Single-roller tension measurement deviation correction device

A technology of deviation correction device and tension, which is applied in the direction of conveyor control device, roller column, transportation and packaging, etc., can solve the problems of small space, large investment of tension measuring roller, and inability to arrange tension measuring roller, etc., to achieve flexible process layout and occupy The effect of small space and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

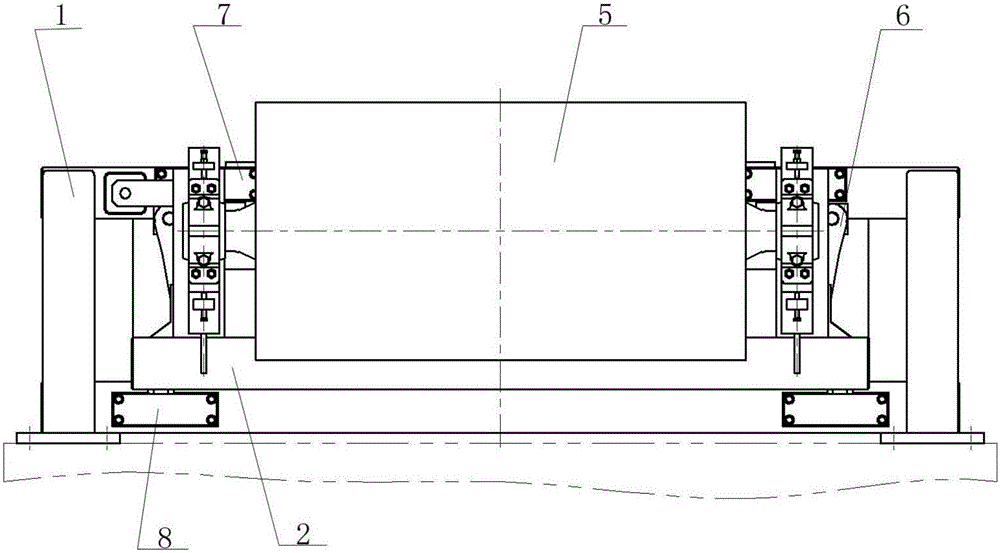

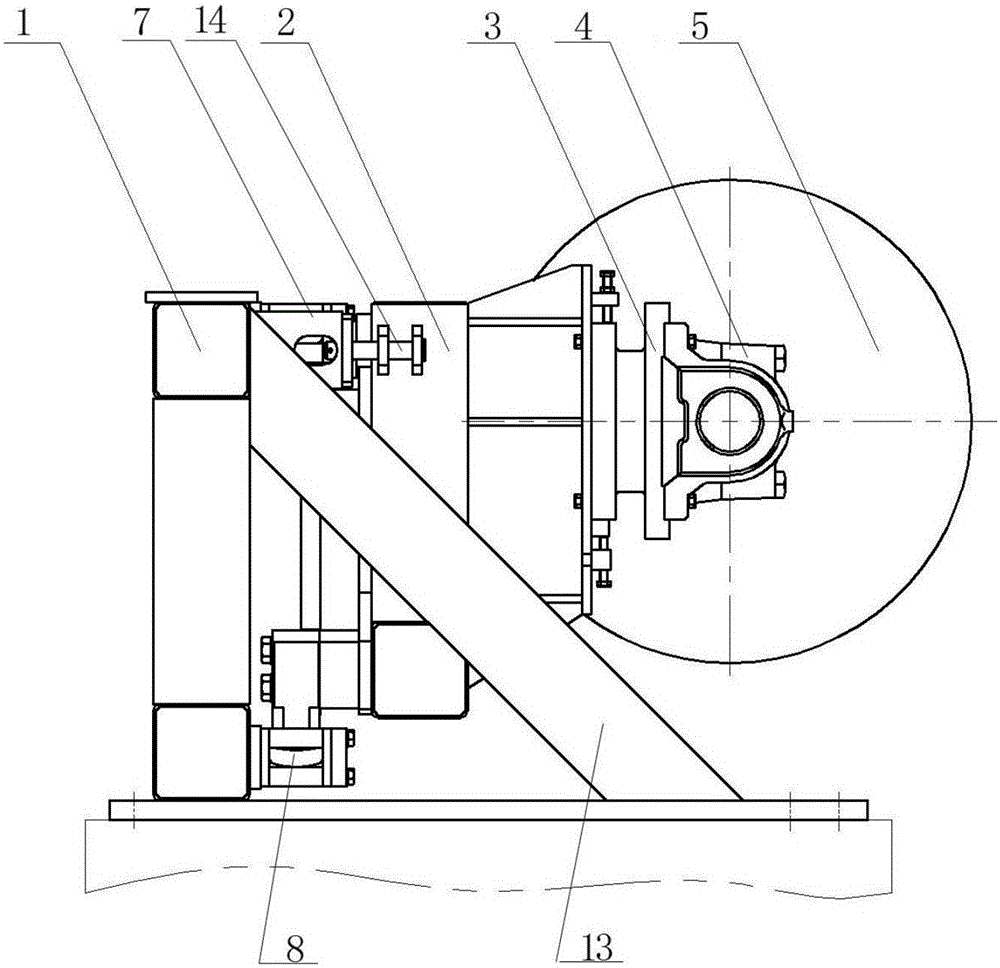

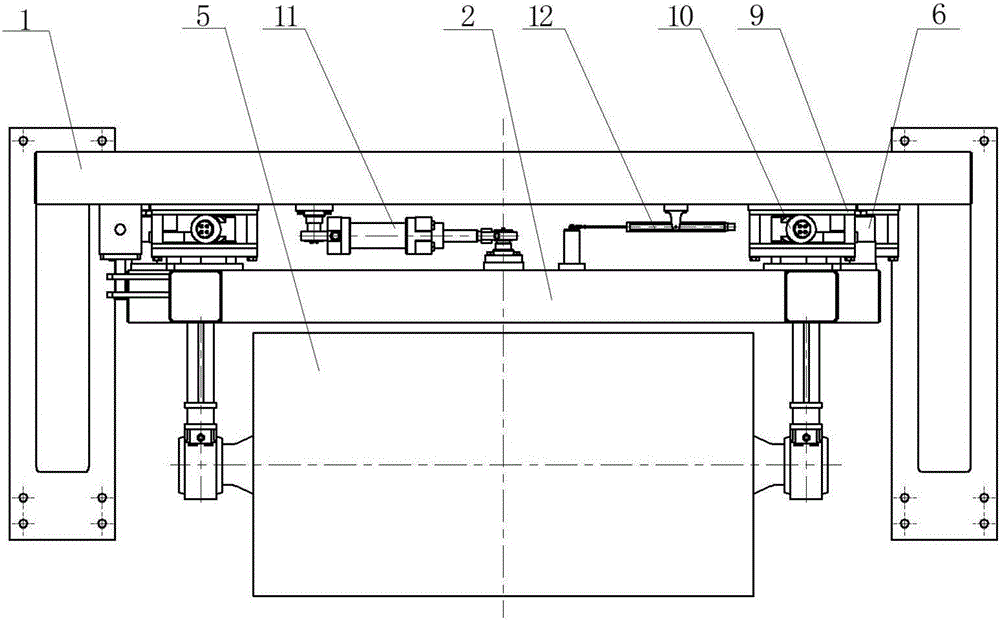

[0016] See Figure 1-Figure 3 , is a structural representation of the present invention. A single-roller tension measurement and correction device of the present invention comprises a fixed frame 1, a movable frame 2, a roller assembly, a tensiometer 3, a swing device and a guiding device, and the fixed frame 1, the movable frame 2 are parallel to the roller 5 in the roller assembly Set, the bearing housings 4 on both sides of the roller 5 are respectively fixed on the movable frame 2 through the tensiometer 3; The hinged connecting rod of the frame 2 and the hydraulic cylinder 11 whose fixed end is hinged with the fixed frame 1 and whose extended end is hinged with the movable frame 2; 10. The roller 10 can roll in the corresponding slideway 9; the beam of the fixed frame 1 is also provided with a position sensor 12 for detecting the position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com