Automatic mixing and spraying device and method applicable for perlite thermal insulation product

A spraying device, perlite technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problem of reducing pressure, achieve the effect of reducing pressure, improving uniformity, and facilitating gas discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

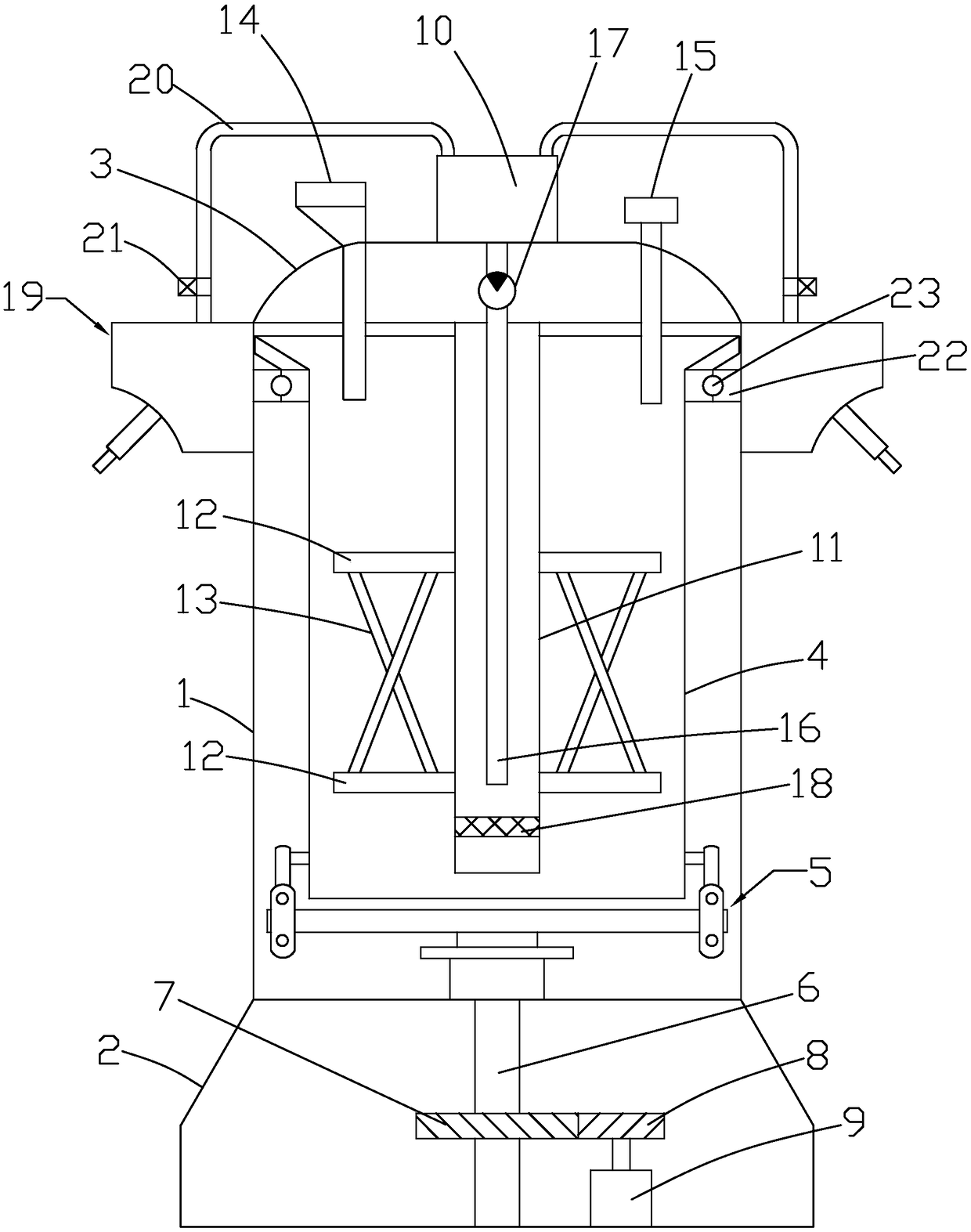

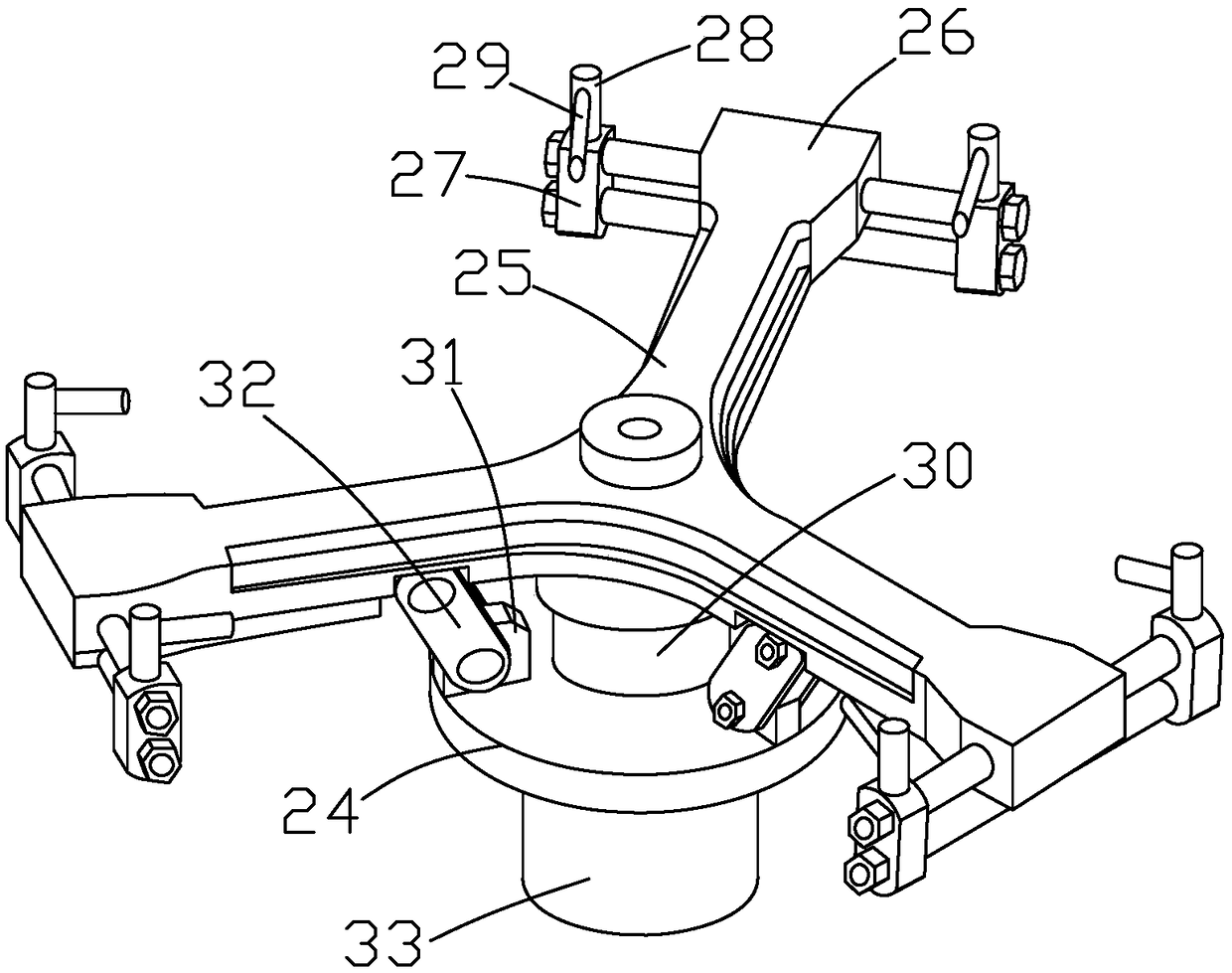

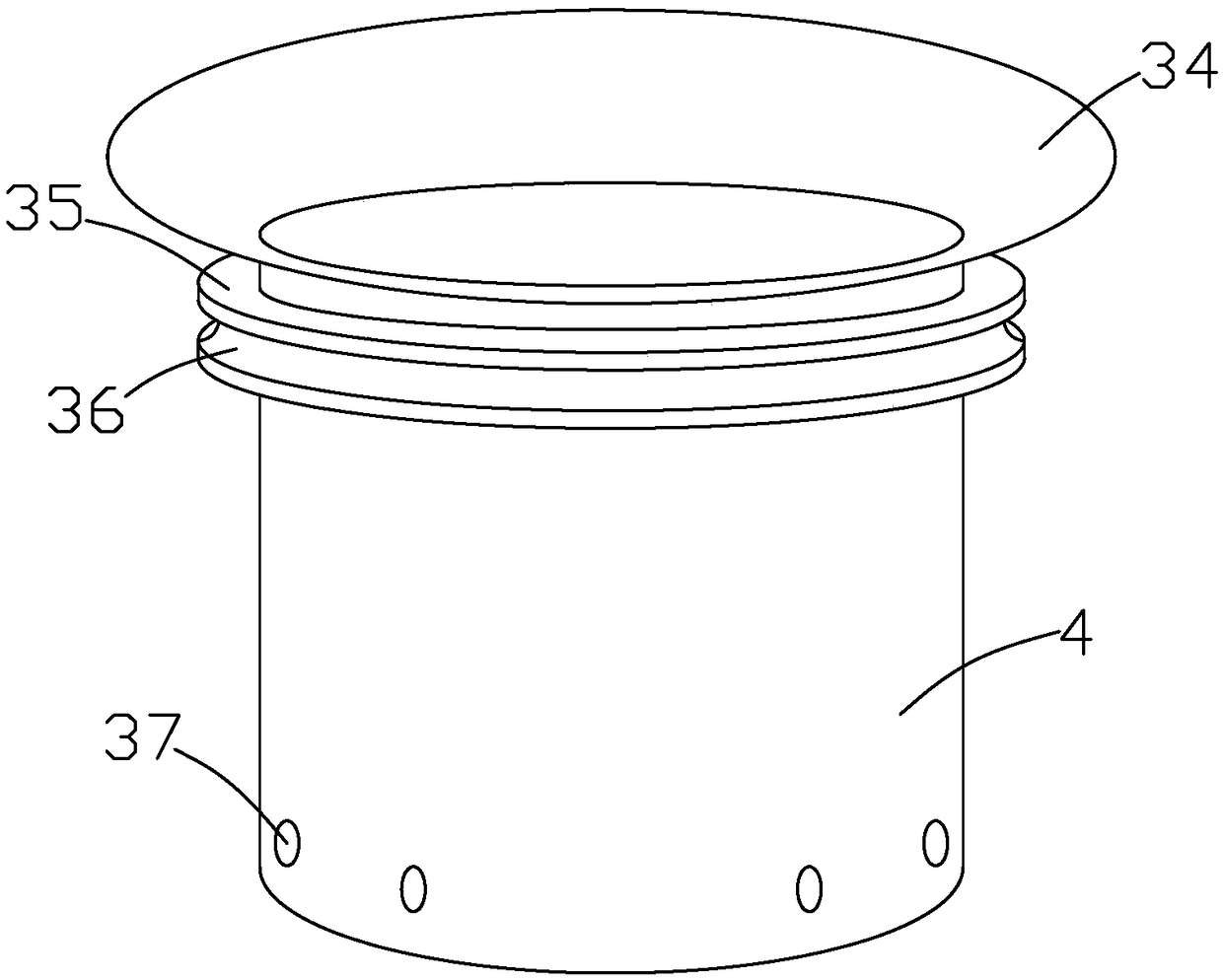

[0050] Such as Figure 1 to Figure 4 As shown, it is an automatic mixing and spraying device suitable for perlite heat insulation products according to the present invention, which includes a box body 1, the upper and lower sides of the box body 1 are respectively provided with end covers 3 and bases 2, and the inside of the box body 1 is connected by rotation There is a staving 4, the bottom side of the staving 4 is provided with a positioning hole 37, the top of the staving 4 is provided with a shroud 34, the cross-sectional area of the shroud 34 decreases gradually from top to bottom, and the shroud 34 The design can reduce the overflow of liquid from the upper part of the barrel body 4 when the barrel body 4 rotates together.

[0051] The side wall of barrel body 4 is connected the inner wall of casing 1 by limit mechanism, and limit mechanism comprises first locating ring 22 and second locating ring 35, and first locating ring 22 is fixedly connected on the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com