Cigarette producing method and intelligent cigarette machine group thereof

A production method and cigarette technology, applied in the fields of tobacco, cigarette manufacturing, computer control, etc., can solve the problems of waste of production time, health hazards of consumers, prone to oil leakage, etc., and achieve increased intelligent management, operation stability and Improve the effective production rate and solve the effect of easy oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

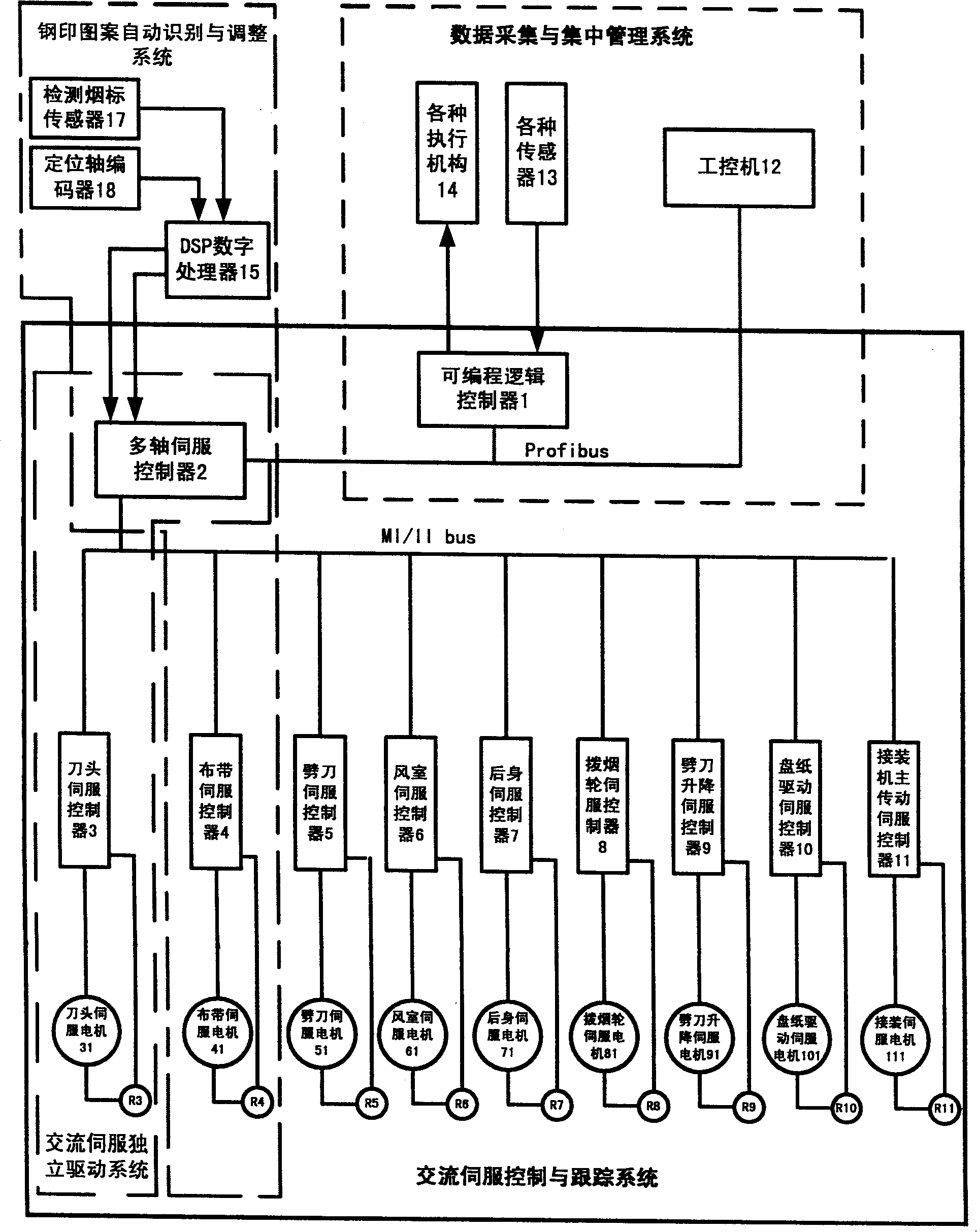

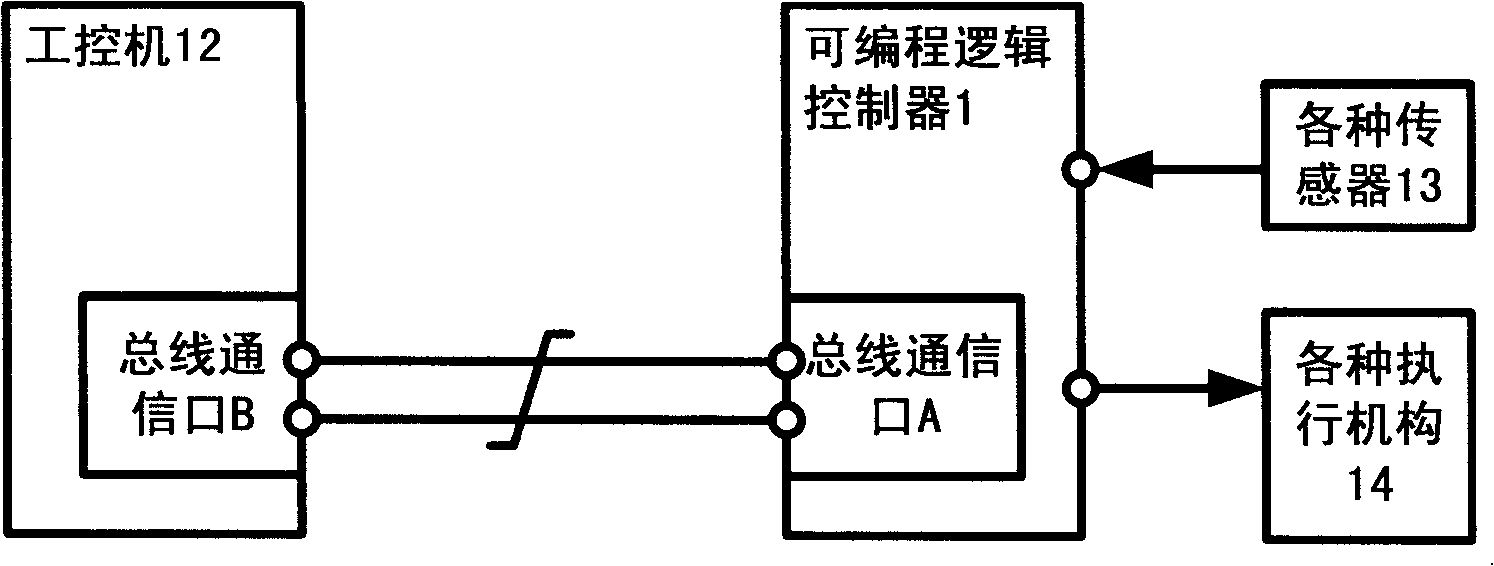

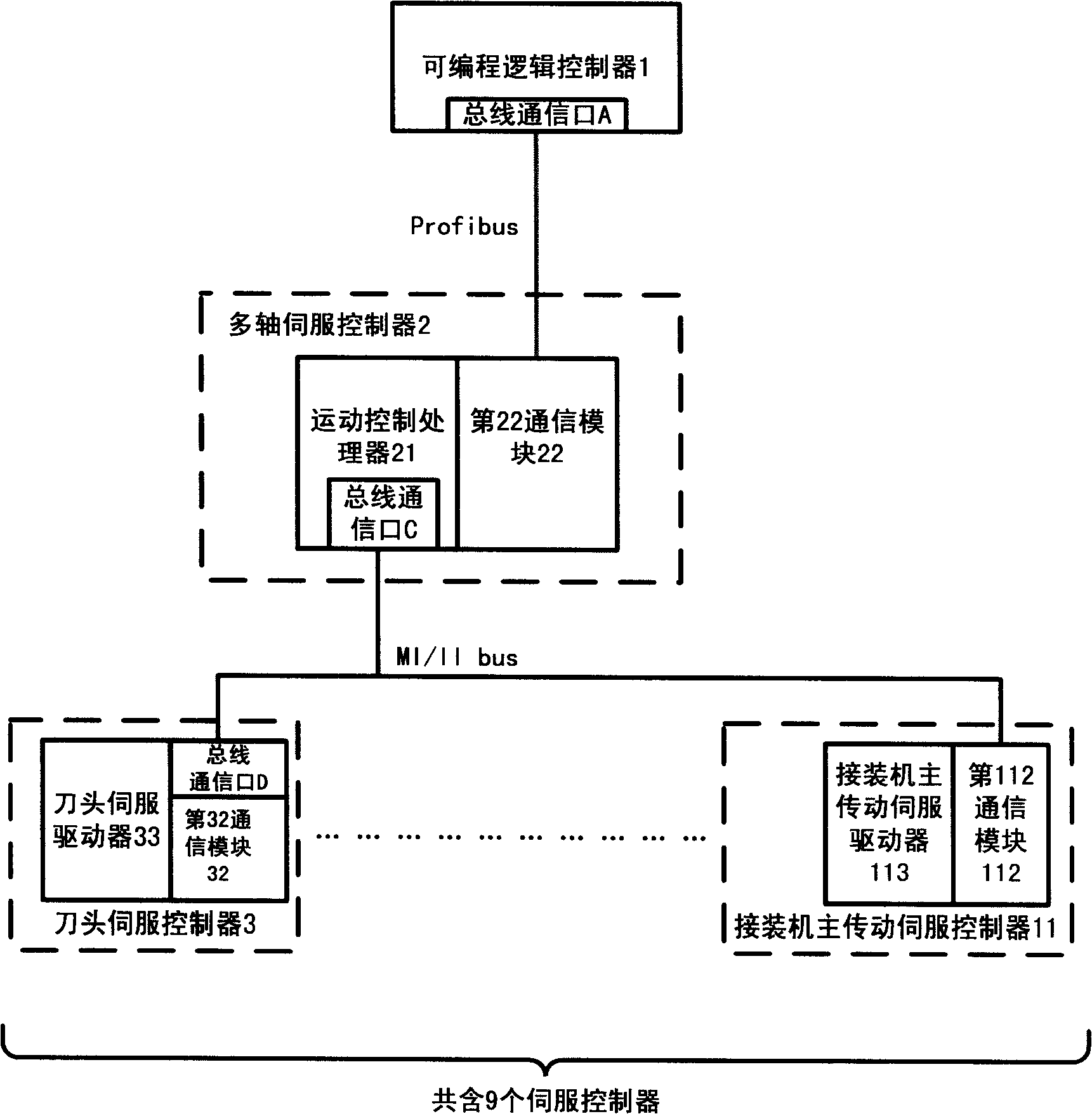

[0038] The production method of the present invention: the cigarette production process is divided into two steps of printing on the coil paper and cigarette production, which are carried out step by step; firstly, the required pattern is printed or steel stamped on the coil paper, and then a printing process for the printed paper is added in the cigarette production. The coil paper with a good pattern is fixed-length positioned, and has real-time dynamic adjustment steps of the steel stamp; in the synchronous motion control, the electronic gear system is used for transmission through phase control. Since the required pattern is printed or stamped on the paper coil first, complex patterns can be printed, and the appearance of cigarettes produced by the new process can be significantly improved because it can be designed according to requirements; this new ciga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com