Technique for proportioning different materials in steel plant

A technology for iron and steel plants and materials, which is applied in the production of metal pellets, sintered ore in the iron and steel industry, and pelletized ore fields. It can solve the problems of long batching belt, serious dust, and large dust on the batching belt to achieve shortened length and flexible process layout. , Strengthen the effect of dust control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

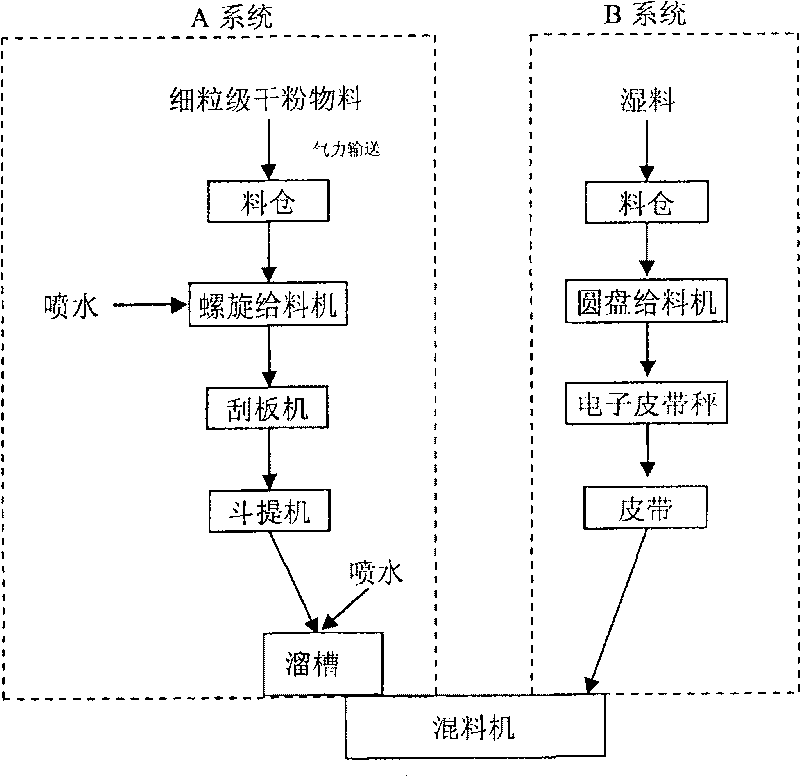

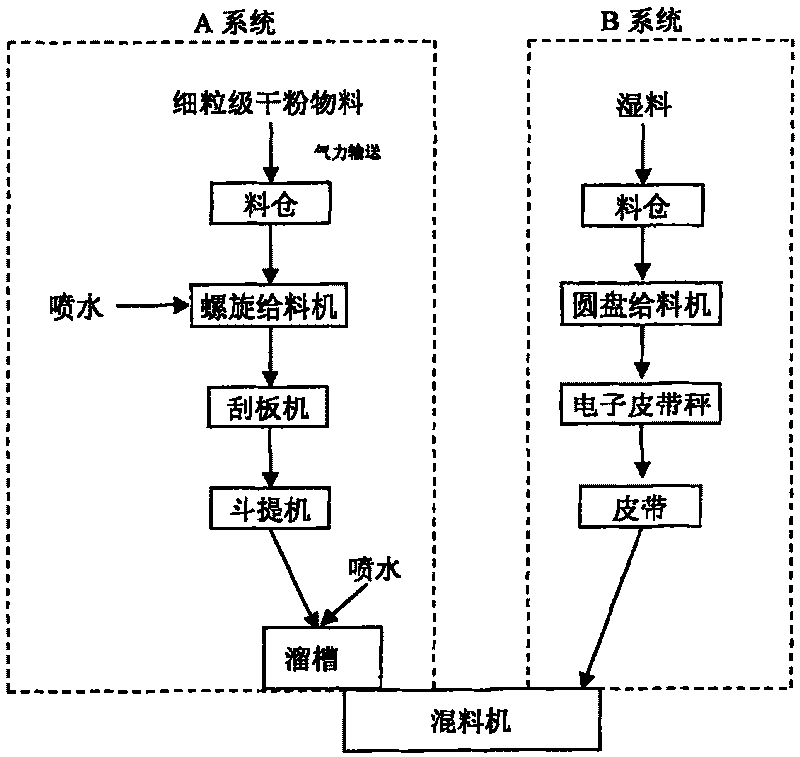

[0017] Embodiment 1. Batching technology of different performance materials in iron and steel plant

[0018] The batching system adopts two sets of systems A and B, of which the A system is used to transport blast furnace gas ash, blast furnace environmental dedusting ash, converter fine ash, converter environmental dedusting ash and electric furnace ash; B system is used for transporting coal powder, fine powder after selection and Rolling line sludge. The various dry powder materials added to the batching line of the A system are measured and batched from their respective silos through the screw feeder, and the material is humidified by spraying water in the screw feeder to make the material moisture Reach 2~6%wt; the material from the screw feeder enters the airtight scraper machine, is conveyed by the scraper machine to the bucket elevator, and then enters the mixer through the bucket elevator, and is used in the chute before entering the mixer. The material is humidified...

Embodiment 2

[0019] Embodiment 2. As described in embodiment 1, the difference is:

[0020] The batching system adopts two systems, A and B, of which system A is used for conveying blast furnace gas ash, coking dedusting ash, converter fine ash, converter environment dedusting ash and electric furnace ash; system B is used for conveying rolling line sludge and rolling steel sheet (auxiliary ). The two systems are placed in parallel, and after the calculation of the ingredients, the two systems send various raw materials to the mixer according to the fixed ratio. Among them, the powder in system A is easy to generate secondary dust, and the dry dust is pumped from the closed pneumatic tanker into the silo by means of pneumatic conveying, and a dust collector is installed on the top of the silo; at the same time, the length of the plant can be shortened by 50%, and the width can be widened by 50%. %.

Embodiment 3

[0021] Embodiment 3. As described in embodiment 1, the difference is:

[0022] The batching system adopts two systems, A and B, of which system A is used to transport coking dust, blast furnace environment dust, converter fine ash, converter environment dust and electric furnace ash; system B is used to transport coal powder, rolled steel sheet and rolling line sludge. The two sets of systems are placed vertically. After calculating the ingredients, the two sets of systems send various raw materials to the mixer according to the fixed ratio. Among them, the powder in system A is easy to generate secondary dust, and the dry dust is pumped from the closed pneumatic tanker into the silo by means of pneumatic conveying, and a dust collector is installed on the top of the silo; at the same time, the factory length design does not require a square space, and two 90 °The bar-shaped site.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com