Spiral conveyor with universal ball joint

A technology of screw conveyor and universal ball, which is applied in the direction of packaging, etc., can solve the problems of unadjustable direction and inability to achieve the conveying effect, and achieve the effect of small cross-sectional area, light weight, and avoiding material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

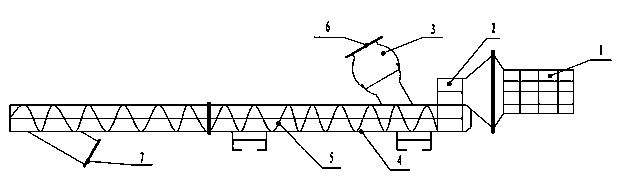

[0010] Universal ball joint screw conveyor, the screw conveyor includes a motor 1, a reducer 2, a feed port 6, a discharge port 7, an outer tube 4 and a screw blade 5, and the output shaft of the motor 1 is driven to the reducer 2 , the output shaft of the reducer 2 is driven to the screw blade 5, the screw blade 5 is arranged in the outer tube 4, the feed inlet 6 is connected with a universal ball joint 3, the feed inlet 6, The joint between the discharge port 7 and the outer pipe 4 is provided with an anti-seepage device. The outer pipe 4 has several sections, which are fixedly connected to each other through flanges. The spiral blade 5 is a one-time molding blade, and the blade The pitch between them is not equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com