Combustor having fuel cell tail gas catalytic combustion function, and applications thereof

A catalytic combustion and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of reducing the performance of electrocatalysts, destroying the current conduction interface, affecting the electrode gas mass transfer, etc., to achieve system thermal stability The flow characteristics are convenient, conducive to cooling and ensuring the effect of stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

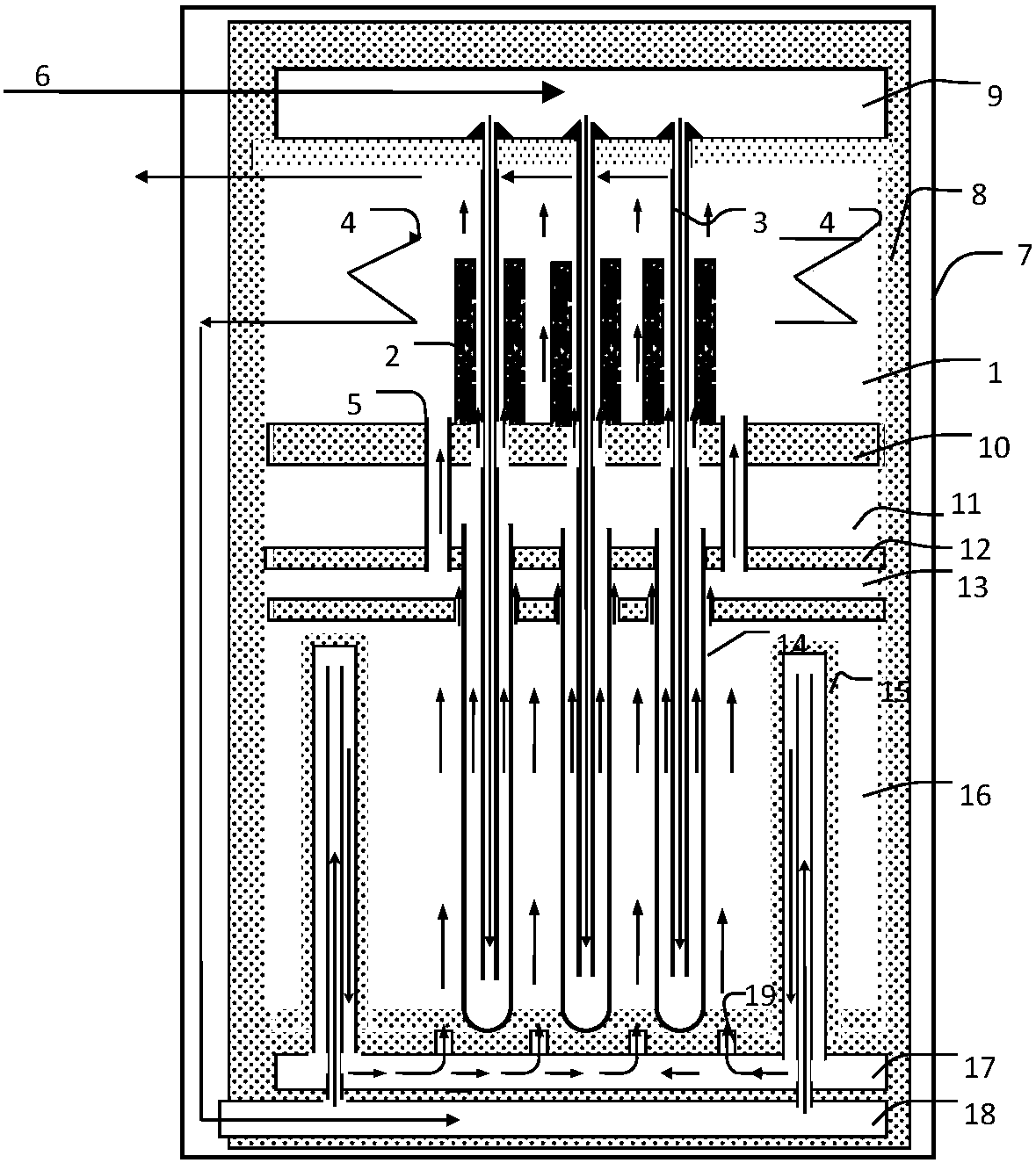

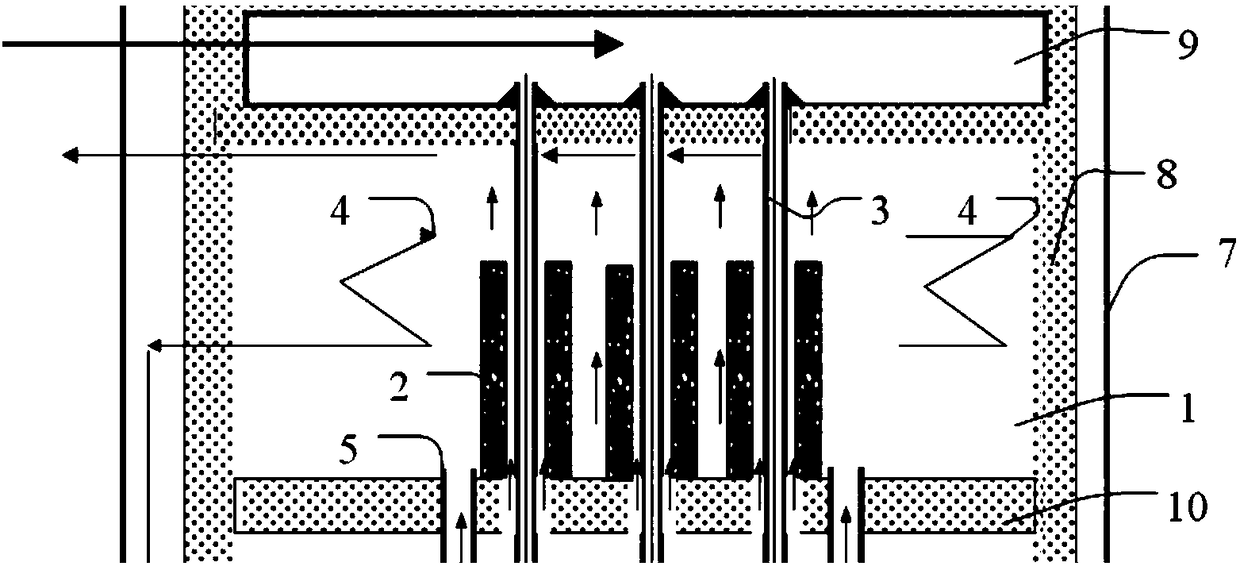

[0018] The present invention aims at the characteristics and requirements of the power station structure of an anode support tubular solid oxide fuel cell with one end closed (Chinese patent application number 2011101978022), and is based on a fuel distribution tube with functions of fuel reforming and tail gas catalytic combustion (Chinese patent application number 2011104135697) , aiming at the above-mentioned tail gas combustion requirements, a burner with tail gas catalytic combustion and fuel gas catalytic reforming functions is designed, which mainly has the following characteristics: (1) The reforming reaction and combustion reaction are respectively placed in the combustion chamber (2) The fuel reforming reaction and the catalytic combustion reaction of the fuel tail gas can be thermally coupled through the wall of the fuel distribution pipe.

[0019] The present invention will be described in further detail and specifically below.

[0020]First, a high-temperature fue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com