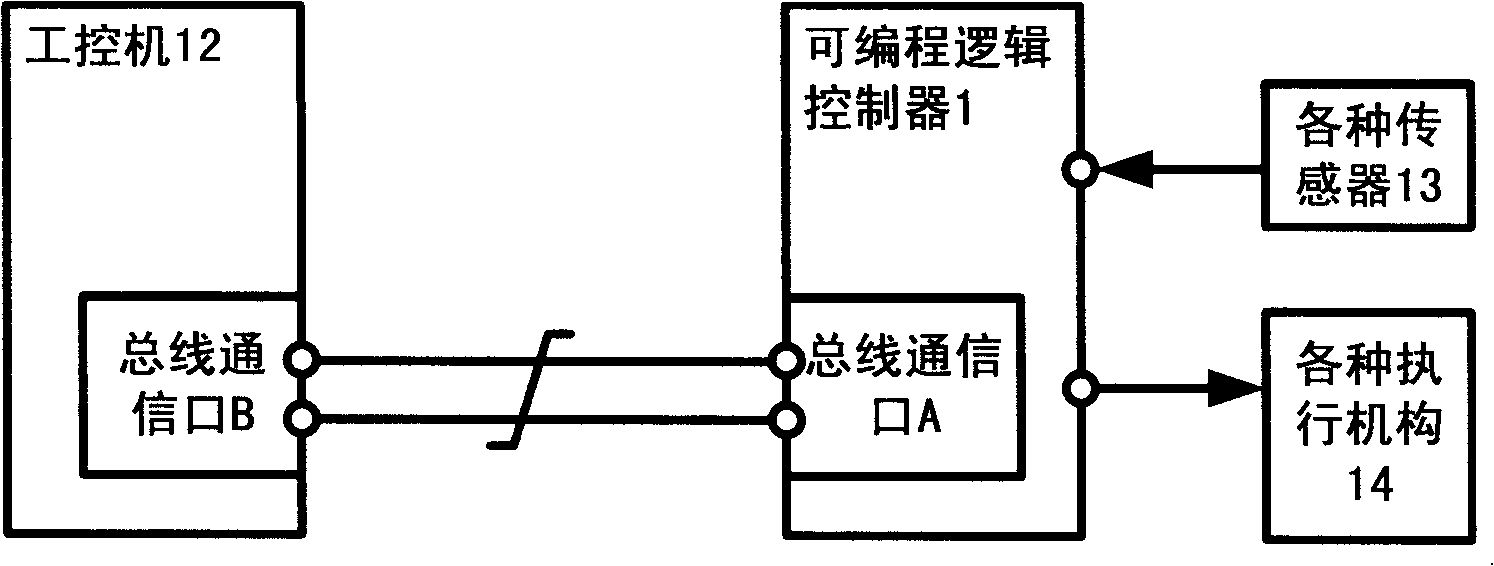

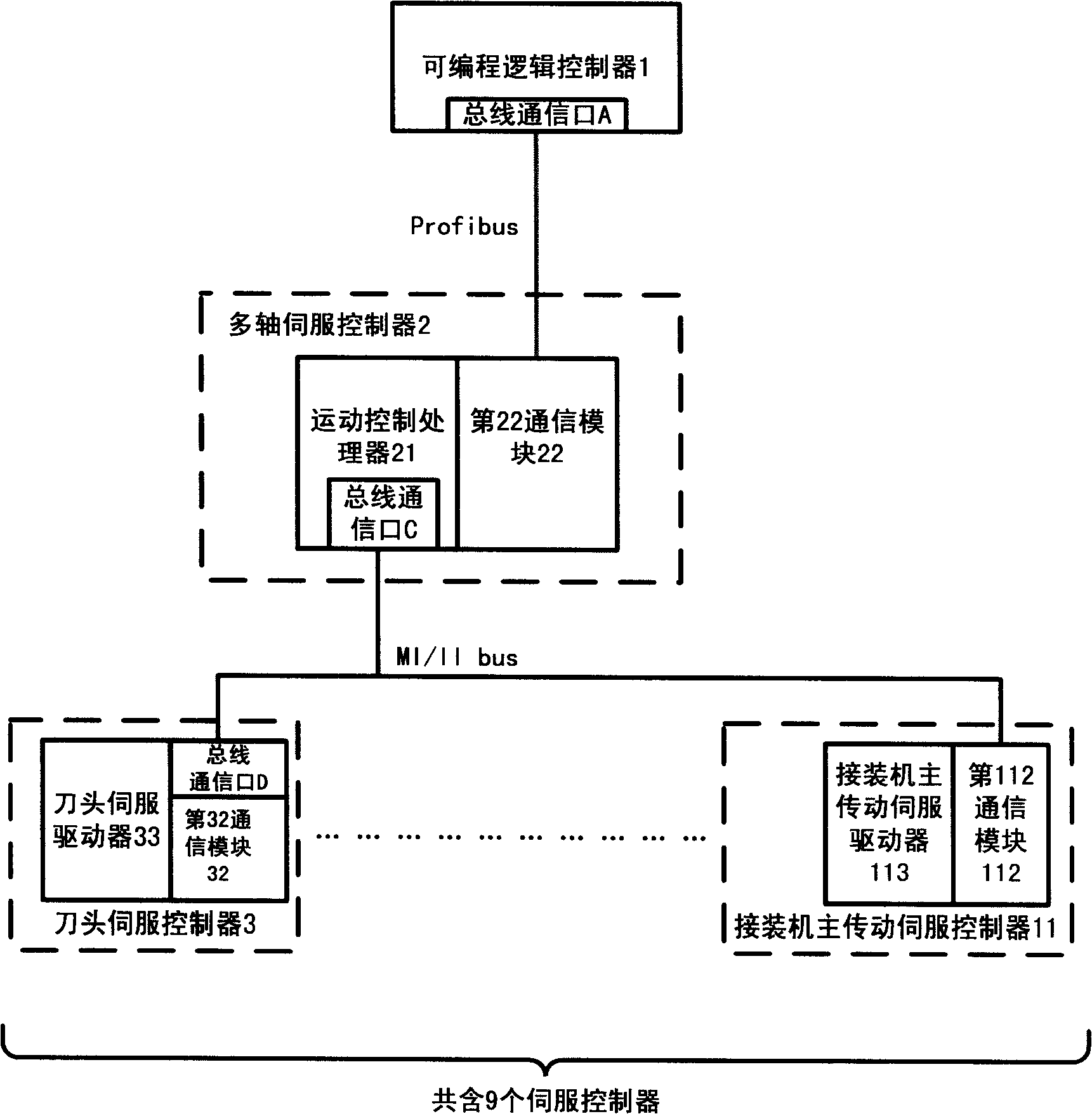

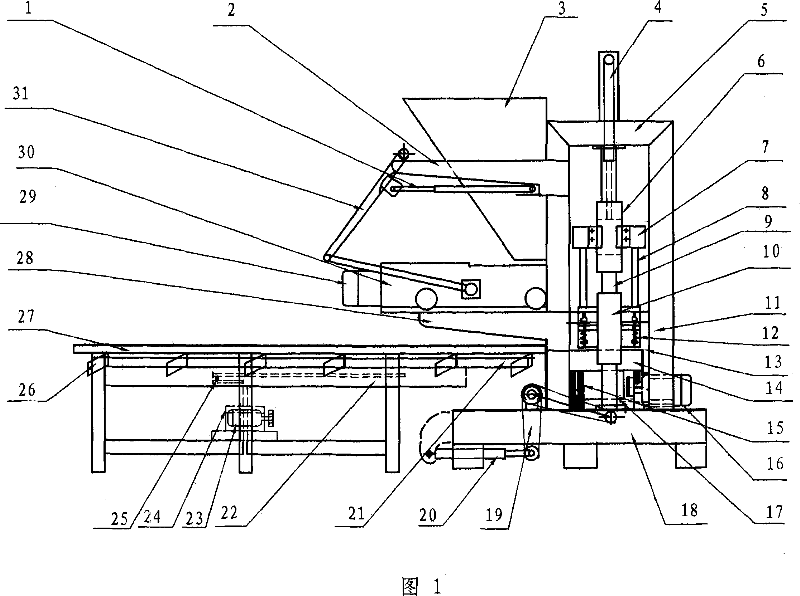

Cigarette producing method and intelligent cigarette machine group thereof

InactiveCN101297714AFacilitate intelligent managementWith centralized control functionComputer controlCigarette manufactureProgrammable logic controllerData acquisition

The invention relates to a cigarette production method and an intelligent cigarette machine set thereof, comprising a data collecting, centralized control and management system which takes an industrial computer and a programmable logic controller (PLC) as a control core, an AC servo control and tracking system which takes a multi shaft servo controller as the control core, an independent AC servo driving system and an automatic stamp mark identifying and adjusting system which takes a DSP digital signal processor as a core, wherein, the input signal of the data collecting, centralized control and management system is a detection signal and is electrically connected with the multi shaft servo controller in the AC servo control and tracking system, meanwhile, the multi shaft servo controller is electrically connected with a servo controller in the independent AC servo driving system, thus realizing the driving of a servo motor in the independent AC servo driving system; the automatic stamp mark identifying and adjusting system receives the signals of a locating shaft encoder and a cigarette mark-detection sensor and outputs the signals to an independent strap servo driving system, thus finishing the relative position adjustment of the stamp mark and realizing the high-speed cigarette production with the real time dynamic adjusting of the stamp mark.

Owner:CHINA TOBACCO SHANDONG IND +1

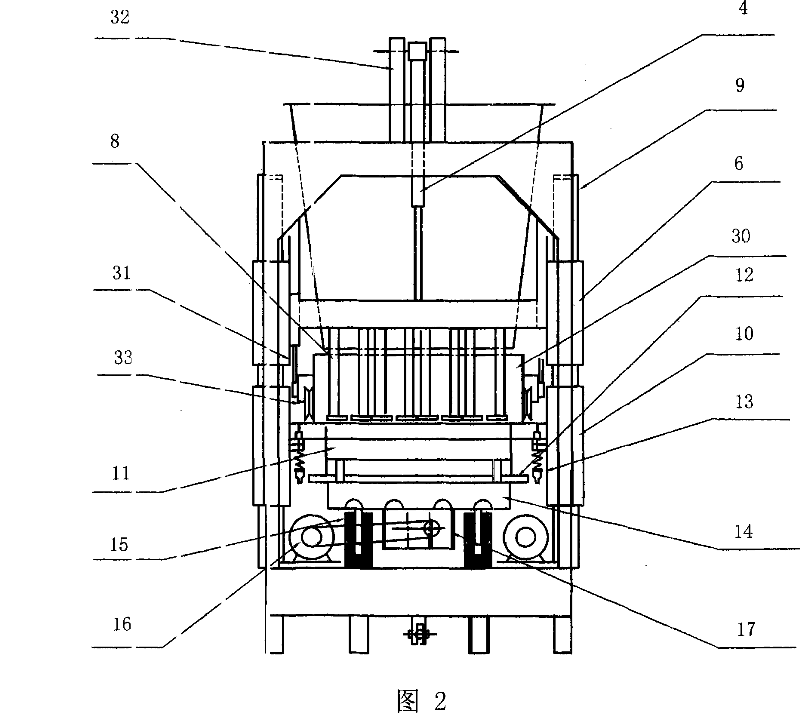

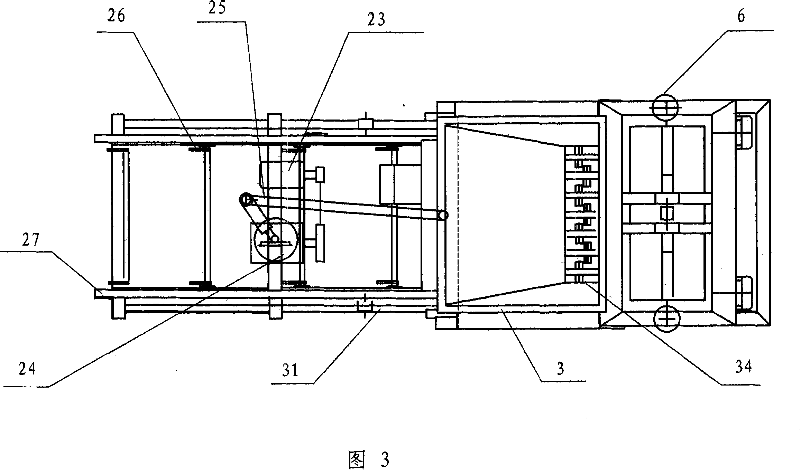

Full-automatic small type block machinery having environment-protecting and energy-saving functions

InactiveCN101037009ALow costReduce power consumptionDischarging arrangementCeramic shaping plantsElectricityManufacturing technology

A full automation minitype building block forming machine with environmental protection and conservation of energy, belongs to machine manufacturing technology field, while relates to machine, electricity, fluid, magnetism technology. The invention includes a storing module system, a distributing module system, a building block forming module system, a hydraulic pressure demouding module system and a feeding plate module system; the storing module system is provided on the topest part of the rectangle machine frame, the distributing module system is provided on the lower part of the storing module system, both are connected by automatic discharge tube of the storing box, the forming module system is provided on the lower part of the distributing module system, and is connected to the distributing module system by the discharge port of the distributing box, the hydraulic pressure demouding module system is provided on the lower part of the forming module system, and is connected to the forming module system by the crank connecting rod and, the feeding plate module system is provided on the side lower part of the forming module system, and is connected to the forming module system by the bearing plate conveying car. The invention has advantages of small investment, low energy consume, high automation degree, low cost of produced building block and so on.

Owner:HEBEI AGRICULTURAL UNIV.

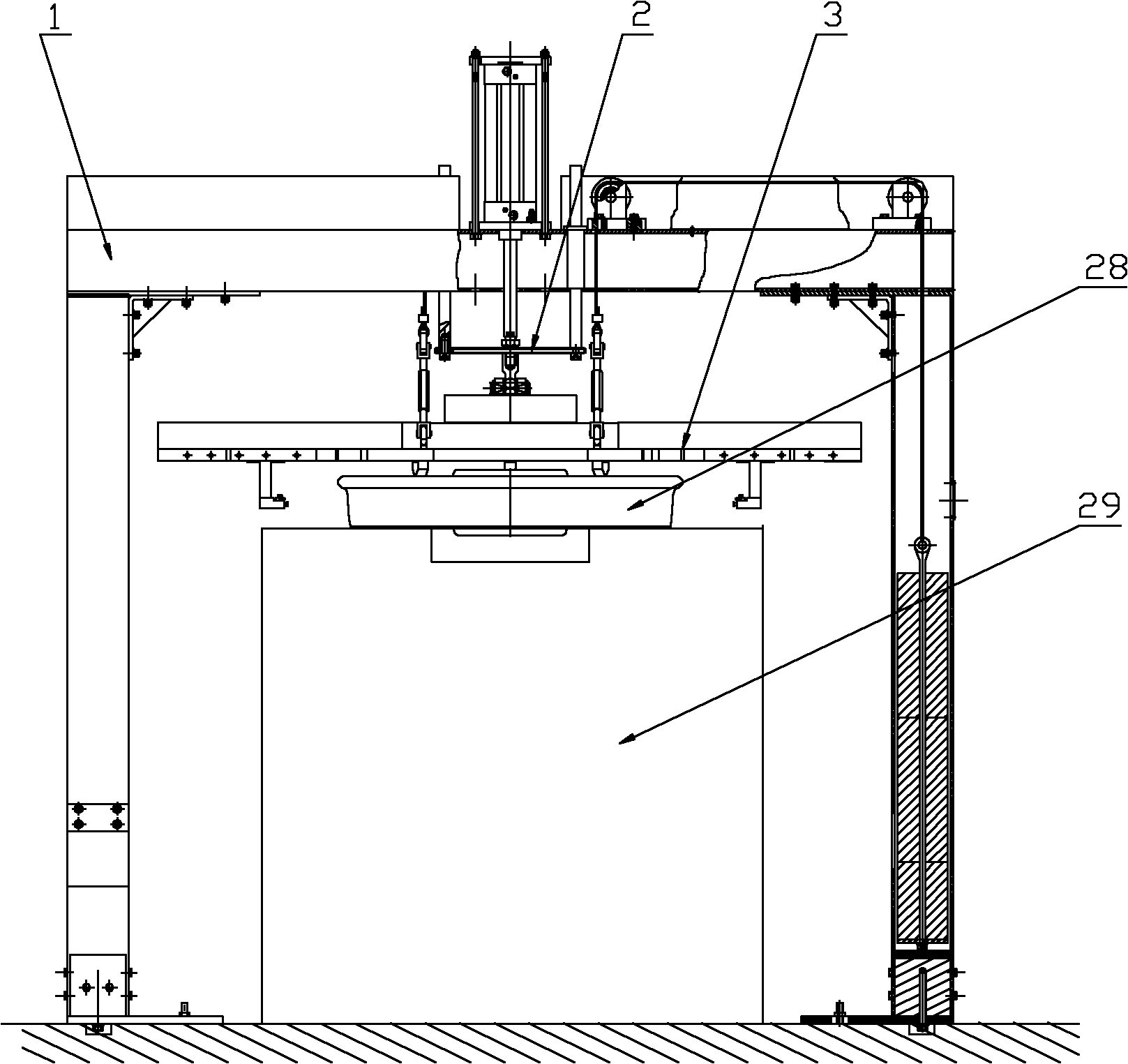

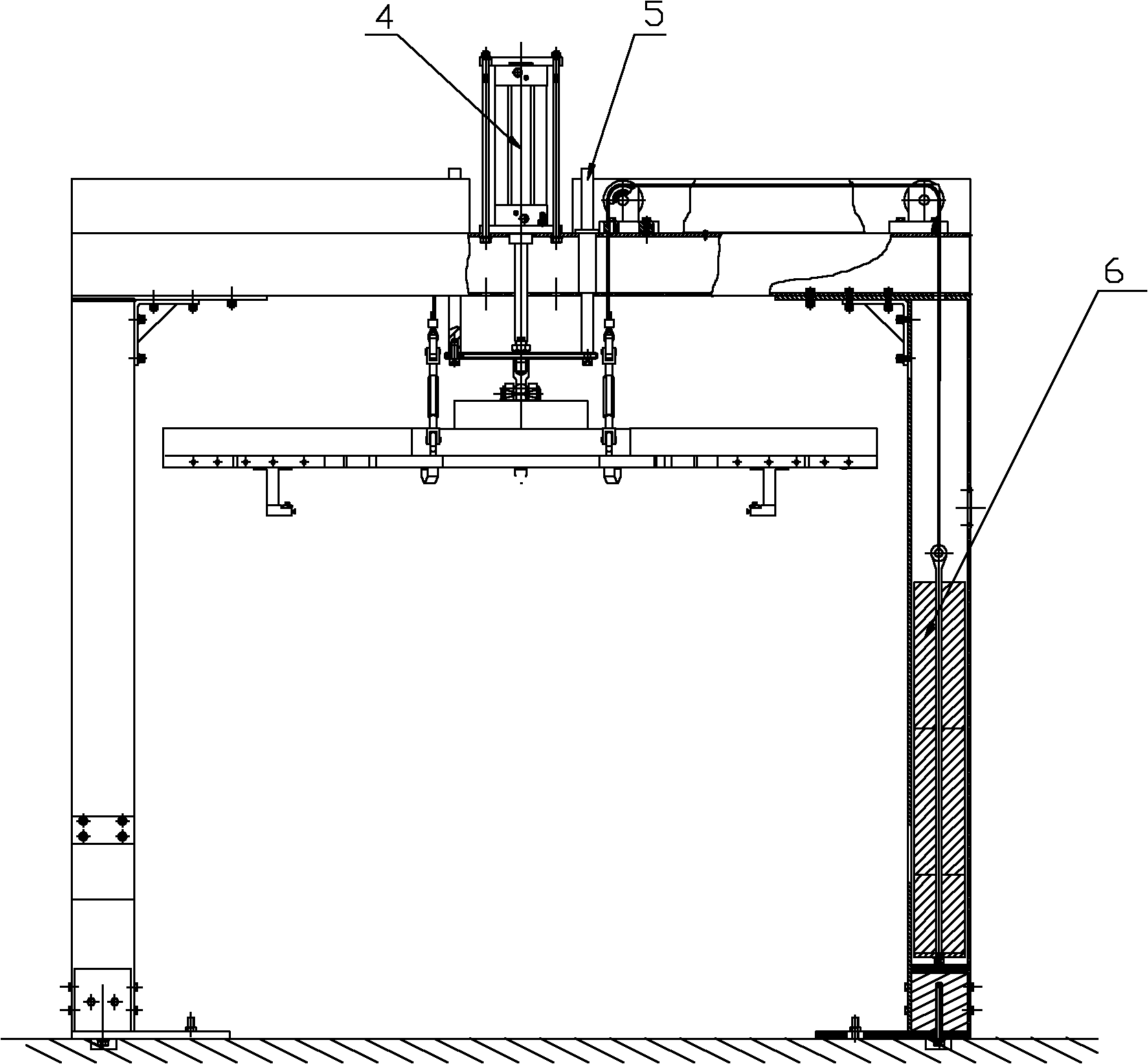

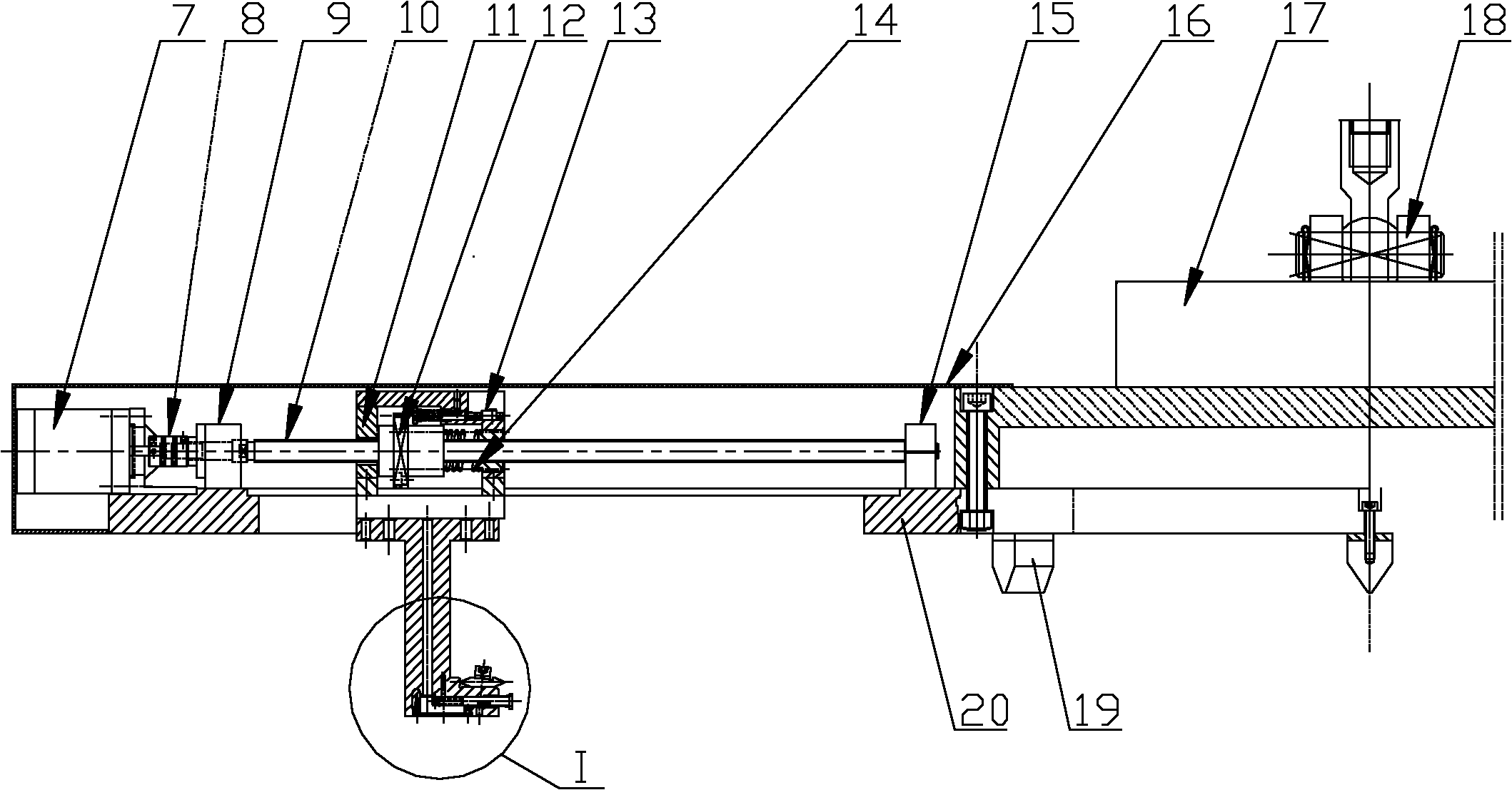

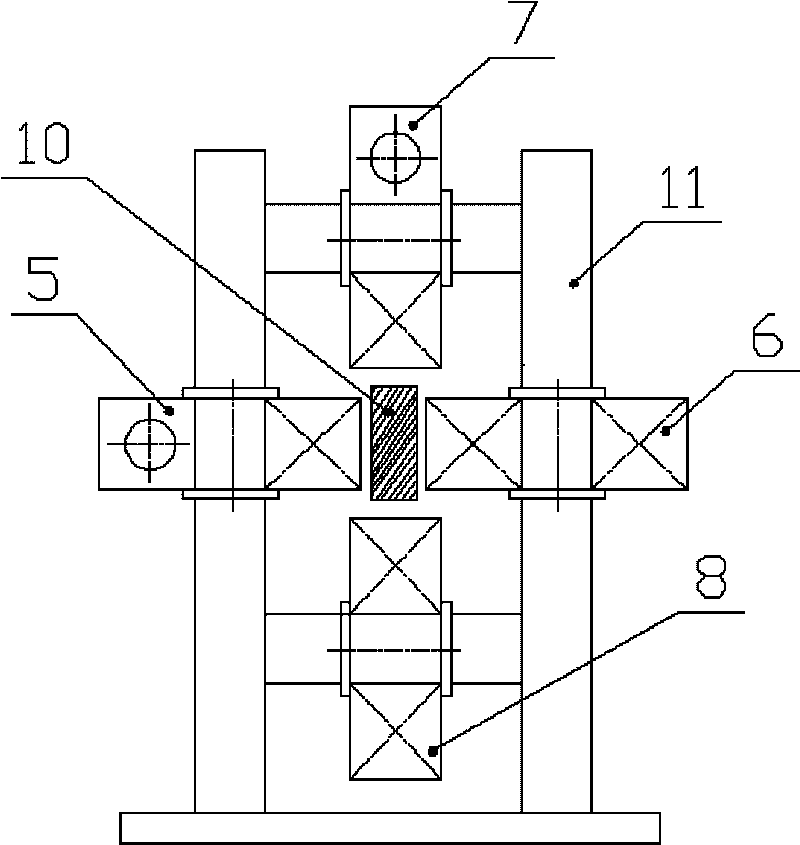

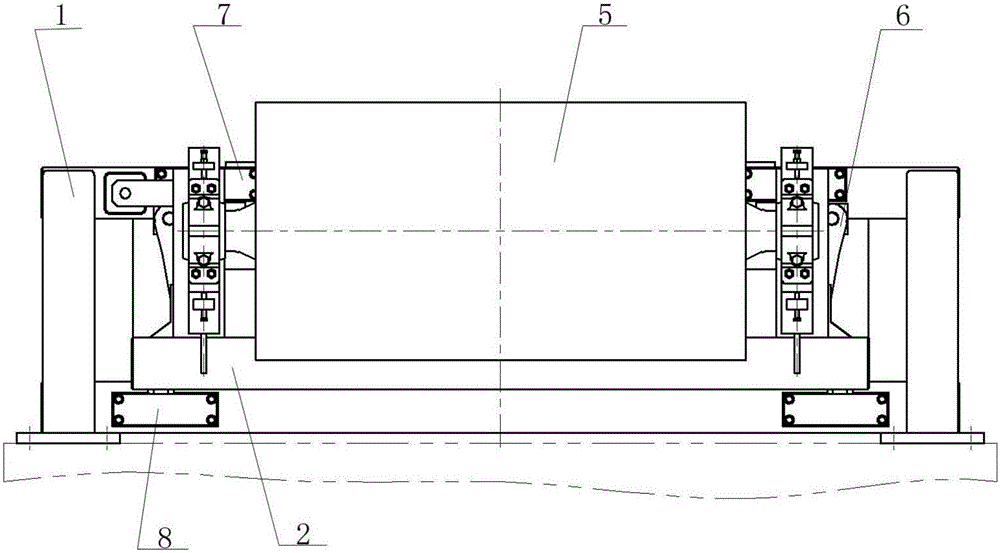

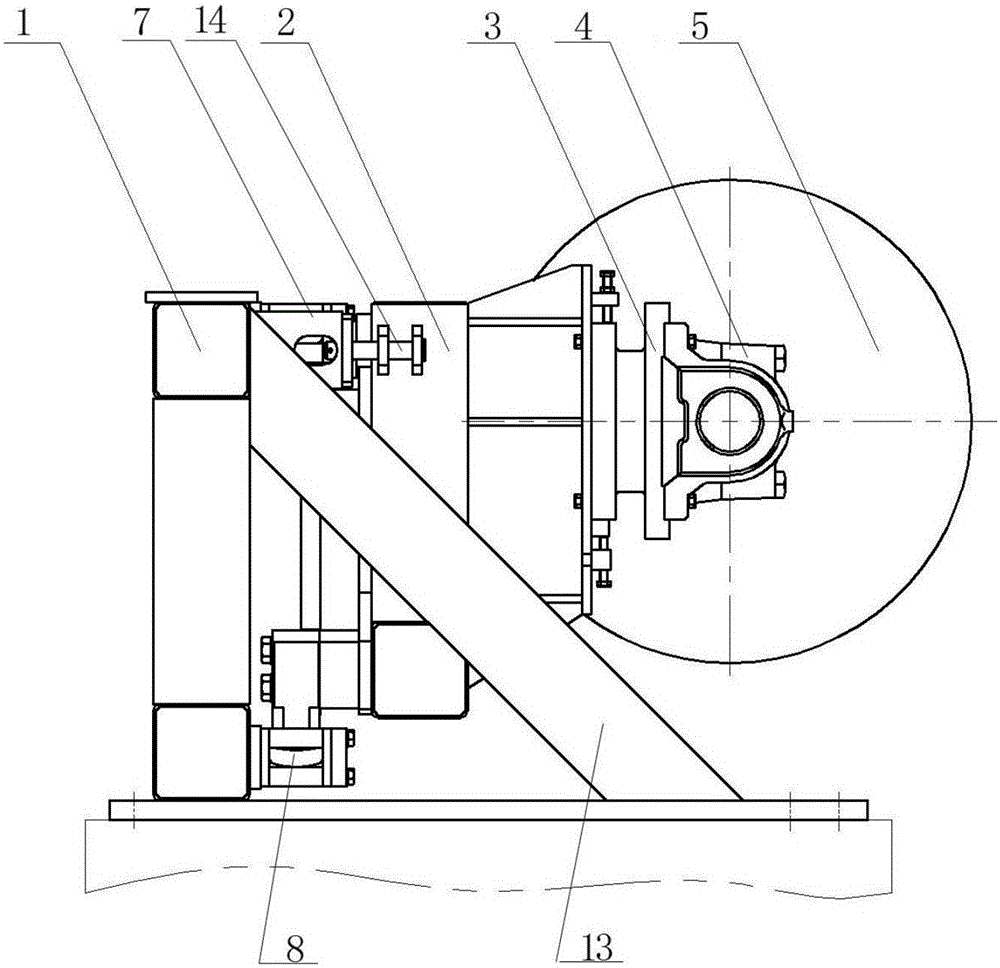

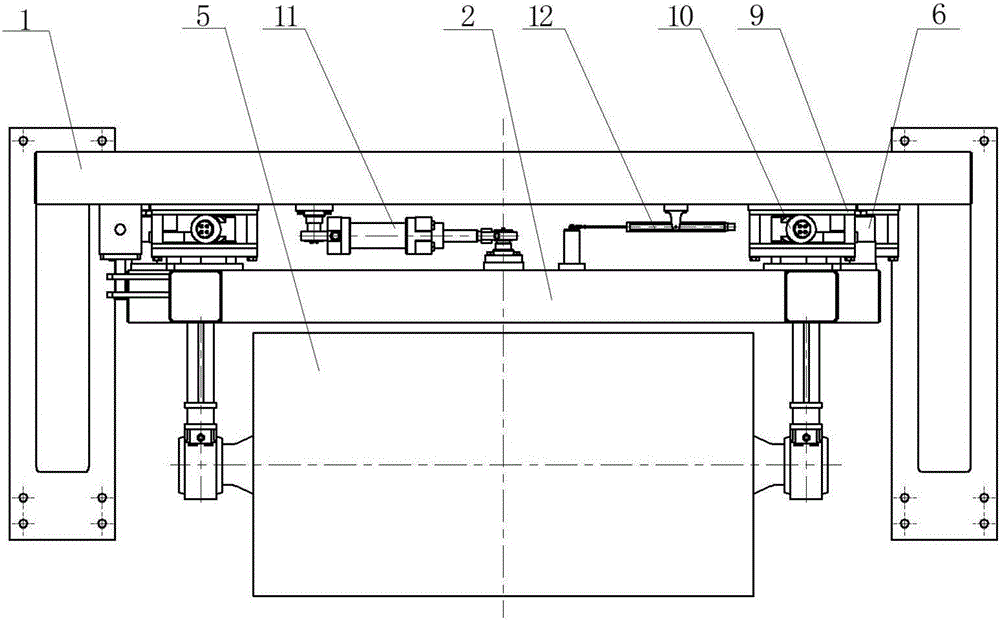

Device for automatically measuring outer diameter of vehicle wheel on line and measurement method thereof

ActiveCN102147235AHigh measurement accuracyHigh precisionUsing optical meansMeasurement deviceDevice Wheel

The invention discloses a device for automatically measuring an outer diameter of a vehicle wheel on line and a measurement method of the outer diameter of the vehicle wheel. The device for automatically measuring the outer diameter of the vehicle wheel on line is mounted on a vehicle wheel finished product detection line conveyor roller, and comprises a bracket, a lifting mechanism and a measurement mechanism. The bracket is in a door-type structure and is spanned on the conveyor roller; the lifting mechanism is mounted in the middle of the bracket to complete the lifting movement of the measurement mechanism; the measurement mechanism is mounted below the lifting mechanism, and comprises measurement heads positioned at two ends of a measurement mechanism body for measuring the outer diameter of the vehicle wheel; and each measurement head moves back and forth along a linear guide rail mounted below the measurement mechanism body, and a moving distance of each measurement head is read by a grating ruler mounted on the measurement mechanism body, and an original point is calibrated by a standard gauge. By the device for automatically measuring the outer diameter of the vehicle wheel on line with the special structure, a device for measuring disc parts is more perfect, the measurement precision is improved to 0.05mm, so the measurement precision is greatly improved, and the production technology requirements are met.

Owner:MAANSHAN IRON & STEEL CO LTD

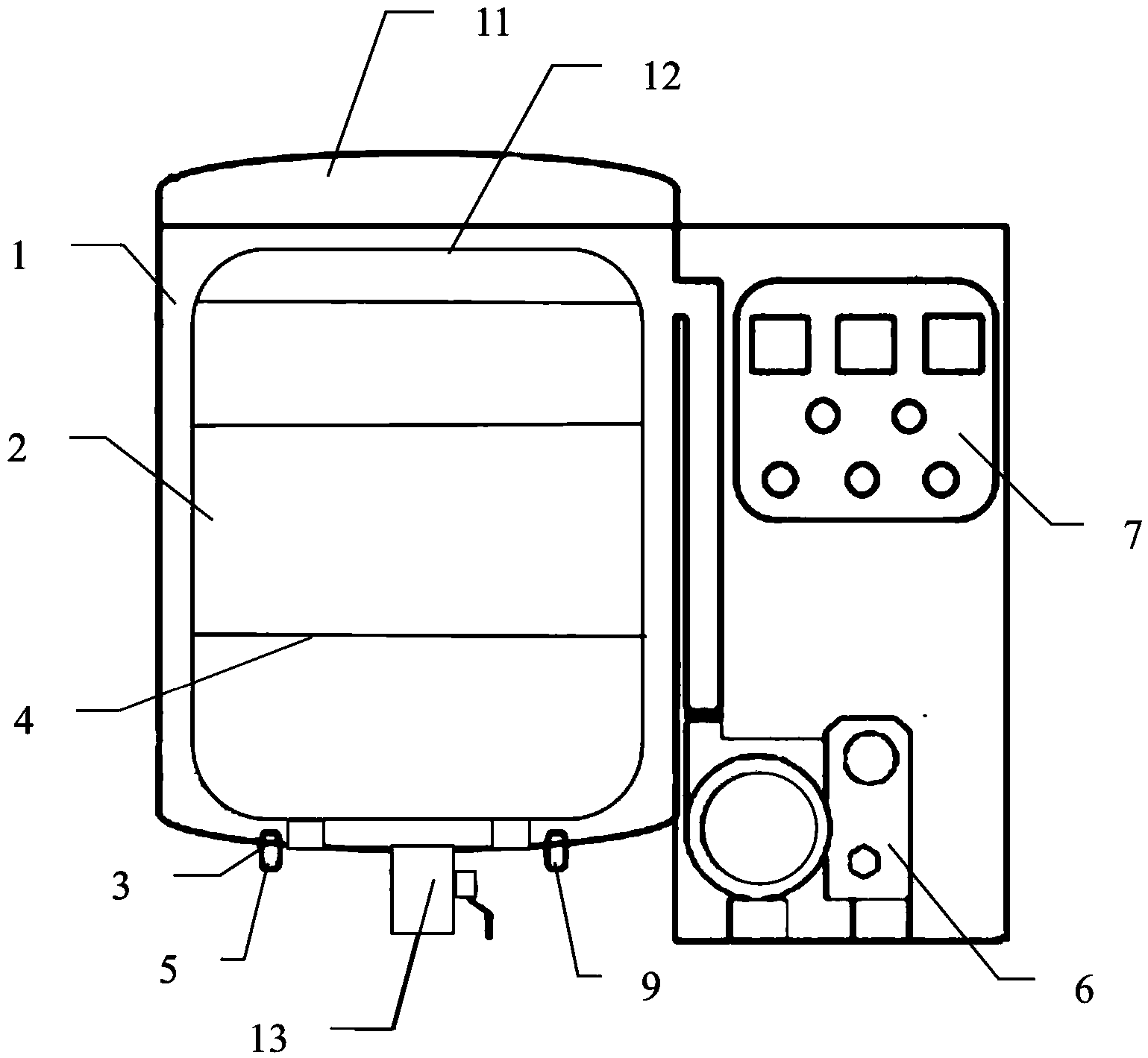

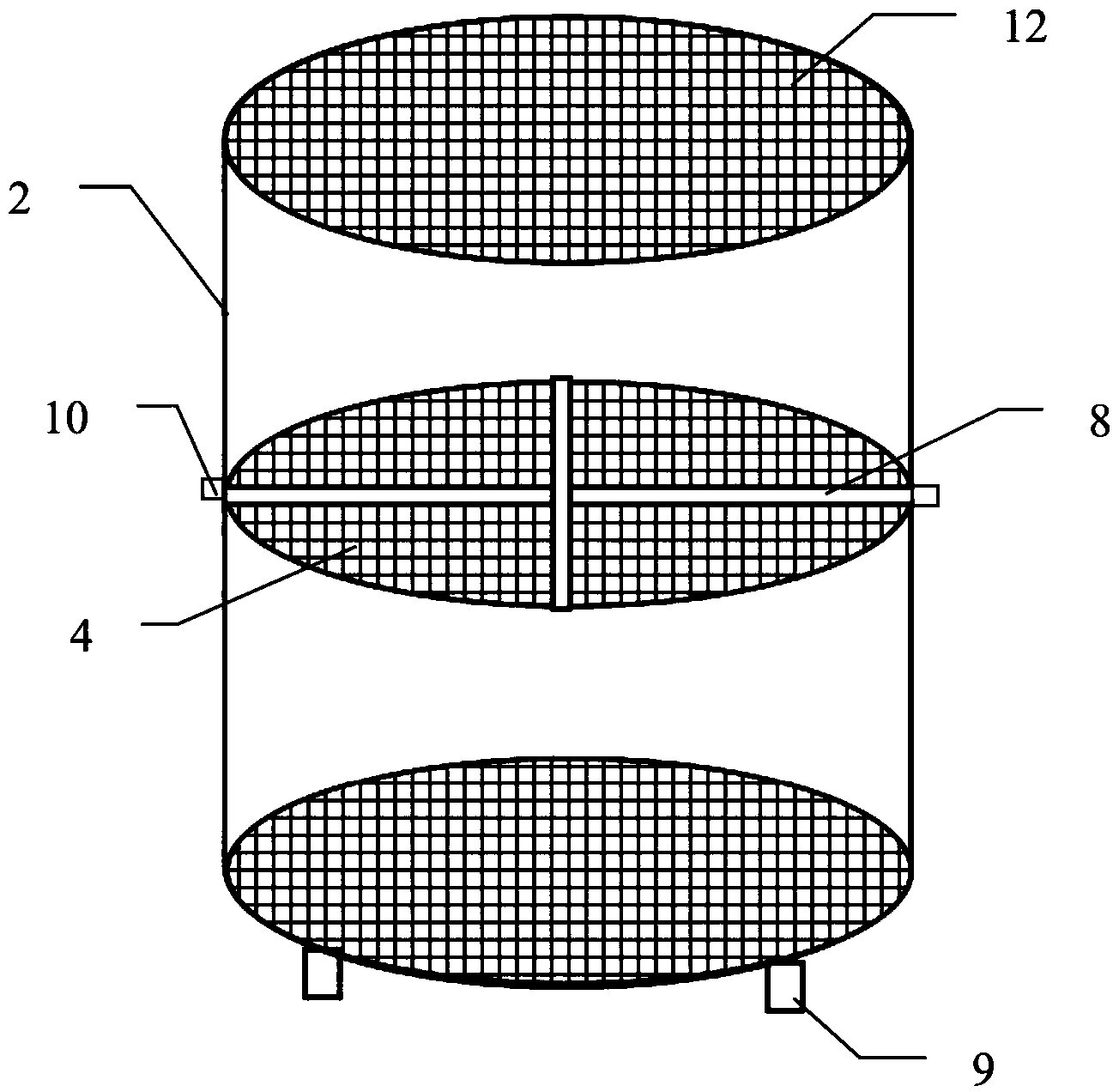

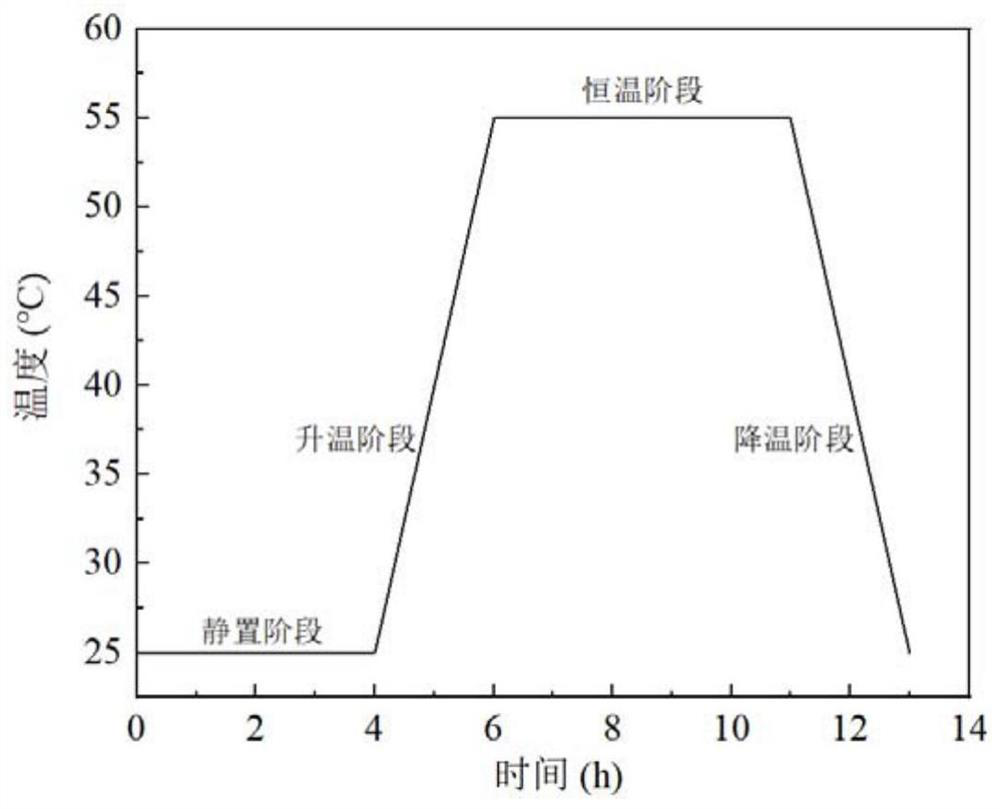

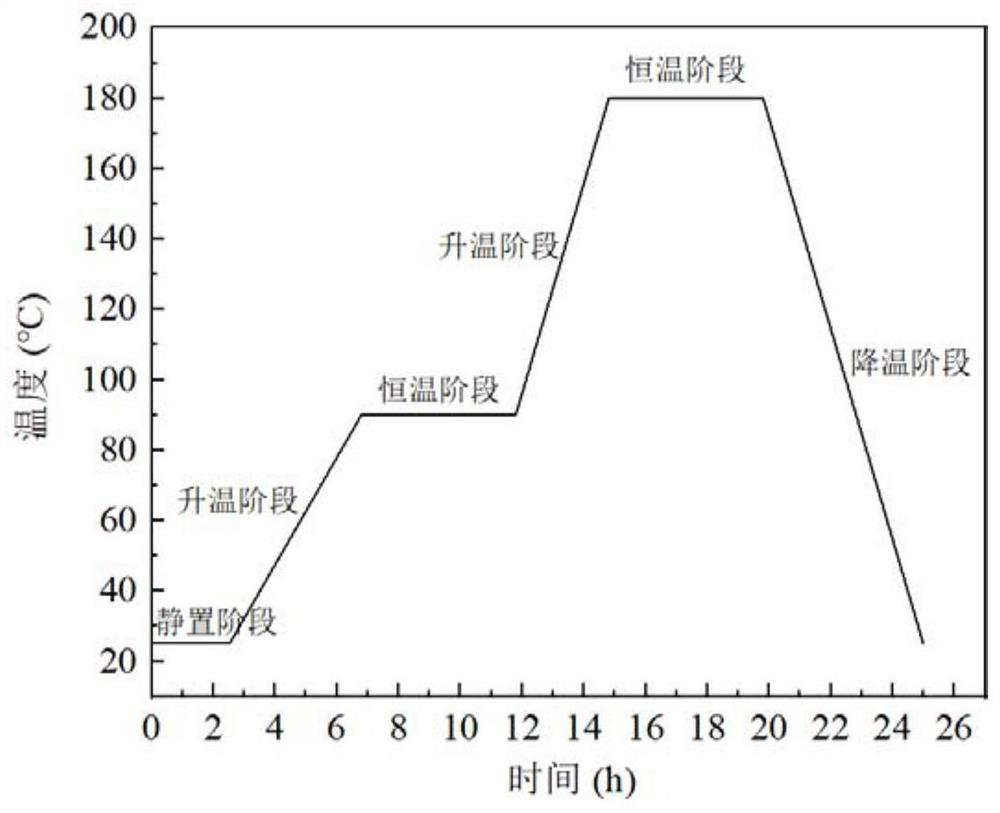

Transformation static curing equipment for foods and curing method thereof

ActiveCN104256848AIncrease impactAccelerate the speed of penetration into the tissue of the material to be marinatedFood preservationPositive pressureEngineering

The invention discloses transformation static curing equipment for foods and a curing method thereof. A pressure regulation device which is capable of increasing or decreasing pressure in a curing pot is connected onto the curing pot; by utilizing pressure change in the curing pot, the materials to be cured are cured; particularly, when the curing pressure in the curing pot changes from negative pressure to positive pressure, the impact of the curing liquid entering into the materials to be cured is enlarged, so that the speed of the curing liquid permeating into the tissues of the materials to be cured is accelerated, the curing efficiency is improved and the requirements of the production process are satisfied. Moreover, the curing pot is designed into a double-layer structure of a latticed inner cylinder, and latticed separation plates are added in the inner cylinder to divide the inner cylinder into a plurality of communicated curing units, so that the structural strength of the curing pot is effectively improved, the extrusion between the materials to be cured can be decreased and the integrity of the cured materials is kept.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Static pressure-variable pickling system

The invention discloses a static pressure-variable pickling system. The static pressure-variable pickling system comprises a pickling tank, a pickling liquid stewing pool, a cooling storage pool and a control system, wherein the pickling liquid stewing pool, the cooling storage pool and the pickling tank are sequentially communicated with one another through liquid transmission pipelines, a pressure regulating device which conducts air exhaust and inflation on a tank body is arranged at the top end of the pickling tank, and the pressure regulating device is electrically connected with the control system. An air inlet hole is formed in the bottom of the pickling tank, a control valve which is electrically connected with the control system is arranged on the air inlet hole, and the control system controls the pressure regulating device and the first control valve so that the pressure state of the pickling tank can be switched among the negative pressure state, the normal pressure state and the positive pressure state by turns and in sequence. The static pressure-variable pickling system integrates stewing of pickling liquid and cooling of the pickling liquid and pickling conducted through the pickling tank, the operation of the whole system is controlled through the automatic control system, therefore, full automation is achieved, and the pickling efficiency is greatly improved due to the conversion of the pickling mode.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

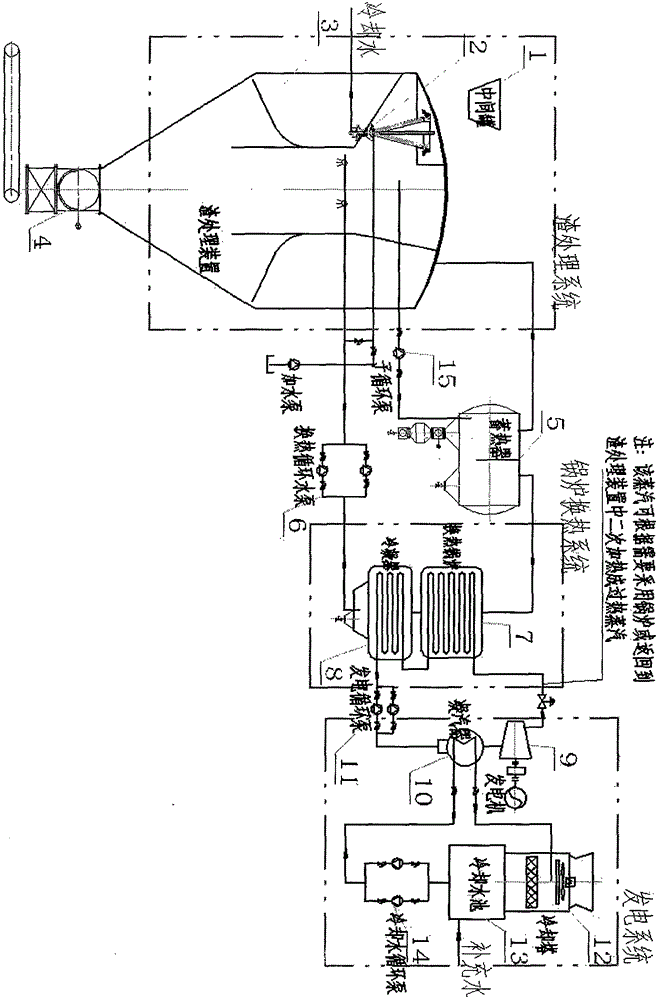

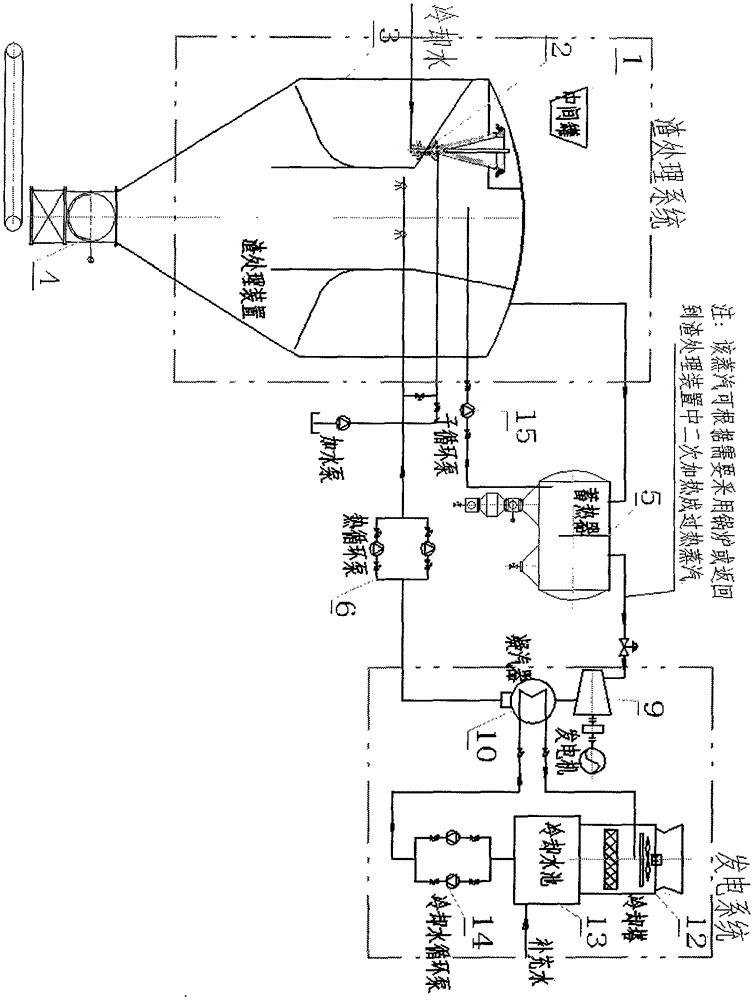

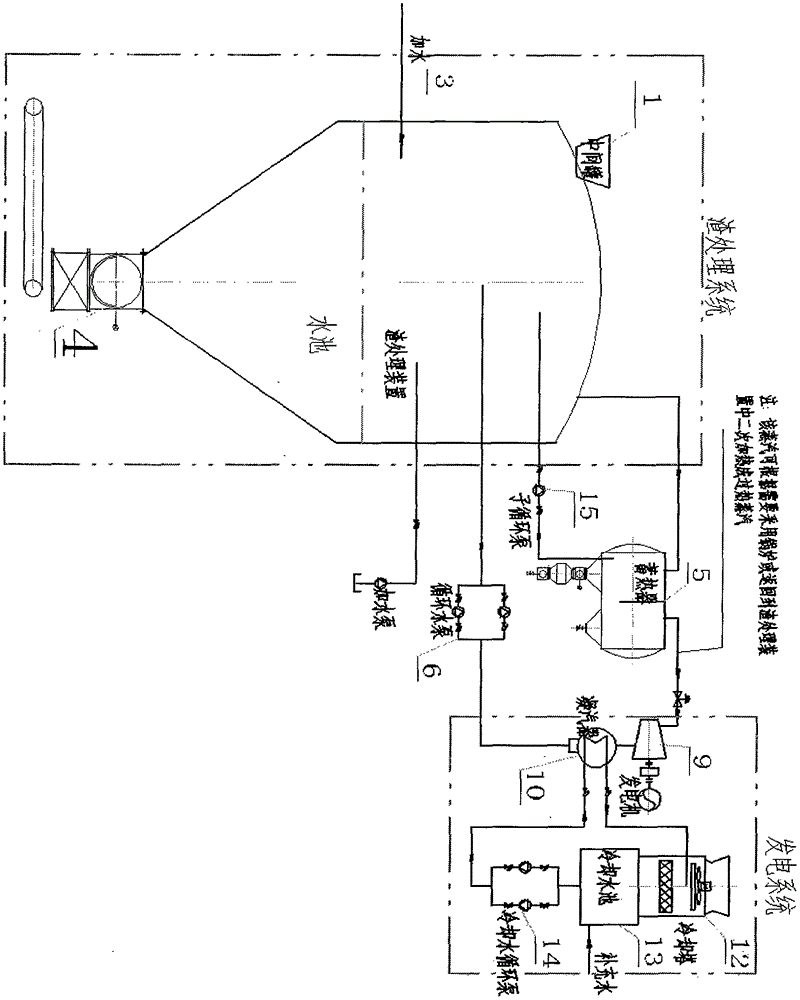

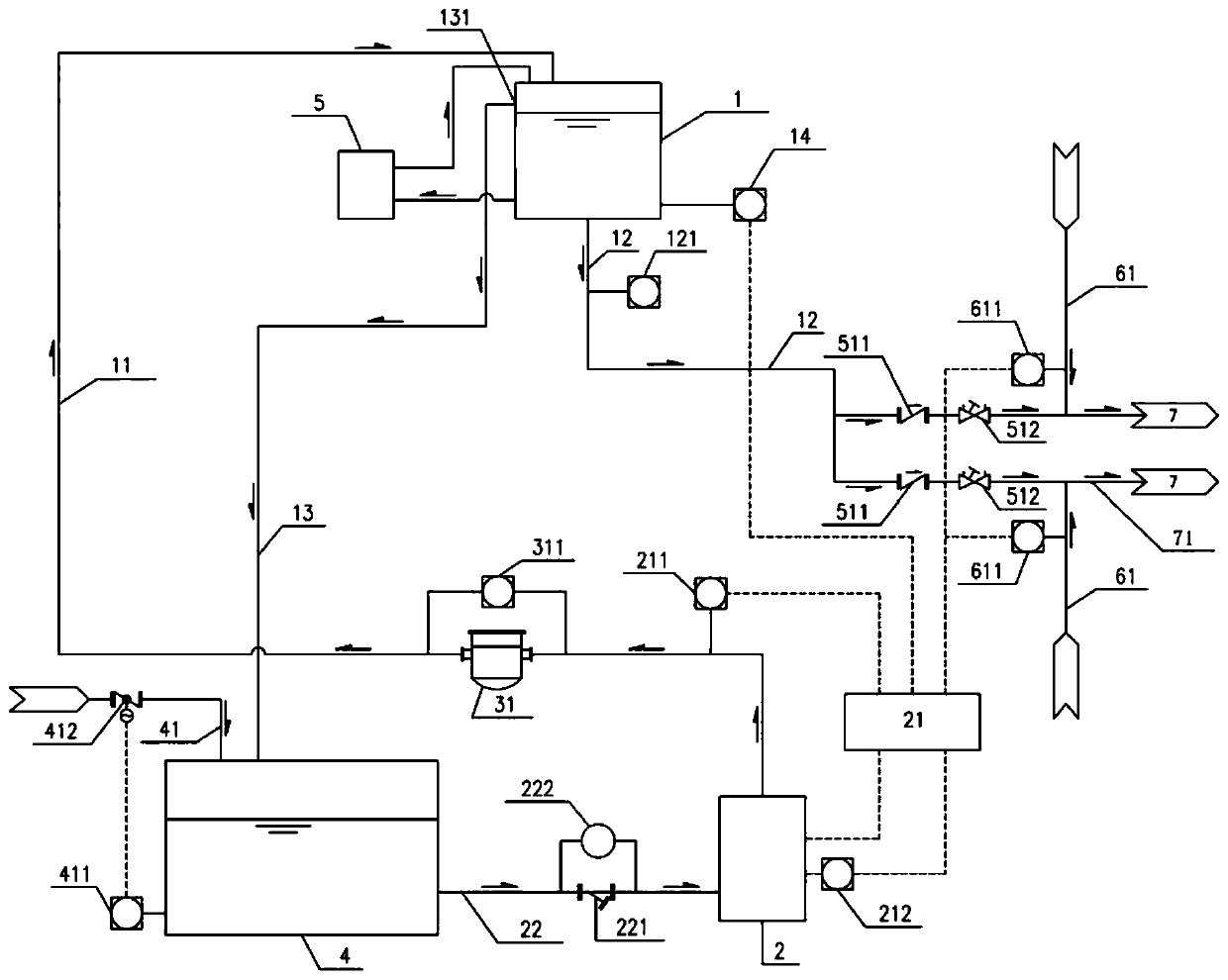

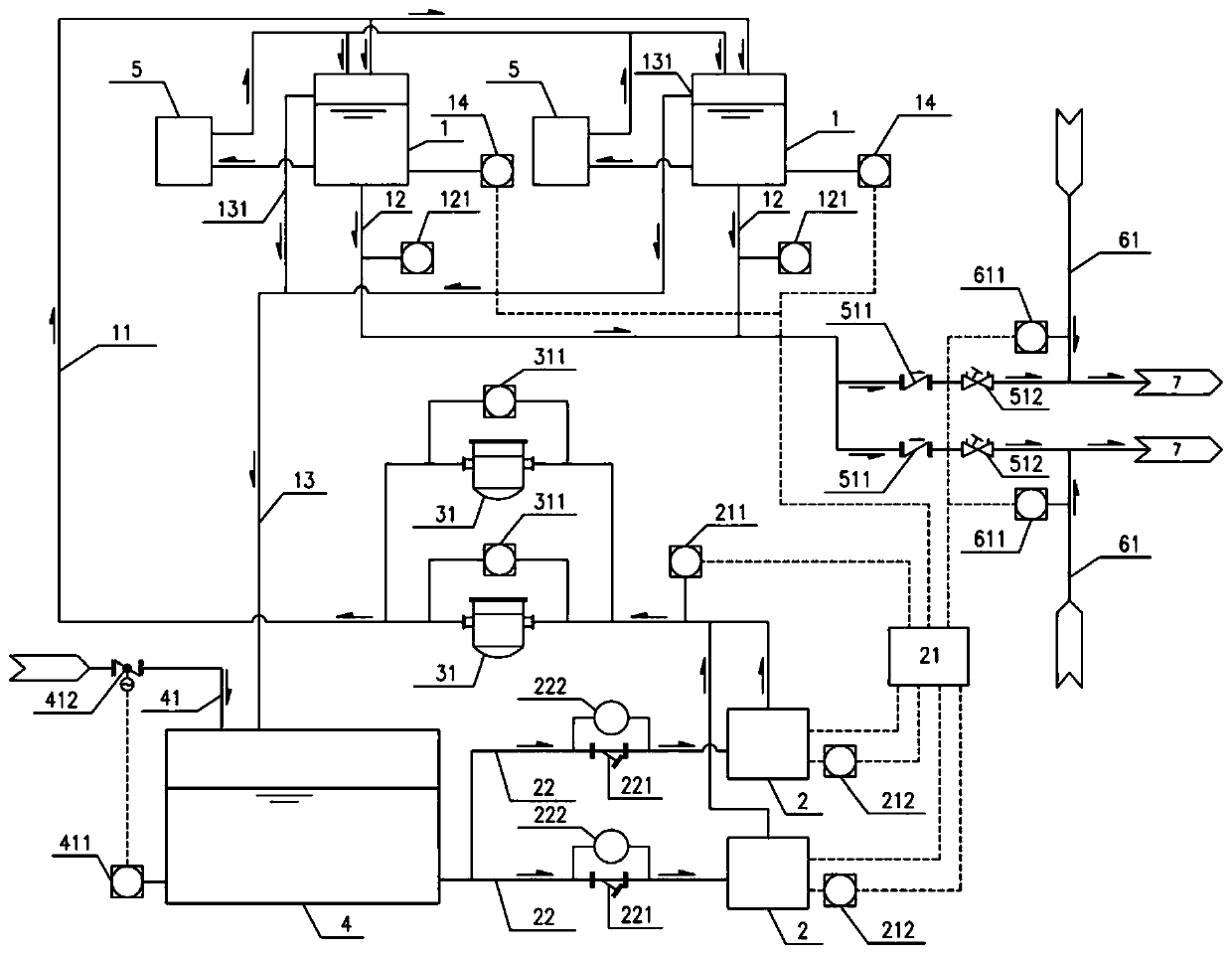

Method for treating slag through boiler steaming-water circulation process

InactiveCN106498102AMeet the production process needsSubsequent use has no effectProcess efficiency improvementSlagWater circulation

The invention provides a novel method for treating blast furnace slag and recycling slag heat energy and a device thereof. The novel slag treatment method is characterized in that a process of quenching and cooling slag via water is adopted, the slag is mechanically granulated, then water is sprayed to the slag, the slag is cooled by steam, saturated superheated steam is directly generated, then the steam passes through a heat accumulator or a boiler and is condensed into saturated water by a condenser, and a water pump is used for circulating the saturated water (steam) to cool the slag. According to the method, a process principle of high heat absorption in a water vaporization process is used; the processes of quenching the slag via water and vaporizing the water are combined with the boiler heat exchange theory; vaporization and condensation processes of water are cyclically utilized; the steam is used for taking away sensible heat of the slag; and the utilization of the slag heat is achieved. The slag treatment process of the method is completely carried out in a container in a sealing manner; the generated steam can carry pressure, can be directly output for use or can be output for use after exchanging heat for a second time. Compared with the existing wet treatment process of slag, the method has the advantages of water conservation, energy conservation, environment friendliness, high heat recycling efficiency and good economic benefit, and has value of practical application and popularization.

Owner:姜学仕 +1

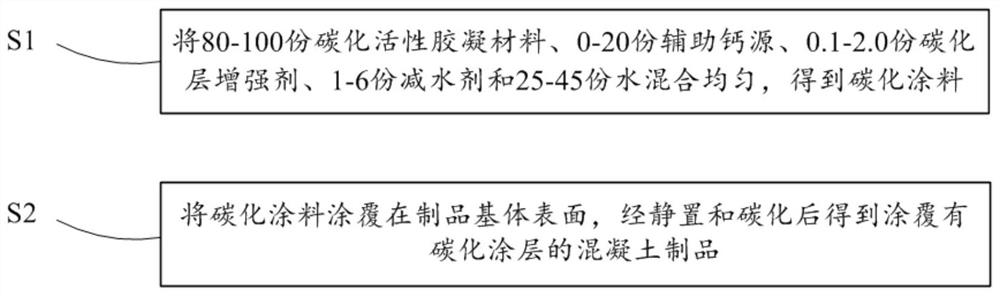

Method for improving durability of concrete product by using carbonized coating

The invention discloses a method for improving durability of a concrete product by using a carbonized coating, which comprises the following steps: uniformly mixing 80-100 parts of a carbonized active cementing material, 0-20 parts of an auxiliary calcium source, 0.1-2.0 parts of a carbonized layer reinforcing agent, 1-6 parts of a water reducing agent and 25-45 parts of water to obtain a carbonized coating; and coating the carbonized coating on the surface of a product matrix, and standing and carbonizing to obtain the concrete product coated with the carbonized coating. By introducing the auxiliary calcium source, the carbonization time can be shortened, the utilization rate and the production efficiency of the carbonization device can be improved, and the requirements of a product production process are met; and by applying the carbonized coating prepared from the carbonized active cementing material such as the steel slag to the surface of the concrete product, the purpose of economically, conveniently and effectively improving the durability of the concrete product through the calcium carbonate coating is achieved, meanwhile, the application range of the carbonized active cementing material is widened, a large amount of carbon dioxide can be immobilized, and the method has obvious environmental benefits.

Owner:WUHAN UNIV OF TECH

One-step completing method for chemical finishing of yarn cone before weaving

ActiveCN1807728ANo generationAvoid breakingSucessive textile treatmentsFibre treatmentYarnEngineering

The invention discloses a one-step finishing chemical finishing craft in cheese winding course after yarn dyeing and drying, which comprises the following steps: weighting chemical material in weight matching; building chemical material and then entering oil groove; putting chesses winded yarn in oil groove to coil yarn round the guide roller by motor; steeping yarn in chemical material; finishing drenching craft of chemical finishing after yarn absorbing liquid of chemical material; adjusting tension by tension adjuster; squeezing out surplus chemical material; coiling squeezed yarn round yarn roll by yarn break, clearing yarn with clearing yarn inducer, drying with far-infrared drying device.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

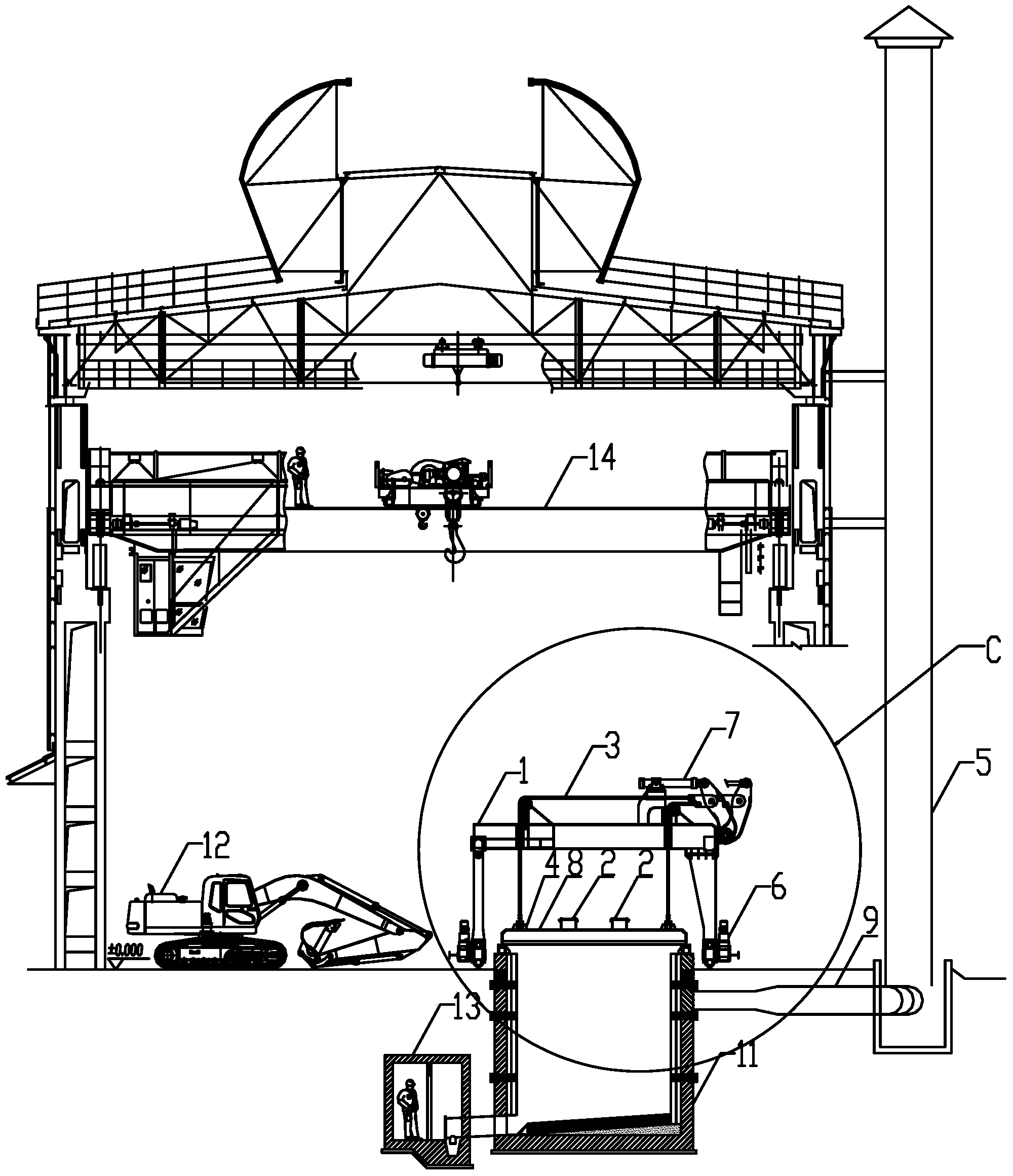

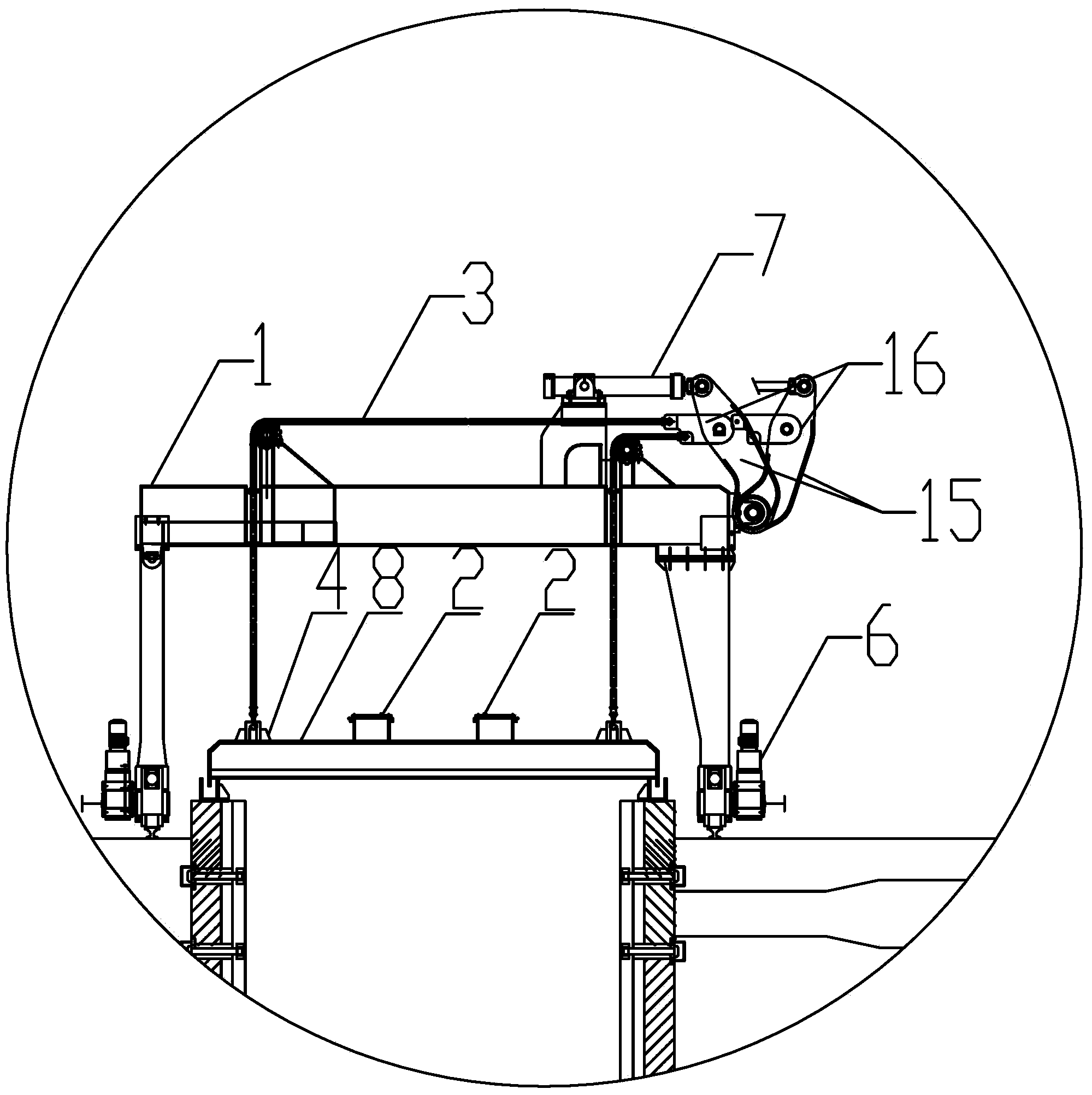

Mobile hot smoldering slag treatment line

The invention discloses a mobile hot smoldering slag treatment line comprising a plurality of hot smoldering slag tanks on a working station of a factory building, wherein each hot smoldering slag tank is communicated with a steam diffusing chimney by virtue of a steam pipeline; two steel rails are arranged on two sides of the plurality of hot smoldering slag tanks; a hot smoldering slag cover mobile trolley with a transmission device is arranged on each steel rail; a car frame of the hot smoldering slag cover mobile trolley is connected with a hot smoldering slag cover by virtue of a lifting device; an explosion-discharging device and a water spraying device are arranged on the hot smoldering slag cover. The hot smoldering slag cover mobile trolley is used as a carrier of the hot smoldering slag cover so as to achieve rapid and flexible switching of the hot smoldering slag cover among a plurality of hot smoldering treatment stations and waiting stations and meet the requirements of production processes.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

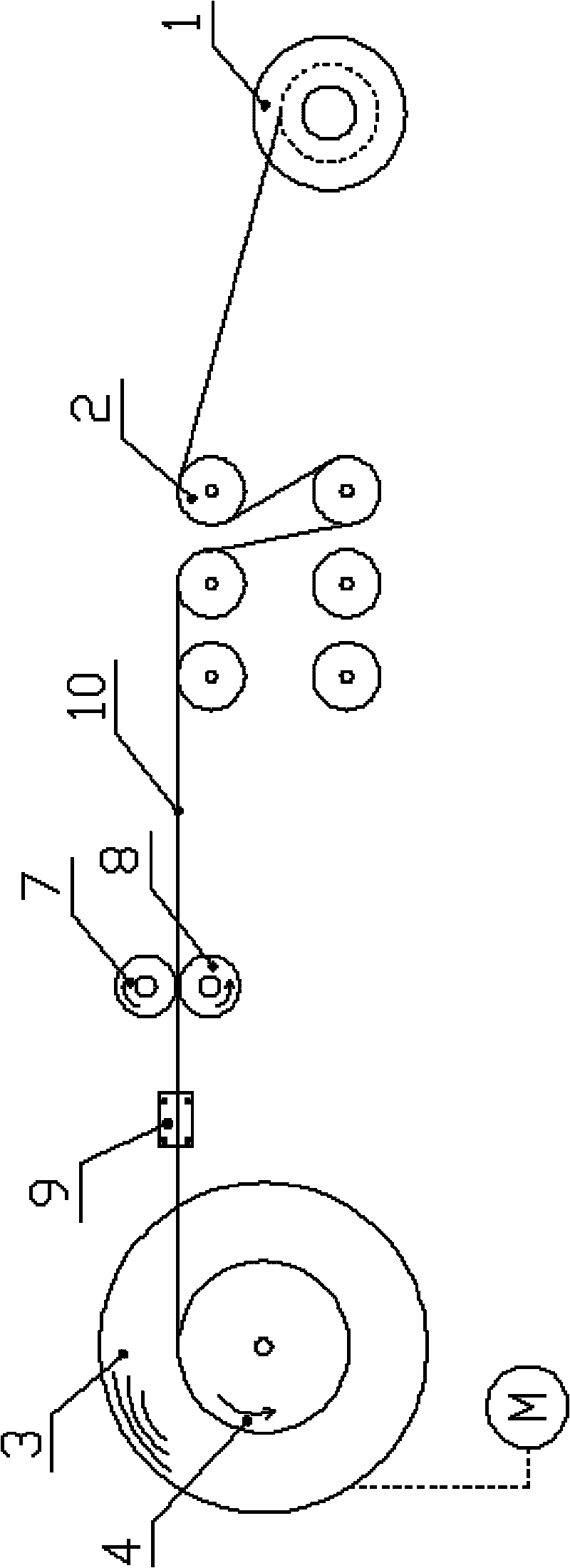

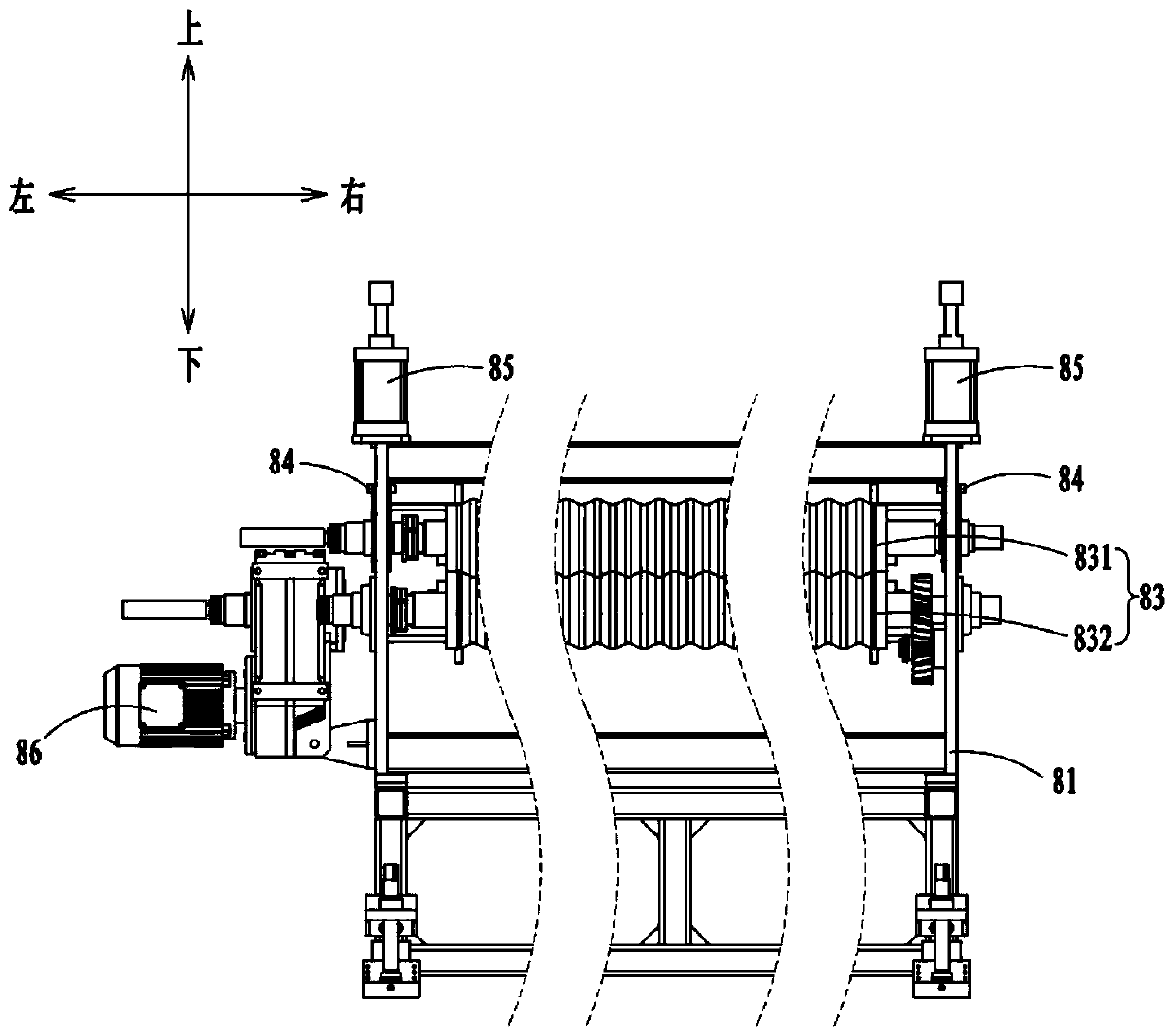

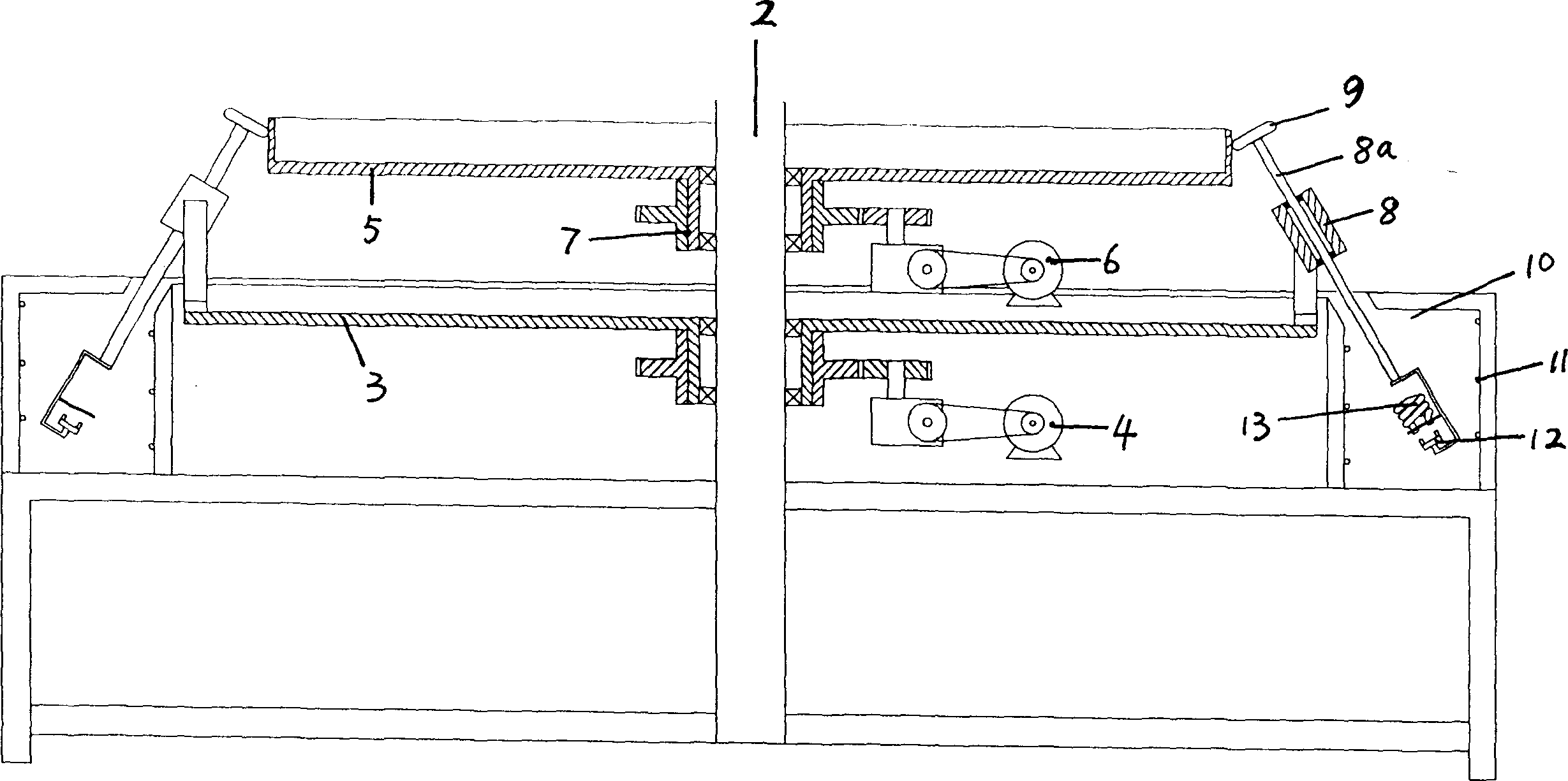

Device for winding coil by rectangular conducting wire

InactiveCN101702373AAxially arranged tightly and neatlyReduce labor intensityCoils manufactureWinding machineEngineering

The invention discloses a device for winding a coil by a rectangular conducting wire, which can enhance the winding quality of the rectangular conducting wire. The device for winding the coil by the rectangular conducting wire comprises a wire coil disk, a wire pressing device and a horizontal type wire winding machine which are sequentially arranged, wherein a coil framework is arranged on the horizontal type wire winding machine, and a positioning device which can penetrate and sleeve the rectangular conducting wire and enable the narrow side of the section of the rectangular conducting wire to be in a horizontal state is arranged between the wire pressing device and the horizontal type wire winding machine. The device has simple structure, very low cost and very convenient turning, lightens the labor strength of operators, reduces the number of the operators, lowers the winding difficulty, also shortens the winding time, ensures the tight and tidy axial arrangement and the tight radial winding of the coil after the winding is completed, ensures the winding quality and is especially suitable for popularization and use on a winding device which needs to wind the narrow side of the section of a conducting wire onto a coil framework; in addition, the rectangular conducting wire only needs to penetrate through the positioning device.

Owner:攀枝花钢城集团瑞泰电器有限公司

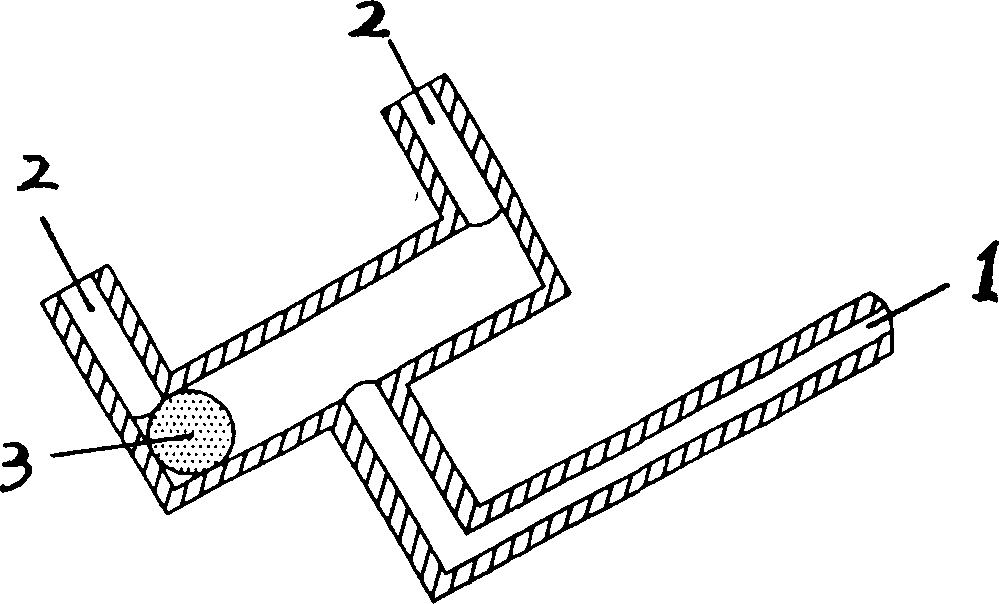

Complex material distributing method in wall and floor tile production

InactiveCN1403259ALower the altitudeGuaranteed accuracyAuxillary shaping apparatusSurface patternBrick

The present invention relates to the production of building ceramic product, and especially wall and floor tile with stone-imitating pattern. The present invention aims at producing wall and floor tile with precise, stable and fine stone-imitating pattern. During the production, several color material distributing units and color material distributing plates corresponding to the material distributing units separately are used to distribute color material cavity, and the color material cavity and the tile adobe are fed forwards to subsequent production steps. Altering the plates can change the pattern in the tile product. The present invention is suitable for use by ceramic producer.

Owner:黄国权

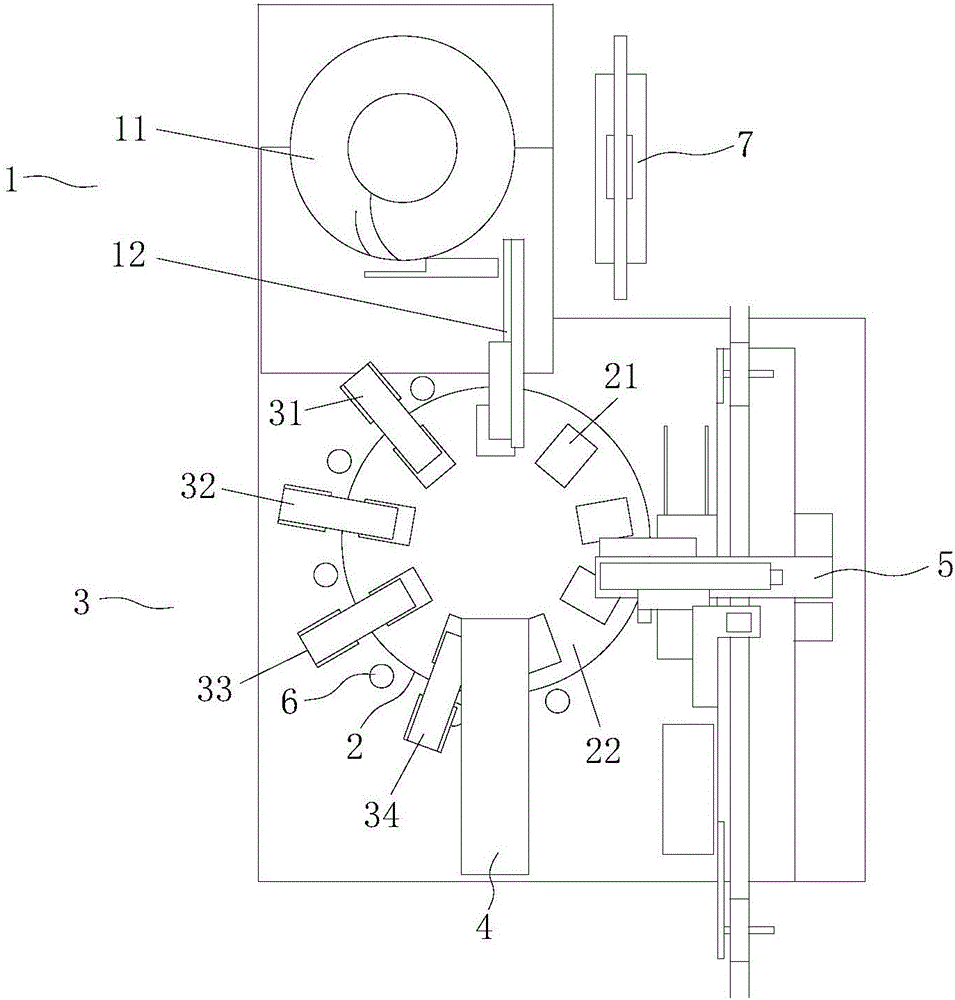

Apparatus and method for detecting tongue tube

InactiveCN105929329ARealize automated detectionImprove pass rateMaterial analysis by optical meansCircuit interrupters testingEngineeringLaser

The invention relates to the technical field of tongue tube detection, and discloses an apparatus and method for detecting tongue tubes. The apparatus comprises a feeding mechanism, a rotary mechanism, a detection mechanism, a laser marking mechanism, a packaging mechanism, a reclaiming mechanism and a control mechanism, wherein the feeding mechanism conveys tongue tubes, the rotary mechanism bears tongue tube and drives the tongue tube to rotate, the detection mechanism detects the parameters of the tongue tubes on the rotary mechanism, the laser marking mechanism conducts laser marking on the tongue tubes detected by the detection mechanism, the packaging mechanism packs the tongue tubes subjected to the laser marking, the reclaiming mechanism takes and places the tongue tubes, and the control mechanism controls the operation of the mechanisms. Automatic detection of the tongue tubes is realized, a plurality of parameters of tongue tubes are tested, the test precision is improved, and the technical demands of modern SMT are met.

Owner:SUZHOU INDAL PARK INST OF SERVICES OUTSOURCING

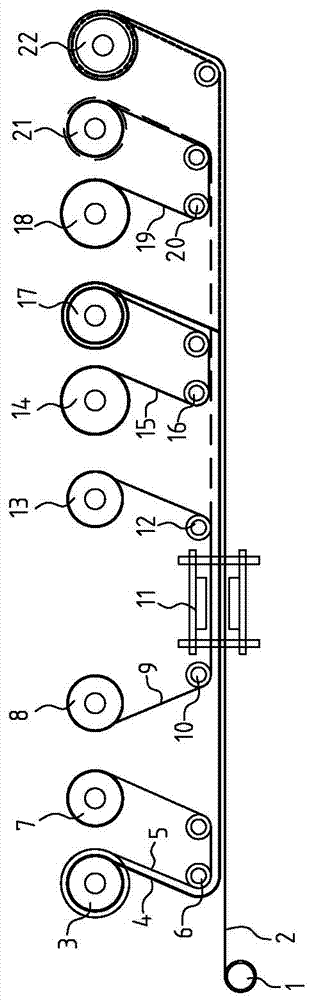

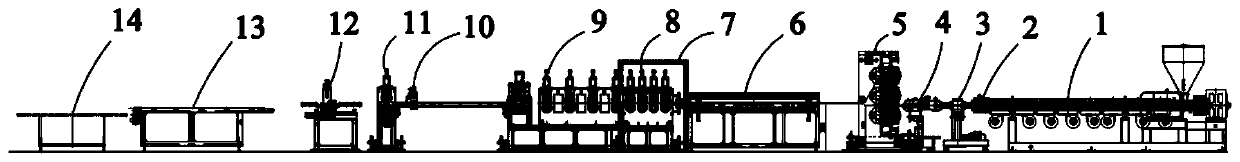

Postage stamp gum tape automatic production line and method

ActiveCN108003808ALow costMeet the production process needsFilm/foil adhesivesMetal working apparatusProduction lineEngineering

Provided is a postage stamp gum tape automatic production line and method. The production line comprises successively, according to material processing order, a release film replacement device for replacing original release films of original postage stamp gum tapes, a first peritoneal device for applying first release papers on the other sides of sponge tapes, a die cutting device for die-cuttingthe first release papers and sponge postage stamp gum tapes to form fonts or patterns, a first collection device for collecting the first release papers with which fonts or patterns are not covered and a second collection device for collecting waste postage stamp gum tapes. The method comprises the steps of (1) replacing the original release films of the original postage stamp gum tapes with firstrelease films; (2) pasting the first release papers on the exposed sides of the sponge postage stamp gum tapes of the postage stamp gum tapes; (3) die-cutting the first release papers and the spongepostage stamp tapes of the postage stamp tapes to form the fonts or the patterns; (4) collecting the first release papers with which the fonts or the patterns are not covered; (5) using original filmsto fit the waste postage stamp gum tapes with which the first release papers are not covered to conduct aligning for collection. The automatic production line and the method can automatically discharge wastes, and improve production efficiency.

Owner:GUANGZHOU JINZHONG AUTO PARTS MFG

Flue fire extinguishing purifier for roasting furnace

InactiveCN102872554ASolve the problem of overheatingSimple structureFire rescueIncreasing energy efficiencyEngineeringThermocouple

The invention discloses a flue fire extinguishing purifier for a roasting furnace. The flue fire extinguishing purifier is characterized by comprising an outer pipe, a coil pipe, a water inlet pipe, nozzles, an electromagnetic valve, a thermoelectric couple and a control instrument, wherein the outer pipe is a pipeline of which the both ends are opened; the coil pipe is welded on an inner wall of the outer pipe and is communicated with the water inlet pipe; a plurality of nozzles are arranged on the coil pipe; the water inlet pipe penetrates through the outer pipe and is connected with a water pipe through the electromagnetic valve; the thermoelectric couple is fixed in the outer pipe and is connected with the control instrument; the control instrument is connected with the electromagnetic valve; and the outer pipe, the coil pipe, the water inlet pipe and the nozzles are all made of stainless steel materials. According to the flue fire extinguishing purifier for the roasting furnace disclosed by the invention, a temperature of a flue is monitored by the thermoelectric couple, and the electromagnetic valve is controlled to spray water so as to extinguish fire; the flue fire extinguishing purifier is not only simple in structure, low in construction cost, and production cost can be effectively saved, but also the flue fire extinguishing purifier is convenient to use, safe and reliable. Therefore, the flue fire extinguishing purifier is particularly suitable for enterprises in which carbon calcination is implemented.

Owner:JINAN WANRUI CARBON

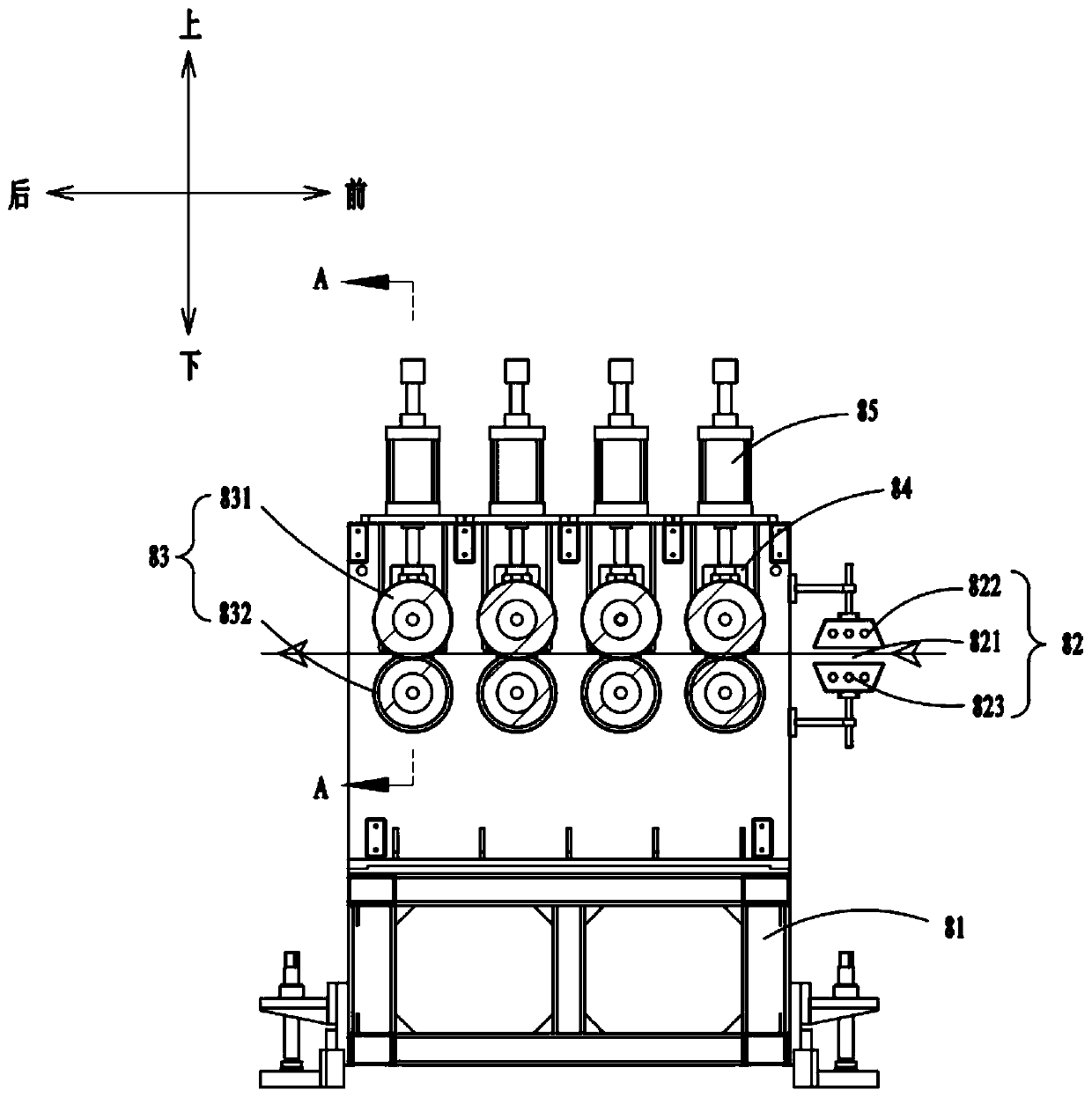

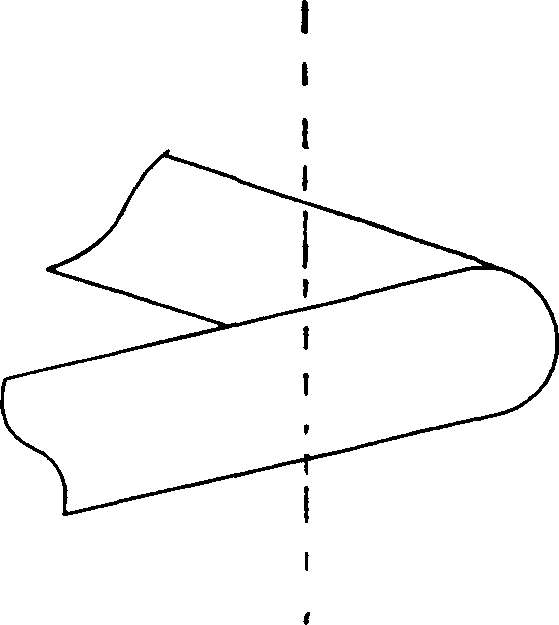

PP wave plate production line

The invention discloses a PP wave plate production line. The PP wave plate production line comprises a plastic extruder, a mold, a three-roller calender and a waveform forming machine, the waveform forming machine is positioned at the downstream of the three-roller calender, the waveform forming machine comprises a forming frame, a forming plate set, at least one forming roller set and a tractionmechanism and a waveform sharping machine wherein the forming plate set is arranged on the forming frame, and at least one forming roller set and the traction mechanism are positioned at the downstream of the forming plate set; the forming plate set is provided with a first gap, at least one forming roller set comprises an upper waveform forming roller and a lower waveform forming roller which arearranged on the forming frame, the traction mechanism is in transmission connection with the lower waveform forming roller, and the upper waveform forming roller is in tight contact with the lower waveform forming roller; the waveform sharping machine is located at the downstream of the waveform forming machine, and comprises a sharping frame, a shaping plate set and at least one shaping roller set, and at least one shaping roller set is positioned at the upstream of the shaping plate set; the shaping plate set is provided with a second gap, at least one shaping roller set comprises an upperwaveform shaping roller and a lower waveform shaping roller which are arranged on the shaping frame, and the upper waveform shaping roller and the lower waveform shaping roller are in compression contact. According to the PP wave plate production line, production process requirements of PP wave plates on a market are met.

Owner:苏州金纬片板膜智能装备有限公司

Cooling water emergency water supply system and method

The invention provides a cooling water emergency water supply system and method. The system comprises a high-position transfer water tank, an engine control panel, a water supply pump, a low-positionwater storage pool and a water supply pipeline. The elevation of the high-position transfer water tank meets the water pressure required by the emergency water supply to a user. The size of the high-position transfer water tank meets the requirement for at least storing 1 minute of emergency water consumption. A high-position water tank water outlet pipe and a conventional circulating cooling water supply pipe are connected with a user water inlet pipe. The user water inlet pipe supplies water to the user. A check valve is arranged on the high-position water tank water outlet pipe. A pressuresensor is arranged on the conventional circulating cooling water supply pipe. The pressure sensor is connected with the engine control panel through a circuit. The engine control panel is connected with a water supply pump through a circuit. A water outlet of the low-position water storage pool is connected with a water inlet of the water supply pump. A water outlet of the water supply pump is connected with a water inlet of the high-position transfer water tank. The system is safe, stable and convenient to maintain; and the volume of the high-position transfer water tank is small, the volumeof a supporting system of the high-position transfer water tank is smaller, and therefore flexibility of construction is greatly improved.

Owner:S Y TECH ENG & CONSTR CO LTD

Automatic mixing and spraying device and method applicable for perlite thermal insulation product

InactiveCN108906440AExtended service lifePlay a limiting roleLiquid spraying apparatusInternal pressureThermal insulation

The invention discloses an automatic mixing and spraying device and method applicable for a perlite thermal insulation product. The automatic mixing and spraying device comprises a box body of which the upper and lower sides are provided with an end cover and a base, and the interior of the box body is rotatably connected to a barrel body of which the side wall is connected to the inner wall of the box body through a limiting mechanism; the bottom of the barrel body is connected to the base through a rotating mechanism, and the bottom surface of the box body is provided with a communicating pipe; the top surface of the end cover is provided with a flow division box of which the bottom end is provided with a main liquid delivery pipe, and the outer side of the box body is uniformly providedwith spraying mechanisms connected to the flow division box through flow division pipes. The method comprises the steps of installation of the box body and the base, the rotating mechanism, the barrel body, the end cover and the spraying mechanisms, and mixing and spraying of the thermal insulation product. According to the automatic mixing and spraying device and method, the barrel body adopts arotation mode, and a stirring mechanism adopts a fixed mode; solutions are continuously delivered during stirring, and prevented from being solidified in the flow-forbidden state; and gas discharge is facilitated, and the internal pressure of the barrel body is reduced.

Owner:ZHEJIANG ASKER TECH

Single-roller tension measurement deviation correction device

InactiveCN105083917AFlexible process layoutCompact structureConveyorsControl devices for conveyorsHydraulic cylinderFixed frame

The invention relates to a single-roller tension measurement deviation correction device which comprises a fixed frame, a movable frame, a roller, tension meters, swing devices and guide devices. Bearing seats on the two sides of the roller are fixed to the movable frame through the tension meters. The movable frame is connected with the fixed frame in a swinging manner through the swing devices. Each swing device comprises a connecting rod and a hydraulic cylinder, wherein the upper end of the connecting rod is hinged to the fixed frame, the lower end of the connecting rod is hinged to the movable frame, and the two ends of the hydraulic cylinder are hinged to the fixed frame and the movable frame respectively. Each guide device comprises a sliding way arranged on a beam of the fixed frame and an idle wheel arranged corresponding to the movable frame, wherein the idle wheel can roll in the corresponding sliding way and the beam of the fixed frame is further provided with a position sensor used for detecting the position of the roller. By the adoption of the single-roller tension measurement deviation correction device, the strip steel deviation amount can be effectively controlled, strip steel tension can be measured, the structure is compact, the occupied space is small, the device can be installed in the 90-degree turning position of strip steel, the process layout of a strip steel production line is more flexible, and investment is saved while the production process requirements are met.

Owner:鞍钢集团工程技术有限公司

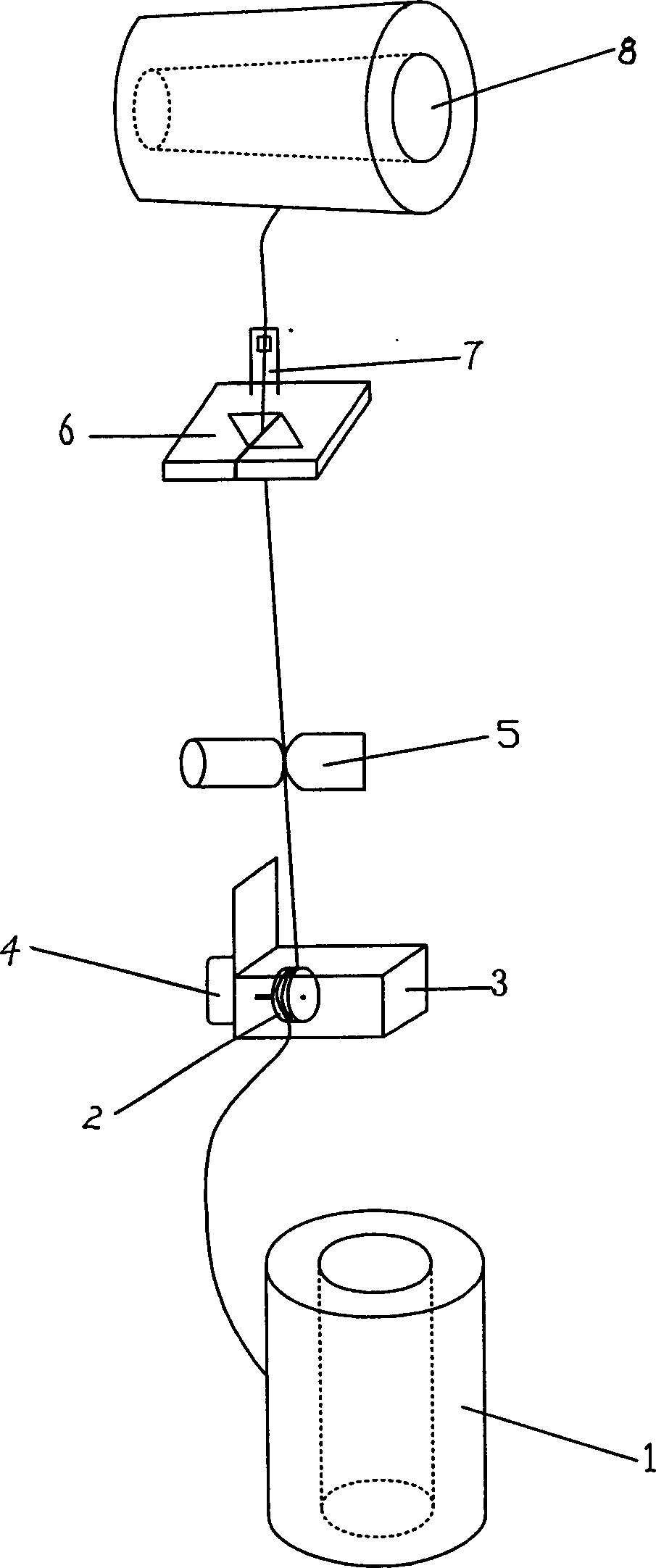

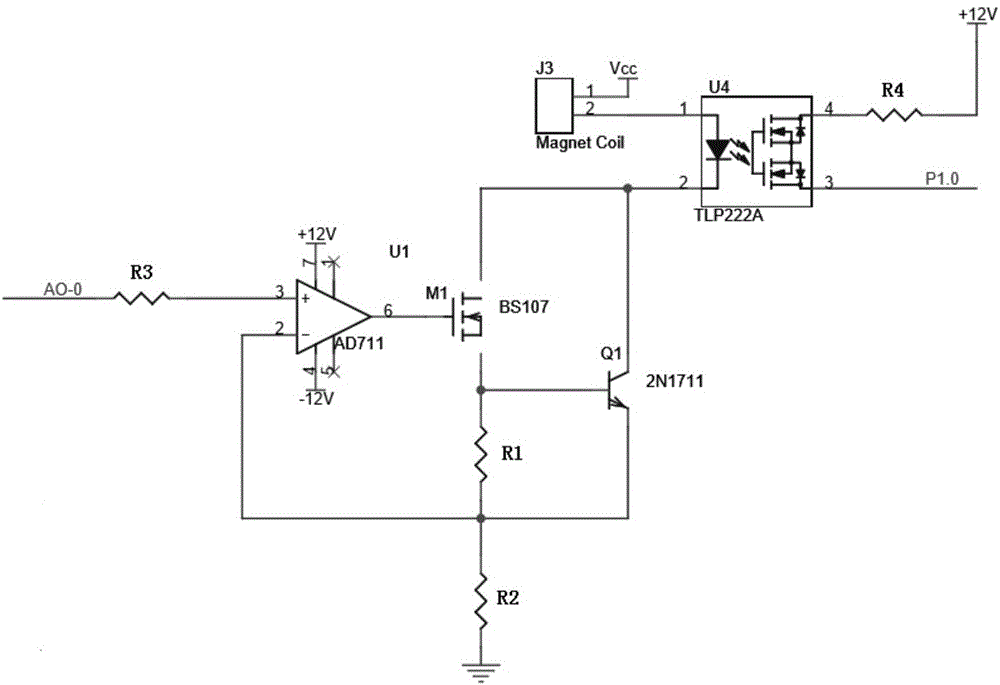

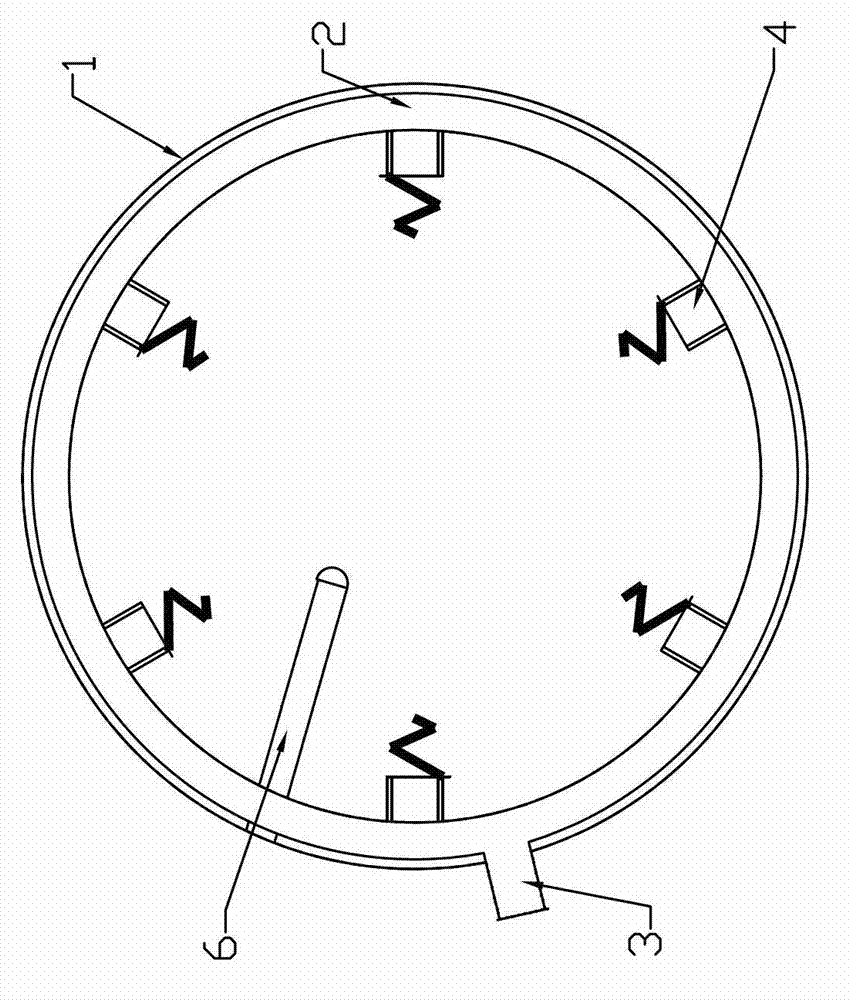

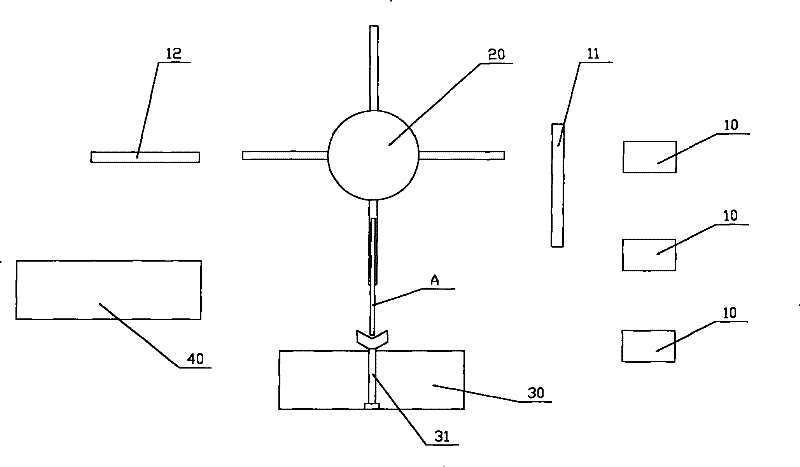

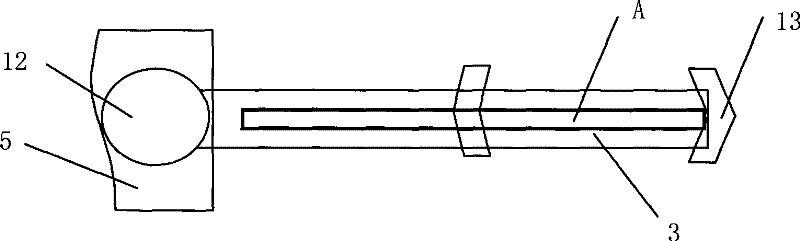

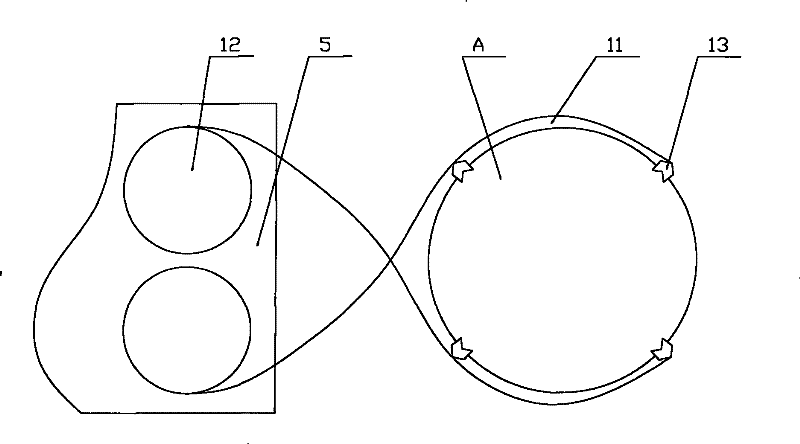

Coating process and equipment for spiral fluorescent tube

InactiveCN1897211AOutflow smoothlyMeet the production process needsLuminescent coatings applicationSpecial surfacesElectric machineryEngineering

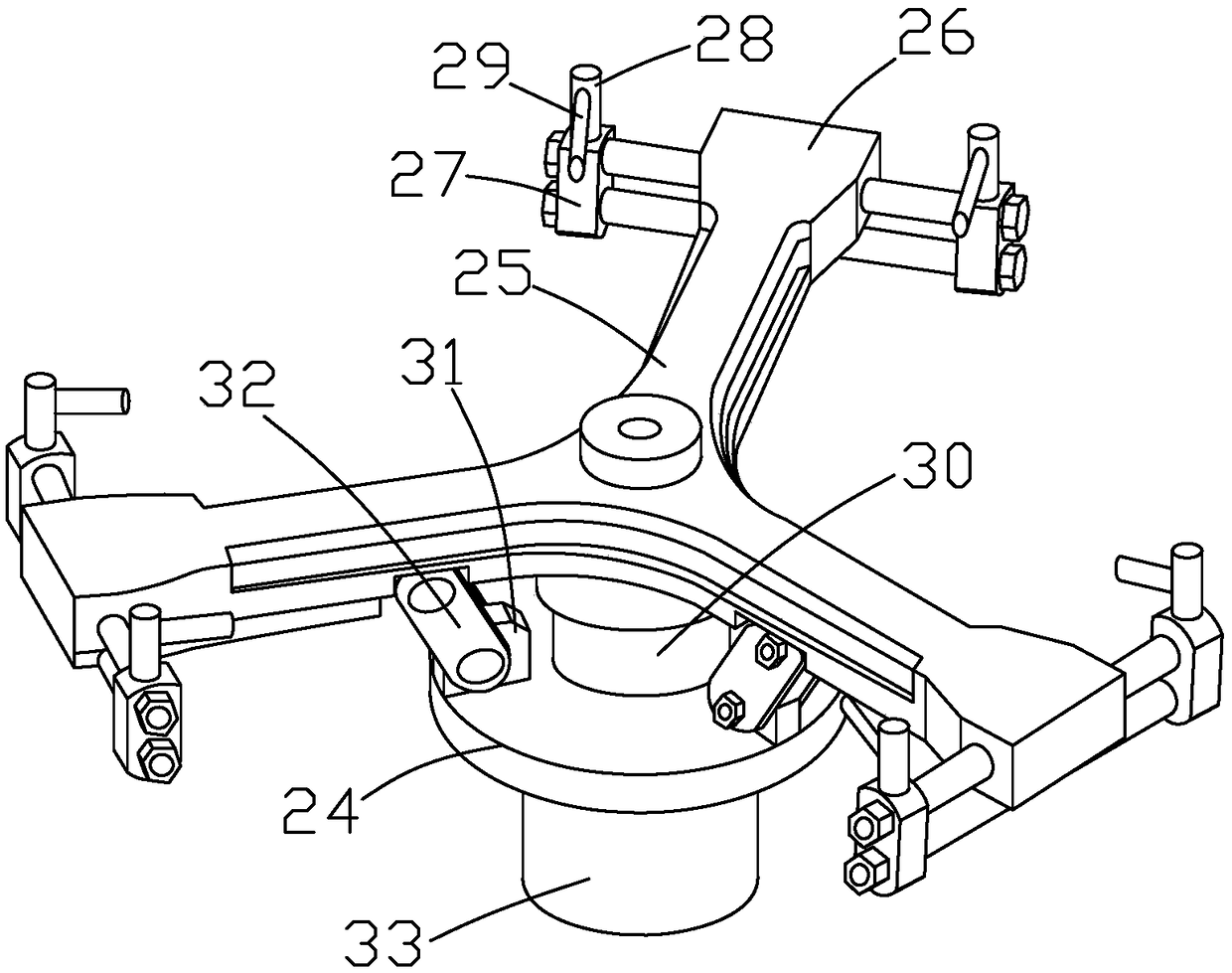

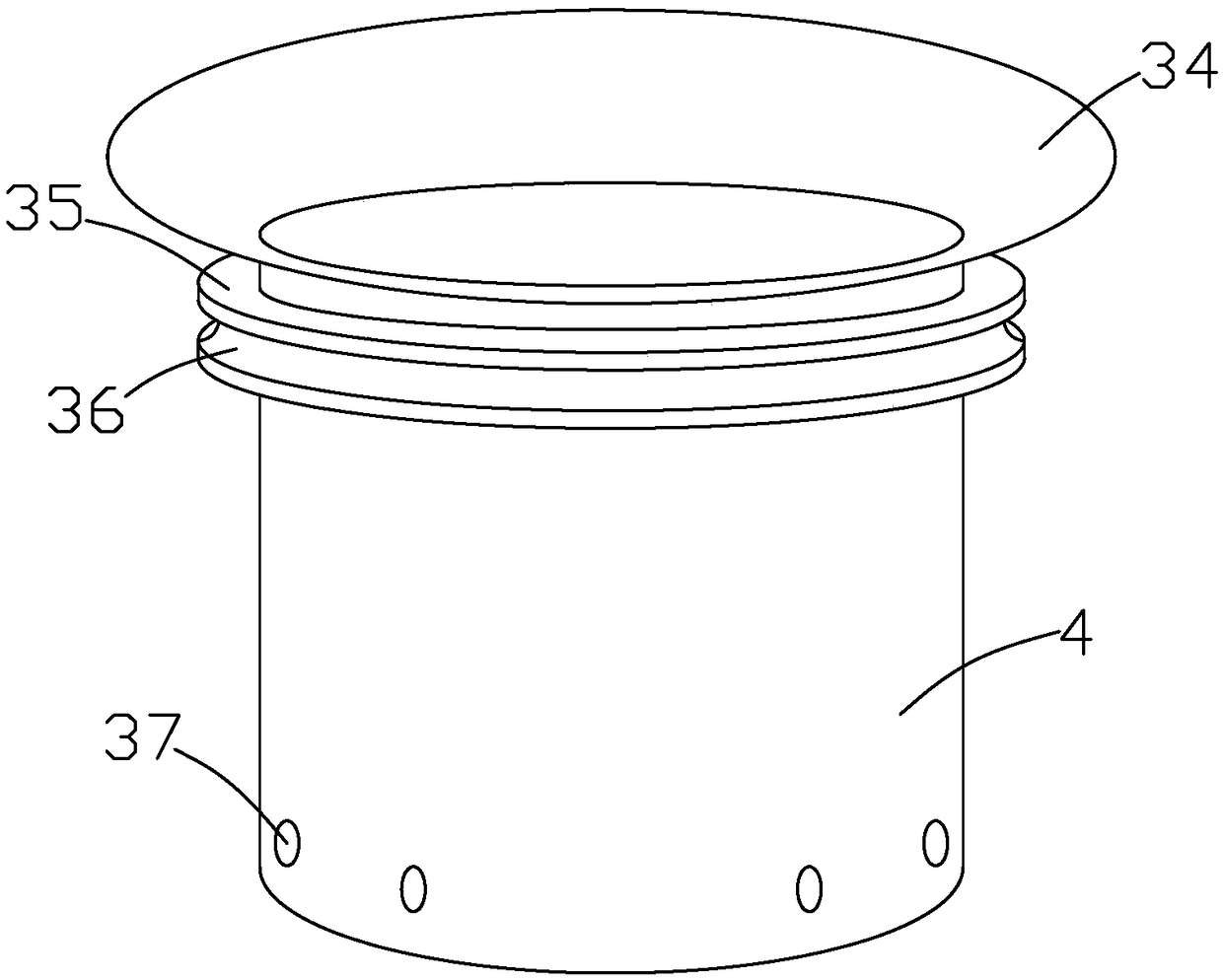

The invention is concerned with the spiral light-tube bepowder equipment and the technics that designs for the bepowder technics of the simulative U-shape pipe. The bepowder equipment comprising with: the framework, the main axis fixing in the middle of the framework, and the circles roasting area setting on the revolution turntable of the framework; the revolution turntable that rotates around the main axis, the revolution electrical machinery that drives the rotation of the revolution turntable, several working-location head setting on the revolution turntable; the rotation turntable setting on the revolution turntable that rotates around the main axis, the rotation electrical machinery setting on the revolution turntable that drives the rotation of the rotation turntable; every working-location head sets a rotating axis with the friction wheel, the front end of the rotating axis fixes the spiral light-tube and the fan opening. The bepowder technics includes the roast and fan technics, the characteristic is: the two opening of the spiral light-tube is downward and rotates continuously by a definite leaning angle during the spiral light-tube bepowder process.

Owner:SICHUAN LIANKAI LIGHTING CO LTD

Solution dehumidification unit based on return air cooling capacity recovery

PendingCN114263992AReduce energy costsMeet the production process needsEnergy recovery in ventilation and heatingMechanical apparatusFresh airCooling capacity

The invention relates to a solution dehumidification unit based on return air cooling capacity recovery, and belongs to the technical field of solution dehumidification. Comprising a unit shell, a fresh air inlet and a return air inlet are formed in one side of the shell, a fresh air outlet is formed in the other side of the shell, a return air outlet is formed in the upper side of the shell, and a filter, a fresh air and return air heat exchanger, a direct evaporation section and an axial flow fan are sequentially arranged in the shell in the flow direction of return air. A filter, a fresh air and return air heat exchanger, a solution dehumidification section and an air feeder are sequentially arranged in the shell in the flowing direction of fresh air. Compared with an existing solution dehumidification unit, a return air cooling capacity recycling method is directly utilized, heat released by solution heat absorption is reduced, fresh air solution dehumidification is achieved on the premise that return air cooling capacity is recycled, compared with a traditional solution dehumidification unit needing a matched refrigerating unit, the operation energy consumption of dehumidification is greatly reduced, energy is saved, environment is protected, and the energy-saving and environment-friendly effects are achieved. And the practicability is very high.

Owner:臣功(北京)科技有限公司

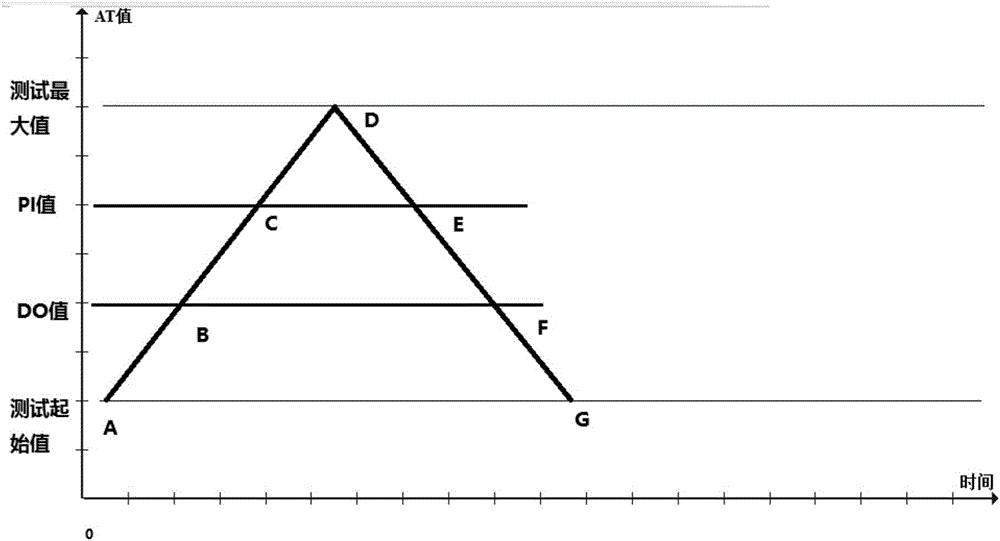

Method for controlling depressurization of warm isostatic press

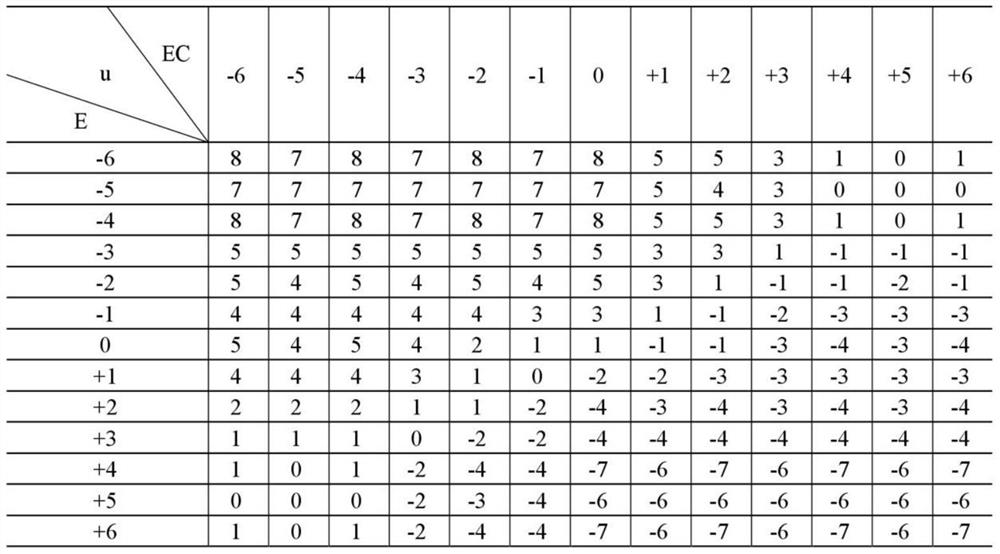

ActiveCN103286984AMeet the requirements of production accuracyMeet the production process needsPressesFuzzy control systemEngineering

The invention discloses a method for controlling depressurization of a warm isostatic press. The method includes: (1) setting working pressure, wherein the working pressure includes working pressure when depressurization is realized in a fuzzy control manner and working pressuer when depressurization is realized in the continuous adjustment manner; (2) collecting real-time pressure of the warm isostatic press during working; (3) comparing the collected real-time pressure with the preset working pressure, depressurizing in the fuzzy control manner when the real-time pressure is the working pressure when depressurization is realized in the fuzzy control manner, and depressurizing in the continuous adjustment manner when the real-time pressure is the working pressure when depressurization is realized in the continuous adjustment manner. The method is simple in steps and convenient to operate, and the warm isostatic press is depressurized by means of combining the depressurization in the fuzzy control manner and the depressurization in the continuous adjustment manner, so that depressurization process of the warm isostatic press can meet requirements on production precision of products, and the warm isostatic press is suitable for popularization and use.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Silicon wafer cleaner and silicon wafer cleaning method

ActiveCN101740324BMeet the production process needsIncrease productivitySemiconductor/solid-state device manufacturingCleaning using liquidsTransfer modeCleaning methods

The invention discloses a silicon wafer cleaner which comprises a silicon wafer bearing stand, a rotating arm, a silicon wafer cleaning tank and a rotating drying unit, wherein the silicon wafer bearing stand is arranged at one side of the rotating arm; the silicon wafer cleaning tank is arranged below the rotating arm; a silicon wafer receiver is arranged in the silicon wafer cleaning tank; the rotating drying unit is arranged at one side or the other side of the rotating arm; and transferring rods are arranged between the rotating arm and the silicon wafer bearing stand and between the rotating arm and the rotating drying unit. In the invention, a full automatic silicon wafer transferring mode is adopted to continuously and automatically treat a single silicon wafer, and can meet the requirements of the increasingly complicated production processes. As the equipment can carry out automatic cleaning, manual cleaning is not needed, thus preventing the risk of contaminating and scratching the silicon wafers and the like caused by manual cleaning, and simultaneously improving production efficiency. The invention also discloses a method for cleaning the silicon wafers by the silicon wafer cleaner.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

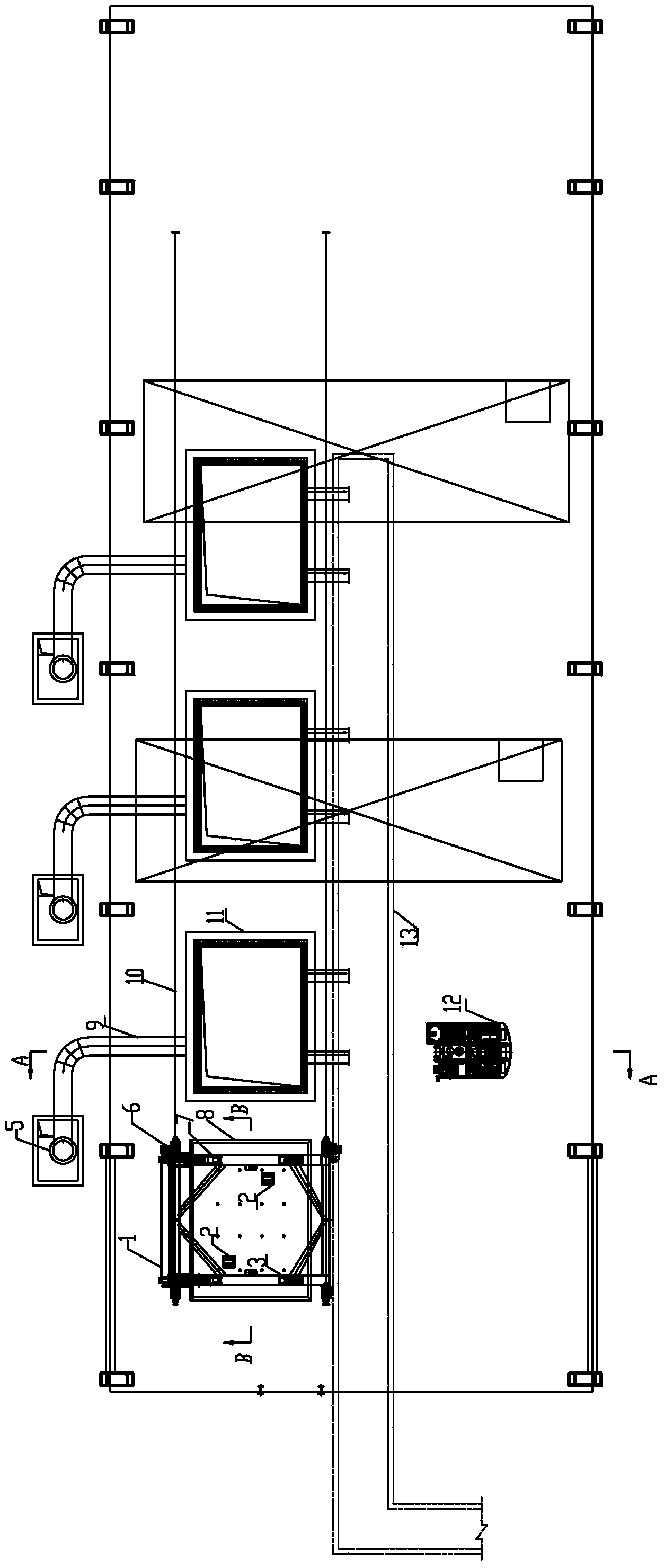

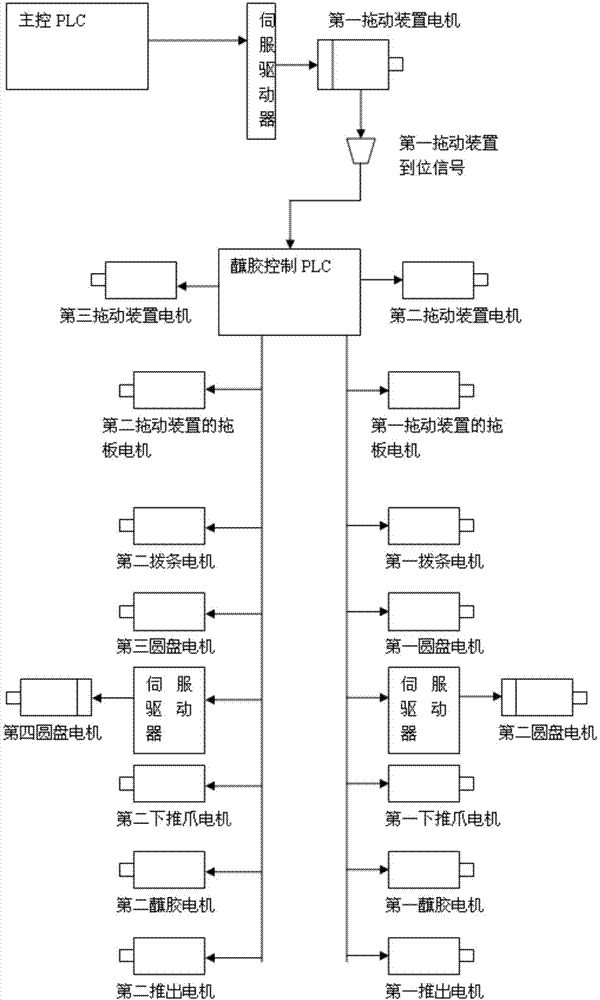

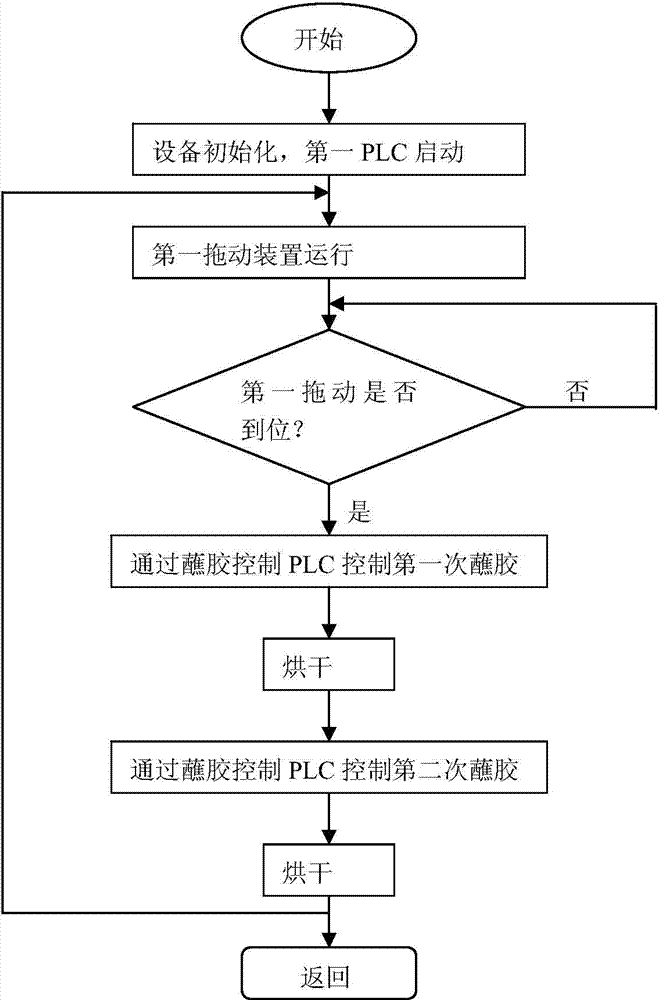

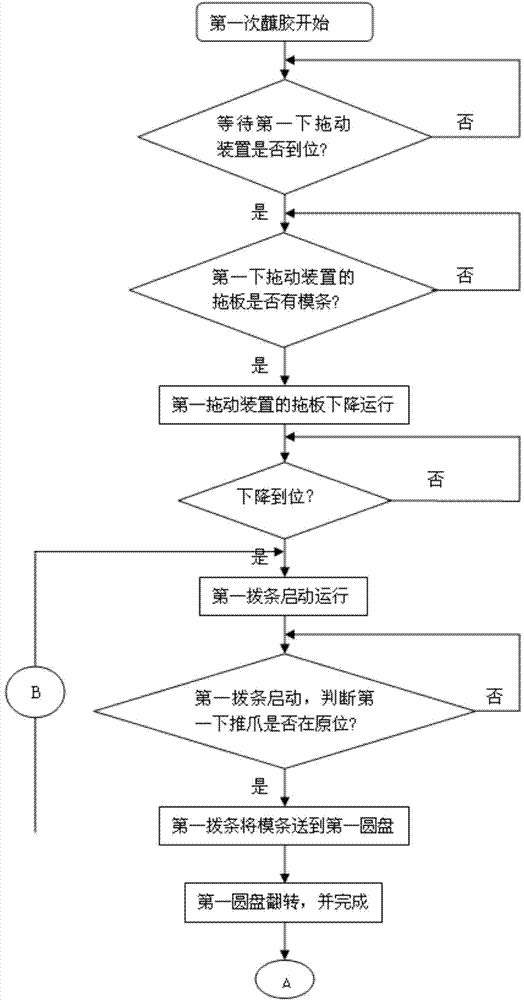

System and method for controlling secondary glue dipping of intestine-dissolvable capsule making machine

InactiveCN104490601AMeet the production process needsQuality improvementCapsule deliveryControl systemEngineering

The invention relates to a system and method for controlling secondary glue dipping of an intestine-dissolvable capsule making machine. The system comprises a main control unit, a glue-dipping control unit, a first dragging device, a second dragging device, a third dragging device, a first dragging device dragging plate, a second dragging device dragging plate, a first poking bar, a second poking bar, a first disc, a second disc, a third disc, a fourth disc, a first lower pushing pawl, a second lower pushing pawl, a first glue dipping machine, a second glue dipping machine, a first push-out machine and a second push-out machine. The method comprises the following steps: a device is initialized; a main control unit is started; the main control unit is used for controlling the first dragging device to run; the first dragging device is used for dipping glue for the first time by a glue-dipping control unit after the first dragging device runs in place; the glue is dried after dipping the glue for the first time; the glue-dipping control unit is used for dipping glue for a second time after the glue is dried; the glue is dried after dipping the glue for the second time; the step in which a main control unit is used for controlling the first dragging device to run is returned after the glue is dried. The requirements of the production process for intestine-dissolvable capsules can be met; the high-quality intestine-dissolvable capsules can be produced; the problem that the medicine simulates the stomach of a patient and the side effect is generated can be solved; the full-automatic production process of making the capsules by a machine can be implemented; the blank of the field of medicine package is fulfilled.

Owner:丹东市金丸药用胶囊机械有限公司

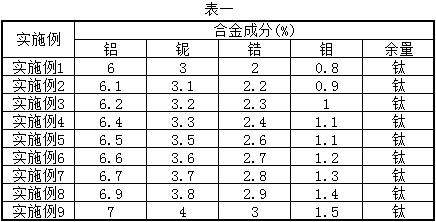

Special titanium alloy wire for 800MPa-grade electron beam additive material and preparation method of special titanium alloy wire

The invention relates to the field of titanium alloy wires for naval architecture and ocean engineering, in particular to a special titanium alloy wire for an 800MPa-grade electron beam additive material and a preparation method of the special titanium alloy wire. The titanium alloy wire comprises, by weight, 6%-7% of aluminum, 3%-4% of niobium, 2%-3% of zirconium, 0.8%-1.5% of molybdenum, and thebalance titanium, wherein aluminum of the alloy elements is an alpha-phase stable element of the titanium alloy wire, molybdenum and niobium of the alloy elements are beta-phase stable elements of the titanium alloy wire, and zirconium of the alloy elements is a neutral element of the titanium alloy wire. The wire can meet the requirement of a manufacturing process of the electron beam additive material, and has good technical application and market prospects on the aspect of manufacturing of electron beam fuse additive materials of naval architecture and ocean engineering components.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

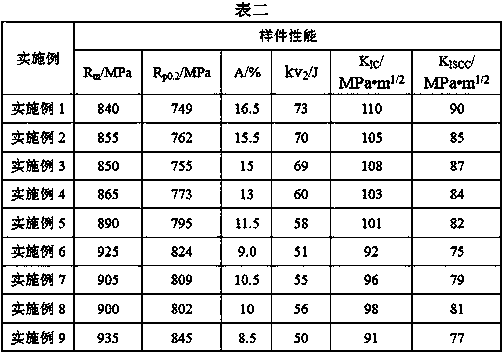

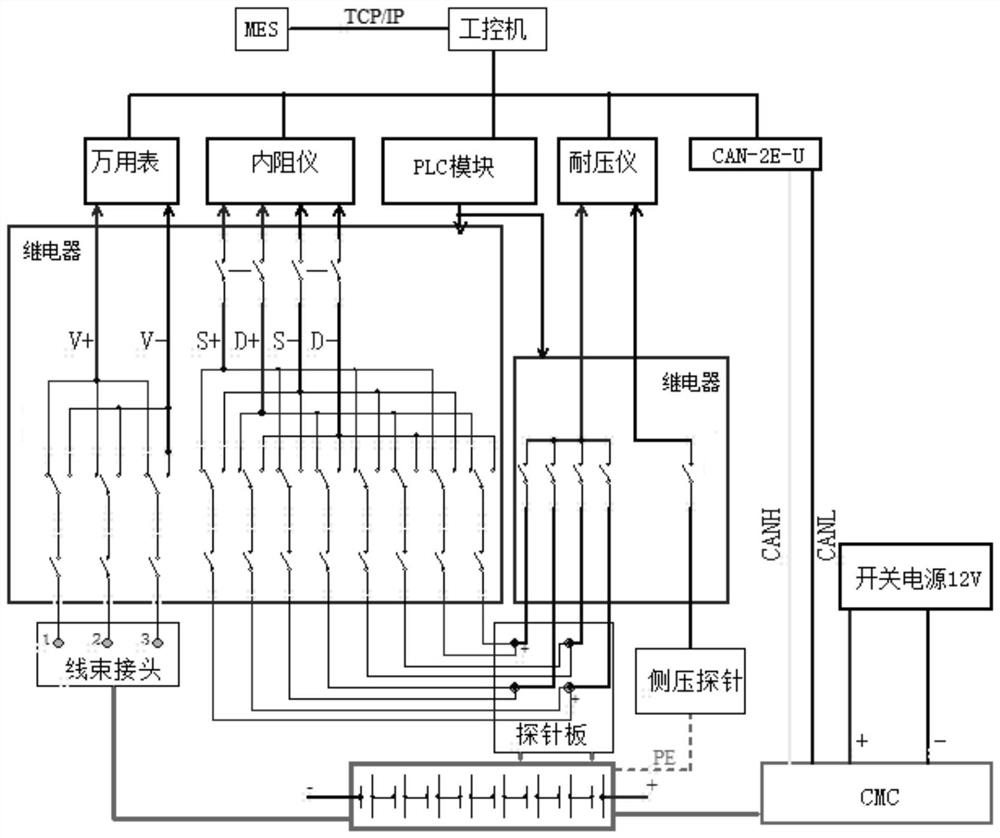

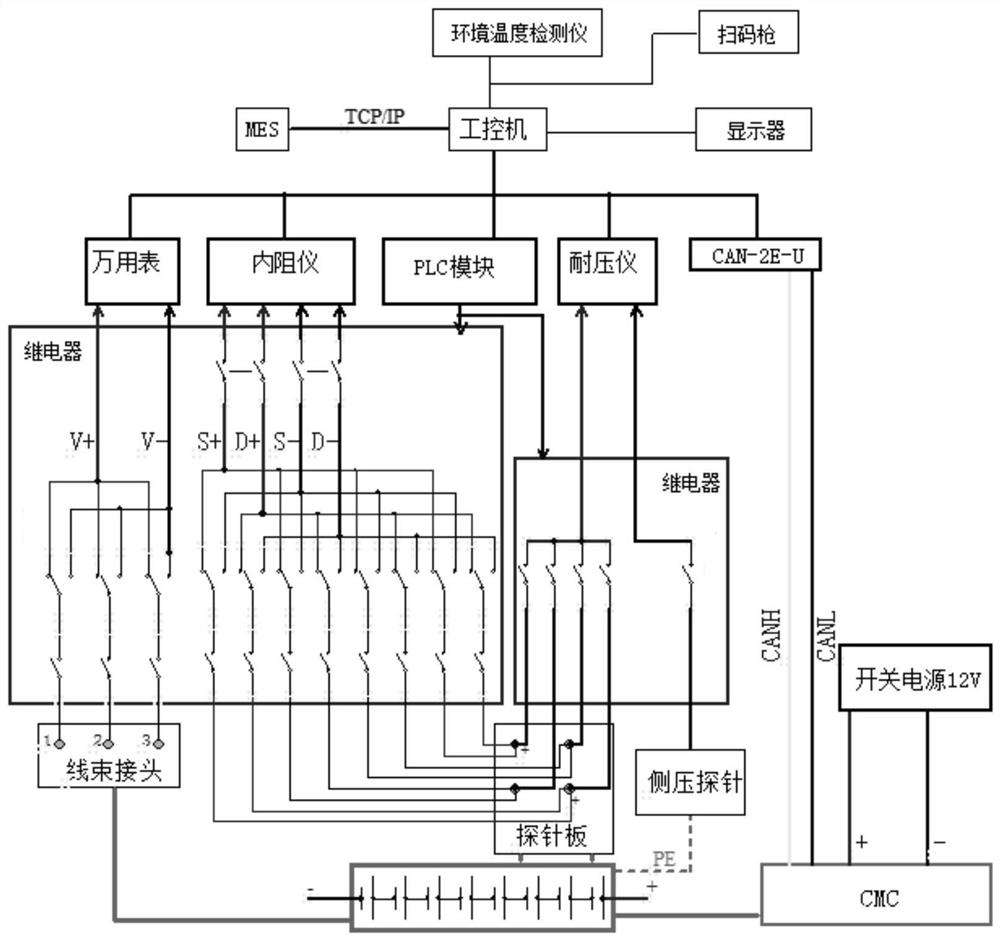

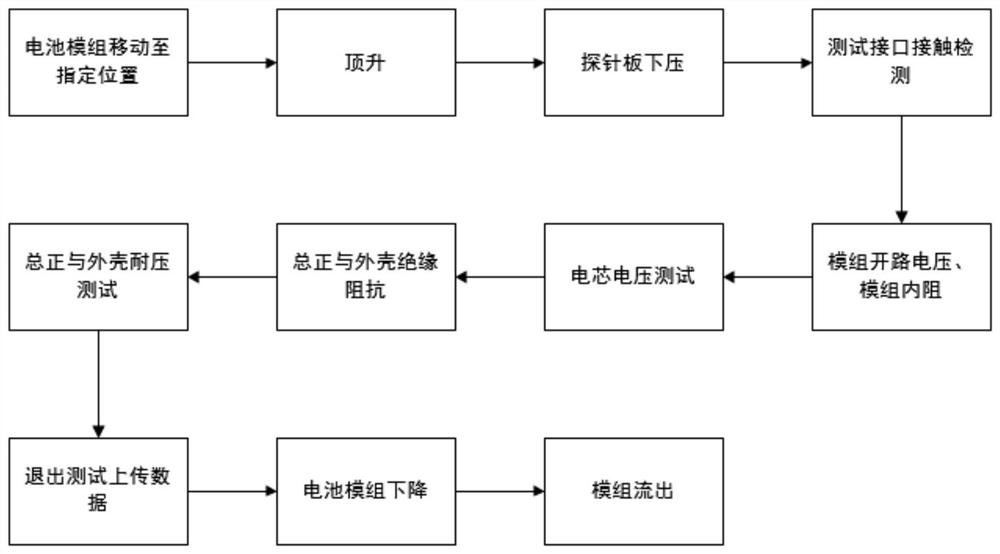

Test all-in-one machine for battery module

PendingCN111781515AProduction capacity matchingMeet the production process needsElectrical testingThermometer applicationsCommunications systemInternal resistance

The invention discloses a test all-in-one machine for a battery module. The test all-in-one machine comprises an MES management system, an industrial personal computer connected with the MES management system, and a universal meter, an internal resistance instrument, a PLC module, a withstand voltage instrument and a communication system which are connected with the industrial personal computer through wires; the universal meter, the internal resistance instrument and the withstand voltage instrument are connected with the relay switching system. The output end of the relay switching system isconnected with a test interface used for being connected with a to-be-detected battery module, the test interface is connected with a probe pressing system, and the probe pressing system drives the test interface to do back-and-forth lifting movement. The relay switching system is connected with the PLC module; the PLC module collects test data of the universal meter, the internal resistance instrument and the withstand voltage instrument which are connected with the relay switching system, and uploads the test data to the industrial personal computer through the communication system, therebyimproving the detection efficiency of the battery module while achieving the matching of the upstream and downstream production capacities of equipment.

Owner:深圳市瑞能创新科技有限公司

Online optimization control system for copper oxygen-enriched side-blowing smelting process

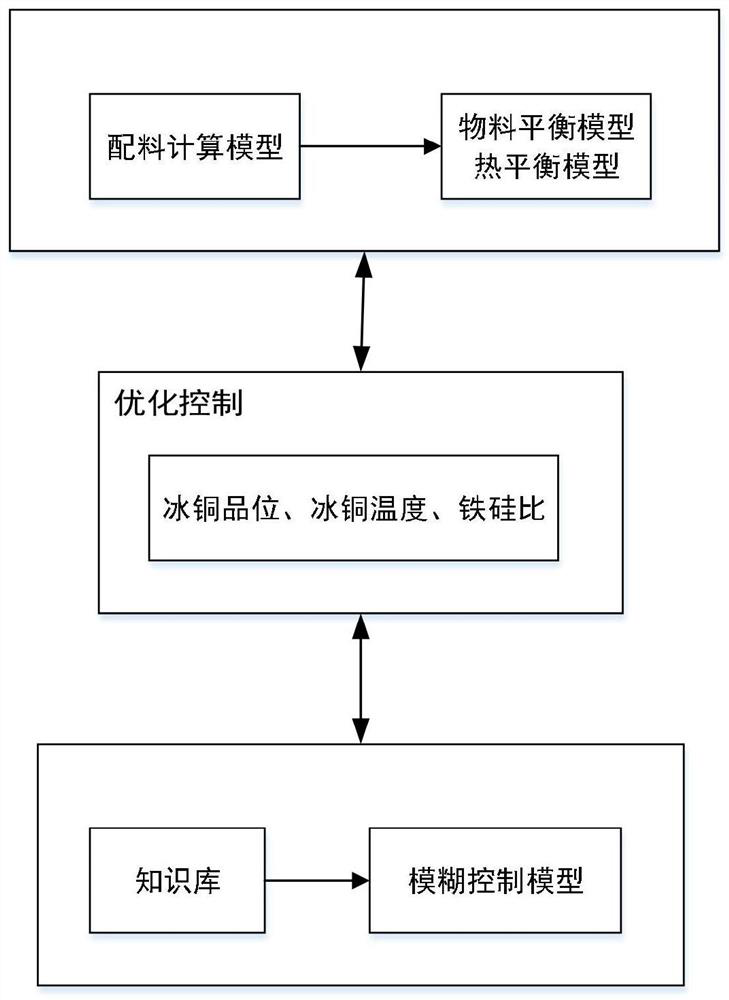

ActiveCN114277260ASolve the problem of improper ratioRealize online automatic adjustment controlCrucible furnacesTotal factory controlComputational modelHeat balance

The invention discloses an online optimization control system for a copper oxygen-enriched side-blown smelting process, and the system comprises a batching calculation model, a material balance model, a heat balance calculation model, a knowledge base, and a fuzzy control model. The material balance model is used for ensuring that the mass of a fed material and the mass of a product in the ingredient calculation model are kept balanced, the heat balance model is used for ensuring that the heat of the fed material and the heat of the product in the ingredient calculation model are kept balanced, the knowledge base comprises expert knowledge of side-blowing smelting and field operation experience, and the fuzzy control model is based on the knowledge base. Control rule modeling is adopted for the control parameters, so that the control parameters are converted into languages which can be realized by program codes, and optimization and adjustment of the control parameters are realized. According to the method, on the basis of side-blowing process mechanism analysis, the stability of target parameters in the side-blowing process is taken as a target, the optimal values of the control parameters are dynamically obtained by utilizing the fuzzy control model, and intelligent optimization control of the side-blowing production process is realized.

Owner:北京瑞太智联技术有限公司

Polycarbonate film of anti-counterfeit label for certificates and preparation method of polycarbonate film

PendingCN112521739AImprove antistatic performanceGood weather resistanceStampsIdentification meansPolymer scienceUltraviolet lights

The invention discloses a polycarbonate film of an anti-counterfeit label for certificates and a preparation method of the polycarbonate film. The polycarbonate film comprises polycarbonate resin, tinoxide antistatic gel, trans-1, 4 polyisoprene, polysiloxane, a lubricant, an ultraviolet light absorber, an antioxidant and a coloring agent. The polycarbonate film of the anti-counterfeit label forcertificates has the advantages of favorable antistatic property, favorable weather resistance, favorable transparency, favorable flame-retardant effect, high firmness, high durability and excellent shape memory characteristic, and is suitable for anti-counterfeit labels for certificates; and the raw materials can be used for extrusion and compression molding so as to meet the requirements of a production process.

Owner:苏州奥美材料科技有限公司

Battery production supervision system

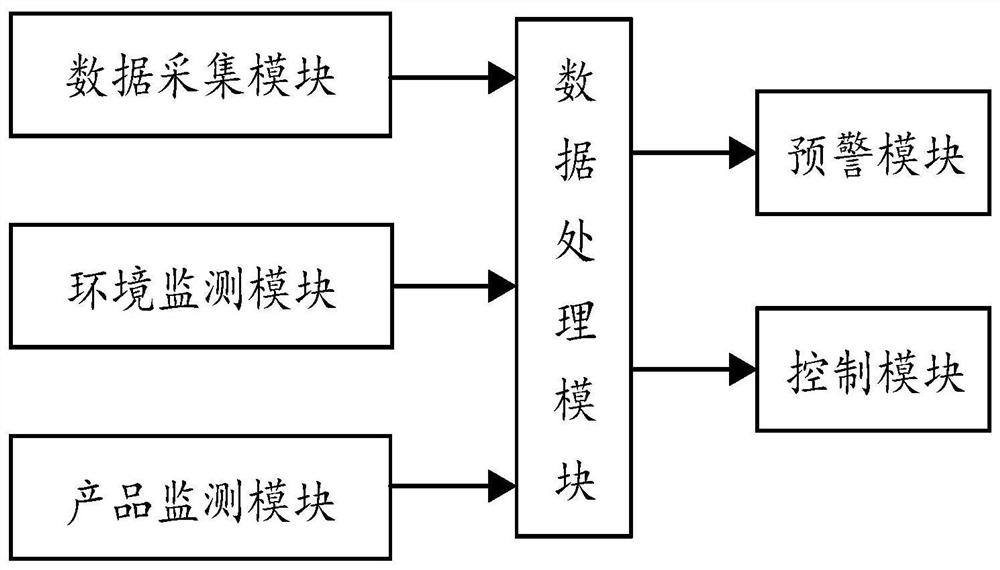

InactiveCN111951539AMeet the production process needsRealize unified supervisionElectric signal transmission systemsMeasurement devicesNew energyControl engineering

One or more embodiments of the invention provide a battery production supervision system, which relates to the technical field of battery new energy, and comprises a data acquisition module, an environment monitoring module, a product monitoring module, a data processing module, an early warning module and a control module; the data acquisition module is used for acquiring operation parameters ofthe battery production equipment, the environment monitoring module is used for acquiring environment parameters on the outer side of the battery production equipment, and the product monitoring module is used for acquiring battery surface parameters; the data processing module processes the acquired corresponding parameters and sends out corresponding signals to the early warning module and the control module, and then the early warning module sends out early warning, and the control module controls the working state of the battery production equipment. By utilizing the battery production supervision system provided by the invention, unified supervision on the battery production process in battery production can be realized, the supervision process is safe, efficient and timely, and the requirements of the battery production process are satisfied.

Owner:ANHUI ZHENGXIBIAOWANG NEW ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com